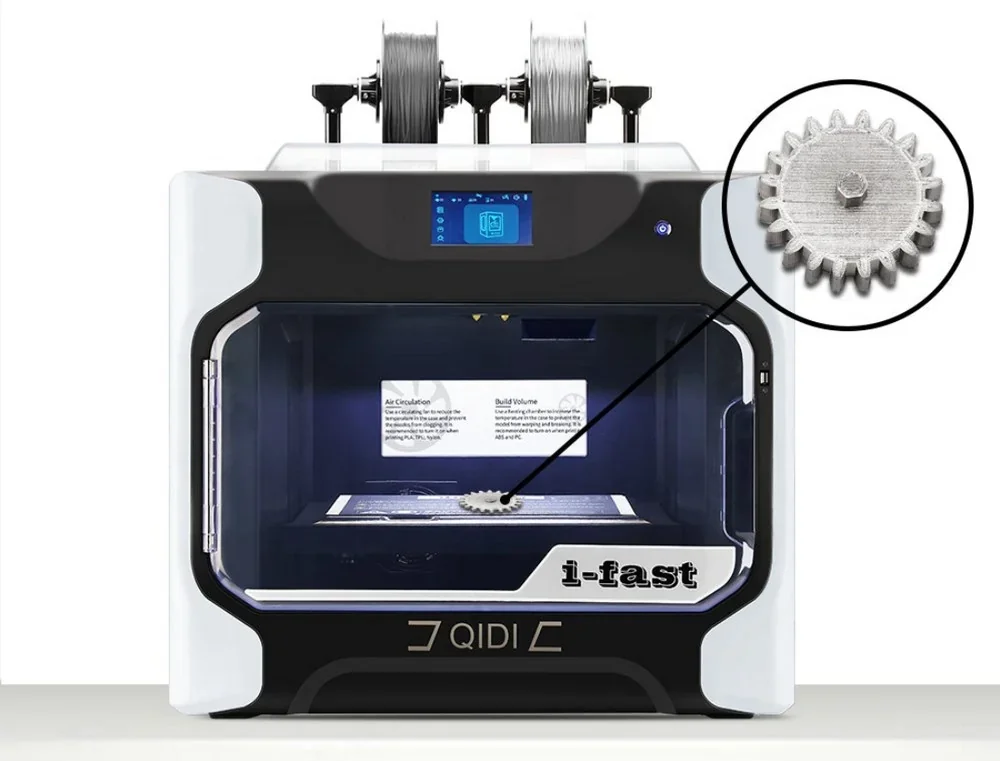

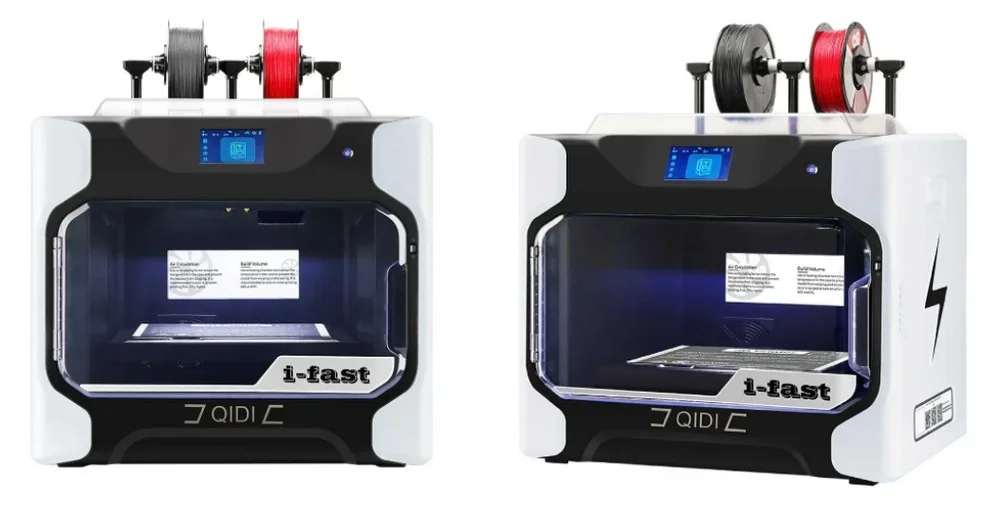

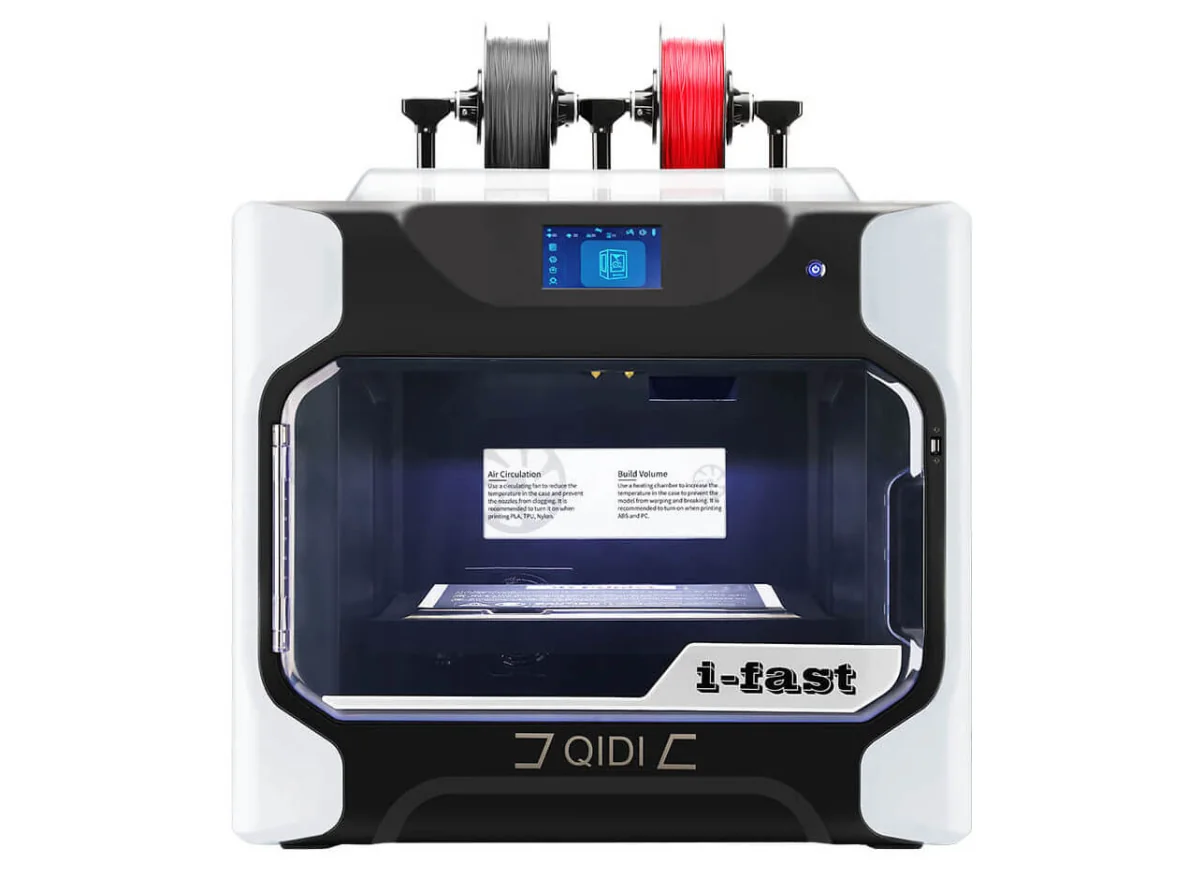

The QIDI Tech i-Fast is a fully enclosed, metal-frame, linear-rail 3D printer offering industrial-grade dual extrusion at a competitive price. It includes two interchangeable extruder systems—a standard dual setup for common filaments and a high-temperature variant up to 350 °C—and a 60 °C heated chamber to boost adhesion and reduce warping in ABS, PC, and nylon; the automatic dual system enables precise multi-material prints with soluble PVA supports. With a 330 × 250 × 320 mm build volume and 50–200 µm layers, it tackles large, detailed parts across materials from PLA to carbon-fiber composites, while QIDI’s slicer provides beginner and expert modes for all skill levels—making it a strong fit for professional, educational, and advanced hobby use.

The QIDI Tech i-Fast offers 50–200 micron resolution and 80–100 mm/s speeds — up to 40% faster than frame printers. Tests show smooth ABS prints at 0.2 mm layers and 80 mm/s, plus dual-extrusion parts with clean PVA removal and production-ready surfaces. For example, the video below shows mechanical components, multi-material parts, and intricate helical structures with great surface finish and dimensional consistency.

