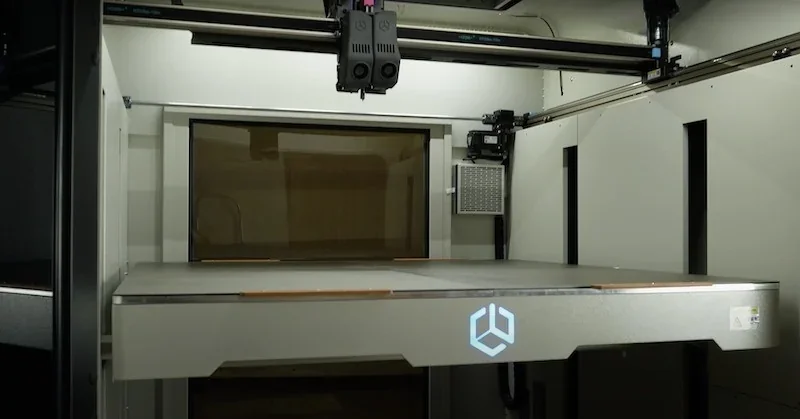

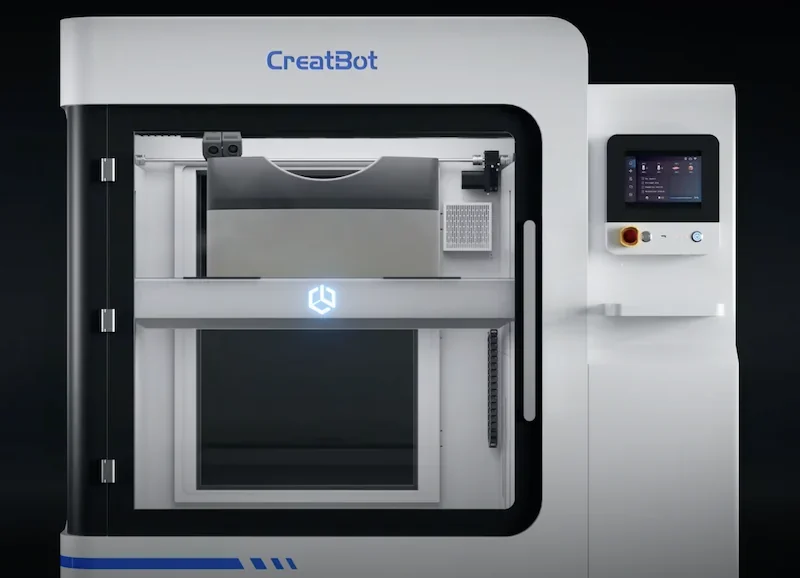

The CreatBot D1000 is a large-scale industrial 3D printer with a 1 m³ build volume, upgraded Klipper firmware for speeds up to 300 mm/s, and a dual-extruder system capable of printing high-performance materials like ABS, Nylon, and carbon fiber composites. Designed for manufacturers and prototyping labs, it combines speed, precision, and reliability with features like a 420°C extruder, heated chamber, auto-leveling, dry filament storage, and remote monitoring. Used by companies like Faurecia for automotive mold production, it enables cost-effective, in-house manufacturing with reduced lead times and expenses.

Exceptional detail is possible with the Creatbot D1000 3D printer, which prints at 50-micron resolution and maintains accuracy across its full 1 m³ build volume. Positioning precision of 11 μm (XY) and 2.5 μm (Z) ensures large-scale prints remain dimensionally accurate while meeting high-resolution standards for industrial use.

Stable speeds up to 300 mm/s—five times faster than the original D1000—are achieved without losing quality. Optimized Klipper firmware and a Volcano-based hotend enable this performance, reaching a 90 mm³/s flow rate.

Consistency on long prints comes from an all-steel chassis for vibration control, linear rails built to resist deflection over 1000 mm, and NEMA 34 servo motors with closed-loop control that prevent step loss while reducing heat and noise.

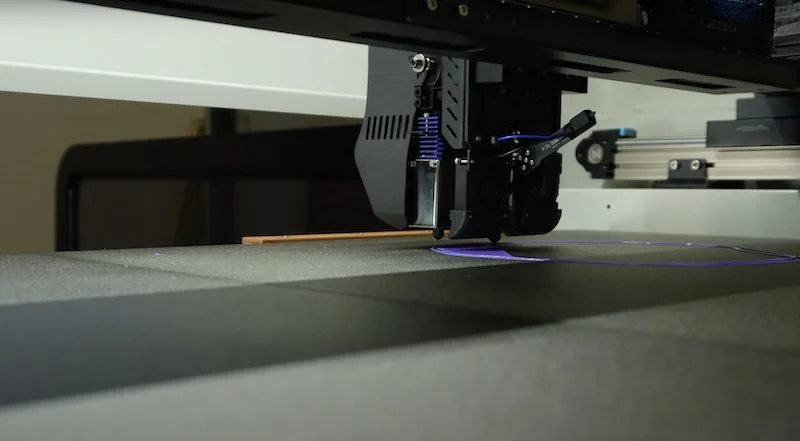

Print quality is reinforced by a 100-point auto-leveling system that maps the build plate with a precision servo probe and compensates in real time through intelligent Z-axis adjustments.

A 60°C enclosed heated chamber maintains stable conditions for high-performance materials, preventing warping and delamination.

