The DOBOT CR5A is a collaborative robot that is primarily designed for efficient and safe manufacturing automation. Featuring powerful integrated joints that boost cycle times by 25%, it represents a compact, easy-to-use, plug-and-play machine with remarkable technical characteristics making it an ideal device for a wide range of industries, including automotive, consumer electronics, semiconductor, healthcare, chemical, and new retail. With the complete installation process taking no more than 20 minutes, the cobot is ready for work in just an hour.

Being the second smallest model in the series, CR5A possesses a yet decent reach coupled with a payload sufficient for the majority of precise lightweight tasks. Alongside high speed and repeatability, the machine provides intuitive and quick-to-learn control options, such as graphical programming interface and drag teaching, making it ideal both for beginners and experienced manufacturers looking for advanced automation opportunities.

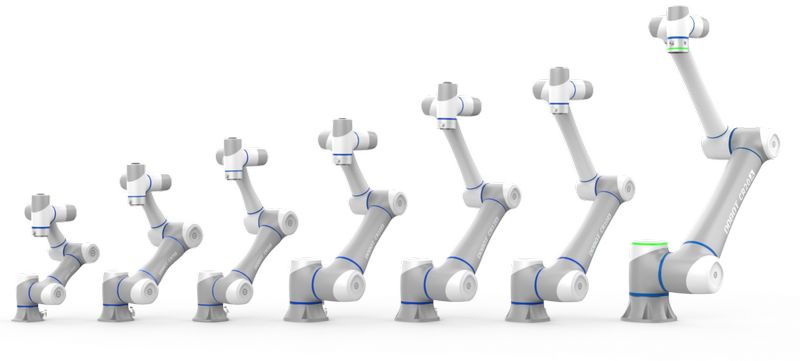

The DOBOT CRA series introduces several payload options — from 3 to 20 kg — and corresponding reaches of up to 1700 mm that cover the majority of automation tasks. Apart from the CR5A model, it includes CR3A, CR10A, and CR20A. Due to advanced safety protocols, easy programming, simple deployment, and increased performance, the cobots from the line are perfect for harmonious work alongside people of various professions and skills.

To further enhance the efficiency of the CRA series implementation, it is possible to use different grippers, cameras, and sensors that can be connected to multiple IO and communication interfaces. Secondary development is supported on 20+ platforms.

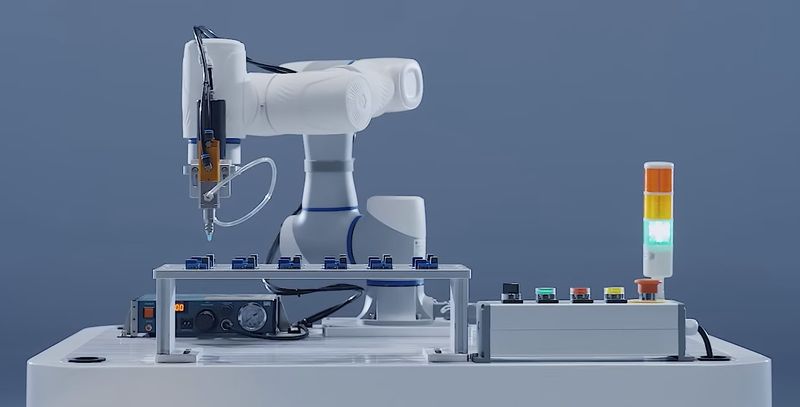

The CR5A collaborative robot combines a compact and flexible design, decent working radius, high precision, and intuitive controls, which makes it great for assembly, machine tending, gluing, polishing, screwdriving, welding, or quality inspection in multiple spheres where repetitive tasks have to be performed in challenging environments and take a lot of human time and effort. Overall, DOBOT software packages cover 50+ tasks that can be used across modern industries.

