Watch the All-on-X provisional printed in 20 minutes using the Sonic CS+.

The Phrozen Sonic CS+ is a compact LCD dental 3D printer designed for both beginners and professionals. It features a 385 nm LCD screen with 22 µm resolution, offering high precision and consistency across dental applications. Ideal for clinics adopting chairside 3D printing, it requires minimal training. The Phrozen Sonic CS+ combines ease of use with professional-quality output. Its chamber and vat heating maintain optimal temperatures for consistent prints. A “slide and lock” resin vat and step-by-step tutorials enable setup and printing within 10 minutes. The Sonic CS+ supports dental practices shifting to digital workflows, cutting down time from print to a completed part to 45 minutes. It uses AI-powered DS Slicer software for automated orientation and support, and validated resin settings for ease of use. Compatible with Keyprint, NextDent, Enlighten Materials, Dreve, Detax, SAREMCO and PacDent, the Sonic CS+ provides reliable performance for improving patient care.

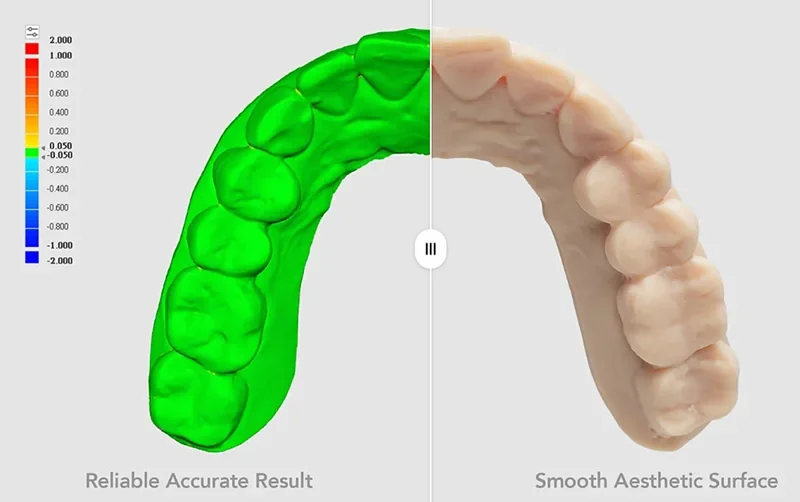

The Phrozen Sonic CS+ delivers sharp, high-resolution prints using a 385 nm LCD screen with 22 µm resolution, offering more precise light beams than standard 405 nm printers.

The Sonic CS+ delivers over 95% accuracy within 50 microns of the original CAD data, ensuring precise, consistent results across the build platform.

The Phrozen Sonic CS+ prints up to 100 mm/hour, enabling dental appliances in under 45 minutes for same-day visits.

