Autodesk Fusion 360 is the powerful cloud-based software that combines advanced tools for every stage of a product development and manufacturing cycle in a single platform. Fusion 360 includes comprehensive 3D modeling, CAD, CAM, CAE, and PCB instruments for designers, engineers, and manufacturers.

The platform provides vast opportunities for effective data management and collaborative work of all team members, regardless of their location, and allows creating a unique versatile environment to communicate and share the progress, thus speeding up the process and reducing the risk of errors.

Fusion 360 is an ultimate design and manufacturing solution, including:

Start your design with sketching using a complete suite of sketch tools. You can use parameters or variables to drive your design parametrically.

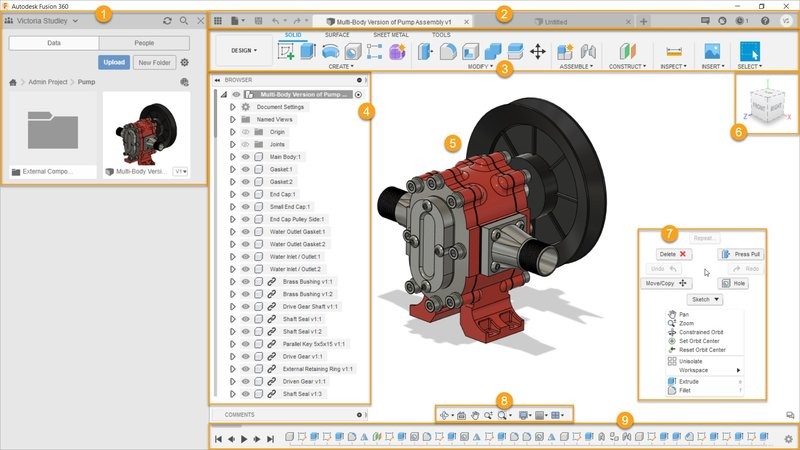

Turn your sketch into a 3D model using one of the available modeling techniques, including direct, surface, parametric, mesh, sheet metal, or freeform modeling.

Rendering function allows you to obtain high-quality realistic renders and start marketing your product even before production starts.

With the assembly modeling feature you can be sure that your design requirements meet the form and functionality of your product.

With Fusion 360 it is easy to program CNC machines. Consistency across the operations and a number of advanced tools make it a complete manufacturing solution. You can use simplified controls for high-efficiency roughing, adaptive clearing, and tool orientation. Fusion 360 allows you to design for 2D up to 5-axis milling. It also includes operations for work coordinate system probing, 2D turning, 3+2 and 4-axis milling, and 2D profiling.

Fusion 360 also provides opportunities for additive manufacturing, giving the access to a library of 3D printers and allowing the user to prepare and build digital models using FDM or PBF printing.

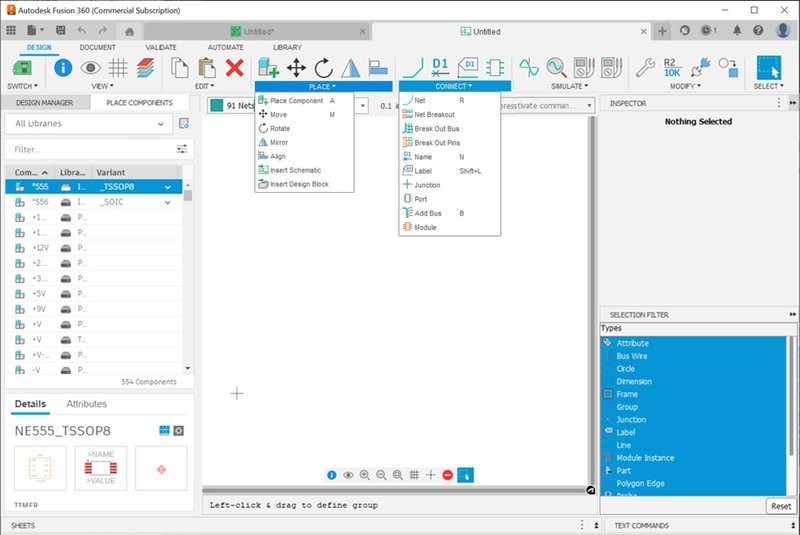

The PCB editor lets you save time with a complete set of PCB layout tools. Use schematic design, PCB layout, and routing capabilities of Fusion 360. The software also allows for easy integration of electronics into your designed models.

At any stage of the development process you can test your project using the provided options for digital simulation. Test your models for eight different failure criteria, including static stress, modal frequencies, thermal, thermal stress, structural buckling, nonlinear static stress, event simulation, and shape optimization.

Generative design function allows you to define material type, manufacturing method, and performance criteria which are used to create a large array of possible solutions answering your requirements.

Autodesk Fusion 360 provides a powerful set of comprehensive tools to be used by inventors, industrial designers, mechanical and electrical engineers, machinists, and fabricators as a complete solution for product development and manufacturing, starting with design creation to final fabrication, and data management during the entire process. Fusion 360 proves extremely useful for startup businesses as well as for educational institutes.

The system requirements for Fusion 360 are as follows:

|

OS |

Apple macOS:

Microsoft Windows:

|

|

CPU |

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported |

|

RAM |

4 GB (integrated graphics recommend 6 GB or more) |

|

Hard disk |

3 GB of storage |

|

Display |

1366 x 768 (1920 x 1080 or greater at 100% scale recommended) |

|

GPU |

DirectX11 (Direct3D 10.1 or greater); dedicated GPU with 1 GB or more of VRAM; integrated graphics with 6 GB or more of RAM |

|

Pointing device |

HID-compliant mouse or trackpad, optional Wacom® tablet and 3Dconnexion SpaceMouse® support |

|

Internet |

2.5 Mbps or faster download; 500 Kbps or faster upload |

|

Dependencies |

SSL 3.0, TLS 1.2+, .NET Framework 4.5 or newer required to submit crash reports |

To learn the current price of the Autodesk Fusion 360, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now