The QIDI Tech i-Fast maintains 80-100 mm/s print speeds with high accuracy and surface quality across varied geometries. Users report 20-40% faster completion times than frame-structure printers. With 100 cm³/hour throughput, it suits small-batch manufacturing and rapid prototyping where speed drives productivity. Multi-hour tests show reliable, uninterrupted extrusion and precise motion control, enabling consistent, unattended overnight prints.

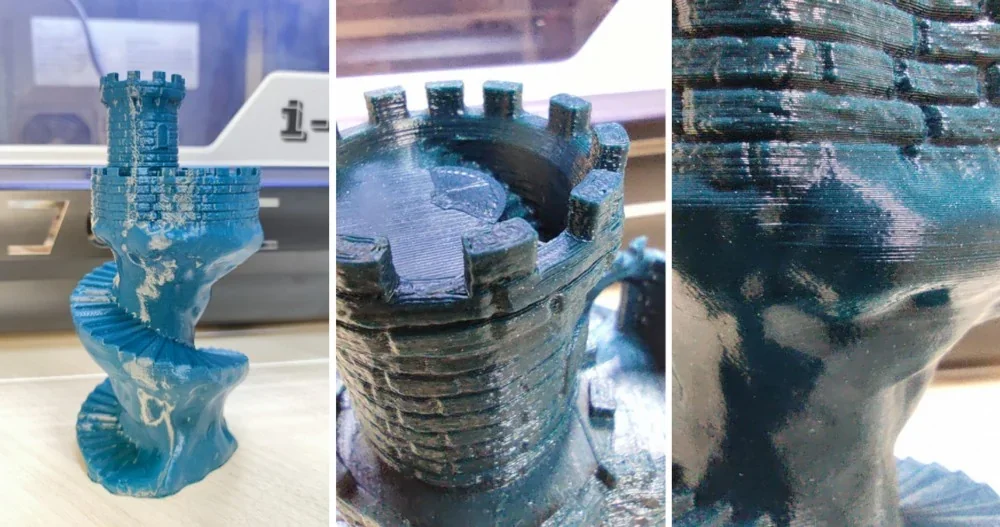

Real-world tests show the i-Fast handles complex designs and varied materials with precision. A spiral ABS tower printed at 245°C, 0.2 mm layer height, and 80 mm/s speed displayed smooth surfaces, strong layer adhesion, and no warping or delamination despite high chamber temperatures.

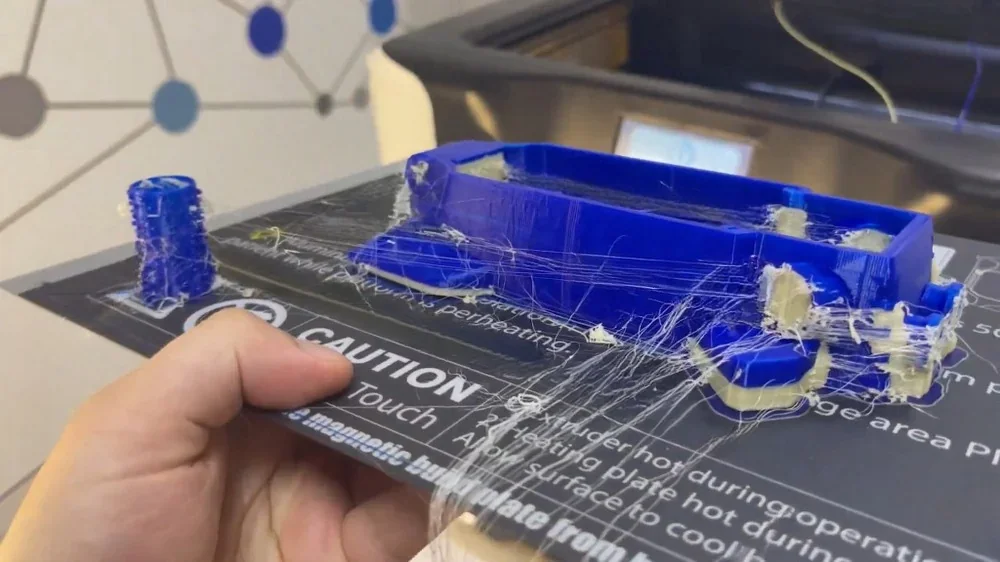

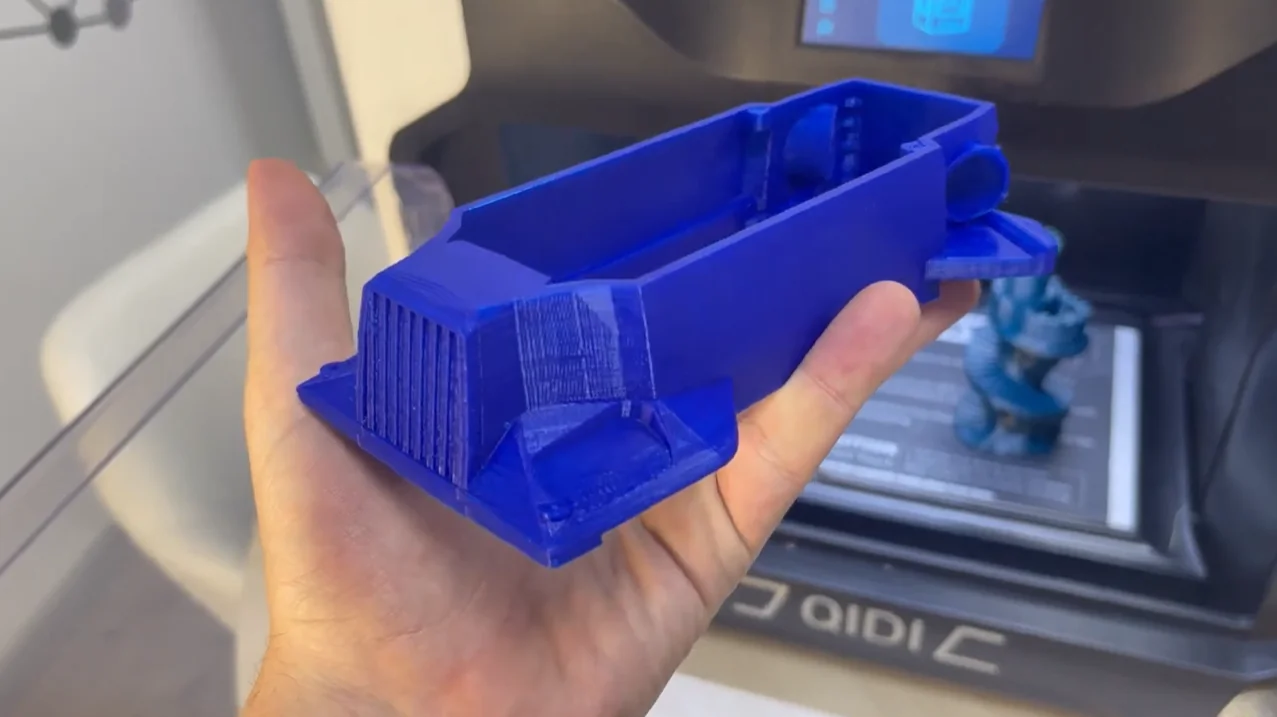

A dual-extrusion quadcopter part printed with blue E-Sun PLA and PVA supports highlights the i-Fast’s precision with soluble materials. Minor stringing from PVA moisture was present, but the purge tower prevented cross-contamination, demonstrating clean material separation even under suboptimal filament conditions.

After a 60-minute warm-water soak removing PVA supports, the model revealed clean overhangs, sharp details, and flawless surfaces. The dual-extrusion system proved capable of producing production-ready parts without post-processing damage.

The QIDI i-Fast supports 10+ filament types — including PLA, ABS, TPU, PETG, PVA, nylon, polycarbonate, and carbon-fiber composites — via a dual-extruder system with a brass nozzle for standard materials and a 350 °C hardened-steel/ruby-tipped hotend for engineering and abrasive filaments. A 60 °C actively heated chamber improves adhesion and reduces warping for ABS and PC, the direct-drive setup reliably handles flexible TPU, and the all-metal hotend maintains stable extrusion across materials. It uses an open-filament approach with third-party compatibility, and QIDI’s slicer includes preset profiles.

PLA 3D Print Sample: Orange L-shaped frame with rounded corners, 3D-printed at 0.15 mm layer height, featuring a glossy finish and uniform wall thickness.

