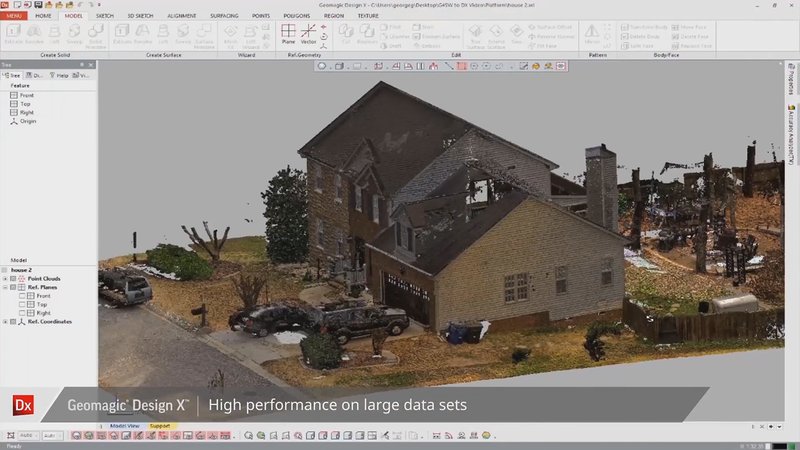

The Geomagic Design X is the leading reverse engineering software that allows creating history-based CAD from captured 3D scans. Forget about building models from scratch. Make 3D scans of real world objects, modify them and use them as a basis for your future projects.

The Geomagic Design X is the perfect reverse engineering software for those who is looking for:

With the Geomagic Design X, you can import point cloud or mesh through direct scanning for the widest range of the most popular devices or import over 60 file formats including polygons, point clouds, and CAD.

The Geomagic Design X stands out against other reverse engineering software due to the following functions:

|

Features |

Geomagic Essentials |

Geomagic Wrap |

Geomagic Design X |

|

Neutral 3D Scan format I/O (xyz, pts, stl, obj, ply) |

✓ |

✓ |

✓ |

|

Extended Scan format support |

✓ |

✓ |

|

|

Direct Live Scanning with Portable Scanners |

✓ |

✓ |

|

|

Neutral CAD File Output |

✓ |

✓ |

✓ |

|

Basic Scan-to-Scan Alignment and Refinement |

✓ |

✓ |

✓ |

|

Advanced Scan-to-Scan Alignment Methods |

✓ |

✓ |

|

|

Scan to World Coordinate System Alignment |

✓ |

✓ |

✓ |

|

Basic Point Cloud Editing |

✓ |

✓ |

✓ |

|

Advanced Point Cloud Editing |

✓ |

✓ |

|

|

Basic Polygon Tools — Polygon Healing and Refinement |

✓ |

✓ |

✓ |

|

Advanced Polygon Tools — Polygon Modeling |

✓ |

✓ |

|

|

Automatic Curve and Sketch Tools |

✓ |

||

|

Automatic Prismatic Feature Detection and Extraction |

✓ |

✓ |

✓ |

|

Constrained Prismatic Feature fitting to Scans — Point, Line, Plane, Sphere, Cone, Torus, etc. |

✓ |

✓ |

✓ |

|

Export of fit features as CAD format |

✓ |

✓ |

✓ |

|

Export of fit features to target CAD systems in real-time |

✓ |

||

|

Cross Section through Models |

✓ |

✓ |

✓ |

|

Advanced Cross Section Tools |

✓ |

✓ |

|

|

3D Curve Drawing and Editing |

✓ |

✓ |

✓ |

|

Automatic Contour and Sharp Edge Extraction |

✓ |

✓ |

|

|

Automatic Surfacing — Fast Polygon to CAD conversion |

✓ |

✓ |

✓ |

|

Exact Surfacing Workflow — Highly Controlled CAD Conversion |

✓ |

✓ |

|

|

Selective Surfacing |

✓ |

||

|

Accuracy Analysis for 3D Solids |

✓ |

✓ |

✓ |

|

3D Measurement Tools |

✓ |

✓ |

✓ |

|

Record and Playback Macros |

✓ |

✓ |

|

|

Batch Process Macros |

✓ |

||

|

Python Scripting, Editor, Manager |

✓ |

✓ |

|

|

Flexible software licensing options |

✓ |

✓ |

The Geomagic Design X allows you to gain a major advantage over other manufacturers in designing, making, and improving your products. The software provides you with all the tools to accelerate reverse engineering operations, simplify them, and lower your costs.

The program can be widely used in:

The Geomagic Design X is compatible with a variety of 3D digitizers, cameras, and scanners in XYZ/ASCII format. The software works with:

The software supports 3DS, OBJ, DXF, PLY, STL, LWO, VRML, and other file formats.

The system requirements are as follows:

|

OS |

Windows 7+ (64-bit Edition) |

|

CPU |

Intel® and AMD® processors with a minimum 2 GHz clock speed |

|

RAM |

8 GB or more |

|

Hard disk |

30 GB or more recommended; temporary file cache requires about 3 GB free disk space for every 100 million points |

|

Display |

32-bit true color required, recommended resolution — 1280 X 1024 or higher |

|

GPU |

Video Card RAM — 4GB or more; OpenGL 4.0 or above; NVIDIA GeForce 900 series or NVIDIA Quadro equivalent or higher; AMD Radeon 400 series or Radeon Pro equivalent or higher |

|

Other |

3 button mouse with scroll Sound card Keyboard Network card Internet browser Microsoft Windows Installer 3.0+ Adobe Acrobat/Reader version 5.x or higher Microsoft Office 2003, 2007 or 2010 for reporting tools Microsoft DirectX 9.0c or later Microsoft .NET 4.0 or 4.5 Framework |

To learn the current price of the software, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now