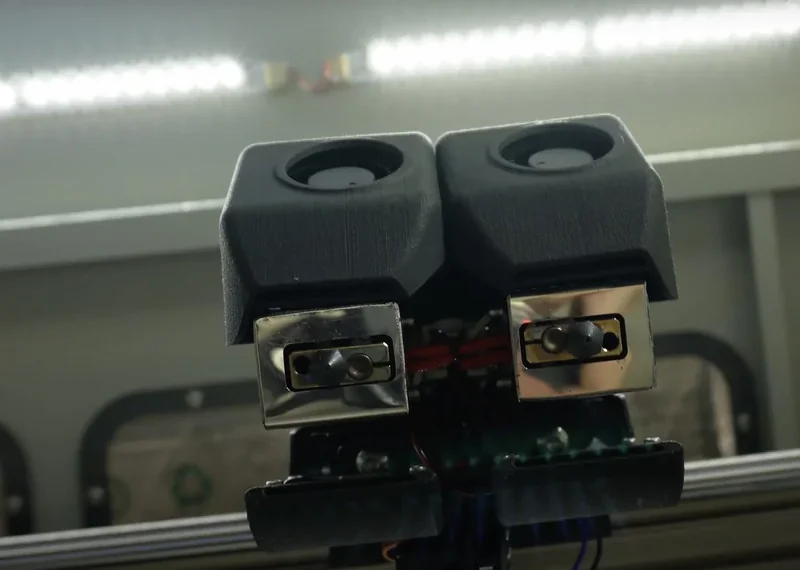

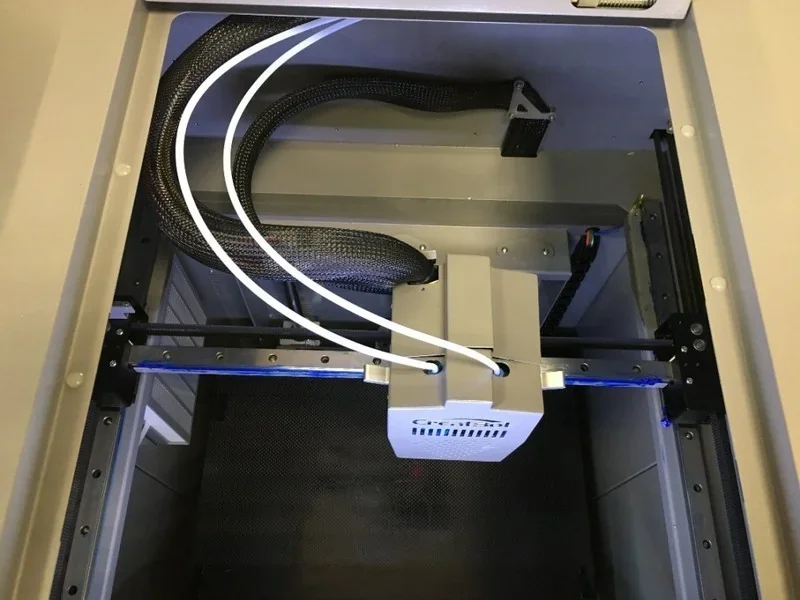

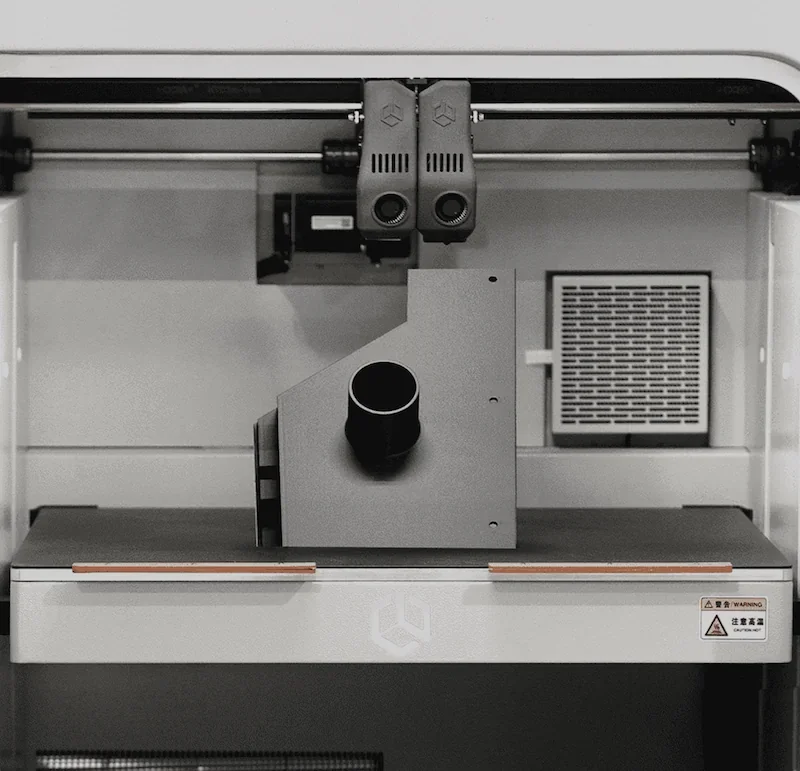

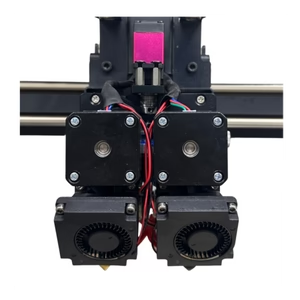

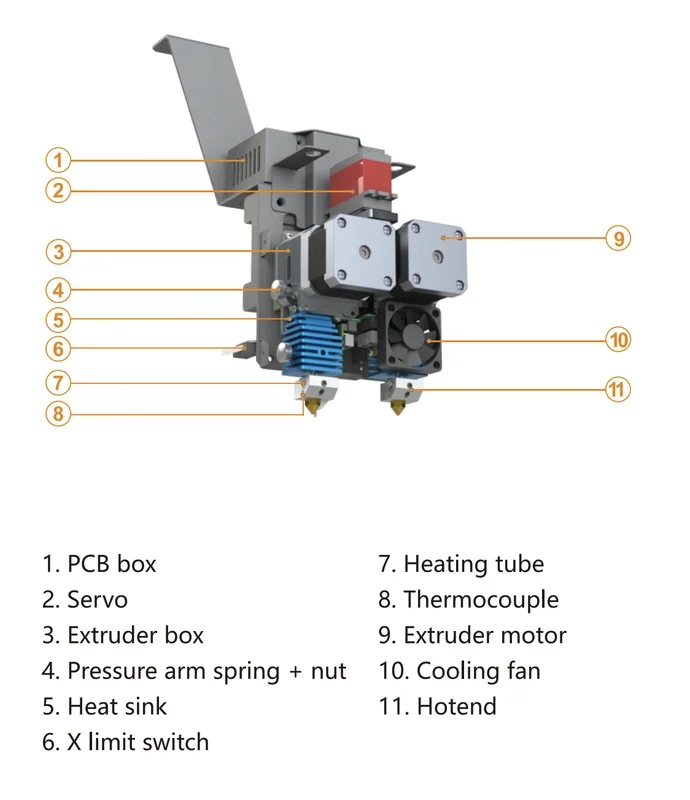

A direct-drive system with auto-rising dual extruders (up to 420°C) delivers steady, uniform extrusion while reducing stringing and oozing—vital for large prints that run for days.

