The Prusa Pro HT90 is a delta kinematics 3D printer with a cylindrical print area specifically designed to maximize the potential of advanced materials and make industrial 3D printing more accessible. Featuring an actively heated build chamber, innovative cooling system, and two swappable printheads, the HT90 easily handles any engineering project, from ultra-fast PLA prototypes to demanding PEI (Ultem) 3D prints, the most used aerospace-certified filament.

The Prusa Pro HT90 combines the advantages of a Delta design, high-speed printing, high-temperature capabilities, and unique cooling mechanism to create an ultimate yet affordable industrial solution for high-performance materials, such as PEEK, PEKK, PEI, etc.

Equipped with a 90 °C heated chamber with a closed HEPA and carbon filter recirculation loop as well as a self-developed cooling system, the HT90 provides unparalleled layer adhesion and print quality. This ensures an optimal environment for even the most demanding filaments and lets one print fairly large objects without any warping, poor overhangs, or layer delamination.

To provide a streamlined experience for both beginners and advanced users, the HT90 3D printer is equipped with multiple quality-of-life features, including a quick-release nozzle system, auto leveling, filament detection, intuitive interface, HEPA filter that ensures a safe environment for the user, long-term support and updates. Prusa Research has also implemented Input Shaper and Pressure Advance technologies into the HT90. The former helps eliminate resonance in prints, while Pressure Advance is used to control the filament flow. Both technologies allow for a significant boost in print speed without losing the quality.

The Prusa Pro HT90 is easy to set up and configure, offering a robust online print management system. The machine integrates seamlessly into the Prusa ecosystem with secure remote management via Prusa Connect and advanced 3D model processing in PrusaSlicer. While offering extensive connectivity options, the HT90 is also fully functional in an offline environment if required for safety reasons.

Due to its impressive accuracy and consistent print quality, high-speed printing capabilities, robust structure, user-friendly controls, and ability to handle a vast array of materials, the Prusa Pro HT90 is perfect for an ample range of professional applications. Easy to use even for complete beginners, the machine offers reliable performance making it an ideal fit for printing engine parts and coolers, medical implants and functional parts of machinery, valves, pipes, chemically-resistant components, durable heat- and cold-resistant parts, and much more.

Many of the advanced 3D printing materials, such as PEI, PEEK, PEKK, PSU, etc., are hygroscopic, which means they rapidly absorb moisture from air. To prevent degraded print performance, high-end filaments need to be kept dry. For this purpose, the Prusa Pro HT90 3D printer can be purchased along with optional accessories — either a Drybox or a full-scale industrial filament dryer (see the Add-ons section to learn more).

Excellent print quality has always been one of the strong points of Prusa 3D printers, and the Prusa Pro HT90 model is not an exception to the rule. Numerous advanced technologies allow the machine to create impeccable models with sharp features at an impressive print speed of up to 250 mm/s, with acceleration of 20000 mm/s². A minimum layer height of 0.05 mm allows producing highly detailed parts with smooth exterior surfaces, clean overhang transitions, and minimal tolerances.

Thanks to its Delta structure, the HT90 model delivers smooth, dimensionally precise prints without typical artifacts present on CoreXY or cartesian 3D printers. This is because the movement of the direct-drive extruder is controlled by a coordinated shift of three lightweight arms, while the printed objects remain stationary. Equipped with Klipper firmware and Input Shaper technology, the Prusa Pro HT90 achieves ultra-fast speeds up to 600 mm/s while maintaining top print quality across the entire cylindrical print area.

Due to its high-flow and high-temperature swappable printheads, the HT90 allows for rapid and versatile printing of the majority filaments on the market. Each of the printheads is held in place using magnets, so it is easy to replace: just detach the head from the arms, disconnect the cable from the top of the printer, and replace it with the other.

The HT90 high-flow printhead with a quick-swap 0.4mm Revo nozzle is the perfect choice for rapid prototyping with materials up to 300 °C. In contrast, the high-temp printhead with an abrasive-resistant quick-swap 0.6mm Revo nozzle reaches up to 500 °C and enables printing with materials such as PEEK, PEKK, or PEI (Ultem). Both printheads are included with the HT90 and the hardware is compatible with all Revo nozzles with diameters from 0.25–0.8 mm.

One of the key features of the Prusa Pro HT90 is the unique air management system designed for real-time airflow control and optimal print quality with all materials. The print fan is on the side of the printer, forcing air through a tube directly into the lightweight print head, while the high-speed flap redirects its flow within milliseconds, faster than any normal cooling fan can do. This enables vastly improved printing of overhangs while the layers in the rest of the printed model do not suffer from overcooling.

Additionally, a closed-loop air recirculation system with a HEPA filter keeps the chamber free of ultra-fine particles, while an automatic intake flap manages temperatures for materials like PLA and PETG, so the user can print them with the chamber closed. The key components are placed outside the heated chamber, prolonging their lifespan.

