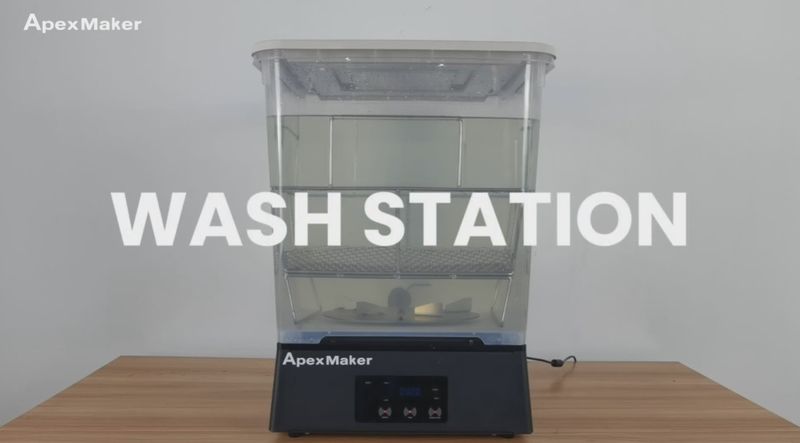

The ApexMaker Washing Station is a magnetic agitation-based resin removal system designed for LCD, DLP, and SLA 3D printed models. The station employs a 50W magnetic fan blade system that generates eddy current cleaning action for removing uncured photopolymer resin residues. The station provides 2 cleaning methods: basket washing removes individual models directly while platform hanging cleaning suspends entire printing platforms to reduce resin exposure.

The ApexMaker resin washing system features a 50L cleaning bucket with 400 x 380 x 280 mm maximum processing dimensions, rated at 99.75% concentration efficiency at 200 μL/min flow rate according to Ramadan from microfluidic research laboratories ("Magnetic-based purification system with simultaneous sample washing and concentration", 2009). The customized magnetic fan blade creates high-speed cleaning turbulence, removing excess resin through super eddy current action. The unit operates at 50W rated power consumption within 430 x 440 x 570 mm production dimensions.

The washing station targets professional 3D printing environments where post-processing represents 17% to 100% of total production time according to Grimm during the "3D Printing Impact of Post-Processing" study. For example, makerspaces utilizing SLA printers require specialized resin removal equipment according to Georgia Tech’s Invention Studio operational protocols (2013). Production facilities implement the ApexMaker resin washing system to address the 75% of users who identify post-processing duration as the primary workflow barrier, according to PostProcess Technologies from Society of Manufacturing Engineers during the annual post-processing trends study. The ApexMaker Washing Station accommodates the 48% of manufacturing users employing photopolymerization technologies, according to PostProcess Technologies from annual additive manufacturing survey during the 2022 post-processing market analysis.

The ApexMaker Washing Station operates through a 50W magnetic fan blade system that produces eddy current cleaning action. The customized magnetic agitator generates turbulent flow dynamics that remove 99.75% of resin particulates through high-velocity cleaning according to Ramadan from microfluidic research laboratories during the "Magnetic-based purification system with simultaneous sample washing and concentration" study (2009).

The station provides 2 cleaning methodologies for post-processing workflows. The basket washing method involves direct part immersion in cleaning solutions, while platform hanging cleaning suspends entire build platforms to minimize resin exposure during handling. The system operates with SLA, DLP, and LCD 3D printers through universal compatibility with photopolymer resins.

The ApexMaker Washing Station provides a 50L cleaning bucket with 400 x 380 x 280 mm maximum processing dimensions. The system operates at 500% larger capacity than standard washing stations such as the Anycubic Wash & Cure Max at 14.9L and Phrozen Wash & Cure Kit at 8L. The 50L fluid volume maintains consistent cleaning performance through extended operation cycles and reduces contamination rates by 50% during consecutive model processing.

The ApexMaker Washing Station operates through a user-friendly touchscreen interface that displays operational parameters during cleaning cycles. The touchscreen provides real-time feedback including cleaning cycle progress, timer information, and system status indicators.

The ApexMaker Washing Station measures 430 x 440 x 570 mm in outer dimensions, providing a substantial workshop footprint of 0.10 m² floor space. The construction employs industrial-grade materials for operational stability during 50W magnetic agitation cycles, ensuring consistent performance through repeated loading and unloading operations. The sealed bucket design incorporates safety-rated materials that prevent cleaning fluid splashing during high-speed magnetic fan blade operation.

To learn the current price of the ApexMaker Washing Station, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now