Example: Dental Crown Printed in Under 15 minutes

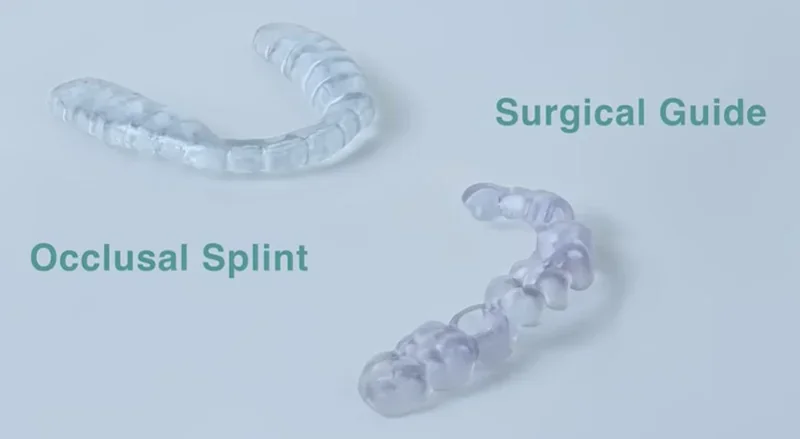

Example: Splint Printed in Under 30 Minutes

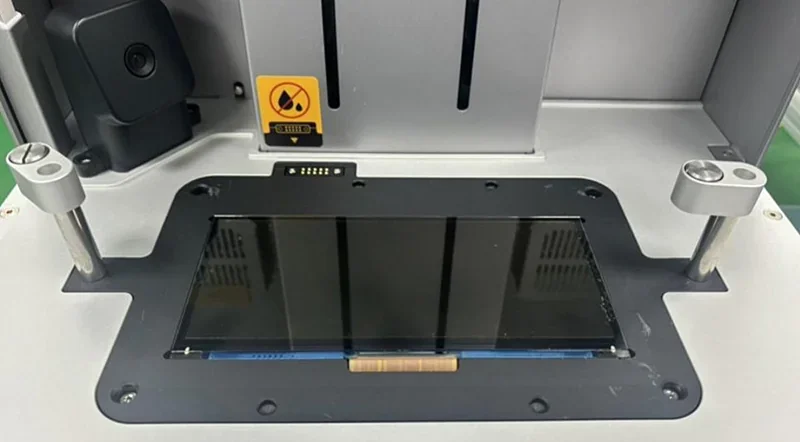

The Phrozen Sonic CS+ LCD screen, built with thermal-resistant liquid crystal and a high UV transmittance polarizer, lasts 600,000 to 1.5 million layers, ensuring long-term, consistent quality for dental use.

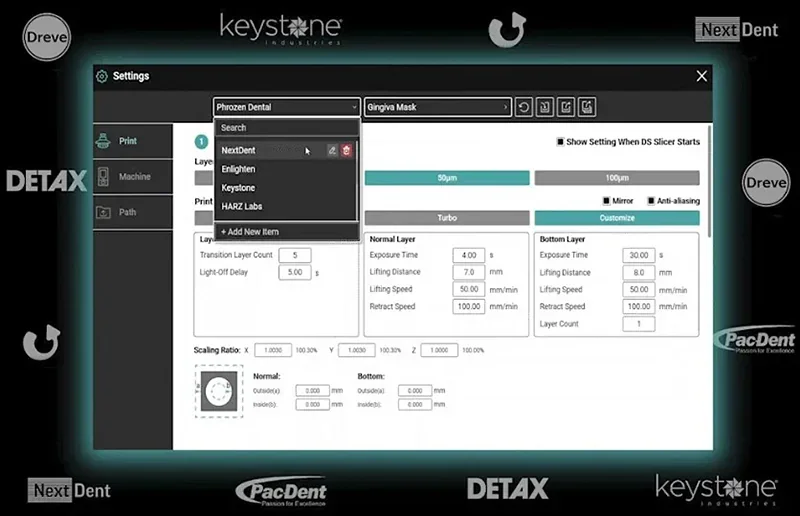

The Phrozen Sonic CS+ supports over 21 resins and operates as an open system compatible with 385 nm dental resins. It works with both Phrozen and validated third-party materials, including Keyprint, NextDent, Enlighten Materials, Dreve, Detax, SAREMCO and PacDent.

Download the latest resin profiles here:

Print Samples completed with Phrozen's Resins:

Dreve FotoDent Print Samples

The Sonic CS+ maintains a 25 ± 5°C temperature range with built-in chamber and vat heating, ensuring consistent resin viscosity and curing across materials.

The Sonic CS+ pairs with the Phrozen Heat & Mix accessory to prepare resin with proper mixing and temperature control, improving material performance.

Pre-validated open-system resin settings remove guesswork when switching materials.