Faurecia, supplier to Audi, Volkswagen, Nissan, and GM, uses the D1000 platform to produce seat molds. One project included a 820 × 748 × 160 mm lid (9 kg) and a 820 × 748 × 200 mm bowl (16 kg), printed in Nylon-carbon fiber with 50% infill. Both parts withstood 100 MPa of pressure and passed rigorous testing.

The Creatbot D1000 FFF 3D printer supports an open material system for any 1.75 mm filament up to 420°C. It works with over 10 types, from PLA, ABS, and ASA to high-performance options like PETG, PC, Nylon, and carbon fiber–reinforced variants.

CreatBot’s UltraPA-CF filament offers 80 MPa strength and 150°C heat resistance, suited for functional prototypes and end-use parts. The dual-extruder setup also supports PVA for dissolvable supports in complex prints.

PC-CF: A 6.5 kg industrial model printed in PC-CF measured 418 × 722 × 665 mm and required 217 hours to complete.

PC-CF: This large black industrial part, printed in PC-CF filament, weighs 6.5 kg, measures 418 × 722 × 665 mm, and took 217 hours to complete.

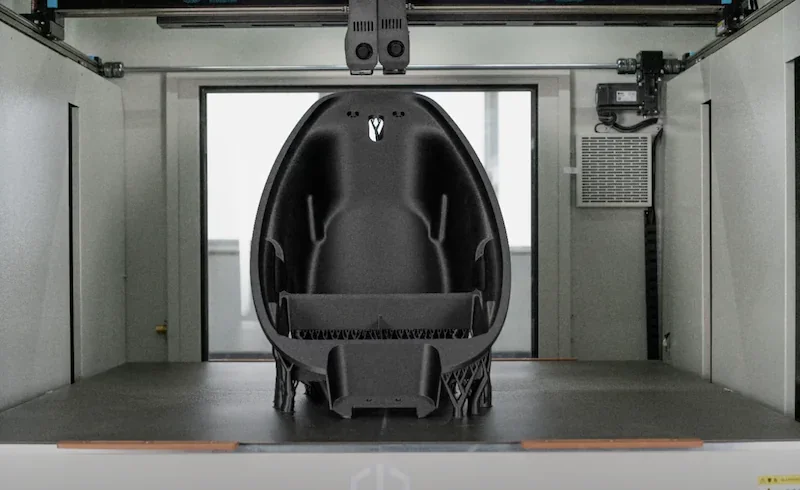

PET-CF: An electric vehicle seat printed in PET-CF filament weighs 2.4 kg, measures 750 × 390 × 375 mm, and required 65 hours to produce.

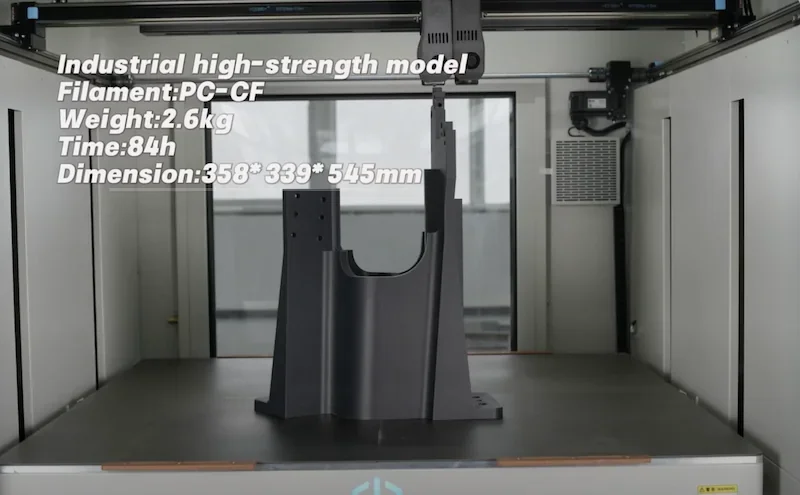

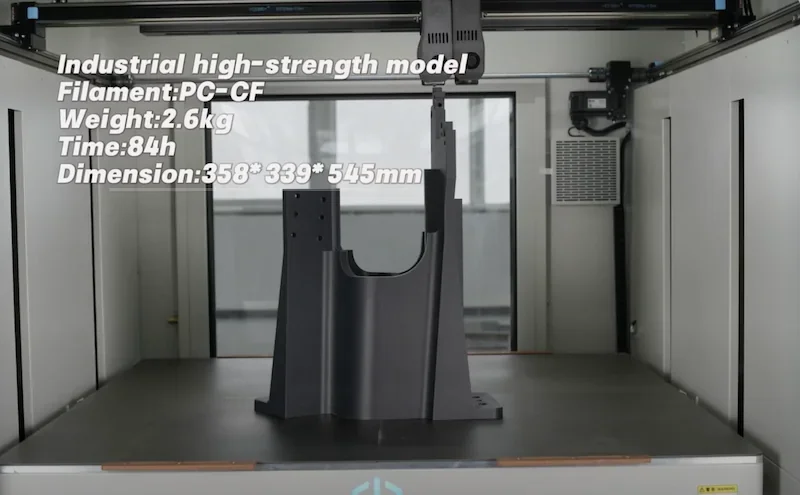

PC-CF: High-strength industrial component, made from PC-CF filament, weighs 2.6 kg, measures 358 × 339 × 545 mm, and took 84 hours to print.