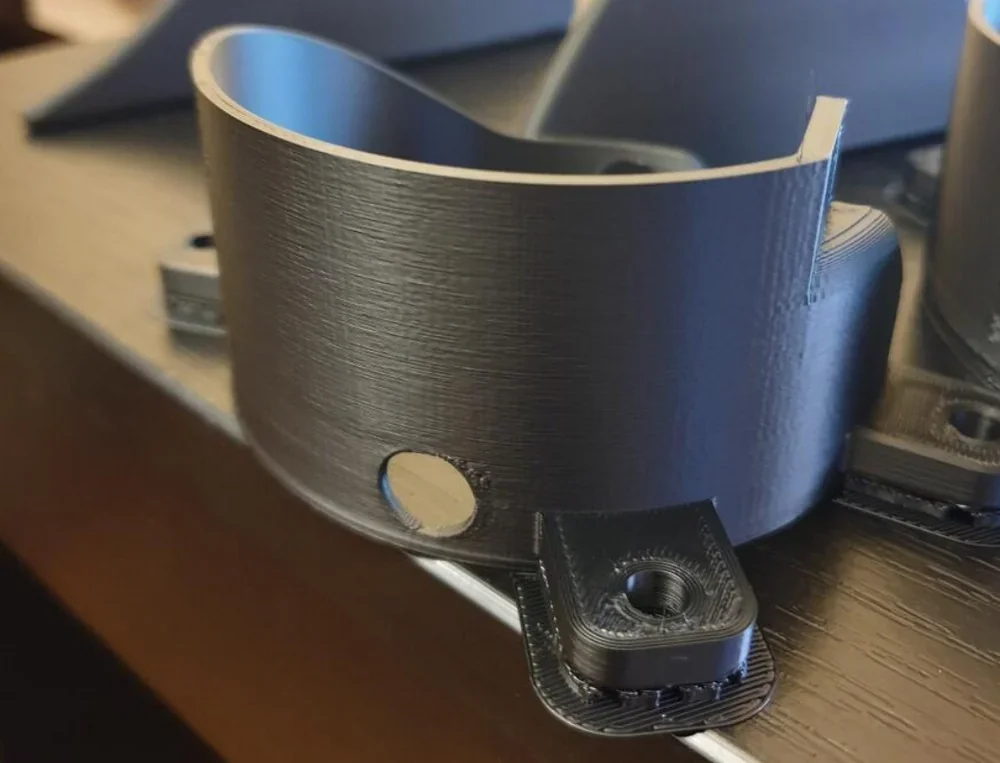

ABS Standard 3D Print Sample: Black curved bracket with a circular mounting hole and platform base, 3D-printed at 0.2 mm layer height with visible layer lines and a matte finish.

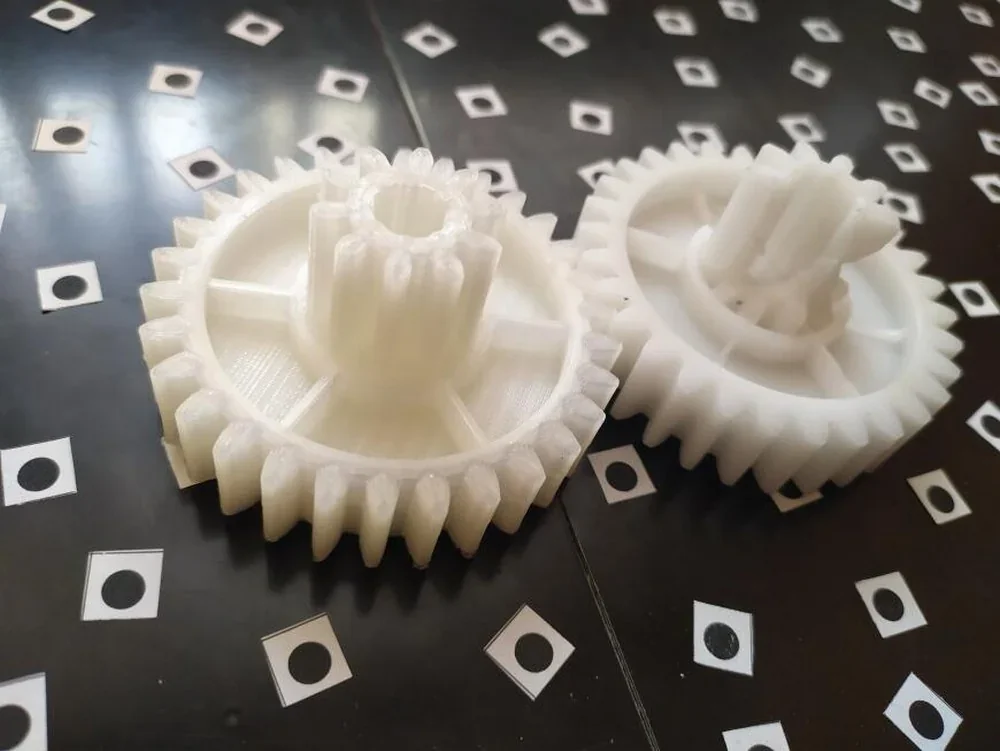

Nylon 3D Print Sample: Two white nylon spur gears with distinct internal structures, 3D-printed at 0.2 mm layer height with precise teeth and a matte off-white finish.

Specialty filaments expand the i-Fast’s range, supporting wood-filled composites and metal-infused materials like BASF 316L stainless steel, which requires post-print sintering for full metallic strength.