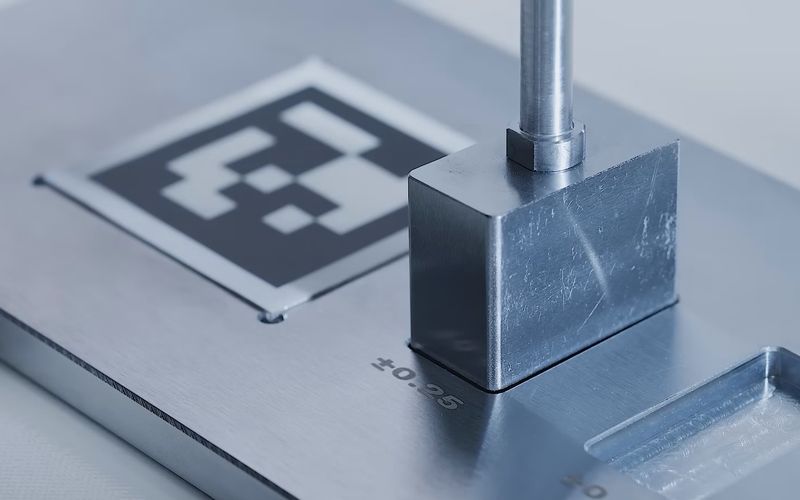

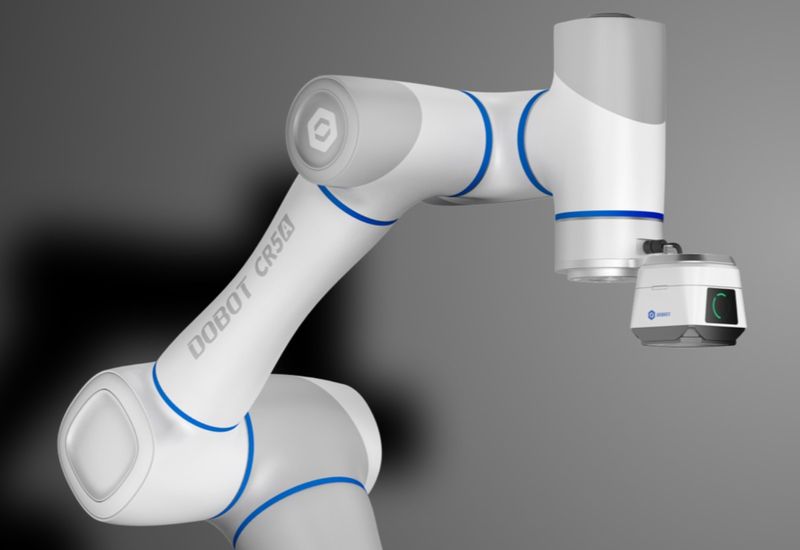

The DOBOT CR5A possesses high reliability coupled with professional accuracy and industry-leading DH parameter compensation technology. It features 6 axes and is able to repeat the same movement within ±0.02 mm at a maximum speed of 2 m/s. In combination with 5 kg payload, this lets the robot perform an ample range of difficult precision tasks with ease.

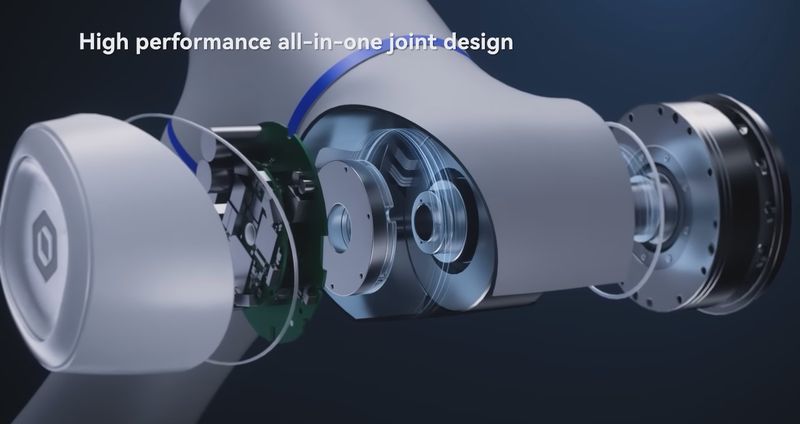

The latest integrated joint enhances the joint speed up to 223°/s, which is the highest in the industry. This improvement allows for a wider range of application scenarios and boosts the production cycle time of common tasks like material handling by 25%. Consequently, it generates greater economic benefits.

Overall, the EtherCAT bus utilized by the joint servo provides a vast bandwidth of hundreds of megabits and a joint response speed in the millisecond range. In combination with a thoughtful all-in-one design, this feature greatly enhances the robot’s movement speed and trajectory smoothness, enabling it to efficiently carry out a wide array of tasks.

Due to a high rating of ingress protection, namely IP54, the CR5A robot can operate in various application scenarios implying potential environmental hazards, like dust and water. Moreover, the machine is fully operational from 0 to 45 °C.