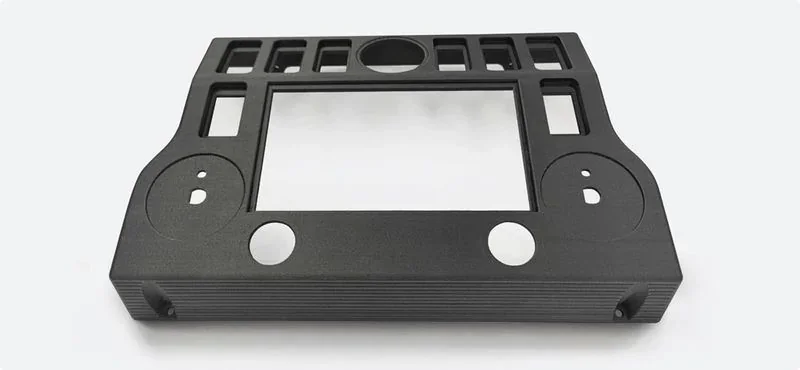

Other Print Samples:

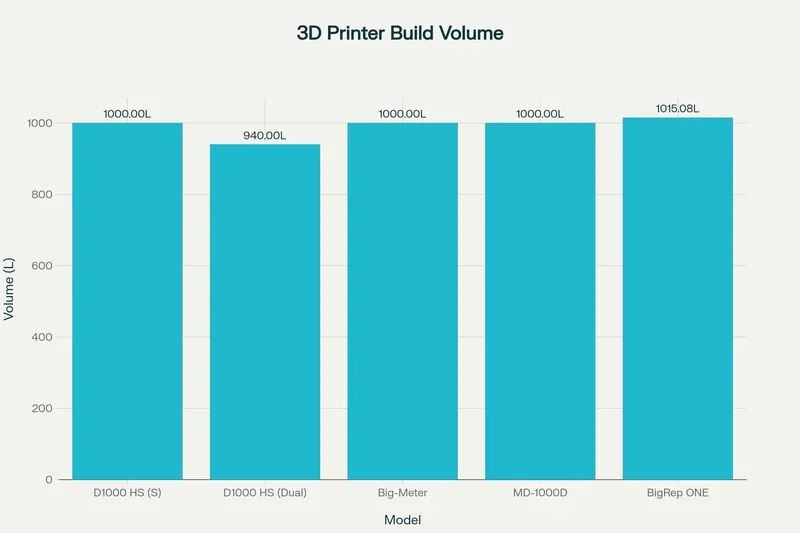

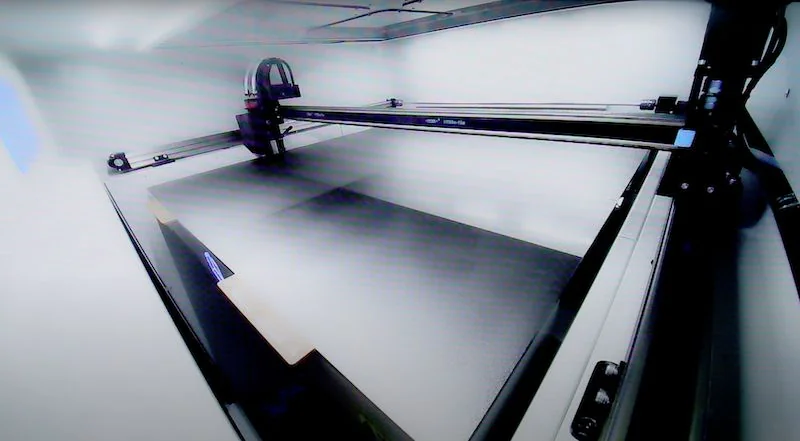

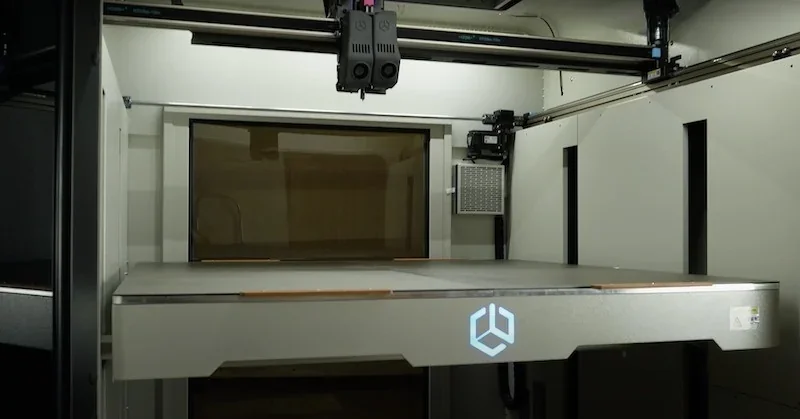

With a 1 m³ build volume (1000 × 1000 × 1000 mm) or 940 × 1000 × 1000 mm in dual-extruder mode, the D1000 HS ranks among the largest industrial grade 3D printers. Its capacity allows full-size parts, tools, and molds to be produced in one job, avoiding multi-part assembly—for instance, a 35 kg snake sample was printed in a single run.

Creatbot D1000 (HS) — turnkey 1 m³ platform focused on high-temp, large ABS/PA jobs: enclosed with an active 60 °C chamber, 420 °C nozzle, ~90 mm³/s flow, factory-assembled; dual (non-IDEX) narrows X to 940 mm and the bed tops out at 100 °C.

