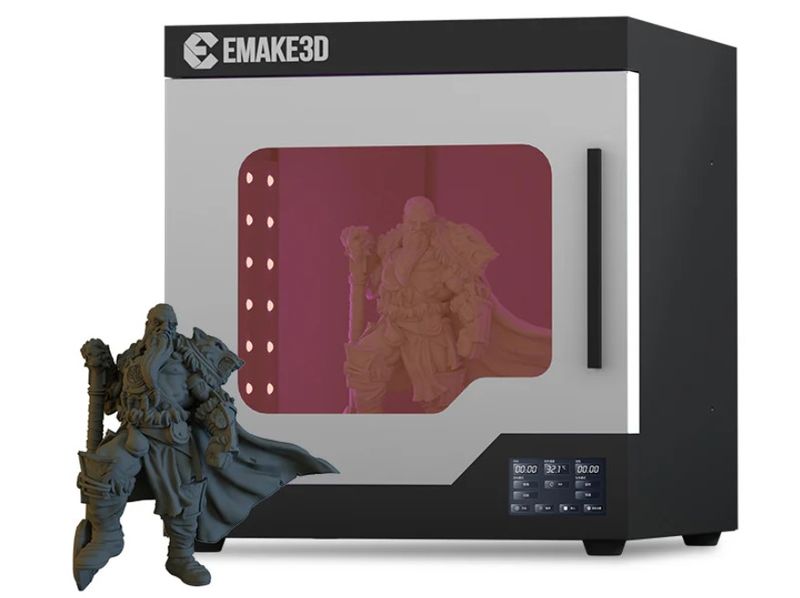

The Emake3D 3D printing post-processing curing box delivers 405nm UV LED curing technology with 120W total power output for professional resin polymerization operations. This Emake3D curing device transforms uncured photopolymer parts into mechanically optimized final products through controlled UV exposure that achieves complete polymerization within 5–15 minutes, according to researchers from University of Limerick during their Impact of Increased UV Curing Time study. The machine’s internal capacity provides 64 liters of curing volume, accommodating large-format resin prints and enabling batch processing operations for dental laboratories, manufacturing facilities, and professional makerspaces.

The professional curing solution from Emake3D supports SLA, DLP, and LCD 3D printing systems through 405nm wavelength compatibility that optimizes curing efficiency for standard photopolymer materials. This post-processing curing device optimizes mechanical properties including 75 MPa ultimate tensile strength improvement compared to uncured specimens, enhancing dimensional stability and impact resistance for professional applications.

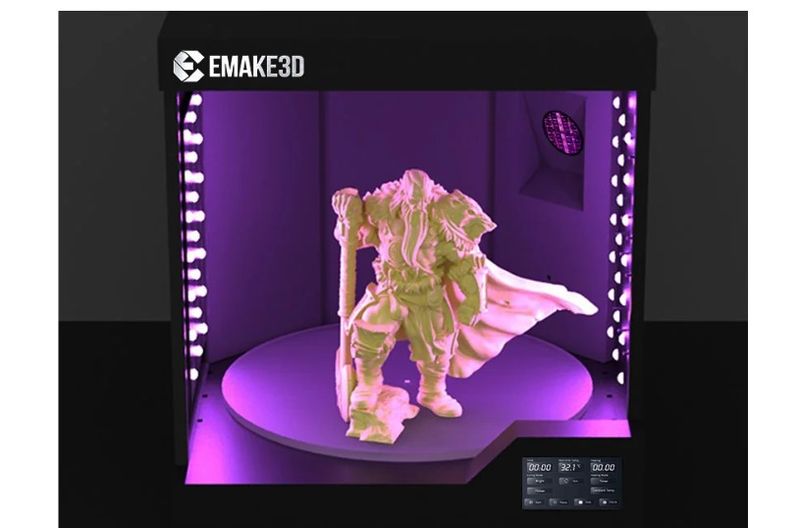

The Emake3D post-processing curing box incorporates 3 independent UV lighting systems with 40W power output per unit, delivering 120W total power from multiple angles throughout the curing chamber. The 360-degree rotating platform eliminates 100% of shadowed areas during the curing process by providing direct exposure to all model surfaces.

The multi-directional LED arrangement creates uniform light distribution with UV LED operational life exceeding 20,000 hours of continuous use, ensuring long-term reliability and reducing maintenance requirements. The 405nm wavelength specification optimizes curing efficiency for standard photopolymer resins, with 405nm representing the optimal wavelength for resin absorption and reaction rates.

