The Emake3D Stellar Mini Pro is a professional 6.8 inch 9K LCD 3D printer engineered for rapid dental production workflows. This desktop 3D printing system delivers 18 micron XY precision using 8520 x 4320 pixel LCD display technology achieving 80 mm/h molding speed for chairside applications. Aluminum alloy construction provides mechanical stability where aluminum exhibits high strength-to-weight ratios with good dimensional stability essential for precision applications, according to Auburn University researchers during 3D printing structural integrity analysis (2021).

The Stellar Mini Pro 3D printer features 6.8-inch 9K monochrome LCD with 8520 x 4320 pixel resolution delivering 18 micron XY precision where pixel size directly correlates with surface quality and dimensional accuracy. The 9K resolution provides 36.7 million pixels compared to 15.5 million in 6K systems, enabling superior detail reproduction for dental applications, according to Aptus Technology from LCD display specifications during 3D printing optimization (2024). The machine supports 405nm UV-curable resins where wavelength compatibility ensures optimal polymerization characteristics for professional dental materials requiring precise exposure control for clinical applications.

Designed specifically for chairside and small laboratory workflows, the Emake3D Stellar Mini Pro delivers reliable performance for rapid crown production where automated dental 3D printing systems achieve 60–80% higher productivity compared to manual workflows, according to Kreimer from dental laboratory efficiency analysis (2025). The printer’s compact footprint enables effective integration into clinical environments where chairside crown production reduces treatment time from multiple visits to single appointments, improving patient experience and practice efficiency.

The Emake3D Stellar Mini Pro achieves 18 micron XY precision through 8520 x 4320 pixel LCD display technology. Pixel densities below 20 μm produce superior dimensional accuracy in dental applications where fine details and precise margins are critical for clinical success, according to Kabot from EnvisionTEC during accuracy optimization analysis (2017). The 9K resolution provides 2.3-fold increase in pixel density compared to 4K systems enabling superior surface finish and dimensional accuracy for crown and bridge applications where LCD systems with pixel sizes below 20 μm demonstrate enhanced detail reproduction capabilities.

The 405nm wavelength provides consistent curing characteristics across the 153 x 78 mm build platform. Professional LCD systems similar to the Emake3D Stellar Mini Pro achieve 96% light uniformity across build platforms enabling consistent exposure per pixel and eliminating dimensional variations between center and edge regions, according to Stansbury from University of Colorado during photopolymer curing analysis (2010). Monochrome LCD screens deliver 2.5–3 second exposure times compared to 8–10 seconds for color screens significantly reducing print cycles while maintaining quality where LCD displays achieve superior UV light transmittance.

The dual-axis guide rail system of the Stellar Mini Pro model eliminates layer shifting and improves print consistency throughout extended production runs. Linear rail systems achieve superior accuracy and stability compared to round rods with linear bearings reducing mechanical tolerances by 60% compared to wheel-based systems, according to 3D Distributed from precision manufacturing analysis (2022). Professional 3D printers utilizing dual-axis guide rails ensure precise Z-axis movement preventing layer misalignment where layer shifting represents one of the most noticeable failures in 3D printing creating distinct stair-step effects that compromise dimensional accuracy, according to QIDI Tech’s layer shift prevention analysis (2025).