In contrast:

| Specification | CreatBot D1000 Pro HS | Modix Big-Meter | Mingda MD-1000D | BigRep ONE (ONE.5) |

|---|---|---|---|---|

| Price (USD) | $35,999+ | $20,000+ | $32,999+ | $49,900+ |

| Build volume (mm) | 1000 × 1000 × 1000 (Single); 940 × 1000 × 1000 (Dual) | 1000 × 1000 × 1000 | 1000 × 1000 × 1000 | 1005 × 1005 × 1005 |

| Enclosure / chamber | Enclosed, Active Heated chamber: 60 °C | Enclosed; No active heated chamber. | Enclosed; No active heated chamber. | Open frame; no heated chamber |

| Extruders / IDEX | Dual, not IDEX | Single; IDEX optional | Dual extruders, not IDEX | Single/Dual/Twin (IDEX) modes available |

| Max nozzle temp (°C) | 420 | Components rated 500 (tested to 340) | ≤ 350 (rec ≤ 320) | 280 |

| Max bed temp (°C) | 100 | 110 | 110 | 80 |

| Volumetric flow (mm³/s) | 90 | Std ~30; High-Flow 45–60; Ultra 160 | 40 | n/s |

| Rated output (g/h) | n/s | Std ~93.8; Ultra >500 | n/s | ~72 |

| Assembly | Assembled | Self-assembly kit (assembly services available in the US/EU) | Assembled | Assembled |

The CreatBot D1000 offers a 1000 × 1000 × 1000 mm build volume, while the D600 HS provides 600 × 600 × 600 mm.

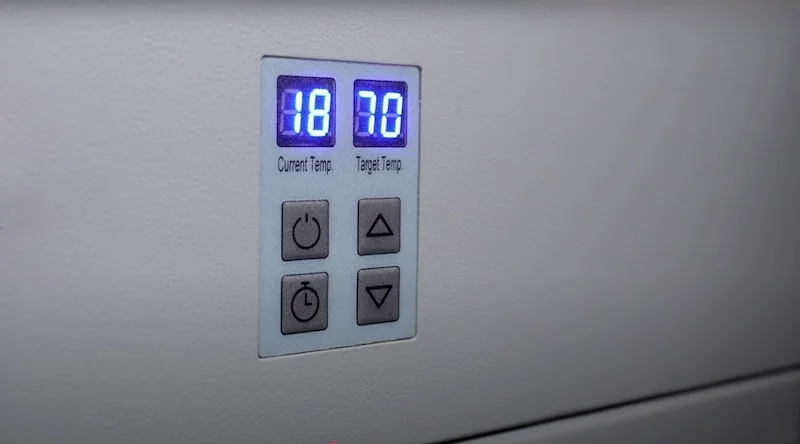

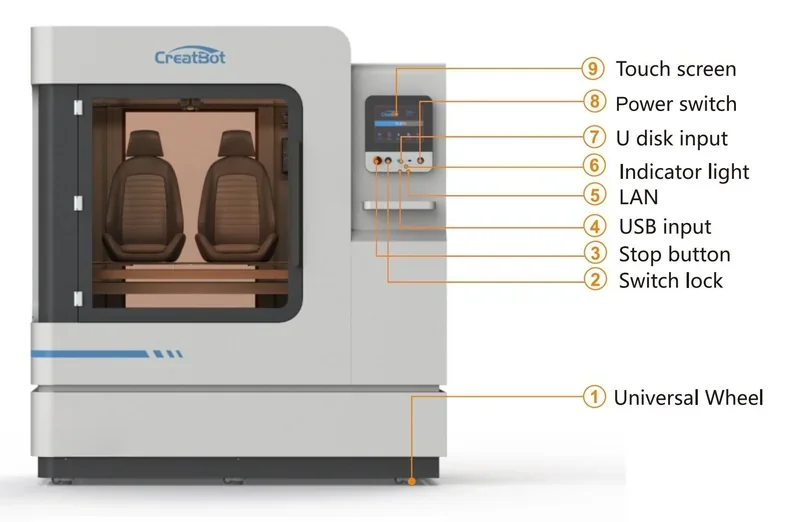

The D1000 HS uses a 9.7-inch full-color touchscreen with multi-language support as its main control hub. It offers six menus: axis controls, filament management, status monitoring, settings, U-disk file access, and print operations with resume function.

Through the touchscreen, users can set nozzle temps up to 420°C, bed temps to 100°C, and control chamber and hot air heating. It also allows real-time pause, stop, and resume, axis movement in 1/10/100 mm steps, filament loading/unloading, and motor calibration for X, Y, Z, and extruders.

The control panel also manages the filament dry room, with settings of 45°C and 65°C to condition moisture-sensitive materials before printing.

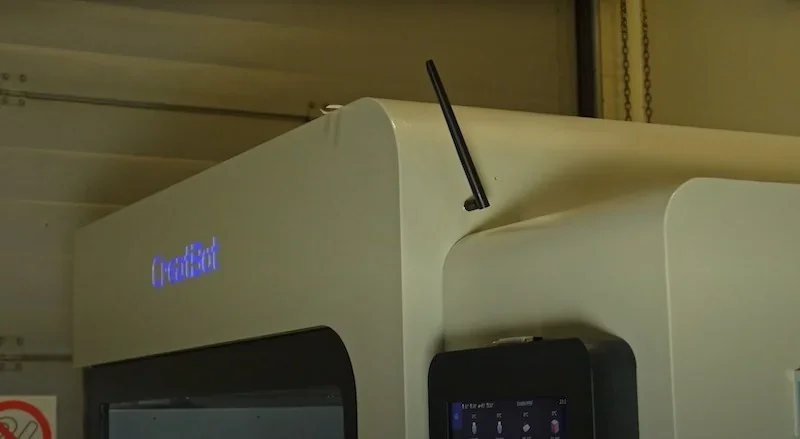

The D1000 HS offers three connectivity options: USB for direct transfer, WiFi for wireless control and remote access, and U-disk support for standalone printing without a computer.

