The Farsoon FS621M is a metal laser sintering solution developed for smooth and continuous additive manufacturing of metal parts. It consists of several integrated modules: build station, breakout station, powder supply system, and filtering module. Their sustainable cooperation is combined with a massive build volume and rapid sintering capabilities ensuring high throughput for large items or extended industrial series production that can be implemented in faster turn-over rates due to a lower price per part.

The Farsoon FS621M boasts a potent scanning system. It applies a single 1000W laser for the original version and quad 500W lasers for the FS621Mx4. Due to the advanced software control and precise scanning, the machine provides stable and uniform performance. The scanning speed reaches up to 15.2 m/s, which makes for fast sintering. With a minimum layer thickness of 20 microns, the FS621M is a perfect solution for a wide range of applications requiring high production rates.

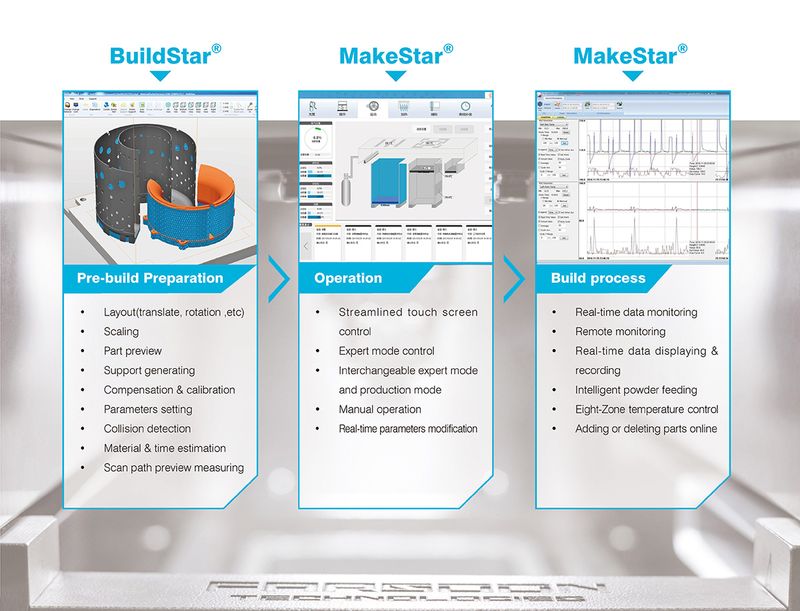

Apart from the mentioned features, the Farsoon FS621M 3D printer comes with flexible software empowering advanced calibration, automated leveling, bi-directional recoating, continuous powder feeding, open settings, real-time build modification, 3D visualization, and diagnostic procedures. The powder handling system is completely sealed and therefore safe.

The Farsoon FS621M is a highly professional device suitable for consistent use in various industrial spheres, such as automotive, aerospace and aviation, medicine, jewelry, mold production, etc.

The Farsoon FS621M can sinter layers with a minimum thickness of 20 microns. It is equipped with a single 1000W laser, while the FS621Mx4 version comes with four 500W lasers. With a brand high-precision digital galvo system, both printers provide exceptional accuracy, high detail, and even processing of printed parts.

Moreover, the machines ensure a uniform melting process of metal materials due to continuous powder feeding, optimized gas flow, and integrated filter module. Powerful control over the printing process allows for structural integration, improved design features, accelerated development cycle, and a significantly reduced cost of production.

The Farsoon FS621M uses a wide variety of metal powders with consistent and predictable properties. In addition, like any company’s solution, the machine is designed with a flexible parameter and material system. The FS621M model as well as its FS621Mx4 counterpart are compatible with IN718, HX, AlSi10Mg, HAYNES 230, TA15, Ti6Al4V, IN625, and 316L. Some of the listed powders are currently in development, while more will be available in the future.

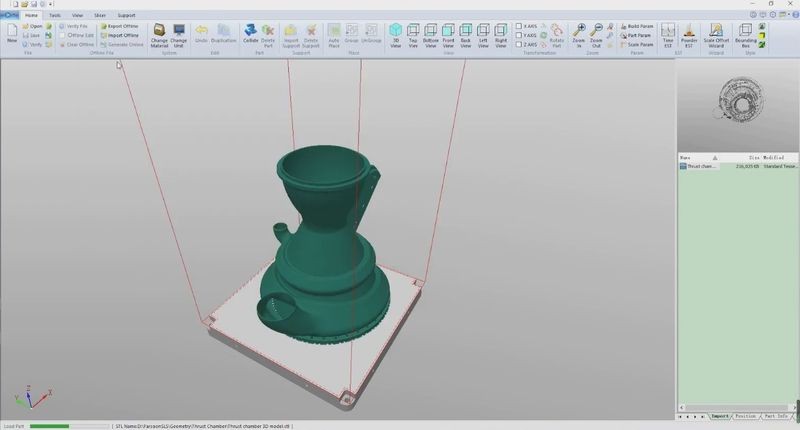

Credit: youtube.com

The Farsoon FS621M 3D printer is engineered with an extensive build cylinder of 24.4 x 24.4 x 43.3 inches (620 x 620 x 1100 mm). With an impressive volume like this, the machine enables you to print sufficient quantities of small-to-medium parts as well as large items in one go, which greatly accelerates the manufacturing process.

The Farsoon FS621M is operated via a mounted control unit with a clear and easy-to-navigate interface. It features the advanced user mode alongside touch screen production mode for convenient usage.

Credit: youtube.com

The solution is supplied with the Farsoon dedicated BuildStar and MakeStar software for efficient pre-build preparation, smooth operation, and full control over the printing process. Both programs offer streamlined designs, complete access to the machine and build parameters as well as numerous useful features ensuring a seamless manufacturing process from start to finish. The software runs on Windows 10 (64 bit) and supports the STL file format.

Credit: en.farsoon.com

The Farsoon FS621M model is available in white with black trimmings. Its stylish look makes it ideal for a range of industrial applications, including aerospace and aviation, automotive, jewelry production, medical, engineering, and more.

The machine dimensions are 228.3 x 129.9 x 157.5 in (5800 x 3300 x 4000 mm). It weighs approximately 19841.6 lb (9000 kg).

To learn the current price of the Farsoon FS621M 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now