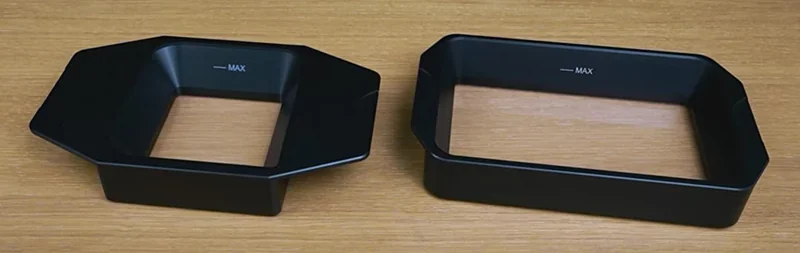

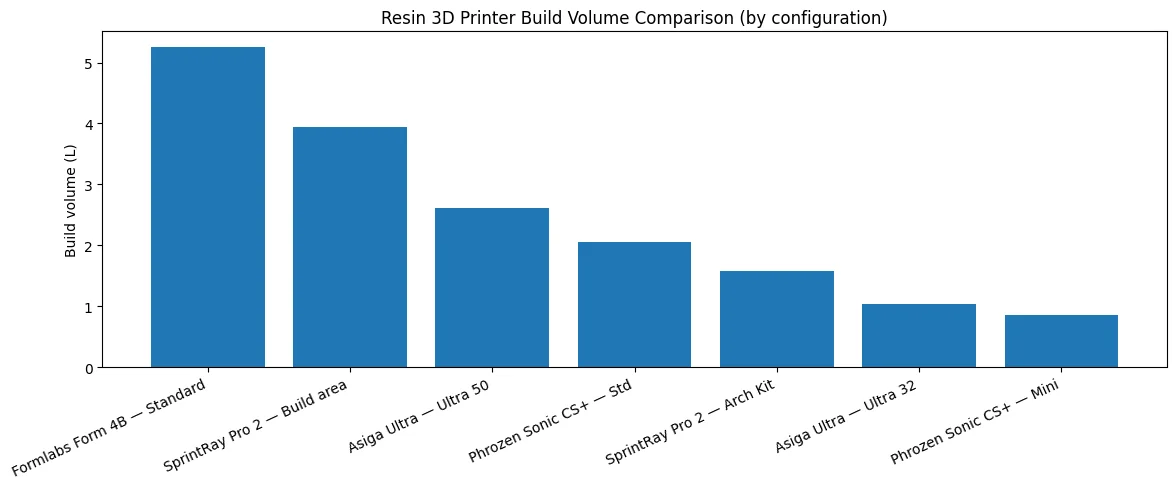

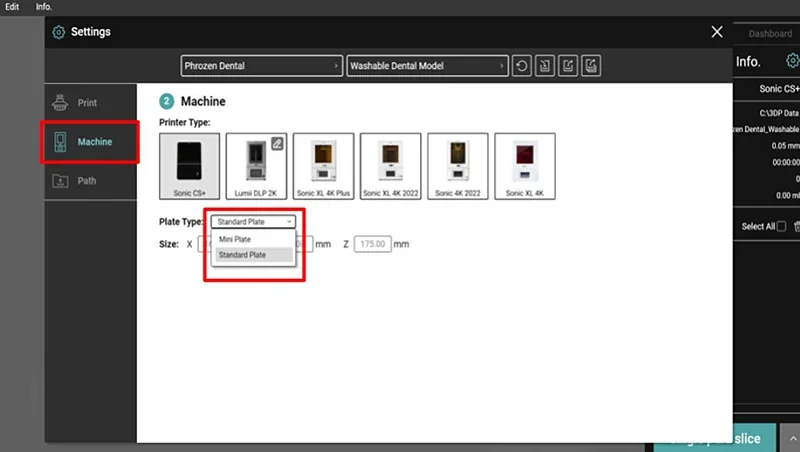

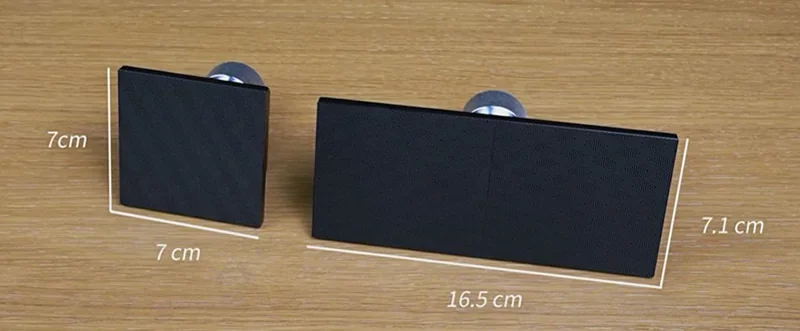

The Sonic CS+ features a dual kit design for flexible build volume. The Standard Kit offers 165 × 71 × 175 mm for larger or multiple models, while the Mini Kit’s 70 × 70 × 175 mm platform suits smaller prints with less material use and faster post-processing. Both share a 175 mm build height.

The Sonic CS+ stands out with its dual-platform design, offering flexibility for different dental needs. The Standard Kit supports cross-arch models, multiple splints, or batch production, while the Mini Kit suits crowns, single splints, or surgical guides requiring high precision in a smaller area.

The Sonic CS+ pairs its build volume with resin vats sized to match. The Standard Kit includes a 350 mL vat for larger prints, while the Mini Kit uses a 150 mL vat to minimize waste on smaller jobs.