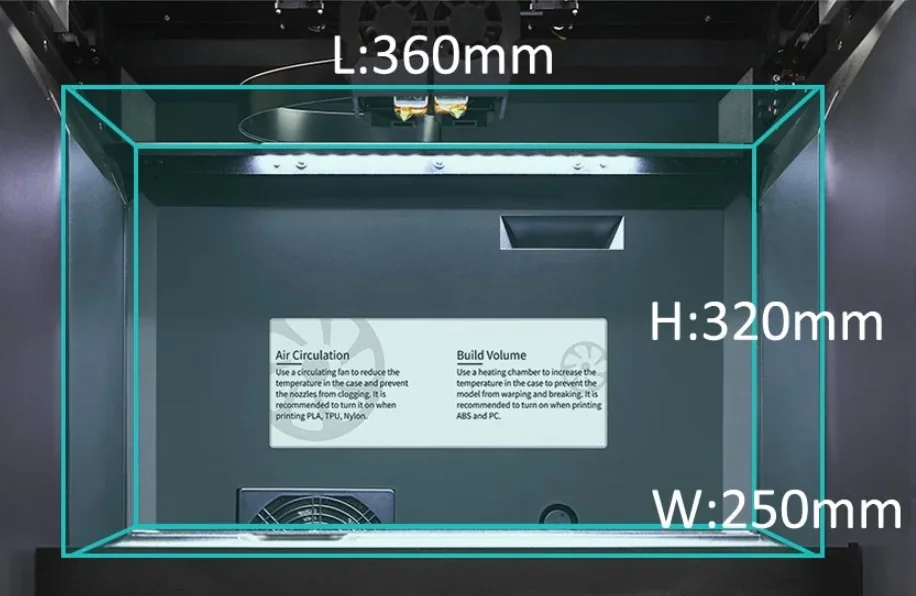

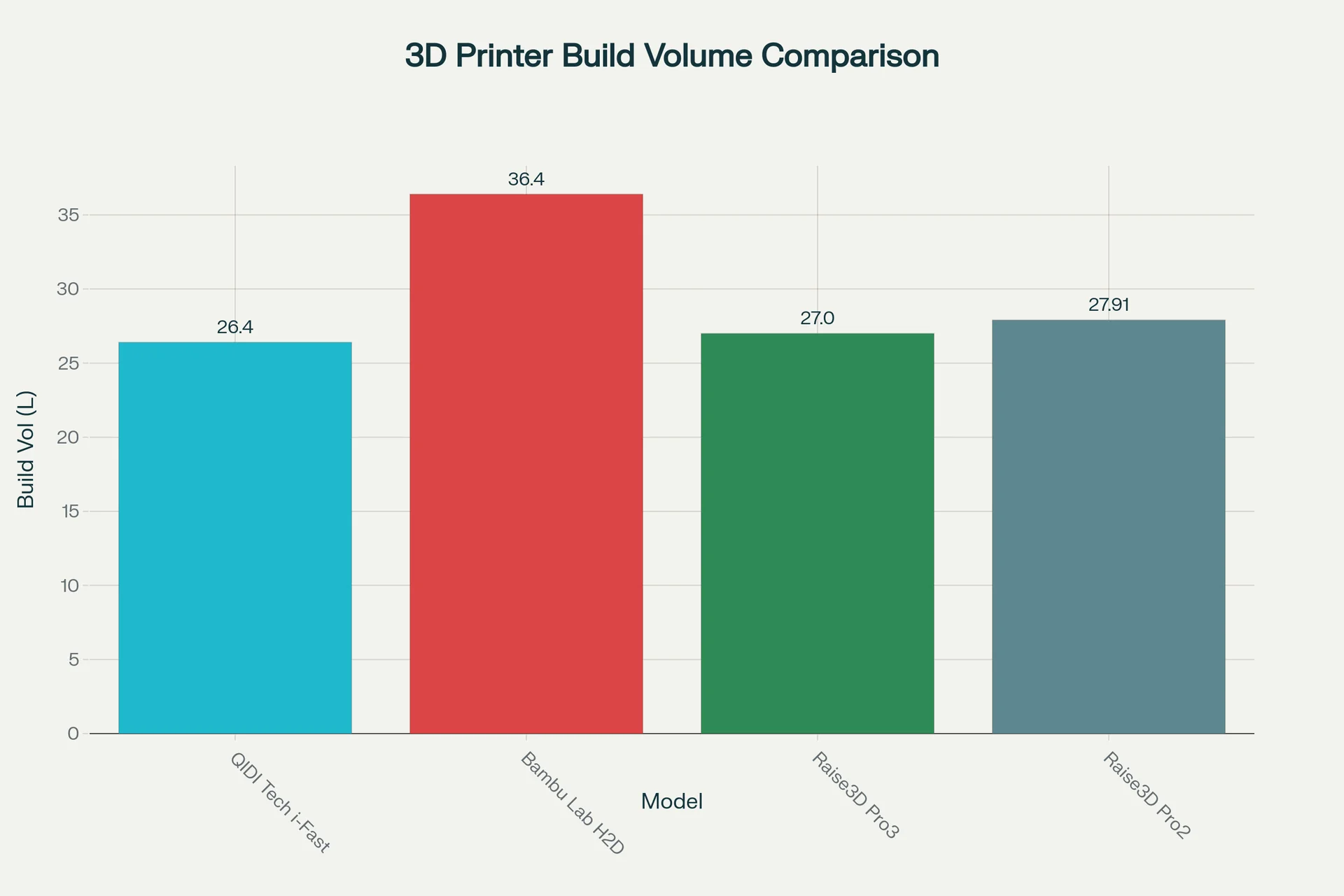

The QIDI Tech i-Fast has a build volume of 330×250×320 mm in dual extruder mode and 360×250×320 mm in single extruder mode, offering flexibility for various projects. Its overall size is 710×510×670 mm and it weighs 33 kg, requiring dedicated workspace.

QIDI Tech i-FAST — lowest-cost enclosed dual-extruder in this set ($1,550+) with a 330×250×320 mm build, 300 °C / 100 °C temps, an actively heated ~60 °C chamber, and open-material flexibility (Wi-Fi/LAN/USB) at 33 kg — the value pick if you don’t need extreme speed.

In contrast:

| Specification | QIDI Tech i-FAST | Bambu Lab H2D | Raise3D Pro3 HS |

|---|---|---|---|

| Price (USD) | $1,550+ | $2,000+ | $5,599+ |

| Build volume (single / dual) | 330×250×320 mm | 325×320×325 mm / 300×320×325 mm | 300×300×300 mm / 255×300×300 mm |

| Max nozzle / bed temp | 300 °C / 100 °C | 350 °C / 120 °C | 320 °C / 120 °C |

| Chamber | Enclosed, active heated up to 60 °C | Active heat ~65 °C; G3 + HEPA H12 + carbon | Enclosed; HEPA + activated carbon |

| Speed / flow (headline) | 30–150 mm/s | Up to 1000 mm/s; 40–65 mm³/s flow | Max 500 mm/s (Hyper FFF®) |

| Extrusion system | Dual extruders | Dual extruders | Dual extruders (electronic lifting) |

| Filament diameter | 1.75 mm | 1.75 mm | 1.75 mm |

| Connectivity / UI | Wi-Fi / LAN / USB | Wi-Fi (2.4/5 GHz), app/PC, 5″ touch | Wi-Fi, LAN, USB; 7″ touchscreen |

| Machine size (W×D×H) | 710×510×670 mm | 492×514×626 mm | 620×626×760 mm |

| Net weight | 33 kg | 31 kg | 54 kg |

| Notable features | Value enclosed dual; open-material list | Active chamber heat, multi-cameras/sensors; optional High-Flow hotend | Air Flow Manager-style filtration, Hyper FFF®, fleet-ready ecosystem |

Bottom-Line:

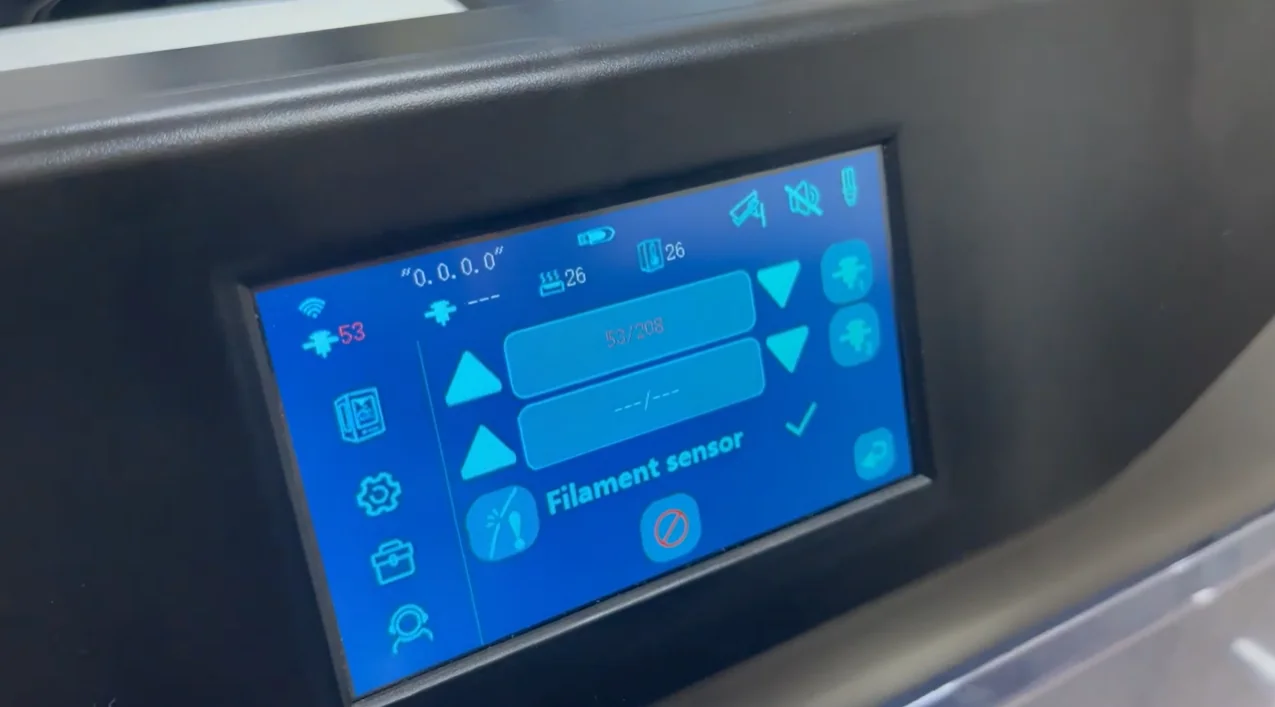

The intuitive ui interface of the QIDI Tech i-Fast offers 11 touchscreen controls divided into primary and secondary functions.

Primary Controls:

Secondary Controls:

The QIDI Tech i-Fast supports WiFi, LAN, and USB connectivity for flexible operation. WiFi enables remote monitoring and control, while the rear LAN port provides a stable wired connection. A front USB port allows local file transfers, though its placement is slightly inconvenient.

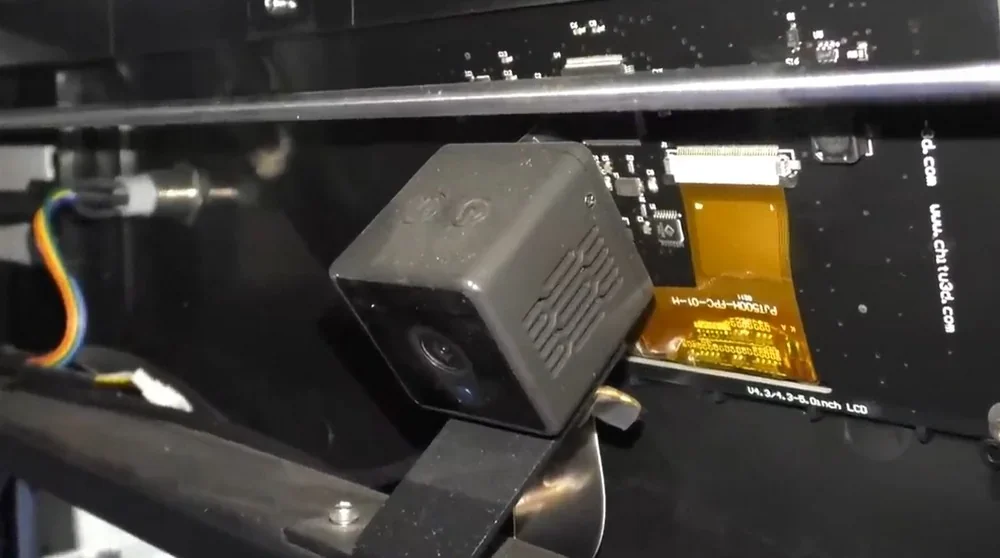

The printer also supports an optional UVC-compatible webcam for live monitoring and time-lapse recording.

