The JAKA Pro 16 is an industrial collaborative robot that is primarily designed for high-precision tasks in harsh operating environments. It represents an easy-to-use machine with remarkable technical characteristics and fast changeover capabilities making for versatile and effectively automated production. Being a powerful robot of the new generation, it can handle repetitive tasks 50000 hours non-stop.

As the largest model in the series, Pro 16 possesses an outstanding reach coupled with a decent payload. Alongside remarkable speed and repeatability, the machine provides intuitive and quick-to-learn control options, such as graphical programming interface and drag teaching, making it a perfect device both for beginners and experienced manufacturers looking for advanced automation opportunities.

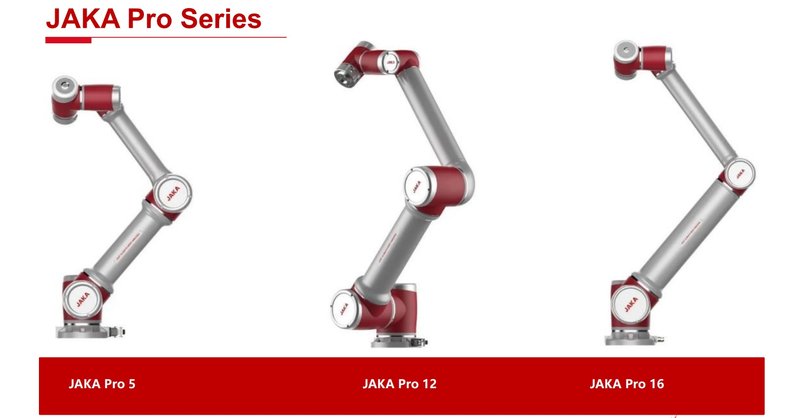

Overall, the company’s Pro series introduces several payload options — from 5 to 16 kg — and corresponding reaches of up to 1713 mm. Apart from the Pro 16 model, it includes the Pro 5 and Pro 12 versions. Due to reliable safety protocols, easy programming, and expanded automation, the cobots from the line are perfect for harmonious work with people of various spheres and skills.

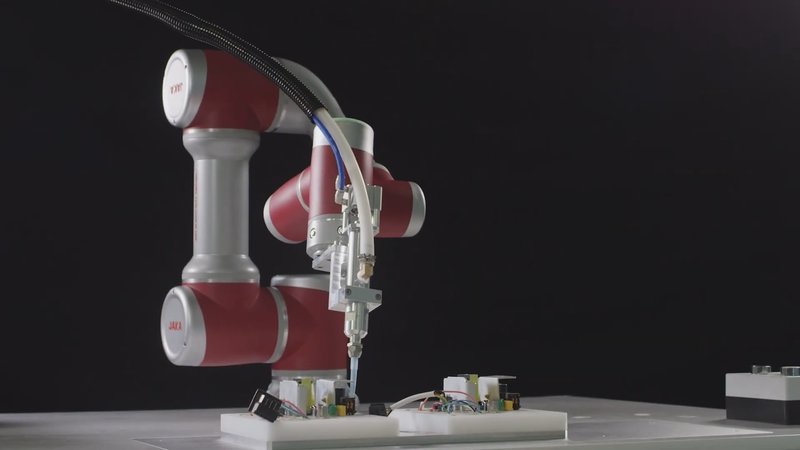

All JAKA cobots are engineered with a quick integration in mind. They can seamlessly master all manner of applications, from inspection to assembly, palletizing to welding and more. Moreover, the robots feature endless adaptability and fit into any mixed or purely automated line.

The JAKA Pro 16 cobot combines lightweight design, superb working radius, impressive repeatability, and intuitive controls, which makes it an ideal device for wood, machining, automotive, agriculture, food, and other industries where repetitive tasks have to be performed in challenging environments and take a lot of human time and effort.

The JAKA Pro collaborative robots are plug-and-play devices that can be used right out of the box.