The Phrozen Sonic CS+ features 3 primary control interfaces for printer operation:

Physical Controls

Touchscreen Interface Functions

The 7" capacitive touchscreen serves as the central control hub, providing access to:

Additional Control Features

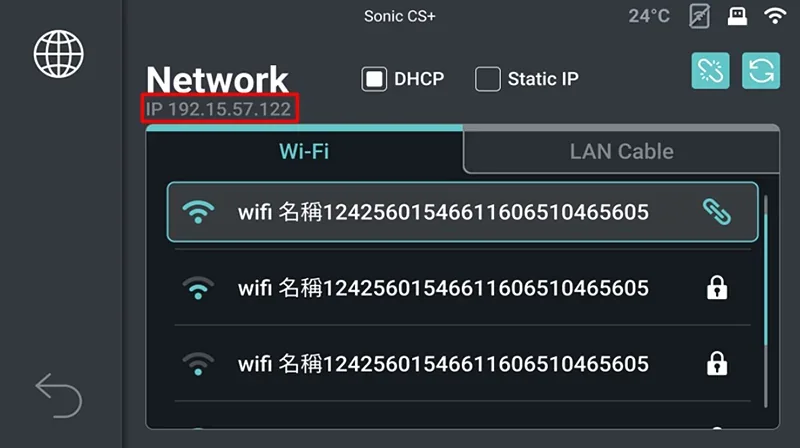

The printer includes built-in heating system controls integrated into the touchscreen interface, allowing users to manage the dual heating system (chamber and VAT heating) with automatic temperature regulation to 30°C. The touchscreen interface also provides access to Z-offset adjustments during calibration procedures and IP address display for network connectivity management.

The Phrozen Sonic CS+ offers 3 connectivity options: USB, Wi-Fi, and Ethernet. USB enables direct transfers, Wi-Fi supports wireless printing, and Ethernet ensures stable, high-speed data transmission for professional use.

The Sonic CS+ features an integrated webcam for remote print monitoring via its web-based control interface, letting users check progress without being on-site.

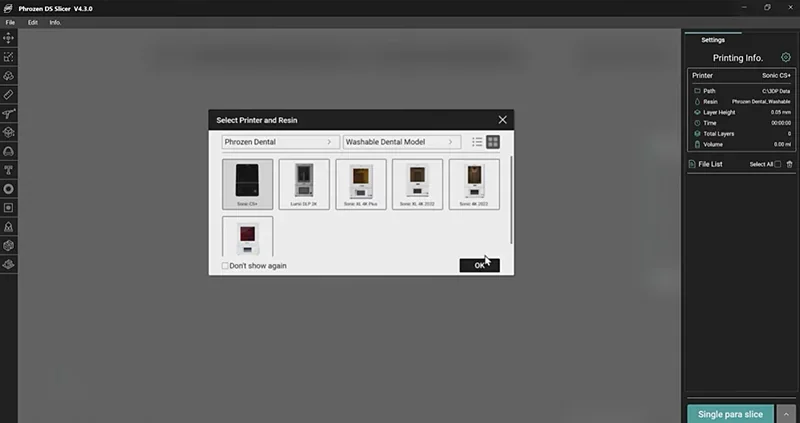

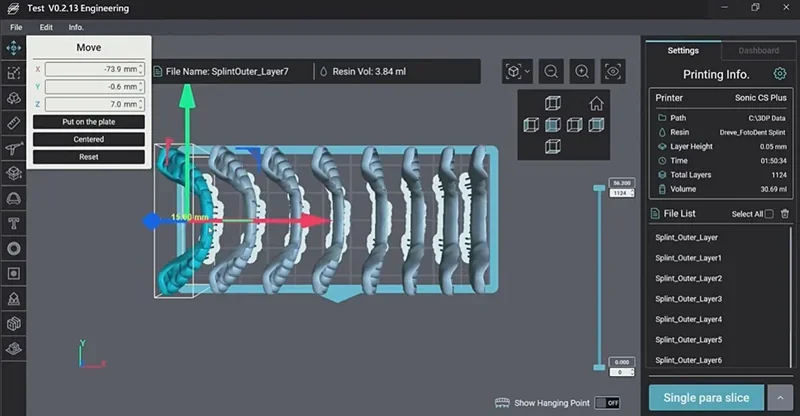

The Sonic CS+ integrates with Phrozen DS Slicer, which uses AI for support generation and model orientation. Users can prepare files on a computer and transfer them to the printer via USB, Wi-Fi, or Ethernet.