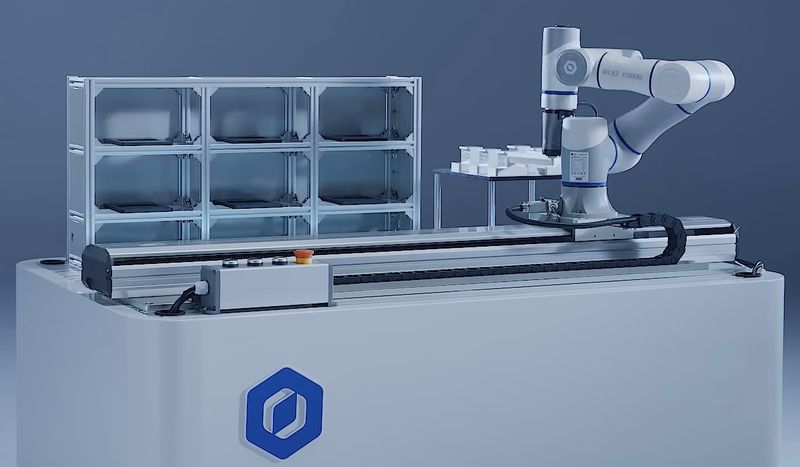

With several range and payload capacities, the DOBOT CRA cobots are suitable for a variety of operations of demanding and repetitive character. Due to its rapid deployment and smart functionality, the CR5A model is perfect for automated polishing, screwdriving, bin picking, and other light tasks for consumer electronics, semiconductor, food and beverage, metal processing, healthcare, and other industries.

Apart from the already mentioned tasks, you can entrust the CR5A cobot with assembly, gluing, quality inspection, loading and unloading, etc.

As an optional add-on, one can also purchase the VX500 Smart Camera. Equipped with a 5MP sensor and an LED light source, it utilizes Dobot’s proprietary 2.5D spatial compensation technology to achieve a positioning accuracy of ±0.26 mm. This technology is ideal for various applications, such as grabbing objects on slanted surfaces, fixed-position assembly, AMMR robot transportation, and loading/unloading tasks. Its user-friendly visual operation software simplifies deployment and eliminates the need for complex development.

The reasonable implementation of the DOBOT CRA series allows one to automate manifold production processes, save time and costs while maintaining the workers’ safety and health.

The DOBOT CR5A model possesses a maximum reach of up to 900 mm in combination with a flexible, ergonomic design.

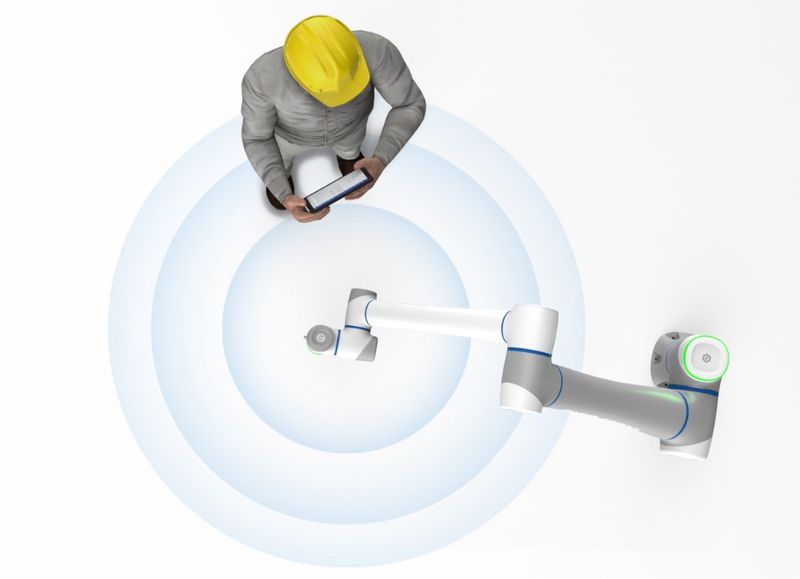

To ensure complete safety around the machine, the DOBOT CRA series is engineered with 20+ safety features and is ISO 13849-1, ISO 10218-1, and ISO/TS 15066 certified. Equipped with a stand-alone safety controller as well as sensors offering 5 adjustable levels of collision detection, it can adapt to a variety of application scenarios.

In the event of an unexpected power outage, the robot swiftly engages its electromagnetic brake within 18 ms and ensures position retention within 1 mm, thus mitigating potential equipment or product damage.

The innovative pre-collision sensing technology known as SafeSkin represents an optional accessory for the CR3A, CR5A, and CR10A models. With high surface coverage, long sensing distance, and quick response time, this mechanism takes human-machine collaboration to a new level.

The DOBOT CR5A can be easily manipulated via a full range of operating terminals, including a smartphone, tablet, PC, and hand-held teaching pendant with a 10.1" HD capacitive screen.

