The Autodesk Fusion 360 Product Design Extension provides a set of advanced tools to automate and simplify the design of complex models. The use of intelligent patterns and shape-altering properties greatly adds to your product performance. Manufacturing-aware guidance helps prepare your designs for manufacturing, allowing you to turn your ideas into finished products in a shorter time.

The chart shows the extended capabilities of the Product Design Extension compared to the original Fusion 360 software.

|

Fusion 360 |

Fusion 360 + Product Design Extension |

||

|

3D Modeling |

Parametric Modeling |

✓ |

✓ |

|

Surface Modeling |

✓ |

✓ |

|

|

Freeform Modeling |

✓ |

✓ |

|

|

Direct Modeling |

✓ |

✓ |

|

|

Mesh Modeling |

✓ |

✓ |

|

|

Sheet Metal |

✓ |

✓ |

|

|

3D Patterning |

✓ |

✓ |

|

|

Geometric Pattern |

– |

✓ |

|

|

Boss Feature |

– |

✓ |

|

|

Web Feature |

– |

✓ |

|

|

Snap Fit |

– |

✓ |

|

|

Manufacturing Aware Tools |

Plastic Product Design Tools |

– |

✓ |

|

Plastic Product Design Rules |

– |

✓ |

|

|

Design Advice |

– |

✓ |

Below are the main features the Product Design Extension adds to your Fusion 360 software capabilities:

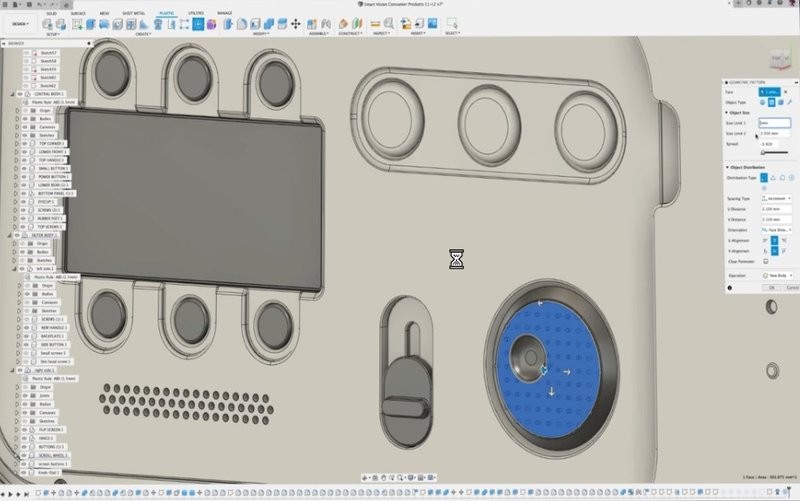

The Assign Plastic Rule command assigns plastic rules to components to automatically control such properties of plastic features, as physical material and thickness. You can either create new rules or edit existing ones, as well as save rules to a library to use them in multiple designs.

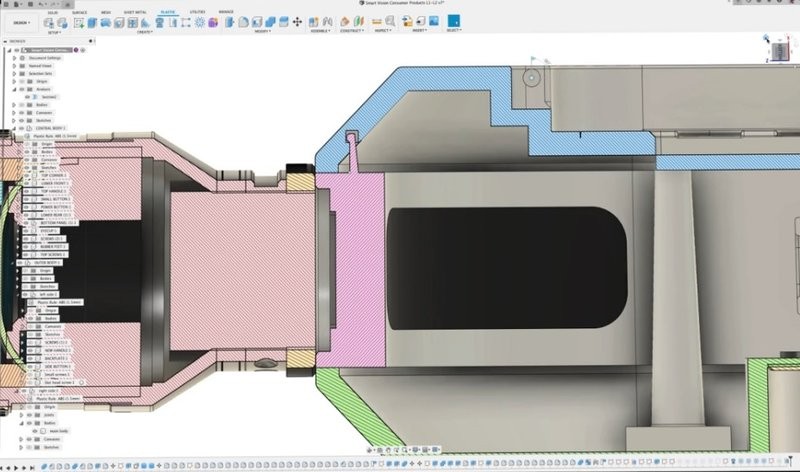

Use the new Boss and Snap Fit tools to create plastic features.The Boss tool lets you configure your parts and store them as a default. Use the Boss command to create a boss feature to fasten two solid bodies together and reinforce thin areas of a design. The Snap Fit feature lets you define a set of standard snap fits and use them when needed.

Presets let you quickly reuse common values in certain commands in Fusion 360. You can create setting presets in the following commands: Extrude, Rib, Web, Boss, Snap Fit, Emboss, Thicken, Shell, and Draft.

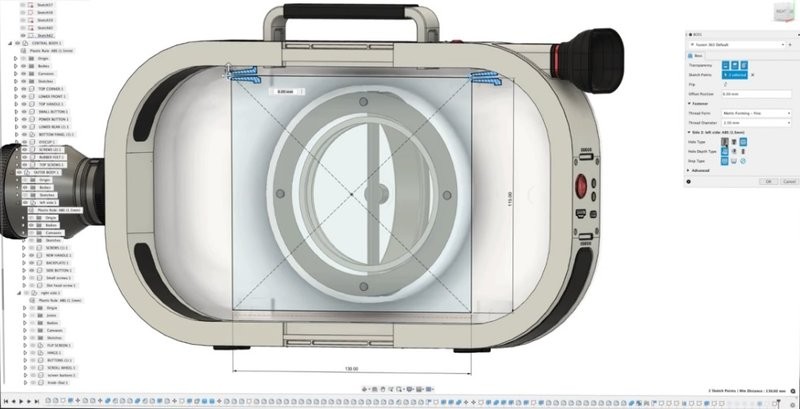

Allows for the creation of complex patterns with adjustable size and distribution gradients across a selected face.

Use the Convert Mesh command to convert organically shaped meshes to solid, surface, or T-Spline bodies.

You can modify existing solid or closed mesh parts to create complex volumetric lattices that alter the shape and appearance of a design.

This feature identifies manufacturability concerns based on best practices for plastic injection molding and company standards. It provides recommendations on how to improve the manufacturability and performance of your design.

The Fusion 360 Product Design Extension expands the design capabilities of the Fusion 360 software and provides product designers with additional tools allowing them to create production-ready high-performance models as fast as it has never been possible.

The system requirements for the Autodesk Fusion 360 software are as follows:

|

OS |

Apple macOS:

Microsoft Windows:

|

|

CPU |

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported |

|

RAM |

4 GB (integrated graphics recommend 6 GB or more) |

|

Hard disk |

3 GB of storage |

|

Display |

1366 x 768 (1920 x 1080 or greater at 100% scale recommended) |

|

GPU |

DirectX11 (Direct3D 10.1 or greater); dedicated GPU with 1 GB or more of VRAM; integrated graphics with 6 GB or more of RAM |

|

Pointing device |

HID-compliant mouse or trackpad, optional Wacom® tablet and 3Dconnexion SpaceMouse® support |

|

Internet |

2.5 Mbps or faster download; 500 Kbps or faster upload |

|

Dependencies |

SSL 3.0, TLS 1.2+, .NET Framework 4.5 or newer required to submit crash reports |

To learn the current price of the Autodesk Fusion 360 Product Design Extension, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now