The ApexMaker Curing Station is a tabletop large sized curing platform engineered to complete the photopolymerization cycle for 3D printed resin parts making them more durable. Photopolymerization involves cross-linking oligomers and monomers through UV-initiated radical polymerization that transforms liquid resin into solid polymer networks. UV curing process initiates a photochemical reaction generating crosslinked polymer networks through absorption of specific wavelengths. The station employs six 405nm curing lights producing 130W LED optical output combined with a 90W thermal system and a 360° rotating platform to eliminate shadow zones and ensure complete curing with no discoloration and uncured residue. With the UV resin curing light LED wavelength range of 405nm, the machine is designed to work with most standard 405nm resins, this curing station supports LCD, DLP, and SLA 3D printed objects, making it a versatile addition to any 3D printing setup.

The ApexMaker Resin Curing Station integrates 4 primary systems: six 405nm LEDs generating 130W optical power, a 360° turntable rotating at 10 rpm to eliminate shadowed areas and ensure uniform exposure, temperature-controlled heating to 90W that enhances polymerization efficiency and mechanical properties at optimal temperatures between 24–30 °C, and a programmable timer with 0–6 minute cycles providing dose rates from 0.6–7.2 J/cm² based on standard 130 W/cm² exposure calculations according to Intertronics from Kidlington, Oxfordshire during the 'UV Curing Energy Requirements Guide' (2017).

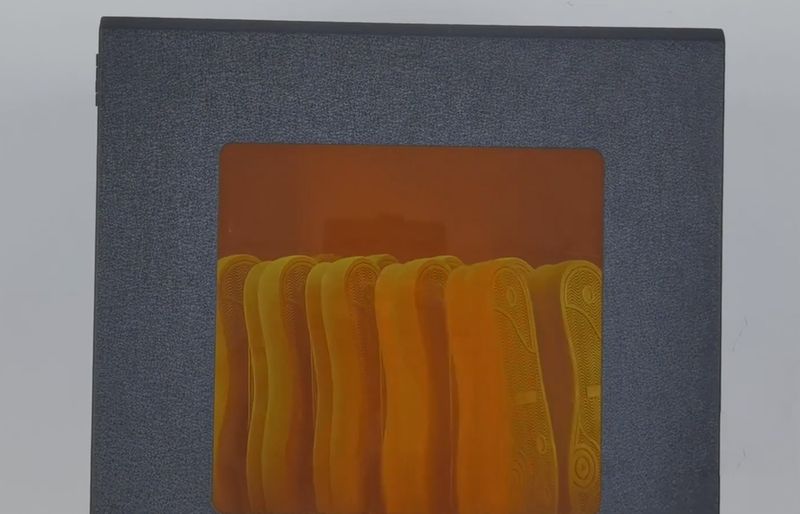

Service bureaus utilize UV curing chambers similar to the ApexMaker machine for batch processing 15–20 tabletop gaming miniatures per cycle, achieving production rates of 45 miniatures in under 2 hours when combined with proper workflow automation (AmeraLabs, "Scaling Miniature Production with 3D Printing"). Cosplay workshops employ large format curing stations for post-processing different armor components and prop assemblies, while dental laboratories require post-curing cycles to meet FDA compliance standards for surgical guides, typically requiring 20–30 minute cycles at 60 °C to achieve biocompatible mechanical properties, according to Pac-Dent Inc. from Brea, California during the 'Rodin Surgical Guide Instructions for Use Guide' (Edition v1.3, 2022).

The ApexMaker Curing Station product integrates 4 primary systems delivering controlled post-curing through optical, thermal, rotational, and time control mechanisms. Six high-power 405nm LED lamps generate 130W optical power that produces power densities exceeding 1.25 mW/cm² optimal threshold for maximum mechanical properties development, according to Formlabs during the "Post-Curing Optimization Study". The 90W thermal system maintains chamber temperatures promoting enhanced cross-linking reactions with polymerization efficiency increasing exponentially above 45 °C, delivering 147.48 MPa flexural strength at 80 °C.

A 360° rotating table operates at 10 revolutions per minute preventing shadow zone formation and uneven curing by ensuring uniform exposure across all surface angles, with rotating systems reducing uncured areas by 75% compared to stationary configurations according to equipment manufacturers during industrial UV curing evaluations. The 0–6 minute timer prevents overcure brittleness while delivering sufficient energy density measured in J/cm² for complete polymerization, with precision timing easily eliminating the 15% strength reduction associated with inadequate curing cycles.