Wi-Fi Antenna:

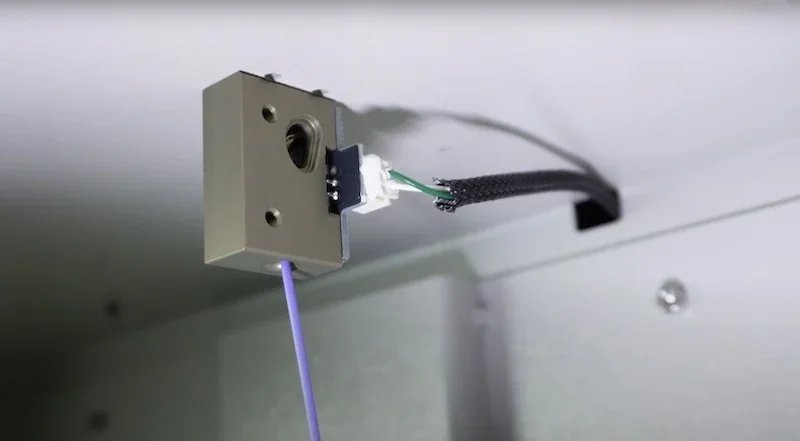

A standout feature is the integrated camera system, which lets users monitor and control prints via a mobile app. Operators can adjust speed, temperatures, and pause/resume in real time—especially useful for multi-day print jobs—ensuring quality and reducing failure risks.

Camera:

Remote Control Interface:

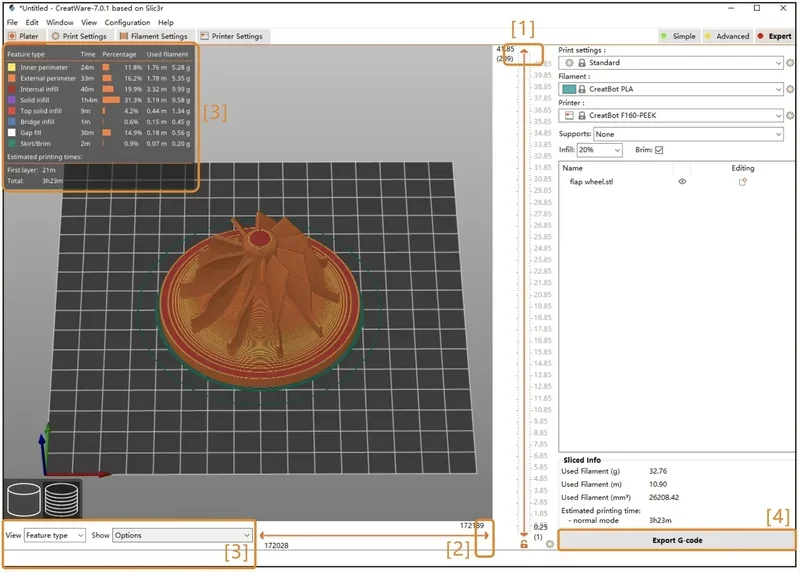

The D1000 HS comes with CreatWare slicing software optimized for CreatBot machines. Its user-friendly interface features fast processing, parameter modes for balancing speed and accuracy, and preview simulations to visualize settings before printing.

Beyond CreatWare, the D1000 HS supports third-party slicers like Orca Slicer, Cura, Simplify3D, and PrusaSlicer, giving users flexibility in workflow.

The D1000 HS features an all-steel chassis tested over 9 years and 30,000 hours, oversized linear rails to prevent sag, and NEMA34 servo drives with 11 μm XY and 2.5 μm Z precision. Its four-segment aluminum platform uses magnetic BuildTak sheets, while a 70°C heated chamber, HEPA filtration, RCD protection, and integrated filament dry room ensure industrial-grade reliability.

Engineered for large-format precision, the D1000 HS uses oversized linear rails with calculated metal thickness to prevent deflection across spans over 1000 mm, eliminating sag common in standard rails.

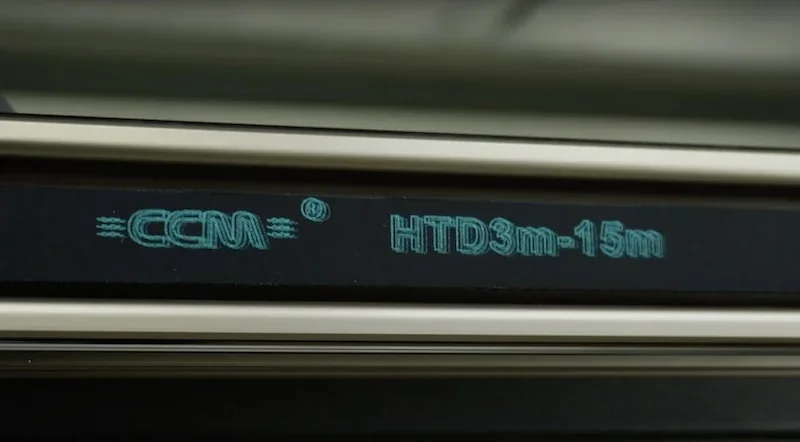

The rail modules use high-strength CCM belts, a trusted brand in industrial drive components.

Motion control relies on NEMA34 servo drives with closed-loop control, delivering fast response, no inertia, and zero delays. This system prevents step loss, lowers heat and noise, and sustains positioning accuracy of 11 μm (XY) and 2.5 μm (Z).

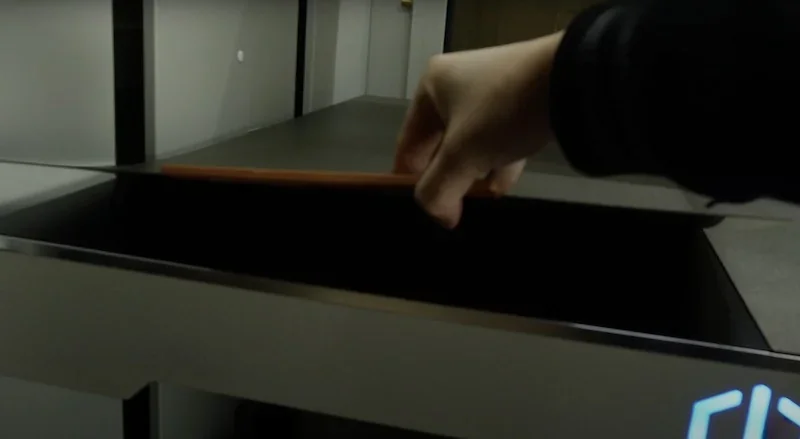

The build platform is made of four aluminum segments, leveled on a single plane and topped with four magnetic BuildTak sheets coated with PEI.

