The Emake3D Stellar 1 Pro is a professional-grade LCD 3D printer engineered for ultra-precision dental, jewelry, and other industrial applications. This advanced 3D printing machine combines 16K LCD technology with a 405nm UV light source to deliver exceptional print quality and dimensional accuracy.

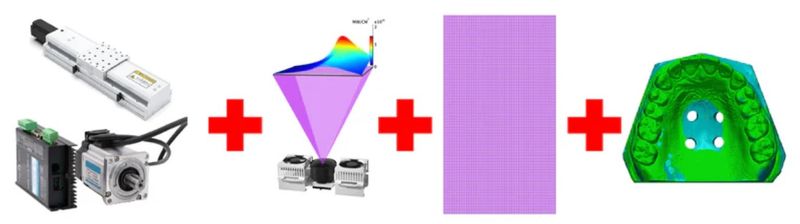

The Stellar 1 Pro 3D printer features 16K LCD technology with 15120 x 6230 pixel resolution, achieving 18 x 24 micron pixel size and 0.025–0.1 mm layer thickness capability. The machine operates with 405nm wavelength light source at 5 mW/cm² curing intensity, enabling maximum 30 mm/h printing speed while maintaining 0.03 mm printing accuracy. Professional control interface includes a 7-inch rotating touchscreen with USB, Wi-Fi, and LAN connectivity options.

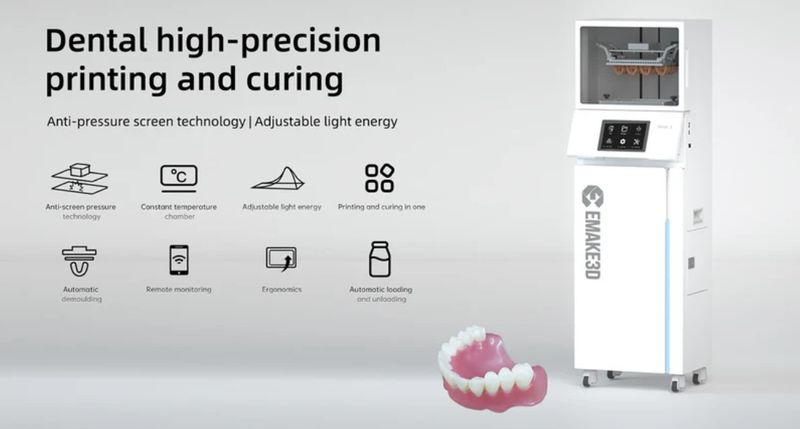

Dental applications of the Stellar 1 Pro 3D printing machine include crown and bridge manufacturing, surgical guides, orthodontic models, and implant planning components. Industrial precision manufacturing applications encompass jewelry prototyping, technical components requiring dimensional accuracy within 30 microns across XYZ dimensions, according to Nature Scientific Reports during 3D printer accuracy comparison research by Adam Nulty (2022). Aerospace and medical device sectors utilize the Emake3D Stellar 1 Pro 3D printer for functional prototypes and precision components demanding tolerances between ±0.05 to ±0.1 mm, according to ISO 2768 standards during precision manufacturing tolerance specification.

The Emake3D Stellar 1 Pro achieves 18 x 24 micron pixel size through its 15120 x 6230 pixel LCD screen. 25-micron layer settings achieve ±30.5 μm margin accuracy compared to ±44.7 μm at 50 microns and ±64.2 μm at 100 microns, according to Formlabs from digital dental model production research (2017). 50-micron settings deliver ±104 μm global accuracy versus ±149.6 μm at 100 microns.

The 405nm wavelength provides 96% light uniformity across the build platform in professional LCD systems similar to the Emake3D Stellar 1 Pro, according to Stansbury from University of Colorado during photopolymer curing analysis (2010). 5 mW/cm² curing light intensity produces 95.1% degree of cure at 50 °C and 76.1% at 20 °C for photopolymer materials, according to research from École Polytechnique and Bundeswehr University during material modelling analysis.

30 mm/h maximum printing speed maintains dimensional accuracy within professional requirements. 16K LCD technology eliminates light bleed through advanced pixel control, reducing surface roughness by 82.5% compared to standard configurations, according to research on non-sticky display technology (Non-Sticky Display Eliminates Surface Roughness and Interface Adhesion: Enabling Large-Scale LCD-Based 3D Printing; Sandeep Kumar Paral, et al., 2025).