The Sonic CS+ includes Phrozen DS Slicer, an AI-powered software built for dental use that automates model orientation and support placement, streamlining print prep.

Phrozen DS Slicer includes pre-validated settings for Phrozen and third-party resins, removing the need for manual configuration. Users can prepare models on a computer and send them to the printer via USB, Wi-Fi, or Ethernet.

The Sonic CS+ integrates with third-party platforms, including official 3Shape support for digital workflows.

Firmware updates and resources like documentation, tutorials, and troubleshooting are available via the Phrozen Dental Help Center, providing a streamlined experience from design to print.

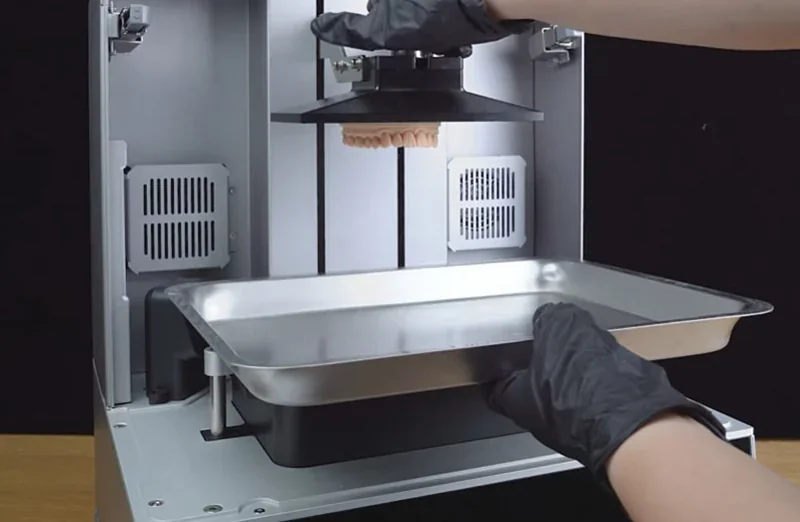

The Sonic CS+ has an all-metal, fully enclosed design that prevents resin spills and containment issues.

The Sonic CS+ has a clinic-friendly, professional design with a flip-up lid for safe, easy access to the build chamber. Its compact 360 × 380 × 550 mm size and 22 kg weight make it suitable for dental operatories while offering ample build volume.

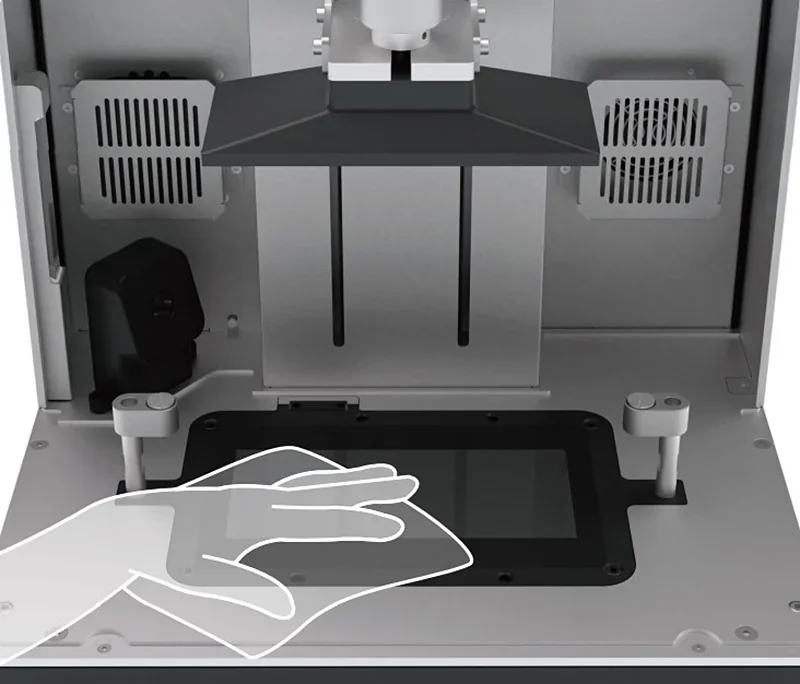

The Sonic CS+ has a fully enclosed design that protects internal components from resin splashes and leaks. A built-in carbon-filter air purifier reduces odors, and the slide-and-lock resin vat system removes the need for manual screwing.