The platform is driven by four heavy-duty ball screws strong enough to support a person’s weight while maintaining precise Z-axis positioning.

A servo probe maps 100 points for auto bed leveling, generating a flatness profile. The system then applies Z-axis compensation during printing to ensure consistent first-layer adhesion across the full 1 m³ build area.

The enclosed chamber uses powerful heaters to reach 70°C, maintaining consistent internal temperatures.

The HEPA filtration system captures particles and volatile compounds released during printing.

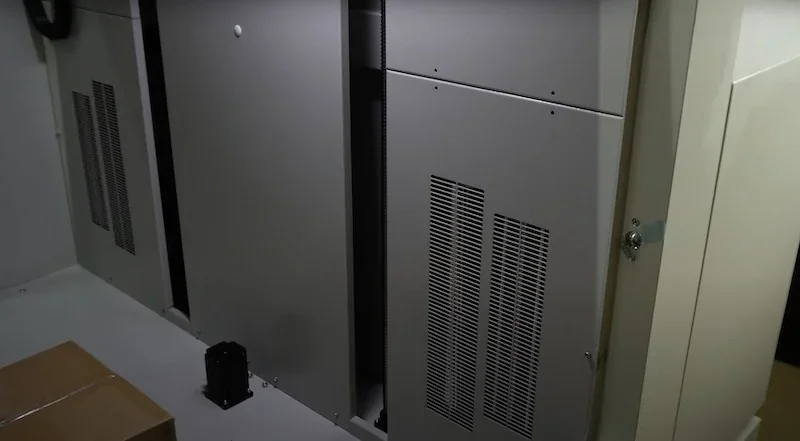

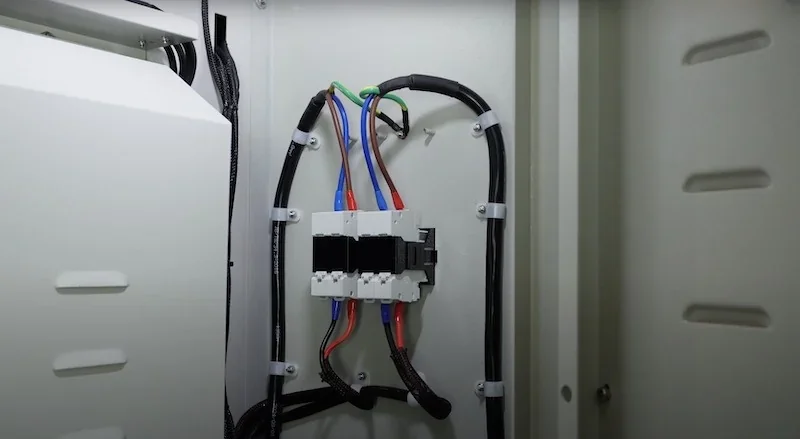

The D1000 HS uses industrial-grade electrical architecture protected behind a removable front panel. A residual current device (RCD) provides ground fault protection for operator safety during high-power use.

A high-capacity power supply ensures stable delivery for the heating zones, servo motors, and electronics running simultaneously.

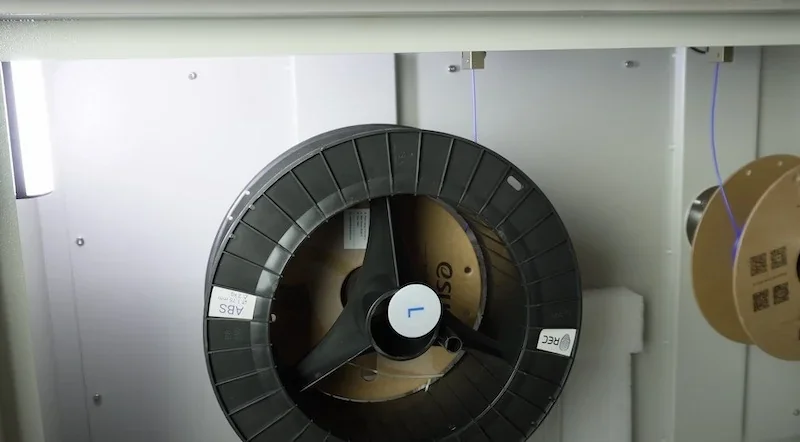

The integrated dry room holds two 5 kg filament rolls and maintains 45°C or 65°C to preserve material quality.

Filament Runout Sensor:

Main Components

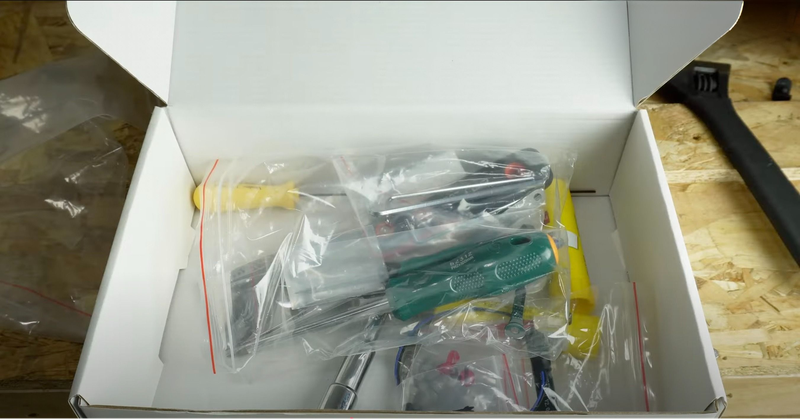

Documentation

Filament

Tools and Accessories

Spare Parts and Consumables

The D1000 HS ships fully assembled and ready to run after calibration. It includes the 420°C dual-extruder system, servo-driven auto-leveling, integrated camera monitoring, and pre-installed Klipper firmware for high-speed printing. Shipping dimensions are 1980 × 1520 × 2200 mm with a total weight of 750 kg, reflecting its heavy-duty build and 1 m³ capacity.