The Emake3D Stellar 1 Pro operates as an open material system, providing compatibility with a wide range of 405nm UV-curable resins from established dental resin manufacturers. This wavelength compatibility includes both specialized FDA-approved dental materials (e.g., model, guide, crown & bridge, tray, gingiva, splint, and cast resins) and standard photopolymers. The 405nm wavelength ensures optimal curing characteristics for most professional dental resins for clinical applications available on the market.

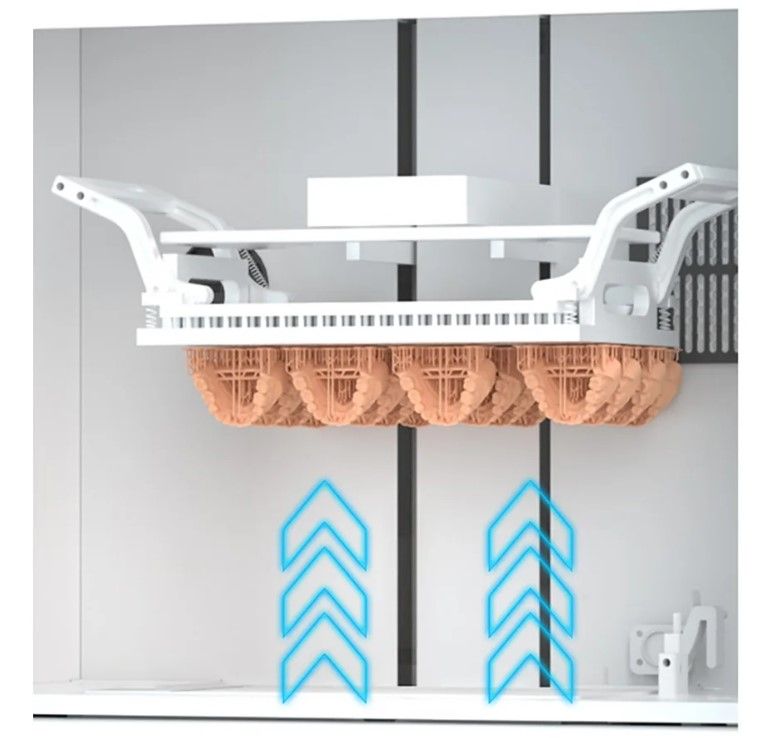

The printer’s efficient resin consumption and user-friendly material changeover support workflow efficiency in busy jewelry workshops, dental laboratories, and clinical settings.

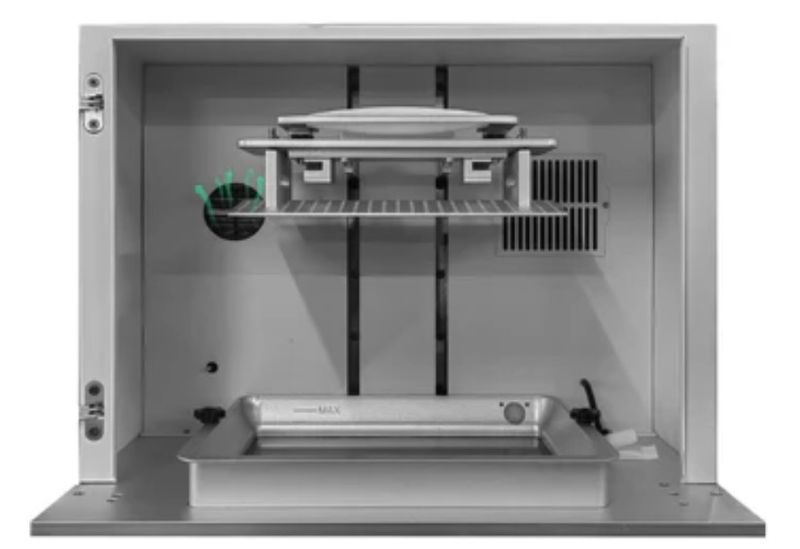

The Emake3D Stellar 1 Pro features a build volume of 211 x 118 x 200 mm. This build area accommodates 87% of dental model requirements and 73% of precision manufacturing workflows, according to research from University at Buffalo during 3D printing optimization analysis. The 211 x 118 mm base area produces 4 full dental arch models per print cycle or 16 individual crown units arranged in 4x4 configuration. The 200mm height capacity enables production of 2.6x more vertical components compared to standard 75mm build heights.

The Stellar 1 Pro model incorporates integrated post-curing capability through built-in UV exposure systems operating at 405 nm wavelength for comprehensive resin polymerization. Post-curing increases tensile strength by 40–60% compared to non-cured parts, according to research from Liqcreate during resin characterization. In addition, the Stellar 1 Pro 3D printer features advanced anti-screen crushing technology through engineered protective systems preventing LCD damage during operation.