All connectivity options work seamlessly with QIDI software, as well as Cura and Simplify3D, for flexible workflow integration, allowing users to send print jobs, monitor progress, and adjust settings remotely from computers or mobile devices.

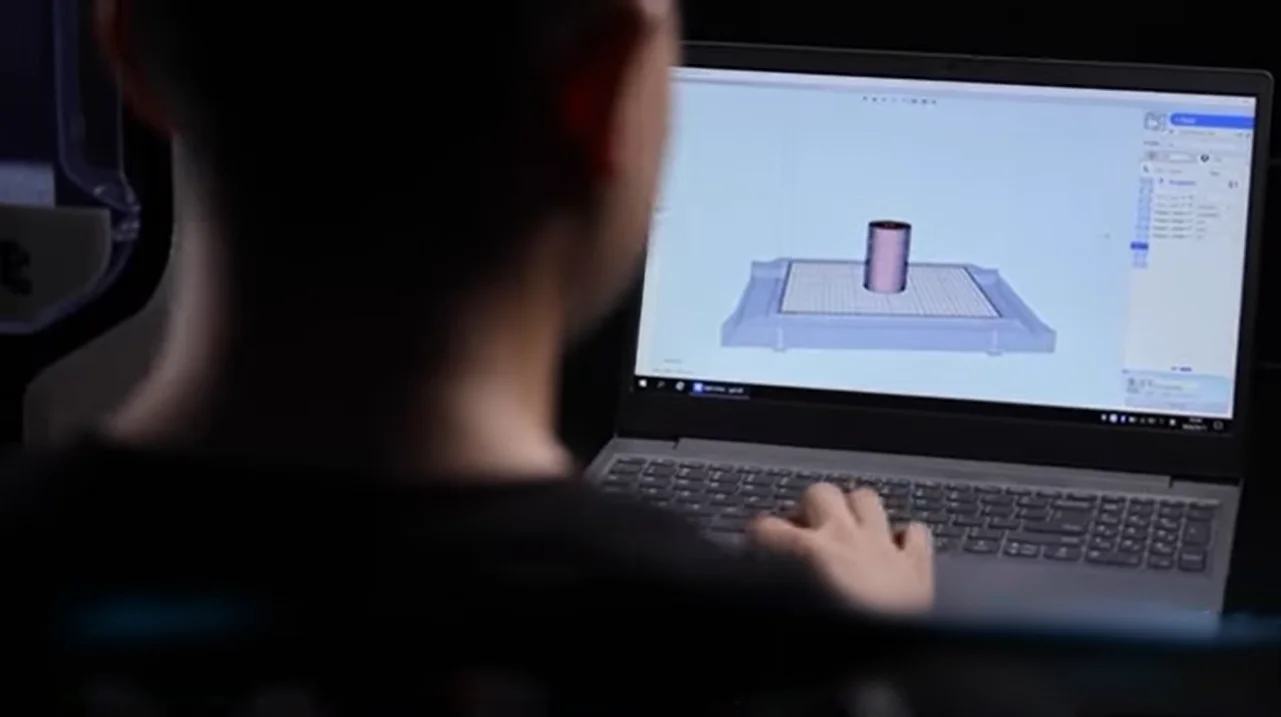

The QIDI Tech i-Fast includes QIDI Print 6.2.2, proprietary slicing software with a redesigned, friendly ui interface that simplifies complex operations. Its improved algorithm boosts print quality by 30% and speed by 20%.

QIDI Print offers two modes:

The i-Fast also supports Cura, Simplify3D, and PrusaSlicer, giving users flexibility to use familiar tools with dedicated printer profiles. Compatible with Windows 64-bit and macOS, QIDI Print is free for life with regular updates for ongoing compatibility.

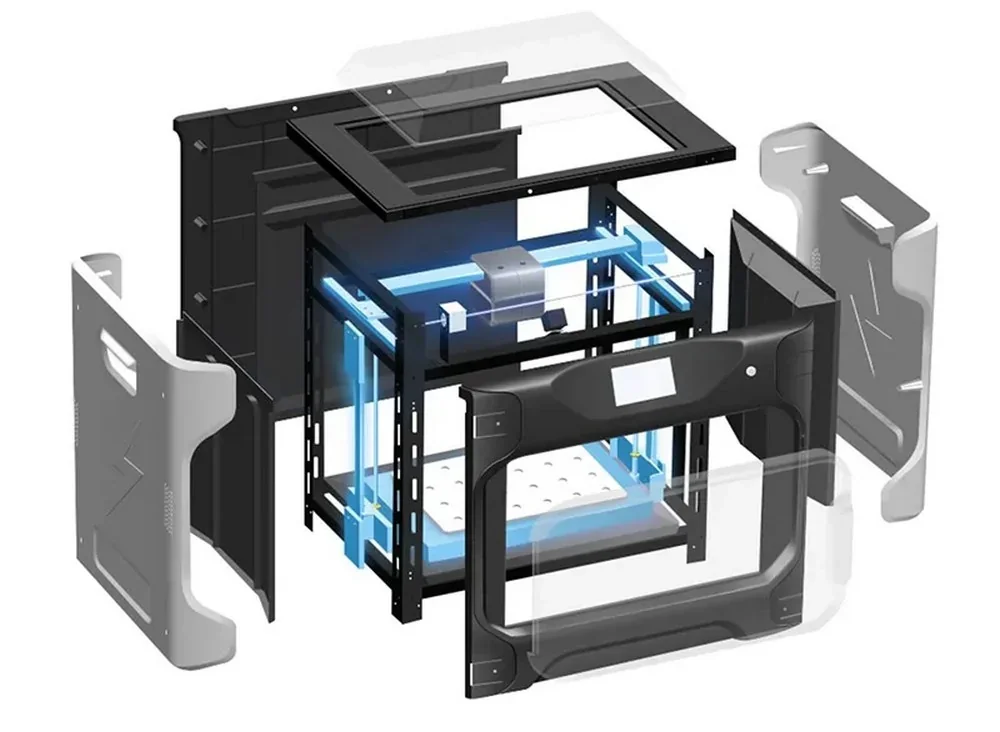

The QIDI i-Fast features a fully enclosed plastic housing with active chamber heating for thermal stability. It measures 710×510×670 mm (27.95 × 20.08 × 26.38 inches) and weighs 33 kg (72.7 lbs). The enclosure includes a transparent locking front door and a magnetically secured top cover for chamber access.

Its aluminum frame provides an excellent mechanical structure that ensures rigidity and reduces vibration during high-speed printing. The printer offers a build volume of (13.0×9.8×12.6 inches) in dual extruder or 360×250×320 mm (14.2×9.8×12.6 inches) in single extruder mode, placing it in the large semi-professional category. Side handles aid transport, and a 31-inch (≈800 mm) depth clearance is required to accommodate rear filament holders and dry boxes.

The QIDI i-Fast uses a Cartesian motion system, upgraded to linear guides on X, Y, and Z axes, delivering improved accuracy and smooth movement over traditional rods.

The X-axis has a machined aluminum beam, the Y-axis uses a trapezoidal lead screw with side-mounted rails, and the Z-axis employs QIDI’s dual-motor system with independent lead screws and linear rails for stable, level movement.

It features NEMA 17 high-temperature stepper motors with silent drivers for quiet operation, though specific motor brands are not listed.

