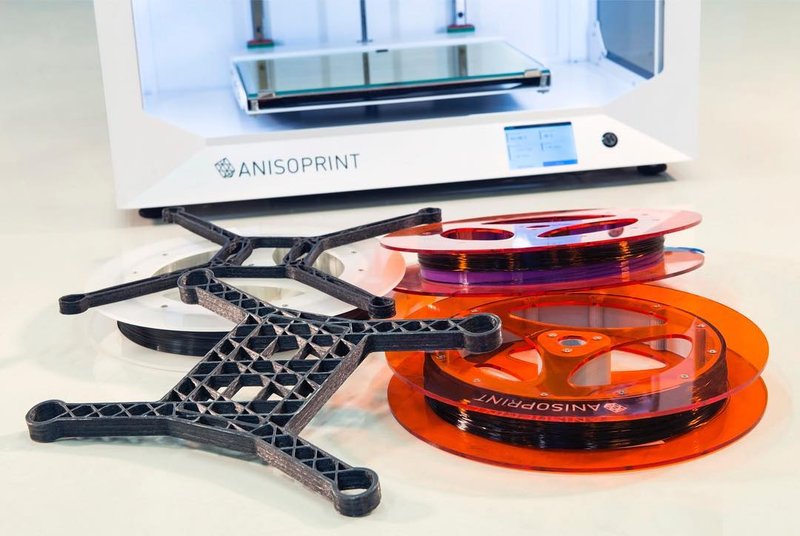

Composer A3 is a continuous carbon fiber professional desktop 3D printer powered by the proprietary, patent-pending Composite Fiber Coextrusion (CFC) technology as well as standard FFF 3D printing technology. The Composer A3 offers an outstanding build volume of 460х297х210mm. Such a print area allows producing large-scale optimized composite structures characterized by high physical and mechanical properties. Final parts are stronger and lighter than parts with similar properties produced with metal, thermoplastics, or non-optimized composites. They are also cheaper to produce. For instance, a continuous fiber-reinforced die for sheet metal forming will come out 75% cheaper than its counterpart made of ULTEM. In a number of cases, it will also greatly contribute to reducing the manufacturing downtime.

Take a look at this lightweight and highly durable fixture for an electric wheelchair drive. Being 7 times lighter than its steel counterpart, this anisoprinted fixture is also 3 times cheaper and can be produced in just 4 hours. By successfully integrating the additive manufacturing technologies into its manufacturing system, the Supreme Motors company is now able to produce such parts in small batches without suffering from additional costs and having to deal with contractors.

Check out these neatly-looking and highly detailed parts. They have been anisoprinted with plastic filled with short fibers. Such housing allows for a smooth surface finish, as well as provides parts with outstanding thermal and hardness properties.

Credit: @anisoprint / Instagram

The Composer A3 is a professional 3D printer that can print layers at 60 microns. This way you can produce parts with smooth exterior surfaces. When printing with the FFF print head, it can reach a print speed of up to 80 mm/s. When using the CFC module, it reaches up to 10 mm/s. CFC continuous carbon fiber technology can print with a variety of thermoplastics, but it provides the best results when printing with PETG filament as a matrix.

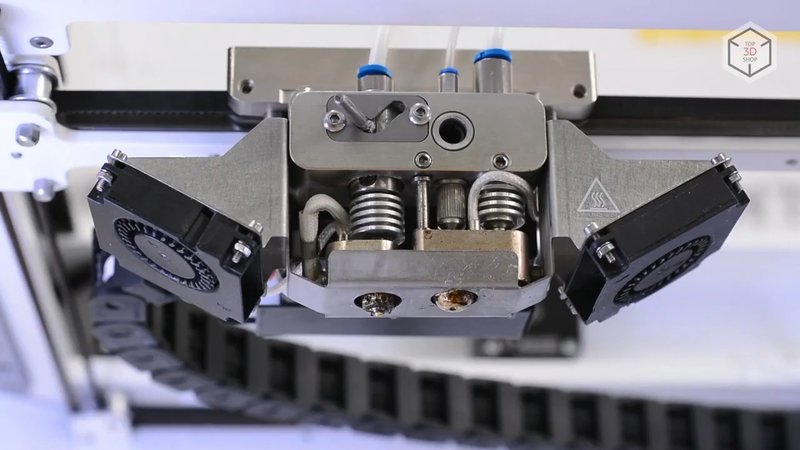

The Anisoprint Composer A3 comes stock with two 0.4mm nozzles, giving you the best balance between speed and detail.