The ApexMaker Curing Station operates with a 350 x 350 x 400 mm chamber delivering precisely 5.95 liters of usable volume. This workspace accommodates 15–20 standard 28mm gaming miniatures per print cycle according to C. Smith from AmeraLabs during the "Batch Production Optimization Study". Standard dental arch impression trays measure 76–80 mm width by 60–67 mm length for full arch applications according to specifications from GC America COE impression tray standards, while the curing chamber supports 1 complete dental arch tray model with adequate clearance.

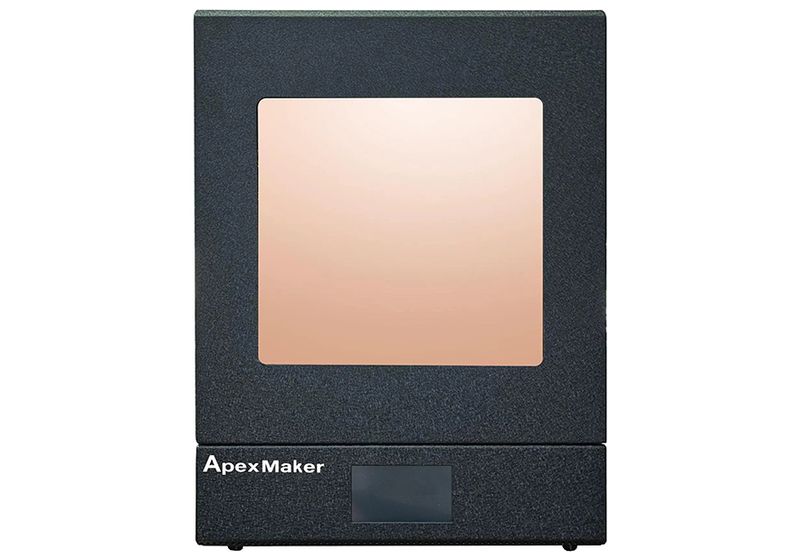

The ApexMaker Curing Station operates via a 4.3" HD color touchscreen displaying temperature, timer, rotation status, and presets through dedicated on-screen widgets. The display delivers a fixed 480 x 272-pixel resolution with 16.7 million-color depth and 300 cd/m² brightness, ensuring clear visibility under workshop lighting. Four soft-key icons beneath the screen provide direct access to three preset cycles (2 min, 4 min, 6 min) and two manual adjustment buttons that change time in 30 s increments.

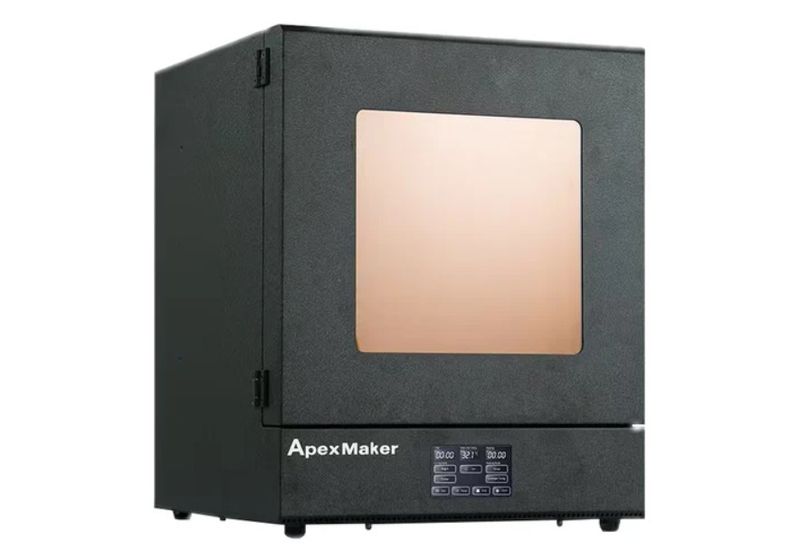

The ApexMaker Curing Station features professional industrial construction with 395 x 395 x 547 mm external dimensions and 10 kg weight providing operational stability during 360-degree rotating platform operation. The sealed chamber design incorporates safety-rated UV-blocking materials that achieve 98% ultraviolet radiation blocking, according to researchers from ARPANSA during their UV Protection Factor testing. The chamber interior features reflective surfaces that deliver 95% specular reflectivity at 365–405 nm wavelengths, according to de Sternberg Stojalowski and Fairfoull from NIST during the “Reflective Properties of Materials Exposed to Ultraviolet-C Radiation” study (2021).

To learn the current price of the Apex-Maker Curing Station, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now