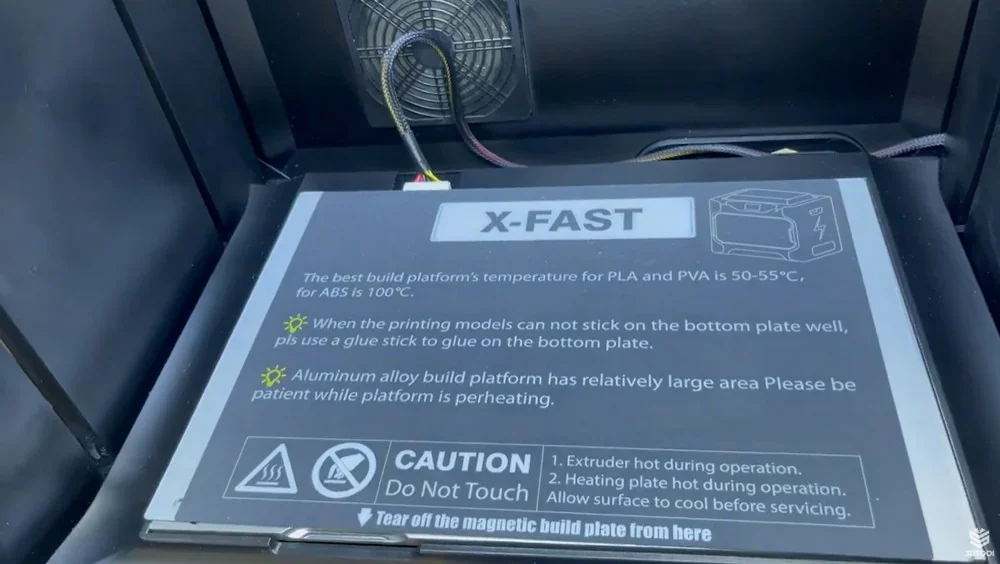

The QIDI i-Fast features an aluminum heated bed with an integrated PCB heater, thermistor, and 30 embedded magnets securing removable flexible build plates. It includes two magnetic surfaces: a textured BuildTak-style plate for PLA and a pebbled PEI sheet for ABS and engineering materials.

The bed heats to 110–120°C with excellent uniformity — within 2°C from center to edge — ensuring strong adhesion and reduced warping. The magnetic plates allow easy part removal once cooled, and extra plates support continuous production by enabling quick swaps between prints.

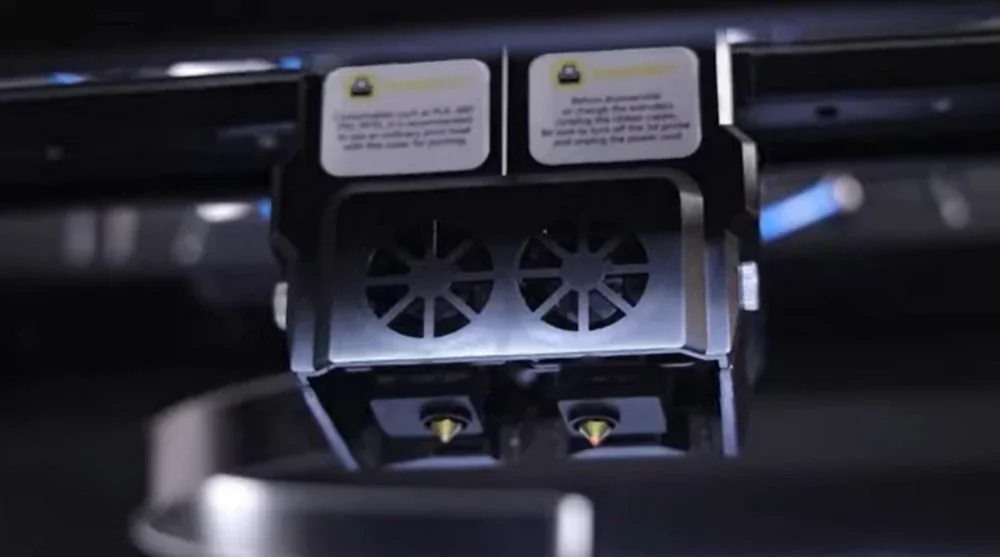

The QIDI i-Fast includes two dual-extruder setups: normal brass nozzles rated to 240°C for standard materials and a hardened steel system rated 250–300°C for advanced filaments. It successfully prints nylon at 280°C and other engineering materials at 300°C.

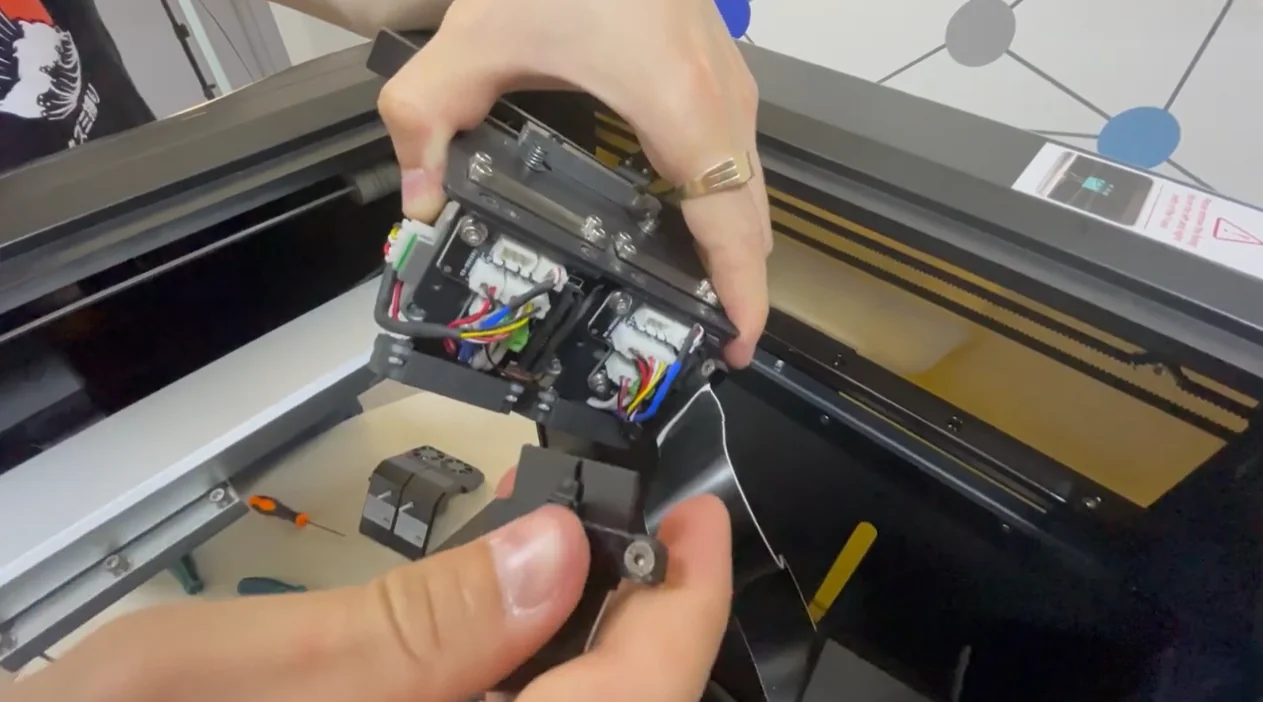

A mechanical cam switch lifts the inactive nozzle to prevent print contact, with software Z-offsets compensating for minor variances. Each extruder uses dual-drive gears for strong filament grip and 25 mm thermostatic fans for heat break cooling. Blower fans provide adjustable part cooling, managed through software.

The high-temperature extruder features 0.4 mm ruby-tipped MK10/M7 nozzles for abrasion resistance. Spare nozzles are included, and the extruder connects via a ribbon cable with strain relief for easy maintenance.

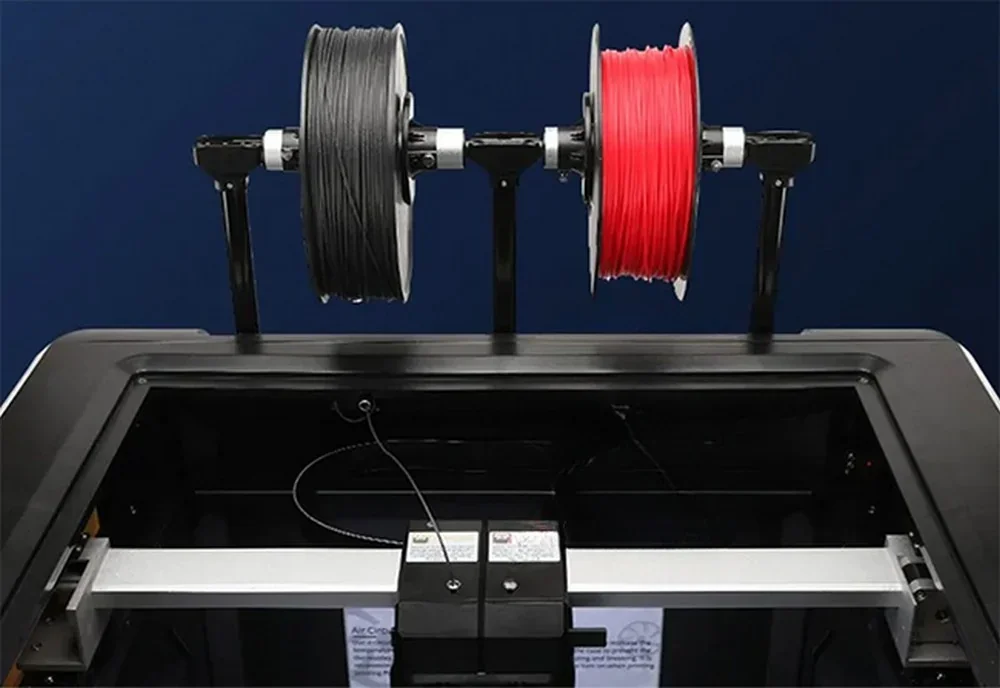

The i-Fast is equipped with three rear retractable spool holders and sealed dry boxes featuring desiccant and roller bearings for moisture-sensitive filaments.

