The Emake3D Stellar III is a professional dental LCD 3D printer engineered for automated high-volume production workflows in dental laboratories and clinical environments. This floor-standing 3D printing system utilizes advanced LCD display technology to deliver continuous 24-hour production capability for demanding dental applications. The Stellar III 3D printer represents industrial-grade automation equipment designed specifically for uninterrupted dental manufacturing processes.

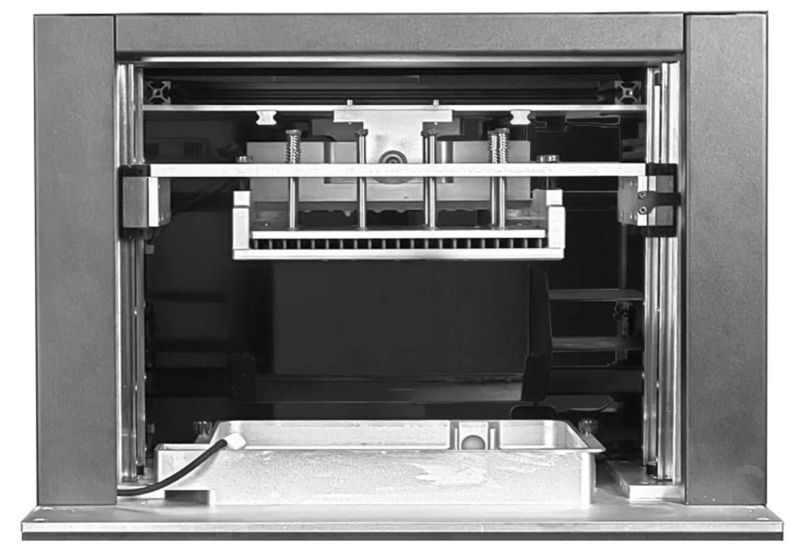

The Stellar III model delivers 0.03mm printing accuracy using 15120 x 6230 pixel LCD display technology across a 211 x 118 x 35 mm build volume. The system operates at 30mm/h print speed with 405nm UV wavelength light source providing 20000-hour lifespan for extended production cycles. The 152kg floor-standing Stellar III incorporates 24-hour continuous automation capabilities enabling unattended production cycles while supporting standard 405nm UV-curable dental resins with USB and Wi-Fi connectivity through CHITUBOX software.

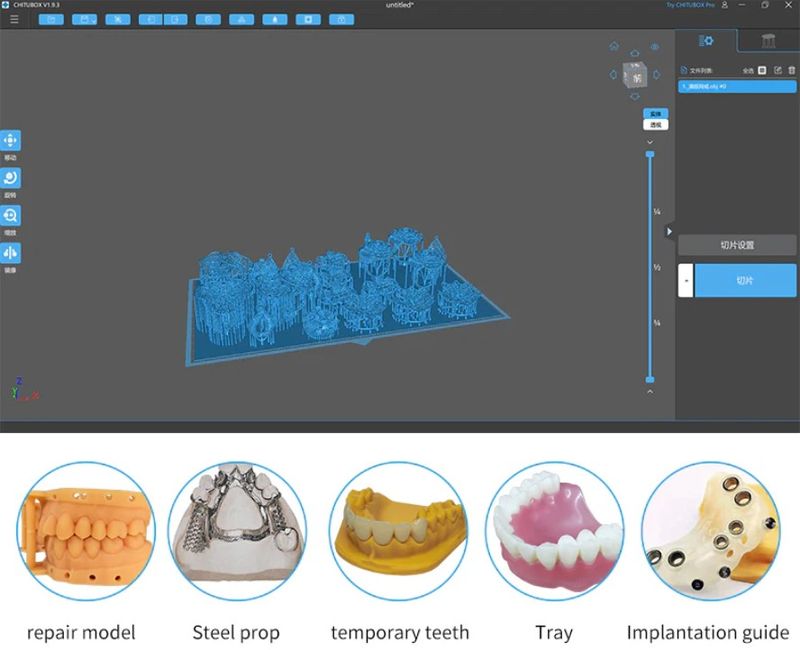

Digital dental laboratories achieve 3-fold output increases using automated LCD 3D printing systems like the Emake3D Stellar III compared to traditional workflows. For example, Kreimer Dentallabor tripled dental model production implementing automated 3D printing workflows, according to Stephan Kreimer during digital workflow optimization (2024). Orthodontic model production represents the primary application sphere where automated systems deliver measurable productivity gains through continuous operation capabilities. LCD 3D printers similar to the Stellar III produce crown and bridge models with 95% surface accuracy within 50μm of CAD designs for restorative applications. For example, dental laboratories achieve 60% material cost reduction and 6-fold output increase compared to conventional milling, according to NextDent during dental workflow analysis (2024). Restorative dental applications benefit from the precision and automation capabilities of the Emake3D Stellar III that enable consistent quality across extended production runs. For instance, automated dental 3D printing systems like the EvoDent D300 produce 180 dental models in 24 hours with 0.07mm deviation for high-volume production environments (UnionTech, Dental South China 2024). High-volume production applications leverage the system’s automation features to maximize throughput while maintaining strict quality standards required for dental applications.

The Emake3D Stellar III achieves 0.03mm printing accuracy through 15120 x 6230 pixel LCD display technology. The system’s layer thickness range of 0.05–0.1mm enables 2 distinct applications where 0.05mm layers deliver optimal surface finish for crown and bridge applications while 0.1mm settings provide 40% faster production speeds for diagnostic models.

