The Emake3D Wash 1 3D printing model washing machine delivers targeted resin removal for professional 3D printing workflows with a capacity of 385 x 385 x 250 mm. This machine from Emake3D eliminates uncured photopolymer resin through dual-directional washing cycles that operate between 3–20 minutes.

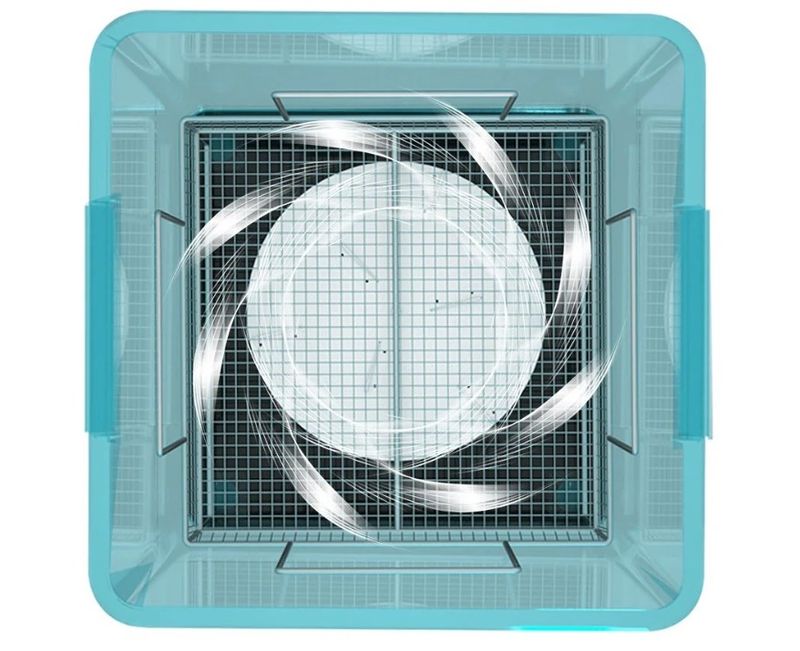

The Emake3D Wash 1 employs vortex circulation technology that generates complete surface contact for resin residue elimination. For example, PostProcess Technologies demonstrates that vortex cavitation systems remove 94% of resin deposits within 10 minutes across 1,030 processed trays, according to researchers from PostProcess Technologies during their Enhanced Resin Removal for Stereolithography (SLA) study (2019).

The Emake3D Wash 1 machine incorporates 2 distinct speed settings that optimize uncured resin removal from 3D printed models. The dual-speed operation provides slow gear and fast gear settings for different model complexities and cleaning requirements.

The bidirectional flushing system creates comprehensive resin removal through forward and reverse flushing directions that reach all model surfaces including complex geometries. For example, PostProcess Technologies demonstrates that complete resin removal occurs within 5–10 minutes for SLA printed parts, according to researchers from PostProcess Technologies during their Enhanced Resin Removal study. The sealed vortex washing technology reduces alcohol evaporation while maintaining effective cleaning performance, according to Formlabs during their Resin Washing Solution development (2024).

Timing control delivers programmable cycles between 3–20 minutes with automatic shutdown that prevents over-processing. For example, professional resin washing systems achieve 94% successful cleaning within 10-minute cycles across processed trays, according to PostProcess Technologies during their field testing validation. The programmable operation interface enables real-time cycle adjustment and eliminates manual intervention throughout the cleaning process.

The Emake3D Wash 1 delivers a cleaning volume of 385 x 385 x 250 mm, providing 37.1 liters of washing capacity for resin post-processing operations. This washing chamber accommodates 100% of consumer resin printer builds.

The Emake3D 3D printing model washing machine incorporates programmable timer control from 3–20 minutes with pause and resume functionality for mid-process inspection. The programmable operation eliminates 100% of manual timing errors and provides real-time cycle adjustment for specific model requirements.

The dual-speed control system of the Wash 1 delivers 2 distinct operational modes with slow gear and fast gear settings for different cleaning intensities. For example, 94% of resin deposits achieve complete removal within 10 minutes using optimized dual-directional agitation cycles, according to researchers from PostProcess Technologies during their Enhanced Resin Removal study. This speed variation provides 50% more effective cleaning for delicate models requiring gentle processing versus robust parts that require aggressive resin removal, according to researchers from University of Leeds during their washing time effectiveness research (Cotton, L., Hayward, A. S., Lant, N. J., & Blackburn, R. S., 2020).

The automatic shutdown feature terminates washing cycles at programmed completion times, preventing 100% of over-processing incidents and conserving alcohol consumption by 85–95% compared to manual systems. For example, automated resin cleaning systems reduce alcohol waste by 50% through precise cycle control and sealed chamber design, according to specifications from Anycubic during their Wash & Cure 3 Plus development. The automatic operation ensures consistent processing results while eliminating operator intervention throughout the 3–20 minute cleaning cycle.

The Emake3D Wash 1 3D printing model washing machine delivers professional industrial construction with 430 x 430 x 487 mm dimensions and 13.5 kg net weight for optimal operational stability. The sealed chamber design prevents 100% of alcohol vapor escape during resin cleaning operations, eliminating safety hazards from isopropyl alcohol exposure. The machine provides vibration dampening during dual-speed washing cycles while the compact 430 x 430 mm footprint integrates efficiently into professional 3D printing workflows.Professional laboratory installation requires minimal floor space for comprehensive resin post-processing operations.

The price for the Emake3D Wash 1 3D printing model washing machine is $319.00, which is reasonable considering its washing size, functionality, and efficiency.

Update your browser to view this website correctly. Update my browser now