The Anisotropic Composer A3 supports two different print heads, FFF and CFC, with a dual-nozzle system. The CFC extruder includes a reinforcing fiber cutting device.

Anisoprint Composer A3 3D printer can process filaments with a melting temperature of up to 270°C and a diameter of 1.75mm. Moreover, each extruder comes with its own fan for printing with PLA-type materials. The fans cool the model during printing, which reduces warping, stringing, and other issues. It lets you print with PLA, ABS, PETG, PA(Nylon), TPU, PC, ASA SBS, and CF/GF filled filaments.

Credit: @anisoprint / Instagram

The printer comes with either a heated glass build plate and an enclosed print chamber, which makes it reliably printing with ABS, Nylon, Polycarbonate and other temperature-sensitive filaments. The removable build plate can heat up to 120°C, while the nozzles can reach a temperature of 270°C. The enclosure keeps the printing temperature stable minimizing the risk of warping or shrinkage.

The Composer A3 is compatible with 1.5k and 3k Composite Carbon Fiber (CCF) and Composite Basalt Fiber (CBF). These reinforcing fibers can be used with PLA, ABS, PETG, PA, TPU, PC, ASA, fiber-filled and glass fiber-filled filaments.

The Composer A3 has an outstandingly large build area of 18.1 x 11.7 x 8.3 inches (460 x 297 x 210 mm). It is more than enough for printing a single large part or simultaneous production of several small-sized parts.

The printer can be operated via a fitted 4.3-inch LCD touchscreen.

The print-ready models can be transferred from a USB-tethered computer or both via a USB stick and SD card.

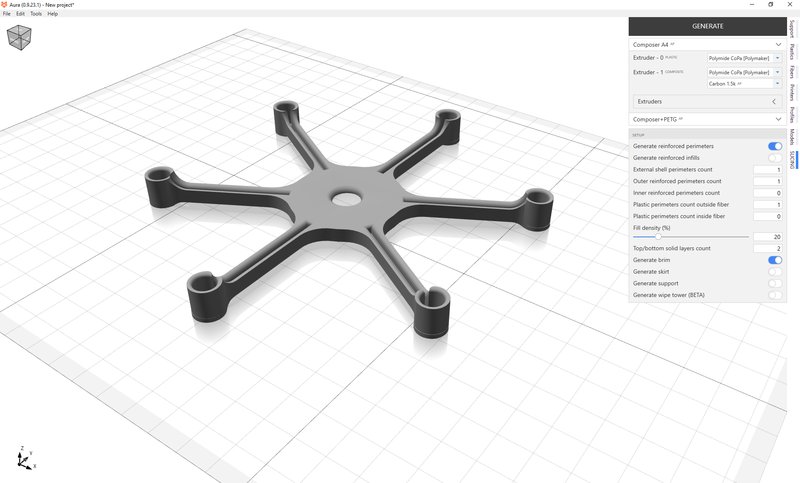

The Composer A3 comes integrated with the self-developed Anisoprint Aura software for both FFF and CFC 3D printing. The device is also compatible with Cura and Slic3r slicing software solutions. The proprietary software runs on Windows 7+. It is packed with several thoughtful features for easy print management. For each layer, it generates reinforcing fiber trajectories. It lets you easily regulate the reinforcement scheme to increase the final strength of the part. In addition, it creates support structures and provides a real-time preview of the final print.

Credit: @3d_cloud / Instagram

For some items, package content may change. In case of any questions, please get in touch.

The Anisoprint Composer A3 is available in a black and white color scheme. Its stylish look makes it ideal for industrial applications and functional prototyping.

The printer dimensions are 28.3 x 24.8 x 19.3 inches (720 x 630 x 490 mm). It weighs 143.3 lb (65 kg). The filament spool holders are located on the rear side of the printer.

To learn the current price of the 3D printer, click the "request a quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now