Filament feeds through PTFE tubes (4 mm OD / 2 mm ID) to runout sensors at each extruder input, which pause prints if filament breaks or runs out.

For non-hygroscopic materials like PLA, filament can feed directly through top cover notches without the PTFE tubes.

The dry box setup adds ~12 inches (300 mm) of rear depth but can be repositioned using longer tubes, preventing moisture absorption when printing with nylon, polycarbonate, or PVA.

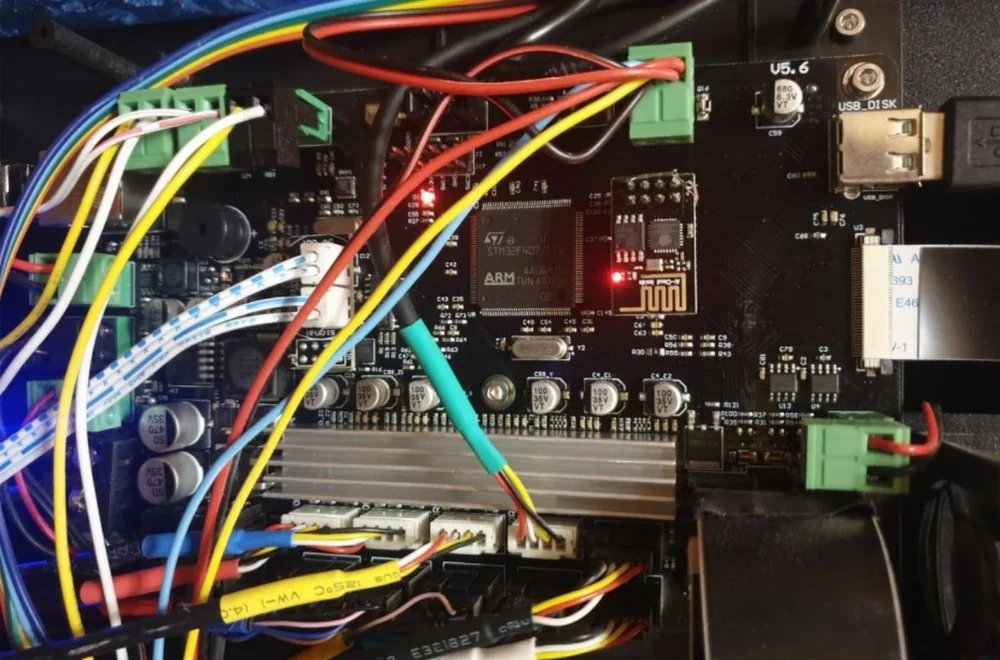

The QIDI i-Fast uses a mainboard with an STM32F407 ARM microcontroller (168 MHz) and silent stepper drivers for low-noise operation. It runs firmware version 3.28 with BluePlus 1.8 UI, though versioning may vary.

The QIDI i-Fast uses two built-in power supplies — "MAIN POWER" and "HOT BED POWER" — in its base, with a total rating of 700W. It supports 115V (for USA/Canada/Japan) or 230V (for Europe) operation via manual voltage selectors underneath the printer. A main power switch and cord port sit at the lower rear.

The dual PSU setup splits load between the heated bed and other systems to prevent voltage drops during heavy use. The manual warns that using the wrong voltage can damage the electronics.

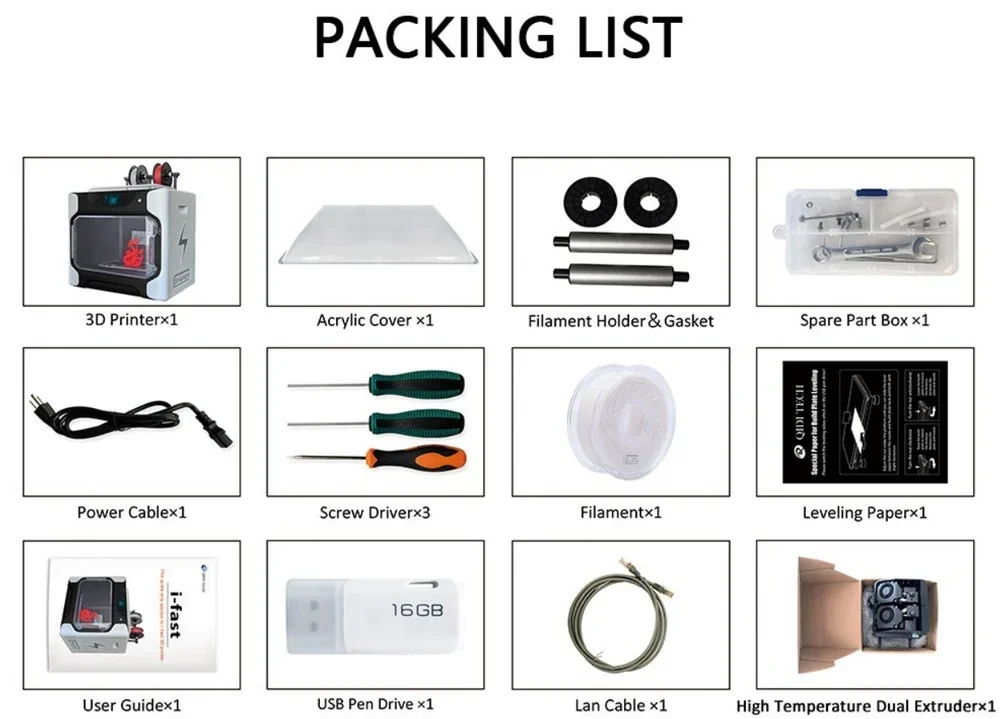

What's Included in the Box:

Power & Connectivity

3D Printing Materials & Components

Build Platform & Accessories

Tools & Hardware

Documentation & Main Unit

The QIDI Tech i-Fast arrives fully assembled with the standard dual extruder pre-installed and a high-temperature extruder included for broad material compatibility. The package also provides maintenance tools, a starter PLA spool, a 16GB USB drive with software and documentation, and a quick start guide for setup and calibration.

Note: Package contents may change without notice. Contact a Top3DShop representative to confirm current inclusions before ordering.

QIDI Tech offers 10+ accessories and upgrades for the i-Fast to improve functionality, durability, and material compatibility.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| QIDI filament dryer box | Removes moisture from hygroscopic filaments during storage/printing | Users printing nylon, PETG, PVA, etc. | $45+ |

| Normal Hotend | Prints standard materials (PLA, ABS, PETG) up to 300°C | Hobbyists and professionals | $55+ |

| High-temp Hotend | Handles engineering materials like nylon, PC, and composites up to 350°C | Advanced users | $65+ |

| Brass Nozzle For Normal-Temp Extruder | Standard brass nozzle for non-abrasive materials | Hobbyists and general users | $10+ |

| High-temp nozzle for all-metal extruder/high-temp extruder | Hardened steel nozzle for high-temp and abrasive filaments | Advanced users | $10+ |

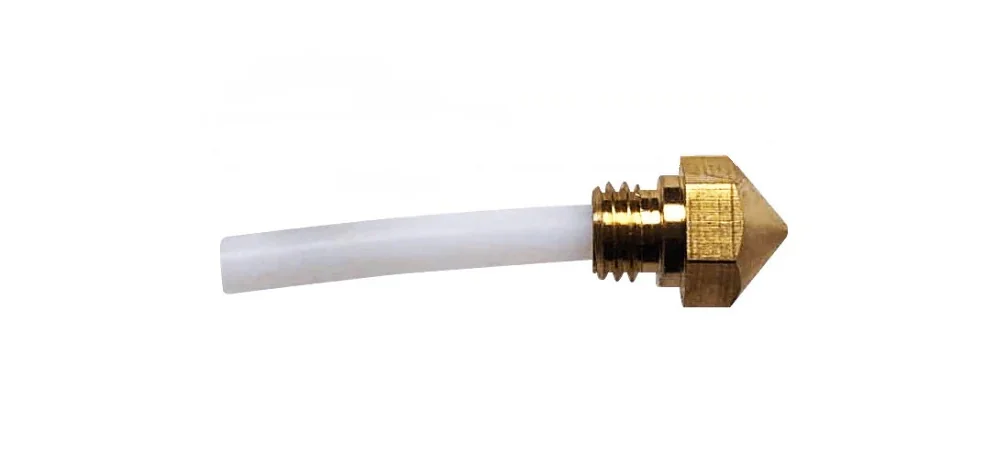

| Ordinary Nozzle and PTFE tube (1pcs) | Standard brass nozzle with PTFE liner for routine replacement | All users | $10+ |

| HF Plate | Textured PEI build plate for strong adhesion and easy part removal | Users seeking reliable adhesion | $55+ |