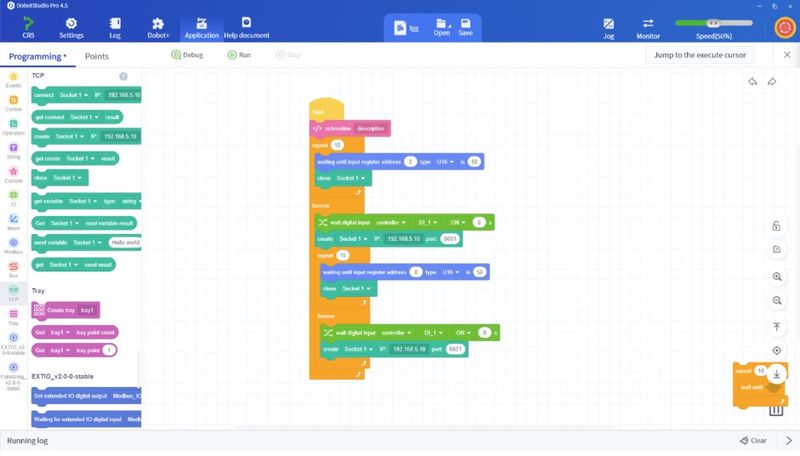

Due to the proprietary DobotStudio Pro software platform featuring intuitive graphical programming interface and simple scripting, the whole DOBOT CRA series allows users to easily set and adjust tasks from any connected device, with no prior programming experience required.

With an intelligent interactive panel, the operator of any skill level can simply drag the cobot to desired positions and teach it necessary functions.

The CR5A cobot also features all-perceptive AI technology with vision, force, and voice controls combined. Smart trajectory tracking and portable learning algorithms enable imitation of human hand motions, which makes the experience with the DOBOT CRA series even more efficient and convenient.

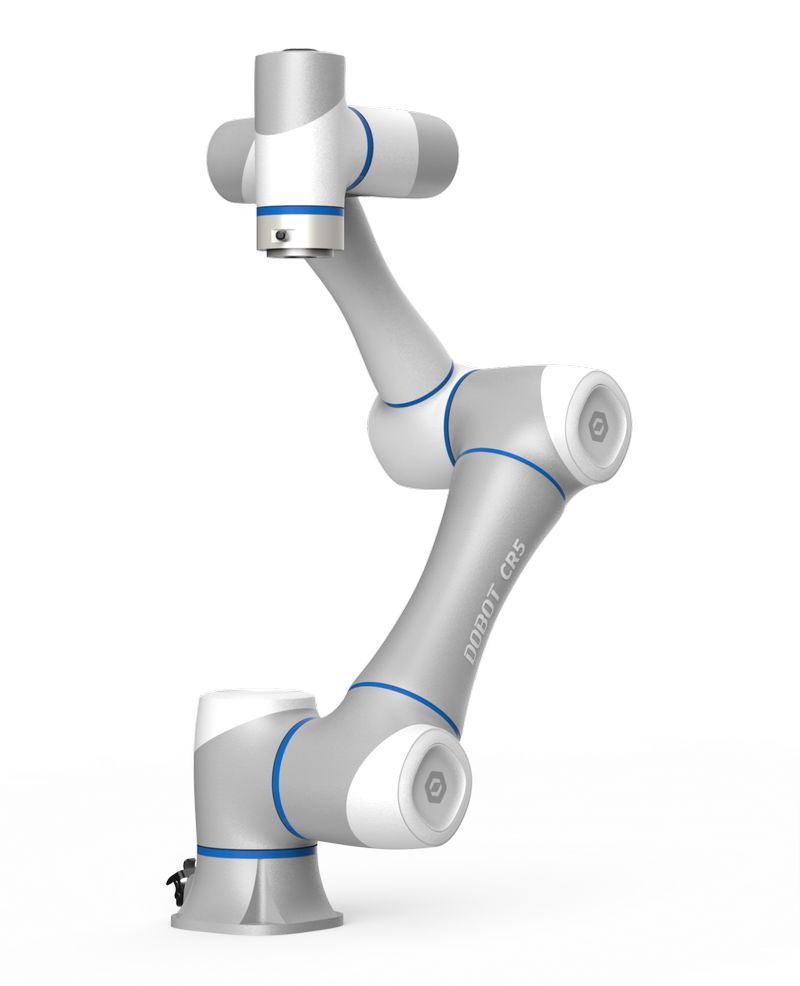

The DOBOT CR5A is available in white with light gray trimmings. Its stylish look makes it ideal for a wide number of applications and will decorate any factory, workshop, lab, etc.

The device offers a flexible design with simplified wiring and overall durable aluminum construction. It weighs 55 lbs (25 kg).

To learn the current price of the DOBOT CR5A collaborative robot, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now