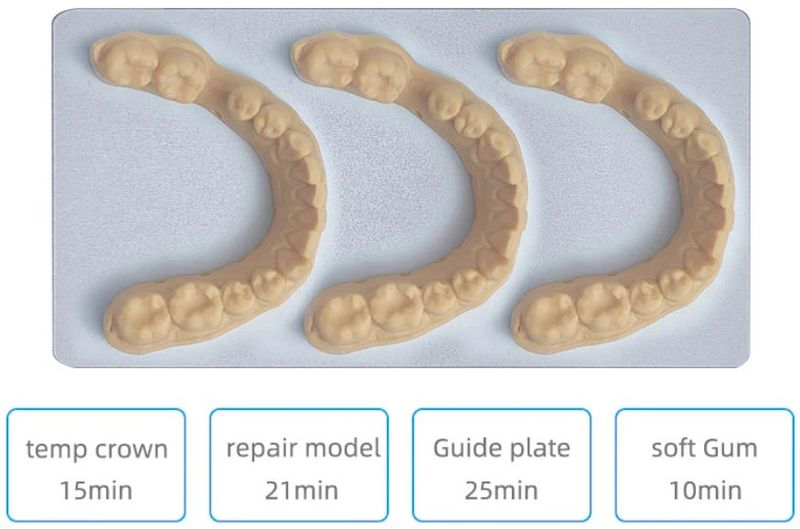

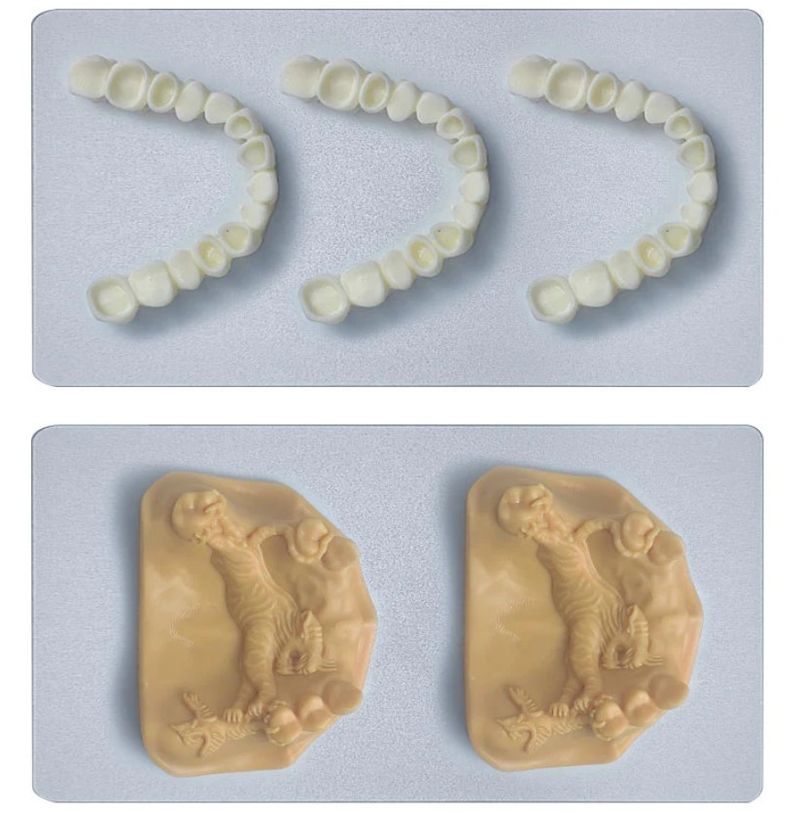

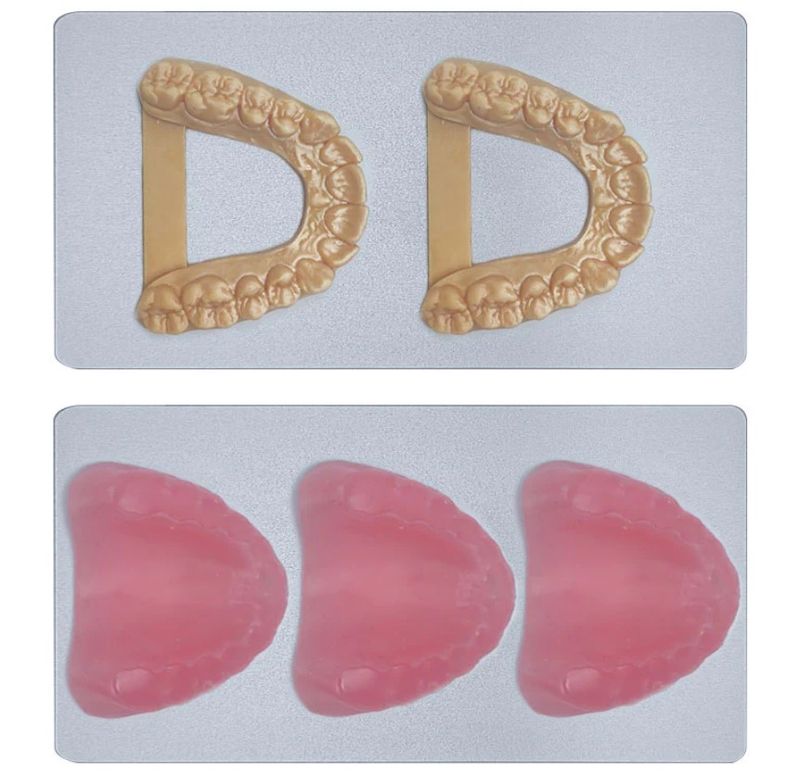

The Emake3D Stellar Mini Pro operates as an open material system, providing compatibility with a wide range of 405nm UV-curable resins from established dental resin manufacturers enabling cost-effective material selection based on specific clinical requirements. This wavelength compatibility includes both specialized FDA-approved dental materials (e.g., model, guide, crown & bridge, tray, gingiva, splint, and cast resins) and standard photopolymers. The 405nm wavelength ensures optimal curing characteristics for most professional dental resins for clinical applications available on the market.

The printer’s efficient resin consumption and user-friendly material changeover support workflow efficiency in busy dental laboratories and clinical settings.

The Emake3D Stellar Mini Pro features a build volume of 153 x 78 x 180 mm optimized for dental restoration workflows. Smaller build platforms reduce peeling forces significantly enabling faster lift speeds and improved productivity in dental applications reducing cycle times by 25–40%, according to Institute of Digital Dentistry from smaller build platform advantage analysis (2024). The specialized dimensions accommodate individual crowns, bridges, and small appliances while maintaining the 18 micron precision required for clinical applications.

The Emake3D Stellar Mini Pro incorporates intuitive control systems designed for straightforward operation in clinical environments. The system features touchscreen controls with clear menu navigation enabling efficient workflow management for busy dental practices.

The Stellar Mini Pro 3D printer features USB connectivity that ensures reliable file transfer for seamless integration with dental CAD workflows. USB connection facilitates fast and effortless file transfer from computer to printer with more stability compared to Wi-Fi connections, according to Phrozen from dental 3D printer connectivity analysis during connection method evaluation (2024). The system’s memory capacity supports offline printing with robust data handling preventing production interruptions during clinical procedures.