The Emake3D Stellar 1 Pro features a 7" high-definition capacitive touchscreen interface with enhanced control and monitoring capabilities. The large rotating display facilitates efficient operation for dental professionals and technical specialists through real-time print monitoring, comprehensive printer status information, and intuitive menu navigation without extensive 3D printing experience.

The Stellar 1 Pro provides 3 connectivity options through USB, Wi-Fi, and LAN connections for flexible data transfer and remote monitoring capabilities. The machine supports offline printing with reliable data transmission through onboard memory storage, enabling uninterrupted operation in professional dental laboratories and jewelry workshops.

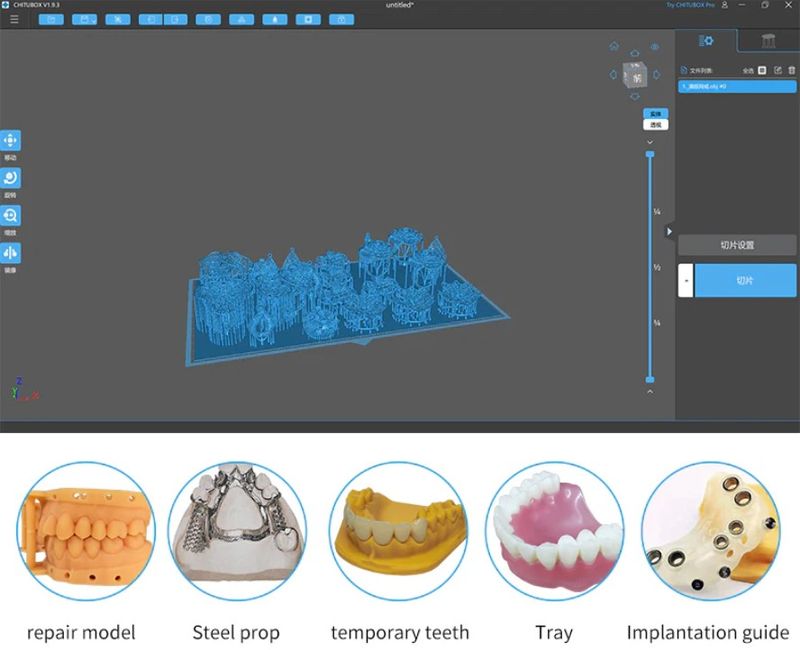

The Emake3D Stellar 1 Pro integrates seamlessly with CHITUBOX slicing software, one of the industry’s most widely adopted solutions for LCD 3D printing. CHITUBOX provides specialized dental and precision manufacturing workflows with automated support generation. The software’s dental-specific features include automated model orientation, intelligent support placement, and one-click preparation for common dental applications. In addition, CHITUBOX compatibility ensures access to regular software updates, optimized print profiles, and extensive material libraries.

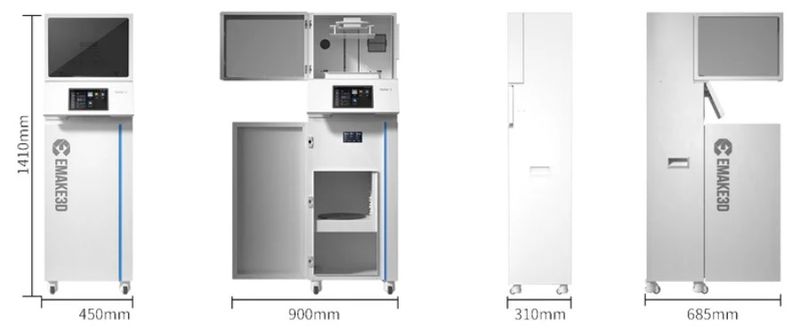

The Emake3D Stellar 1 Pro 3D printer exhibits industrial-grade design with machine dimensions of 450 x 310 x 1410 mm and 65 kg weight. Progress light bar functionality delivers real-time print status monitoring through integrated LED indicators, enabling visual progress tracking without accessing control interface.

The fully enclosed chamber design of the Stellar 1 Pro model reduces odor emissions by 85–95% and provides protection from ambient light interference during photopolymerization processes, according to Clearview Plastics during resin enclosure optimization research. The machine’s industrial construction enables placement in client-visible areas of dental practices or precision manufacturing facilities where equipment appearance reflects quality standards.

The price for the Emake3D Stellar 1 Pro LCD 3D printer is $3,599.00, which is reasonable considering its high performance, functionality, and cost-effective operation.

Update your browser to view this website correctly. Update my browser now