The Sonic CS+ uses dual linear rails with ball screws for stable, precise Z-axis motion at 10 µm resolution, ideal for dental applications. It maintains 22 µm XY resolution and features failure and debris detection sensors that can auto-retract the build plate if obstructions are detected.

The Sonic CS+ is quieter than FDM printers, typically operating below 50 dB. A peeling sound during printing is normal and indicates proper layer separation.

The Sonic CS+ includes two anodized aluminum build plates: a 165 × 71 mm standard plate and a 70 × 70 mm mini plate, both with laser-etched surfaces for better adhesion.

The build plates have a hard coating to resist scratches from ceramic-filled resins. Their deep laser-etched pattern improves adhesion while allowing easy part removal. The coating also prevents anodization and resin darkening seen with standard aluminum surfaces.

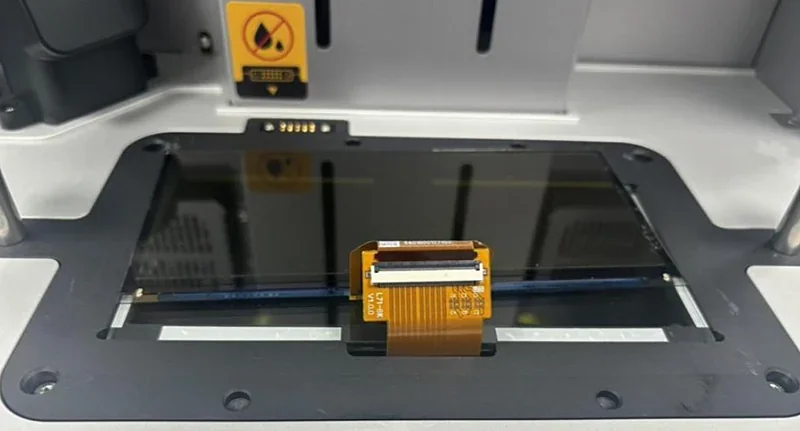

The Sonic CS+ uses a 7.1-inch 8K LCD at 385 nm, delivering 5 mW/cm² light intensity and 22 µm XY resolution. This industrial-grade screen offers deeper curing, better layer penetration, reduced yellowing, and stronger prints than 405 nm systems. It features thermal-resistant liquid crystal, a high UV transmittance polarizer, and lasts 600,000 to 1.5 million layers.

The Sonic CS+ includes two heated resin vats: a 350 mL standard vat and a 150 mL mini vat, both with pogo pin connections. They feature protective lids, a stackable design, and a slide-and-lock system that removes the need for manual screwing.

Built-in heaters warm resin to 30 °C for optimal flow, targeting only the vat to extend printer lifespan. The pre-installed PFA (nFEP) film can be replaced in 15 minutes.

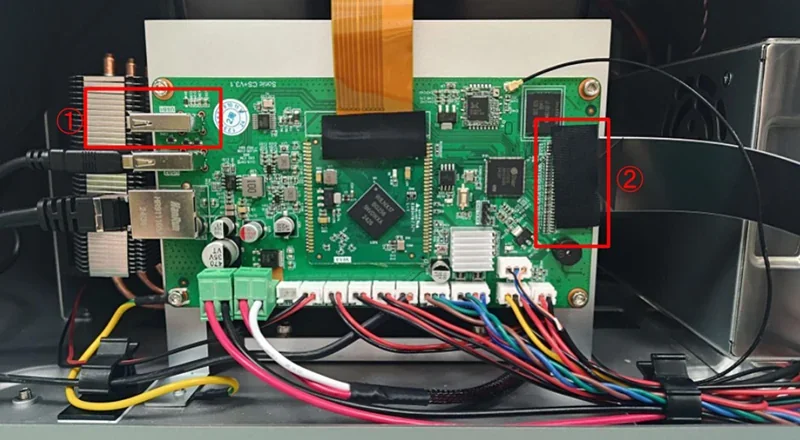

The Sonic CS+ runs firmware V1.2.9/IAPV1.02/PRZV1.28 with regular updates. Its mainboard supports USB, Wi-Fi, and Ethernet for file transfer and remote monitoring. Integrated sensors handle failure and debris detection, while the board controls dual heating with auto temperature regulation. Phrozen Go integration enables mobile monitoring, time-lapse creation, and automatic preheating at print start.

The Sonic CS+ supports 100–240V AC at 50–60Hz with a max power draw of 240W, enabling global use without converters. Its power system runs the LCD, motion control, and dual heating, maintaining 25 ± 5 °C in the chamber and up to 30 °C in the vat with automatic regulation.