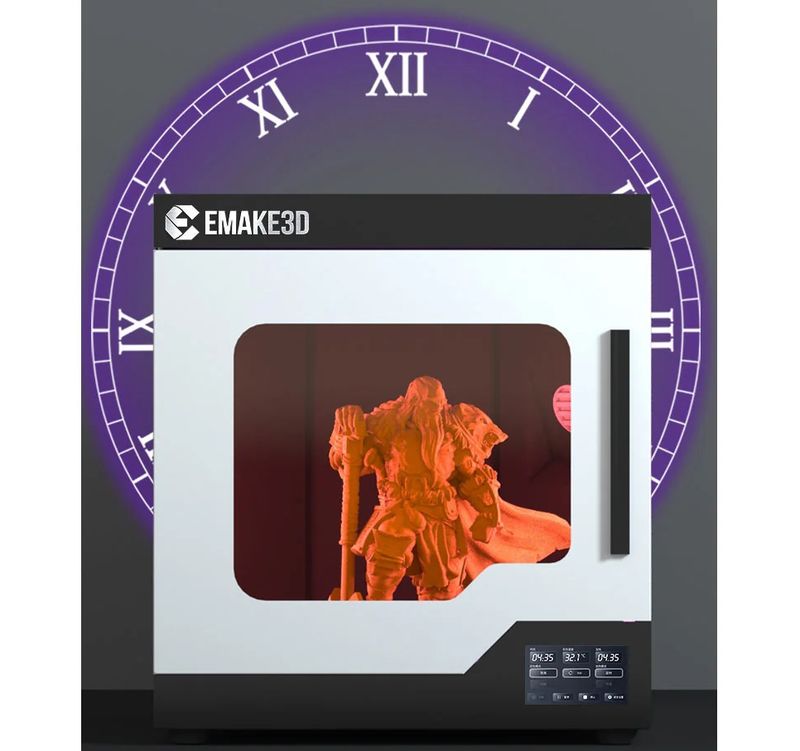

Programmable timing controls enable precise curing cycles from 5–60 minutes with automatic shutdown functionality preventing 100% of over-processing incidents. The dual-mode operation supports both curing and heating functions, allowing temperature-controlled processing that enhances mechanical properties of cured parts. For example, elevated temperature curing at 60 °C achieves highest flexural strength and modulus values compared to room temperature processing, according to researchers from University of Technology Malaysia during their Effects of post polymerization time and temperature study (Journal of Dental Sciences, 2024). This temperature-controlled curing delivers 18.19% increased flexural strength after 30-minute exposure cycles compared to non-cured specimens, according to material testing conducted by researchers from University of Limerick during their Effects of Post-UV-Curing study (2023).

The Emake3D curing box delivers a curing volume of 400 x 400 x 400 mm, equating to 64 L of workspace. This substantial capacity accommodates 100% of consumer and prosumer resin printer build volumes and supports comprehensive batch processing capabilities, enabling simultaneous curing of multiple large models or extensive quantities of smaller components. For example, dental laboratories achieve production throughput of 50–100 models per curing cycle using similar large-capacity systems, according to workflow optimization studies conducted by Formlabs during their professional dental applications research. This capacity eliminates sectional processing requirements for oversized models while maintaining uniform curing results across all chamber positions.

The Emake3D curing box operates with a 4.3-inch full-color touch screen interface that provides programmable timer settings from 5–60 minutes with automatic cycle termination. The dual-mode functionality supports both curing-only and combined heating-curing operations through digital controls that display real-time process monitoring including elapsed time, remaining cycle duration, and operational status indicators.

The touchscreen system incorporates safety interlocks that prevent 100% of UV activation when the chamber door remains open, protecting operators from harmful UV exposure. For example, professional UV equipment requires secondary safety interlocks that automatically disconnect power when access covers are opened, according to safety standards from RadTech during their UV Equipment Safety Topics documentation. The interface enables mid-process cycle pausing for inspection or repositioning without losing programmed settings, providing operational flexibility for 10–15 minute optimal curing cycles that achieve stabilized degree of conversion, according to researchers from Operative Dentistry during their Effects of UV Postcuring Times research (2024).

The Emake3D post-processing curing box features professional industrial construction with 445 x 445 x 515 mm external dimensions and 20 kg weight providing operational stability during 360-degree rotating platform operation. The sealed chamber design incorporates safety-rated UV-blocking materials that achieve 99.8% ultraviolet radiation blocking, according to researchers from ARPANSA during their UV Protection Factor testing. The chamber interior features reflective surfaces that achieve 97% light utilization efficiency compared to standard diffuse finishes, optimizing UV distribution and enhancing curing uniformity across all model positions.

The price for the Emake3D 3D printing post-processing curing box is $499.00, which is reasonable considering its washing size, functionality, and efficiency.

Update your browser to view this website correctly. Update my browser now