The HBD 350 is an industrial SLM (Selective Laser Melting) machine capable of producing high-quality prototypes and functional parts in a variety of materials. It comes as a comprehensive, fully customizable solution with a number of auxiliaries that meets most demanding metal 3D printing needs while still being an affordable entry point for SLM technology.

The HBD 350 machine features a fairly large build chamber that is perfectly combined with their outstanding sintering capacity. Thanks to the scanning speed of 10000 mm/s, the build process is characterized by elevated productivity. The flexible multi-purpose software with a set of user-friendly functions allows for smooth operation. To make it even better, you can opt for additional equipment available for optional order.

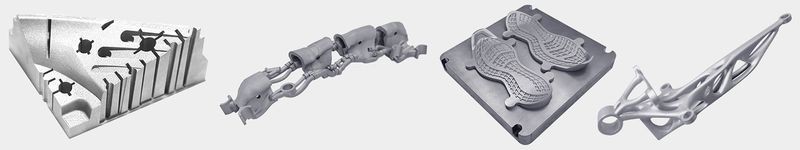

Due to its advanced capabilities, automated operation, and mainstream forming size, the HBD 350 SLM system is ideal for professional use in a number of intense and demanding industries, including mold, aerospace, aviation, automotive, medical equipment and functional parts production, research and development, jewelry, prototyping, and more.

The HBD 350 can sinter layers with a minimum thickness of 20 microns that can be further adjusted to the user’s needs. The printer is equipped with a single IPG fiber laser with a power of 500W and powerful SCANLAB galvo system with a minimum scanning track width of 70 microns to ensure high accuracy up to 0.05 mm and rich detail of printed items.

With the HBD 350, you can create unique models of complex geometries unachievable with traditional materials and simplify the manufacturing process by directly printing your final design in precious metals instead of producing wax castings.

The HBD 350 SLM system works with a wide selection of metal powders with different properties that suit various applications. The machine is fully compatible with stainless steel, tool steel, and aluminum alloy. This open system lets the printer build both prototypes and end-use parts without any issues.

The HBD 350 SLM 3D printer is engineered with a capacious forming space of 12.8 x 12.8 x 15.8 inches (325 x 325 x 400 mm). It lets you print fairly large items as a whole, without splitting them into several parts, or small to medium objects in batches. This makes for sufficient production speed and effective material usage.

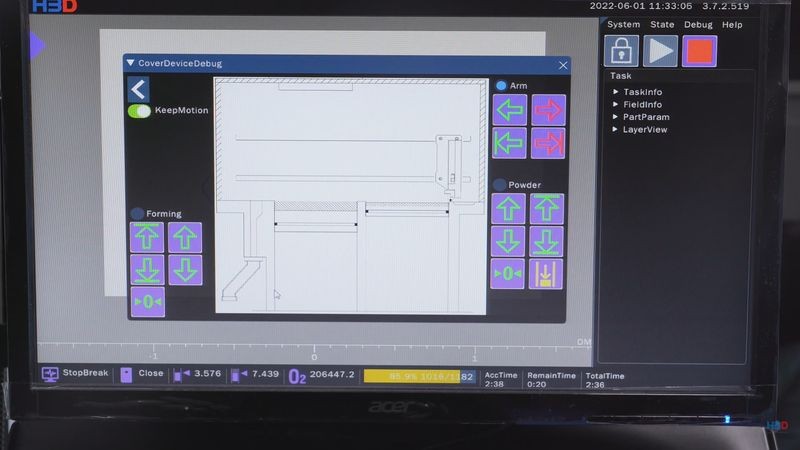

The HBD 350 can be operated via a built-in control unit with a clear and user-friendly interface.

The SLM system is supplied with the independently developed multifunctional HBD Build Expert slicing software. The program provides a variety of smart tools for data slicing, path planning, intelligent measurement, material development, printing parameter editing, multi-laser coordinating, and other handy functions.

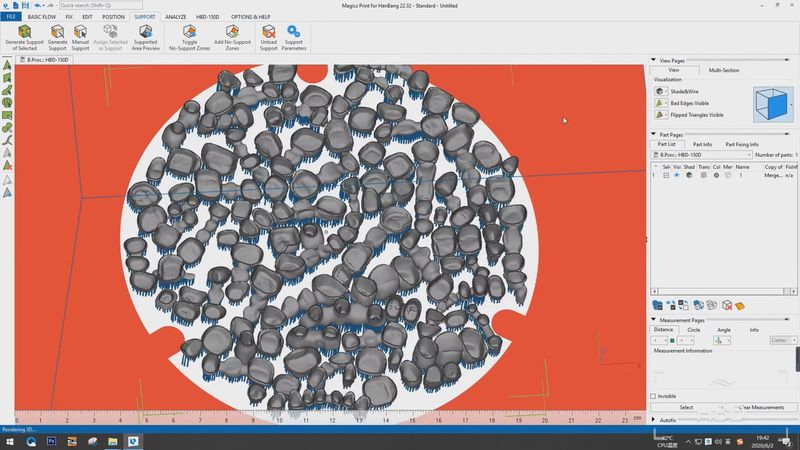

The HBD 350 supports the use of VoxelDance allowing for advanced data and build preparation. Due to this software solution, you can efficiently control the entire process chain by using such innovative features as CAD model import, STL file repair, smart 2D/3D nesting, support generation, and more.

To tailor the machine to your specific production needs, you can also order optional items from the list below:

For some items, package content may change. In case of any questions, please get in touch.

The HBD 350 model is available in white with black trimmings. Its stylish look makes it ideal for a range of professional applications within multiple industries, including medical, mold, jewelry, prototyping, scientific research, automotive, aviation, aerospace, education, and more.

The outer dimensions of the printer are 72 x 51.1 x 90.5 in (1830 x 1300 x 2300 mm). It weighs approximately 4409,3 lb (2000 kg).

To learn the current price of the HBD 350 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now