Note: Package contents are set by the manufacturer and may change without notice. Confirm current inclusions with a sales representative before ordering.

Creatbot offers over 30 spare parts and accessories.

| Product | Price (USD) | Image |

|---|---|---|

| Hotend and heating parts | ||

| CREATBOT QUICK-REMOVE HOTEND FOR CREATBOT D1000 HS | $329.00 |  |

| CREATBOT HEATBREAK WITH PTFE TUBE FOR 260°C HOTEND FOR CREATBOT D1000 HS 3D PRINTER | $29.00 |  |

| CREATBOT HEATBREAK FOR 420°C HOTEND FOR CREATBOT D1000 HS 3D PRINTER | $29.00 |  |

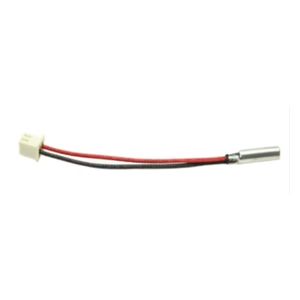

| CREATBOT HEATING SENSOR FOR CREATBOT D1000 HS | $54.00 |  |

| CREATBOT HEATING TUBE FOR CREATBOT D1000 HS | $54.00 |  |

| Extruder and nozzle parts | ||

| CREATBOT DUAL-GEAR EXTRUDERS FOR CREATBOT D1000 HS 3D PRINTER | $1,499.00 |  |

| CREATBOT EXTRUDER PCB FOR CREATBOT D1000 HS | $179.00 |  |

| CREATBOT EXTRUDER MOTOR DRIVER FOR CREATBOT D1000 HS | $113.00 |  |

| CREATBOT HARDENED STEEL NOZZLE FOR CREATBOT D1000 HS 3D PRINTER | $29.00 |  |

| CREATBOT BRASS NOZZLE FOR CREATBOT D1000 HS 3D PRINTER | $19.00 |  |

| Build plate and surface parts | ||

| CREATBOT PEI SHEET FOR CREATBOT D1000 HS 3D PRINTER | $259.00 |  |

| CREATBOT REMOVABLE MAGNETIC SHEET WITH PEI COATING FOR D1000 HS | $369.00 |  |

| CREATBOT REMOVABLE MAGNETIC SHEET FOR D1000 HS | $349.00 |  |

| Cooling and air filter parts | ||

| CREATBOT SINK FAN FOR CREATBOT D1000 HS | $83.00 |  |

| CREATBOT COOLING FAN (FRONT) FOR CREATBOT D1000 HS | $83.00 |  |

| CREATBOT COOLING FAN (BACK) FOR CREATBOT D1000 HS | $83.00 |  |

| CREATBOT HEPA & CARBON AIR FILTER FOR CREATBOT D1000 HS | $195.00 |  |

| Sensors | ||

| CREATBOT FILAMENT SENSOR NEW 2P / 3P FOR D1000 HS 3D PRINTER | $49.00 |  |

| Motion actuators (servos) | ||

| CREATBOT SERVO FOR AUTOMATIC RISING NOZZLE FOR CREATBOT D1000 HS | $94.00 |  |

| CREATBOT HEAT SINK FOR CREATBOT D1000 HS | $49.00 |  |

| CREATBOT SERVO FOR BED LEVELING FOR CREATBOT D1000 HS | $84.00 |  |

| Motors | ||

| CREATBOT Z MOTOR FOR CREATBOT D1000 HS 3D PRINTER | $349.00 |  |

| CREATBOT X MOTOR FOR CREATBOT D1000 HS 3D PRINTER | $440.00 |  |

| CREATBOT Y MOTOR FOR CREATBOT D1000 HS 3D PRINTER | $440.00 |  |

| Main control electronics (boards + drivers) | ||

| CREATBOT MOTHERBOARD FOR CREATBOT D1000 HS | $499.00 |  |

| CREATBOT AC POWER CONTROL BOARD FOR CREATBOT D1000 HS | $369.00 |  |

| CREATBOT X MOTOR DRIVER FOR CREATBOT D1000 HS | $369.00 |  |

| CREATBOT Y MOTOR DRIVER FOR CREATBOT D1000 HS | $369.00 |  |

| Power | ||

| CREATBOT POWER SUPPLY-150W FOR CREATBOT D1000 HS | $229.00 |  |

The CreatBot D1000 requires8 primary maintenance procedures.

Motion System Maintenance (3 items)

Electrical System Maintenance (2 items)

Environmental Controls (2 items)

Platform Maintenance (1 item)

Preventive Maintenance Requirements

The D1000 HS includes a 12-month warranty covering defects and component failures from delivery, with free replacement parts and repair guidance. Hotends and nozzles, treated as consumables, carry a 6-month warranty.

As an authorized reseller, Top 3D Shop offers added support via phone, chat, and email Monday–Friday. Assistance covers not only troubleshooting but also print optimization, material selection, and operational guidance.

CreatBot provides lifetime online support, including firmware updates, software help, and technical consultation. Users can contact support@creatbot.com with 24-hour weekday responses or schedule Skype sessions for complex issues. Customer feedback highlights fast, helpful responses, especially on filament compatibility, ensuring continuous expert support to maximize uptime and productivity.

Full up-to-date warranty terms are available on the manufacturer's website: https://www.creatbot.com/en/warranty.html

The price of the CreatBot D1000 is $33,107.07. This investment offers a 1 m³ build volume, 300 mm/s print speeds, and compatibility with engineering-grade materials. With a 90 mm³/s flow rate hotend, heated chamber, and remote monitoring, it reduces costs and lead times by enabling in-house production of full-size prototypes, tooling, and end-use parts that would otherwise require outsourcing or multi-part assembly. Buy CreatBot D1000 at Top 3D Shop!

Update your browser to view this website correctly. Update my browser now