The Sonic CS+ comes with a dual kit design that includes:

The Sonic CS+ comes fully assembled with both Standard and Mini Kits, allowing users to switch between high-output and quick, low-maintenance prints. The setup is ready to use within 10 minutes of unboxing.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a sales representative before placing your order.

The Phrozen Sonic CS+ supports 5+ accessories and replacement parts enhancing workflow and extending functionality for chairside applications.

| Accessory | Function | Target User | Compatibility |

|---|---|---|---|

| WASH+ | Dual-tank cleaning system for post-processing dental 3D prints with 5-minute wash cycles, supporting up to 24 models simultaneously | Dental laboratories and high-volume clinics requiring efficient post-processing workflows | $940+ |

| CURE+ | Multi-wavelength (365/385/405nm) post-curing unit with controlled heating at 60°C for biocompatible dental appliances in 5-10 minutes | Professional dental practices requiring biocompatible standards for same-visit treatment | $1,600+ |

| Phrozen Heat & Mix | Automated resin heating and mixing station with temperature control up to 50°C for homogeneous material preparation | Professional users working with viscous or composite-filled dental resins requiring consistent quality | $150+ |

| Replacement PFA (nFEP) Film | High-performance vat film with lower suction force and superior release properties for improved print success rates | All users requiring periodic consumable replacement for optimal print quality | $15+ |

| LCD Screen Replacement | 7.1" replacement monochrome LCD display for the Sonic CS+ with 22µm resolution and 385nm wavelength compatibility | Users needing screen replacement after extended use or damage | $125+ |

The Phrozen WASH+ is a dual-tank system that automates 5-minute cleaning cycles for up to 24 dental models, ideal for labs and high-volume clinics. Its separate tanks prevent cross-contamination between FDA and non-FDA materials while ensuring consistent cleaning quality.

The Phrozen CURE+ is a multi-wavelength curing unit (365/385/405 nm) with 60 °C temperature control, curing biocompatible dental appliances in 5–10 minutes. Designed for same-visit treatments, it ensures consistent results across various dental resins.

The Phrozen Heat & Mix is an automated resin station that heats and mixes materials up to 50 °C for uniform preparation. Designed for viscous or composite-filled dental resins, it ensures consistent viscosity, color, and material distribution.

Replacement PFA (nFEP) film offers lower suction and better release than standard FEP, improving print success and extending vat film lifespan. It’s a high-performance consumable for maintaining print quality.

The replacement LCD screen for the Sonic CS+ is a 7.1-inch monochrome display with 22 µm resolution and 385 nm compatibility. It restores original precision and curing performance after wear or damage.

The Phrozen Sonic CS+ requires 15+ maintenance procedures to ensure optimal print quality, extend component lifespan, and prevent mechanical failures.

After Each Print Session

Weekly Maintenance

Monthly Maintenance

Periodic Maintenance (As Required)

Quarterly Maintenance

The Sonic CS+ includes a 12-month warranty for core components like the printer body, LCD, build plate, Z-axis, and resin vat. Consumables such as FEP, PFA (nFEP), and ACF films are excluded due to regular replacement. Phrozen offers technical support through the Dental Help Center, which includes manuals, tutorials, videos, and troubleshooting guides. It covers Sonic CS+ maintenance tasks like Z-axis cleaning, touch panel checks, and LCD or FEP replacement. Users can also download firmware updates, resin profiles, and third-party integration guides. Phrozen provides direct support through an online request system, offering personalized help for the Sonic CS+. Dreve qualification adds access to maintenance and repair services at Dreve locations, ensuring expert support throughout the printer’s lifecycle. The Sonic CS+ includes a step-by-step tutorial system that guides users from unboxing to printing. Combined with detailed documentation and support channels, it ensures reliable help throughout ownership.

Full warranty terms: https://dental.phrozen3d.com/pages/warranty-policy

The Phrozen Sonic CS+ is available at $0.00 and includes both Standard (74 × 168 mm) and Mini (75 × 75 mm) build platforms and vats, offering immediate production flexibility. It features a 385 nm LCD with 22 µm resolution, a fully enclosed design with air purifier, and a 10-minute setup via guided tutorials. For bundle pricing with WASH+, CURE+, or Heat & Mix accessories, contact the sales team.

Update your browser to view this website correctly. Update my browser now