The 405nm UV wavelength provides consistent curing characteristics across the 211 x 118 mm build platform. LCD-based systems achieve 4-fold irradiance variation across build platforms leading to 15–25% dimensional changes in printed features, according to Subedi from North Carolina State University during illumination uniformity analysis (2022). The pixel size of 14 x 19 microns enables detail reproduction where smaller pixels below 20 μm produce superior dimensional accuracy in dental applications.

The Emake3D Stellar III operates as an open material system, providing compatibility with a wide range of 405nm UV-curable resins from established dental resin manufacturers. This wavelength compatibility includes both specialized FDA-approved dental materials (e.g., model, guide, crown & bridge, tray, gingiva, splint, and cast resins) and standard photopolymers. The 405nm wavelength ensures optimal curing characteristics for most professional dental resins for clinical applications available on the market.

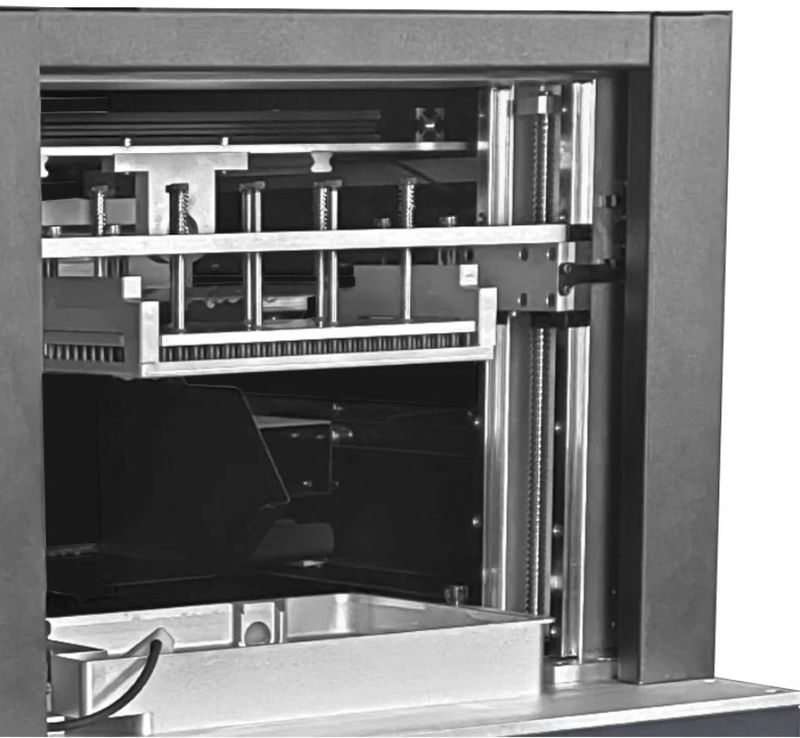

The automated resin handling system of the Emake3D Stellar III model supports efficient material changeover and consumption monitoring, essential for high-volume production environments. Professional dental resins typically require specific handling and storage protocols, and the Stellar III’s design accommodates these requirements while maintaining material integrity throughout extended production cycles.

The Emake3D Stellar III features a build volume of 211 x 118 x 35 mm, optimally dimensioned for precision dental applications. This compact build area accommodates 3–4 individual dental arches with optimal automation efficiency where smaller build platforms reduce peeling forces enabling faster lift speeds and improved productivity, according to dental 3D printing workflow optimization studies (Dr Ahmad Al-Hassiny, the Institute of Digital Dentistry, 2024). The 211 x 118 mm base area provides sufficient space for precision dental components including individual quadrant models, crown units, and surgical guides while maintaining the 0.03mm accuracy required for clinical applications.

The 35mm height capacity of the Stellar III accommodates single-level precision builds with minimal support requirements optimized for automated production where height restrictions eliminate multi-level stacking reducing print failures and material waste during automated cycles. Compact vertical capacity enables 24-hour continuous operation with reduced build complexity where automated systems achieve 60–80% higher productivity compared to manual workflows, according to Alves from Smileep during dental laboratory efficiency analysis (2025).

The Emake3D Stellar III incorporates advanced control systems designed for automated operation and remote monitoring capabilities. The printer features comprehensive automation controls that enable 24-hour continuous production cycles with minimal operator intervention. Professional-grade monitoring systems track print progress, material consumption, and printer status to ensure reliable unattended operation.

Data management capabilities of the Stellar III model support USB connectivity along with network integration options for seamless workflow integration. The system’s memory capacity allows for reliable offline printing with robust data handling to prevent production interruptions. Advanced queue management enables sequential print job processing for extended automated production runs.

The Emake3D Stellar III integrates with professional slicing software platforms including CHITUBOX, providing specialized dental workflows and automated support generation. These software packages offer dental-specific features including automated model orientation, intelligent support placement, and one-click preparation for common dental applications, streamlining the transition from digital design to physical production.

The Emake3D Stellar III features professional industrial design with dimensions of 505 x 760 x 1290 mm and 152 kg operating weight delivering mechanical stability essential for 24-hour continuous production cycles. The floor-standing configuration provides accessibility for maintenance and material handling while maintaining a compact footprint for efficient space utilization.

The enclosed design of the Stellar III model provides essential light containment for UV resin printing while incorporating advanced ventilation and safety systems where UV-curable resin 3D printers require built-in safety features preventing operator exposure to uncured photopolymers and UV wavelengths, according to RadTech from UV resin safety documentation during 3D printing safety analysis (2023). Professional aesthetics and build quality reflect the system’s positioning as industrial production equipment rather than desktop prototyping hardware where medical device aesthetics profoundly impact patient acceptance during clinical interactions, according to Bwanbale from Kampala International University during medical device design research (2024).

The price for the Emake3D Stellar III LCD 3D printer is $7,999.00, which is reasonable considering its high performance, functionality, and cost-effective operation.

Update your browser to view this website correctly. Update my browser now