The JAKA Pro 16 cobot possesses outstanding reliability coupled with high maneuverability and professional accuracy. It features 6 axes and is able to repeat the same movement within ±0.02 mm at a maximum speed of 3.9 m/s. In combination with 16 kg payload, this lets it perform even the most difficult precision tasks with ease.

According to the needs of modern industries, the machine is designed to operate in industrial application scenarios implying potential environmental hazards and secure protection level requirements from dust, oil, water, and metal, wood, glass or plastic shavings. The JAKA Pro 16 cobot boasts a high rating of ingress protection — IP68, meaning complete immunity from small particles and liquids. Thus, it is able to consistently operate in harsh conditions 24/7 without supervision.

The JAKA Pro 16 robot is fully operational from -10 °C to 50 °C.

With several range and payload capacities, the JAKA Pro cobots are suitable for a variety of industrial operations of demanding and repetitive character. The recommended applications for the JAKA Pro 16 model include cutting metal, grinding, machine tending, and more.

The reasonable implementation of JAKA collaborative robots allows you not only to automate manifold production processes, but also in many cases save time and costs while maintaining the workers’ safety and health. Apart from the already mentioned tasks, you can entrust the Pro 16 cobot with inspection, flexible assembly, packaging, palletizing, pick and place, polishing, painting, screwdriving, and welding.

The JAKA Pro 16 model possesses a maximum reach of up to 1713 mm. This makes the cobot perfect for a wide spectrum of precise repetitive tasks. Furthermore, due to its highly flexible structure, the machine can be effectively installed at any angle — horizontally, on a wall, mounted from above, or otherwise.

The advanced safety protocols and collision detection mechanisms ensure safe and comfortable work for human staff regardless of their position in relation to the robot.

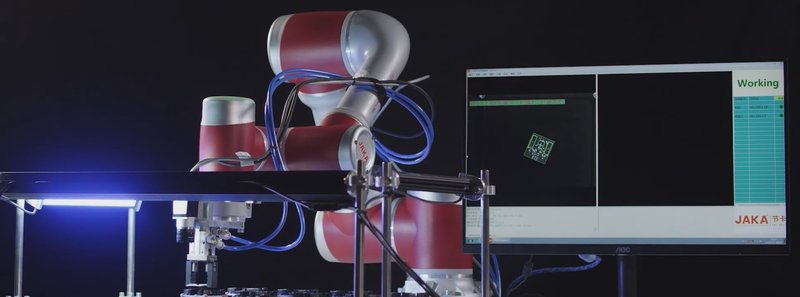

The JAKA Pro 16 cobot uses a TCP/IP and Modbus TCP/RTU control box. It can also be easily manipulated via a tablet included in the supply package. Due to the intuitive graphical programming interface, the JAKA Pro series allows users to easily set and adjust tasks from any connected device, with no prior programming experience required.

With drag teaching enabled, the operator of any level can simply drag the cobot to desired positions and set functions in the programming interface. One can also choose from multiple in-built commands to start the working process in just a few minutes. All these control features ensure smooth and user-friendly operation with the machine.

Due to their network capabilities, the JAKA Pro cobots provide a convenient remote monitoring function to control the tasks performed from anywhere in the world, which makes for effective automation. In case of any issues, alerts will be raised immediately.

As for the software, the JAKA Pro cobots come with an easy-to-use JAKA APP software based on graphical programming methods. It is quite powerful and yet makes robot control accessible for all. The program is available on tablets, smartphones, and PCs.

By purchasing the JAKA Pro 16 collaborative robot you also get:

For some items, package content may change. In case of any questions, please get in touch.

The JAKA Pro 16 collaborative robot is available in light gray with red trimmings. Its stylish look makes it ideal for advanced industry applications and will decorate any factory, workshop, or lab.

The device offers a compact footprint of 246 mm in diameter, lightweight design, and durable construction. It weighs approximately 162.9 lb (73.9 kg).

To learn the current price of the JAKA Pro 16 collaborative robot, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now