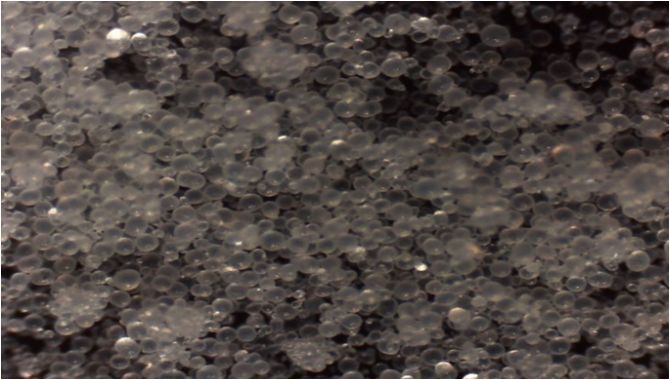

The Kings P440 is a large-scale SLS 3D printer aimed at rapid, time- and cost-efficient production of strong and temperature-resistant industrial parts. One of the key features of the device is the use of white nylon powder developed by the manufacturer. It maintains high color stability in repeated use and gives great mechanical properties to the printed items.

Being an industrial-grade solution, the Kings P440 3D printer represents an advanced machine with high heating capacity and is able to create increasingly complex shapes and designs without structural support that cannot be made by conventional production methods.

To provide precise printing results with outstanding technical characteristics, the Kings P440 is equipped with a decent forming cylinder, smart temperature control system with a multi-zone heater, powerful CO₂ laser, and precise scanning algorithms. Through the optimization of material processing, the replaceable build cylinders can be used continuously to reduce the cooling and heating processes while also reducing energy consumption. Plus, the machine adopts automatic powder feeding and replenishment during the whole printing session.

Considering the aforementioned characteristics, the Kings P440 SLS 3D printer can be widely used in a number of demanding spheres, such as the custom design and small-batch production of functional prototypes and end-use parts for medical, defense, mold, automotive, aerospace, education, scientific research, and other industries.

The Kings P440 SLS 3D printer can sinter layers with a minimum thickness of 100 micron. It is engineered with a powerful 100W CO₂ laser as well as a high-precision 3D dynamic focus scanning system to ensure exceptional accuracy and detail of produced parts.

Apart from this, the printer demonstrates impressive temperature capabilities leading to enhanced molding efficiency. It applies a heated chamber maintaining temperature up to 190 °C, multi-zone heater, and comprehensive temperature control system to reduce the risk of deformation during printing. Ensuring a uniformly heated environment, the machine allows you to smoothly print high-performance materials.

Featuring a dual-scraper intelligent powder supply system for two-way material feeding and even powder distribution, the Kings P440 effectively decreases powder overflow and improves the stability of the temperature field, which guarantees high surface quality of the printed items.

The Kings P440 SLS 3D printer works with the manufacturer’s self-developed nylon powders, such as GFPA12 (both black and white) and glass fiber-reinforced GFPA12GF with remarkable rigidity and high temperature resistance. The nylon powders from Kings provide excellent mechanical properties for the printed items and boast a nearly 100% reuse rate due to the original revival technology.

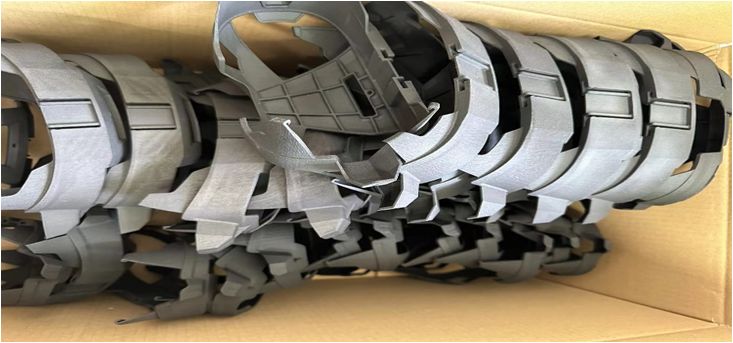

Equipped with the replaceable push-pull build cylinder, the Kings P440 ensures effective material management and continuous printing. In addition, the automated powder supply system controls the amount of material for each project making for improved product quality.

Thanks to intelligent powder spreading with a dual scraper, the machine reduces the amount of powder loss and consequently the cost for materials.

The Kings P440 features a large build cylinder of 17.3 x 17.3 x 17.7 in (440 x 440 x 450 mm). The printer is able to process 5 kg of powder within a day. It can effectively produce small-to-medium-sized parts as well as batches of multiple items, speeding up the production cycle while reducing the cost per part. An easy replacement procedure of the build cylinder further reduces the machine preparation time.

The Kings P440 can be operated via a conveniently mounted computer with a clear menu structure and user-friendly interface. It is powered by in-house developed operational software that comes with the printer.

For some items, package content may change. In case of any questions, please get in touch.

Apart from the equipment supplied with the printer by default, the manufacturer offers additional accessories, including the FHRS-100FB powder activation machine and NPM02 nitrogen generator. To learn more, feel free to contact us.

The Kings P440 3D printer is available in white. With its stylish look and ergonomic design, the machine is ideal for a variety of demanding industrial applications.

The printer dimensions are 72.9 x 52.6 x 89.7 in (1852 x 1335 x 2278 mm). It weighs approximately 4365 lb (1980 kg).

To learn the current price of the Kings P440 SLS 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now