Three high-precision Loadcell sensors measure the distance between the nozzle and the print sheet with exceptional accuracy. This enables the HT90 3D printer to achieve an ideal first layer, no matter which print surface you choose, without any need for manual adjustment.

The high-temperature printhead with the maximum nozzle temperature of 500 °C, 155 °C heated print bed, and actively heated chamber capable of maintaining the temperature of up to 90 °C make the Prusa Pro HT90 one of the most affordable 3D printers capable of handling high-end materials without negative side effects, such as warping or layer separation. The machine is compatible with a wide range of filaments such as PLA, ABS, PETG, ASA, PA, PC, flexible TPU, TPE, and advanced materials like PEI (Ultem), PEEK, PEKK, PPSU, PSU, PPS, PES, and more.

The HT90 3D printer can process both proprietary Prusament and third-party filaments, providing the user with a wide choice of available 1.75 mm thermoplastics.

Check out the Add-ons section to learn more about working with high-performance materials requiring precisely controlled printing conditions, such as PEI, PEEK, PEKK, PSU, etc.

The Prusa Pro HT90 features a build volume of 11.8 inches (300 mm) in diameter and 15.7 inches (400 mm) in height that lets one produce fairly large parts in one go without splitting the 3D model into several pieces or small-to-mid-sized objects in batches. The heated print bed with a textured PEI steel sheet allows for good first layer adhesion and easy print removal. The user can additionally purchase PA steel sheets.

The Prusa Pro H90 3D printer is controlled via a large 7" full-color LCD touchscreen with a clear and intuitive user interface. Furthermore, it is possible to use the built-in camera for print monitoring and chamber lighting or attach an external USB camera. The entire print preparation process for the HT90 is fast and accompanied by easy-to-follow instructions. After finishing the automatic calibration and loading a filament of your choice, you can start printing right away!

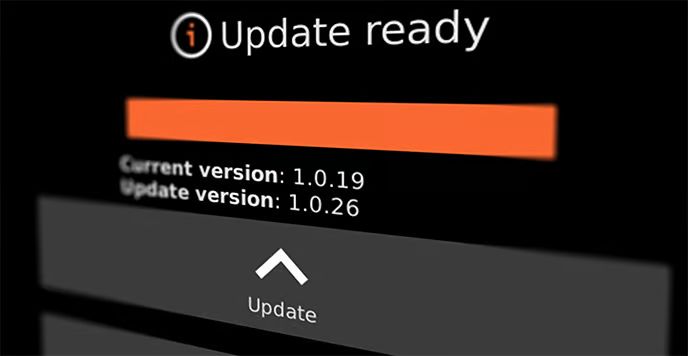

The HT90 model offers both local and remote management modes. In the local mode, the printer can be reached only from the local area networks, but you can also add it into Prusa Connect — a secure remote print management system that allows access from anywhere. The Prusa Pro HT90 can be configured and updated completely without internet access. In addition, the Wi-Fi module can be easily unplugged for environments that require the highest level of security.

The Prusa Pro HT90 is recommended to be used with the open-source PrusaSlicer software with numerous useful tools such as organic supports, cutting, automated object distribution, ironing, and others. The program features timely updated and ready-to-use material profiles (over 180 in total) that ensure perfect print results with different filaments and cut down print preparation time.

One can further improve the performance of the Prusa Pro HT90 3D printer by purchasing the following accessories provided by the manufacturer (check out the Add-ons & Extras section at the top of the page to add them to your shopping cart).

The Prusa Pro Filament Drybox is an essential accessory for working with moisture-sensitive materials. This hermetically sealed box ensures optimal conditions for storing and printing filaments that require low humidity, which is crucial for maintaining optimal print quality. For high-performance polymers like PEI, PEEK, PEKK, or PSU, which need precisely controlled printing conditions, the Prusa Pro Filament Drybox is highly recommended.

The Memmert UF30 is a high-performance lab oven made of high-quality, hygienic, easy-to-clean stainless steel. It represents the perfect solution for precise filament drying, with temperatures adjustable between +20 and +300 °C and chamber volume of 32L.

Most engineering-grade materials are highly hygroscopic, meaning that they absorb moisture from the environment, which severely degrades their performance. With the filament dryer, one can easily reduce the moisture content to optimal levels. Once the filament is properly dry, it is recommended to place it directly into the Prusa Pro Filament Drybox to prevent repeated moisture build-up.

The Prusa Pro HT90 is available in white with black trimmings. Its stylish look makes it ideal for professional workshops, production floors, or educational institutions. The printer has a compact footprint that is further enhanced by a vertically sliding door to save more space.

To learn the current price of the Prusa Pro HT90 FDM 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now