The E-Plus 3D EP-M150 Dental is an industrial SLM 3D printer with a compact cylinder build chamber, designed specifically for digital dentistry. The dental version of the EP-M150 model is characterized by a smaller build volume height and only 200W laser option (single or dual). Providing precise and reliable printing with various metal and metal alloy powders, the machine perfectly suits for manufacturing dental models, crowns, bridges, surgical guides, and other appliances, as well as for efficient production of high-quality metal parts for other industries, such as medical, jewelry, scientific research, and more.

Small laser spot and proprietary laser scanning path technology allow building high-quality parts with great accuracy and repeatability, which is extremely important while printing patient-specific medical appliances. To ensure reliable, safe operation, the build chamber is tightly sealed, the oxygen concentration is kept below 100 ppm during printing and can be monitored in real time. Due to the scanning speed of up to 8 m/s and optimized recoating strategy, the printer ensures time-efficient operation, while its modular design facilitates maintenance and reduces possible downtime.

With improved powder feeding and sieving system and gas consumption level below 0.2 L/min, the EP-M150 Dental is a cost-efficient solution for many applications.

The EP-M150 Dental can print layers with a thickness ranging from 20 to 50 microns. This allows for precise print setting adjustment depending on a certain application and required print quality and level of detail. Single or dual laser system with a spot size of 40–60 microns ensures highly precise and fast printing.

Titanium alloy, ⌀150 x h70 mm, printing time 5 h

Cobalt chrome, ⌀150 x h35 mm, printing time 4.5 h

The machine prints with metal and metal alloy powders that are suitable for direct manufacturing of high-quality metal components with various properties. It can process titanium, aluminum, and nickel-based alloys, maraging steel, stainless steel, cobalt chrome and copper alloys, and others.

The cylinder build volume of ⌀153 x 80 mm is ideal for batch manufacturing of dental models, medical implants, and other small-sized parts. It takes about 5.5 hours to print a full plate (approximately 220 pieces) of dental crowns.

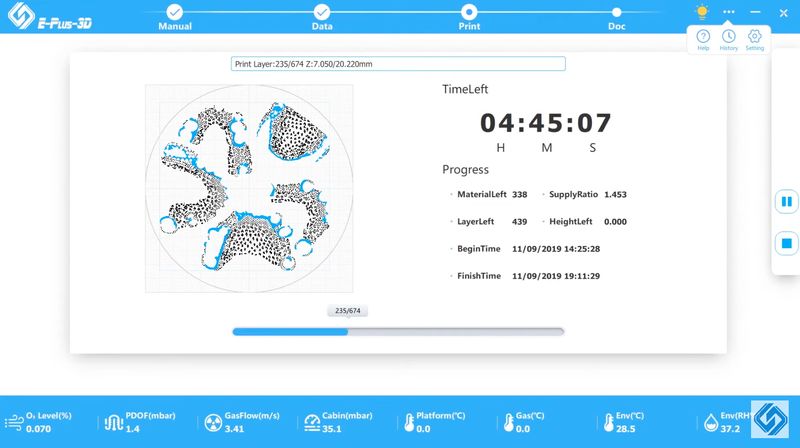

The EP-M150 Dental is operated via an integrated control unit with a user-friendly interface, real-time monitoring and adjustment of printing parameters, and fully automatic one-click printing function. The software calculates the estimated processing time and generates a printing report when the printing is over.

The proprietary EP-Hatch processing software allows using optimized scanning strategies to reduce print times. EP-Hatch can be integrated with the Siemens NX software for improved production efficiency.

For some items, package content may change. In case of any questions, please get in touch.

The EP-M150 Dental SLM 3D printer is available in white with black trimmings. Its stylish look makes it ideal for a variety of applications in the dental and other industries.

The machine dimensions are 68.9 x 31.9 x 86.2 in (1750 x 810 x 2190 mm). It weighs 1984 lbs (900 kg).

To learn the current price of the EP-M150 Dental 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now