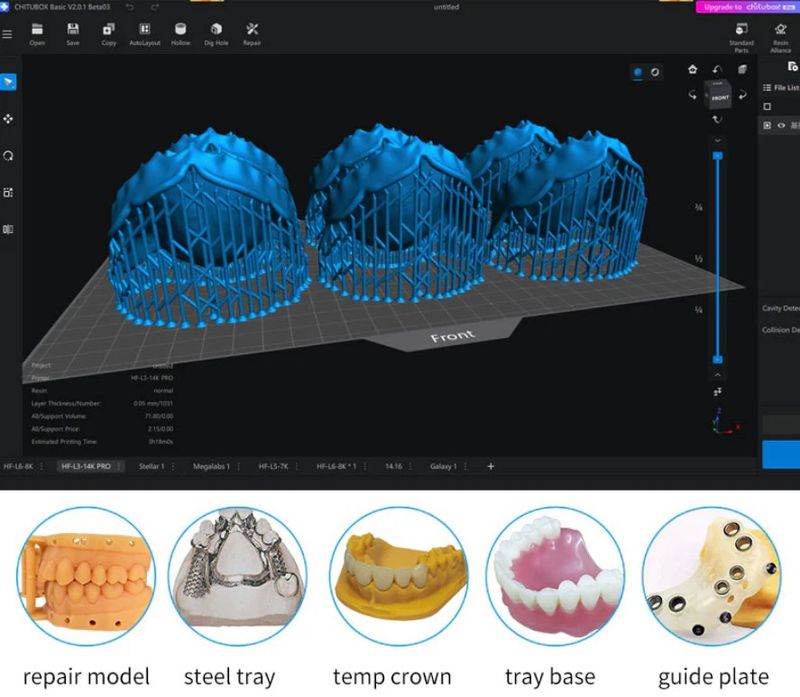

The Emake3D Stellar Mini Pro integrates seamlessly with CHITUBOX slicing software, one of the industry’s most widely adopted solutions for LCD 3D printing. CHITUBOX provides specialized dental workflows and automated support generation. The software’s dental-specific features include automated model orientation, intelligent support placement, and one-click preparation for common dental application scenarios including orthodontic models, restorative models, surgical guides, splints, and temporary crowns. In addition, CHITUBOX compatibility ensures access to regular software updates, optimized print profiles, and extensive material libraries.

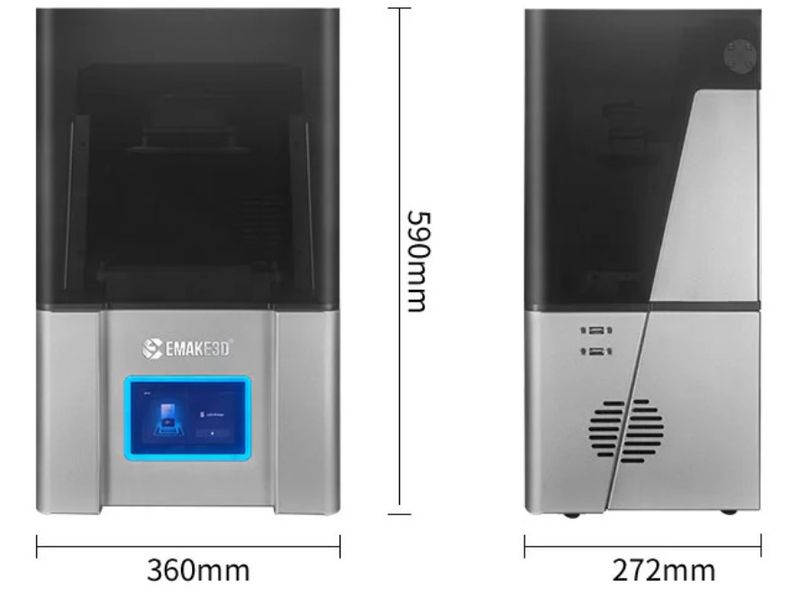

The Emake3D Stellar Mini Pro features professional desktop design with overall dimensions of 355 x 274 x 546 mm and 18.6 kg weight delivering compact stability essential for dental applications. Aluminum alloy construction provides superior strength-to-weight ratios with thermal conductivity of 150–200 W/m·K enabling efficient heat dissipation during extended operation, according to Auburn University researchers during 3D printing structural integrity analysis (2021). The compact desktop footprint enables convenient placement on standard laboratory benches or dedicated workstations without requiring significant space allocation.

The enclosed design of the Stellar Mini Pro model provides essential light containment for UV resin printing while incorporating advanced safety systems. UV-curable resin 3D printers require built-in safety features preventing operator exposure to uncured photopolymers and UV wavelengths through properly shielded enclosures, according to RadTech during 3D printing safety analysis (2023). The machine’s industrial construction enables placement in client-visible areas of dental practices or precision manufacturing facilities where equipment appearance reflects quality standards.

The price for the Emake3D Stellar Mini Pro LCD 3D printer is $1,399.00, which is reasonable considering its high performance, functionality, and cost-effective operation.

Update your browser to view this website correctly. Update my browser now