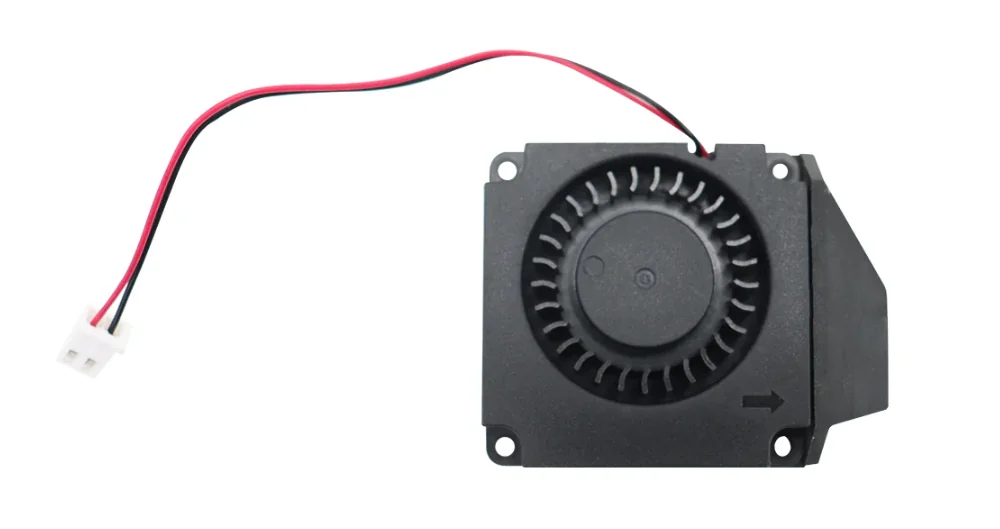

| Turbo Fan | Centrifugal blower for improved cooling and detail quality | Users optimizing print quality | $15+ |

| Filament Run Out Sensor | Detects filament depletion and pauses printing | All users needing print reliability | $25+ |

| Power-off Module | Restores print progress after power failure | Users in unstable power regions | $20+ |

The QIDI Filament Dryer Box is a sealed container that keeps filament dry during storage and printing. Made from PP, ABS, and VMQ materials, it forms an airtight chamber with a desiccant pack that maintains low humidity for up to 30 days. It fits filament spools up to 210 mm in diameter and 85.5 mm high, compatible with 1 kg spools from brands like SUNLU, GEEETECH, ERYONE, ESUN, and Amazon Basics. The design prevents moisture absorption in hygroscopic filaments such as PA12-CF, UltraPA, ABS, and PETG, improving print quality by reducing stringing, clogs, and adhesion issues. Compatible with QIDI X-PLUS, X-MAX, X-CF Pro, i-Fast, X-SMART3, X-PLUS3, and X-MAX3 printers, the kit includes two retaining rings, a 500 mm PTFE tube, and one desiccant pack.

The Normal Hotend is a 300°C replacement assembly for the QIDI i-Fast dual extruder printer (330×250×320 mm build volume). Available in left and right versions, it fits the printer’s independent dual extruder system. The hotend includes a 0.4 mm brass nozzle, thermistor, heating element, and wiring harness, supporting materials like PLA, ABS, PETG, TPU, and nylon. It integrates with the i-Fast’s automatic system for independent vertical adjustment of each extruder.

The High-temp Hotend is a 350°C replacement assembly for the QIDI i-Fast dual extruder printer, built for engineering-grade materials. It prints high-performance polymers like polycarbonate, carbon fiber nylon, and other advanced thermoplastics. Available in left and right versions, it fits the printer’s 330×250×320 mm build volume and dual extruder system. The hotend includes a reinforced heater, high-temp thermistor, and wiring harness, working with the i-Fast’s 60°C heated chamber to minimize warping during high-temperature printing.

The Brass Nozzle for Normal-Temp Extruder is an MK10 M7 brass replacement nozzle for QIDI i-Fast (single gear), X-Max, X-Plus, and i-Mates printers using 1.75 mm filament. Available in 0.2, 0.4, 0.6, and 0.8 mm sizes, it offers strong heat conductivity and supports PLA, ABS, PETG, and TPU at up to 300°C. The M7 threading fits older i-Fast single gear extruders, differing from the newer dual gear M6 design.

The High-temp Nozzle for All-Metal/High-Temp Extruders is a hardened steel replacement nozzle for QIDI printers operating up to 350°C. Available in 0.2, 0.4, 0.6, and 0.8 mm sizes, it offers excellent wear resistance and thermal stability for abrasive, high-performance materials. It handles carbon fiber and glass fiber composites, polycarbonate, and polyamide — materials that quickly degrade brass nozzles — making it ideal for QIDI all-metal extruder setups.

The Ordinary Nozzle and PTFE Tube kit is a brass MK8 M6 replacement nozzle for QIDI i-Fast and X-CF Pro printers using 1.75 mm filament. Available in 0.2, 0.4, 0.6, and 0.8 mm sizes, the brass nozzle offers excellent heat conduction and supports materials like PLA, ABS, TPU, and PETG. The included PTFE tube (2 mm inner diameter) handles high-temperature printing and fits both the X-CF Pro ordinary extruder and i-Fast dual gear setup.

The HF Plate is a 360×250 mm PEI-coated steel build surface for the QIDI i-Fast printer. Its textured PEI layer, applied by powder coating or film bonding, improves first-layer adhesion without additional adhesives and transfers texture to printed parts. The plate supports materials like PLA, ABS, PETG, PC, nylon, carbon fiber composites, and TPU, withstanding bed temperatures up to 120°C. Designed for the i-Fast’s single extruder setup, its steel base allows magnetic attachment to the heated bed.

The Turbo Fan is a 24V DC centrifugal blower for the QIDI i-Fast printer, providing targeted cooling during printing. Its high static pressure airflow improves surface finish and accuracy by rapidly solidifying extruded material. The fan enhances print quality for PLA, PETG, and TPU, reducing defects in overhangs and fine details. Mounted on the extruder housing, it directs airflow toward the nozzle and newly printed layers, connecting to the control board via a cable.

The Filament Run-Out Sensor monitors filament flow in QIDI i-Fast printers and pauses printing when filament runs out. Using a mechanical switch, it detects the absence of 1.75 mm filament, preventing failed prints. When triggered, it pauses the job while maintaining position and temperature, allowing filament replacement and print resumption. The sensor connects to the control board and installs between the spool and extruder, supporting independent monitoring for both extruders in dual-extrusion setups.

The Power-off Module is a power failure recovery unit for QIDI X-series and i-Fast printers. Available in 115V and 230V versions, it detects power loss, saves print data such as position and layer height, and resumes printing from the last point after power restoration. This prevents wasted material and time during long prints. The module connects to the printer’s control board and integrates with its firmware recovery system.

The QIDI i-Fast requires 4+ maintenance tasks to ensure print quality and printer longevity.

Monthly Maintenance:

Quarterly Maintenance:

The QIDI Tech i-Fast a 1-year warranty. The warranty covers manufacturing defects and non-customer-induced damage.

QIDI provides model-specific email support at Afast@qd3dprinter.com and Bfast@qd3dprinter.com. Technicians first troubleshoot via email. If issues persist, QIDI supplies free replacement parts or, for major defects, decides between a refund or replacement.

Warranty claims require proof of purchase. A 1-year warranty extension is available for $250, extending coverage to up to three years.

I-Fast Support Guides: https://wiki.qidi3d.com/en/I-Fast

Full Warranty Terms: https://qidi3d.com/pages/warranty-policy-after-sales-support

I-Fast 1-Year Warranty Extension: https://qidi3d.com/products/1-year-warranty-for-i-fast

The QIDI Tech i-Fast, priced at $1,899.00, offers exceptional value as a professional dual-extruder 3D printer with industrial-grade features, including a fully enclosed heated chamber, linear guide system, and support for high-performance materials. It includes both standard and high-temperature extruders for full material compatibility.

Update your browser to view this website correctly. Update my browser now