The Intamsys PC/ABS-FR utilizes BASF’s Ultrafuse® technology combining polycarbonate strength with ABS processability in a halogen-free flame-retardant formulation. This engineering thermoplastic achieves UL94 V-0 flame retardancy rating at both 1.5mm and 3.0mm thickness, demonstrating self-extinguishing properties with flame extinction within 10 seconds of ignition source removal. The material demonstrates tensile strength of 50.1 MPa in XY orientation and 17.3 MPa in ZX orientation with flexural modulus reaching 2550 MPa, according to ISO testing standards from BASF technical documentation.

The blend exhibits heat deflection temperature of 86 °C at 0.45 MPa with excellent impact resistance properties including Izod notched impact strength of 30.3 kJ/m² in XZ orientation. Processing characteristics include melt flow rate of 46.6 cm³/10 min at 260 °C under 5 kg load, enabling consistent extrusion and layer adhesion during high-speed printing operations. The material requires enclosed chamber printing with passively heated environment and bed temperatures between 90–110 °C for optimal dimensional stability.

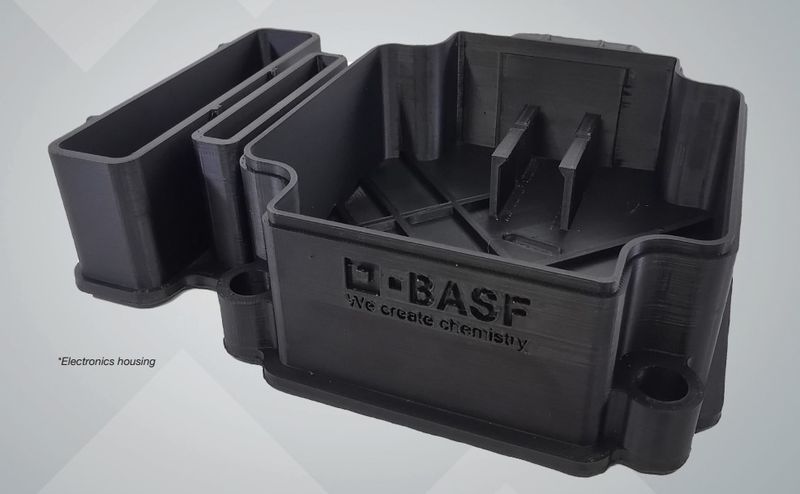

The PC/ABS-FR meets EN 45545-2 railway classification standards for fire safety in rail vehicle applications, according to European railway fire safety requirements. The material serves electronics applications including device housings, sockets, and plugs requiring flame retardancy certification. Automotive applications encompass interior components and underhood parts demanding thermal resistance and impact strength. Railway applications include interior panels, ducting, and electrical enclosures meeting stringent fire safety regulations for passenger protection.

The Intamsys PC/ABS-FR 1.75 mm filament is sold in 750 g spools. It comes vacuum-sealed with desiccant.

Update your browser to view this website correctly. Update my browser now