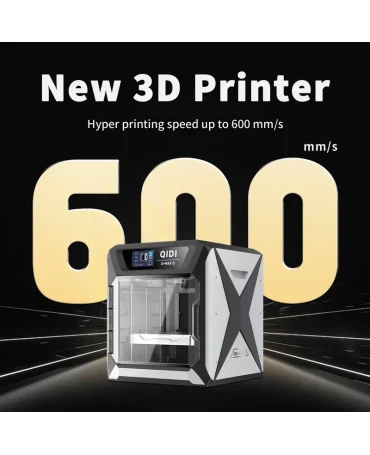

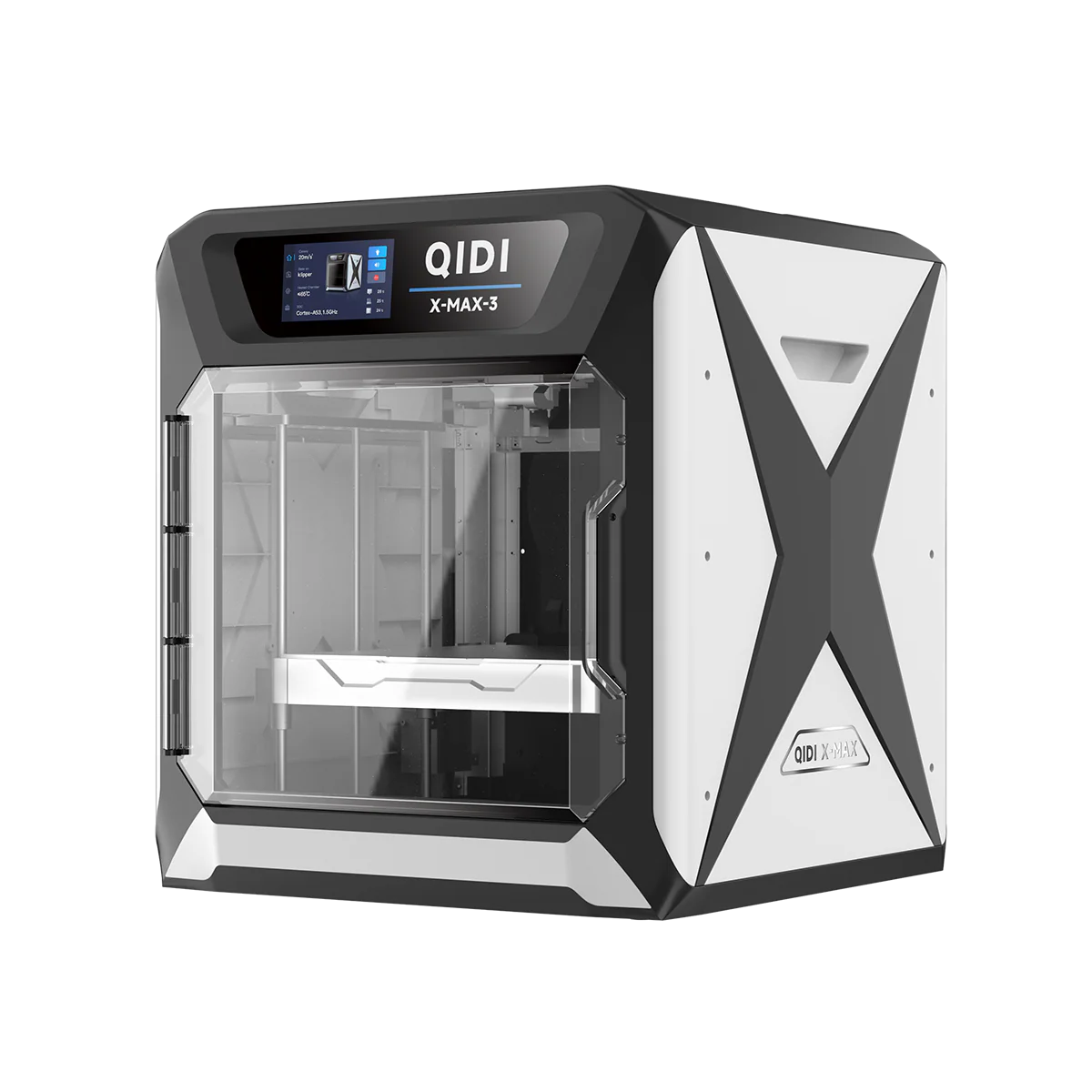

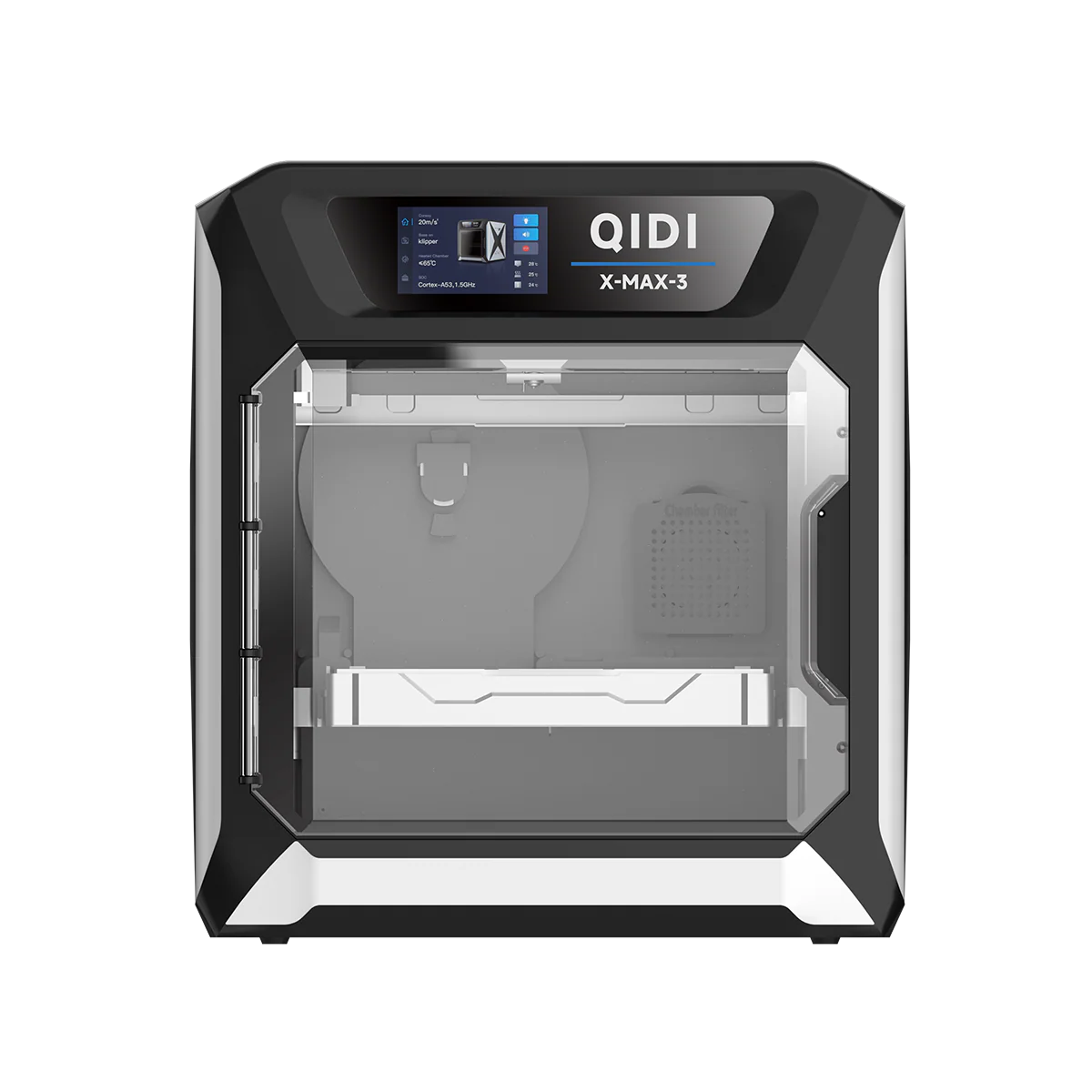

The QIDI Tech X-Max 3 is a large-format CoreXY 3D printer with a 325 x 325 x 315 mm enclosed build area. Running Klipper firmware, it reaches 250 mm/s with high precision via a 32-bit controller and stable sheet metal frame. It includes a 300W heated chamber (up to 65°C) for warp-free 3D printing with ABS, ASA, and carbon fiber materials, and comes with two hotends: copper-plated for standard filaments and hardened steel for abrasives like PA-CF and PET-CF. A 6 mm aluminum plate with dual-sided PEI and embedded magnets heats to 120°C for reliable adhesion.

Designed for professional use, the X-Max 3 suits small businesses and makers alike. It features a 5-inch touchscreen, QIDI Slicer (based on Prusa Slicer), and ready-made material profiles for ease of use. A BLTouch handles auto bed leveling, and the dual-gear direct drive extruder supports both flexible and rigid filaments. Dual 24V 450W power supplies ensure consistent, reliable performance for prototyping and small-scale production.

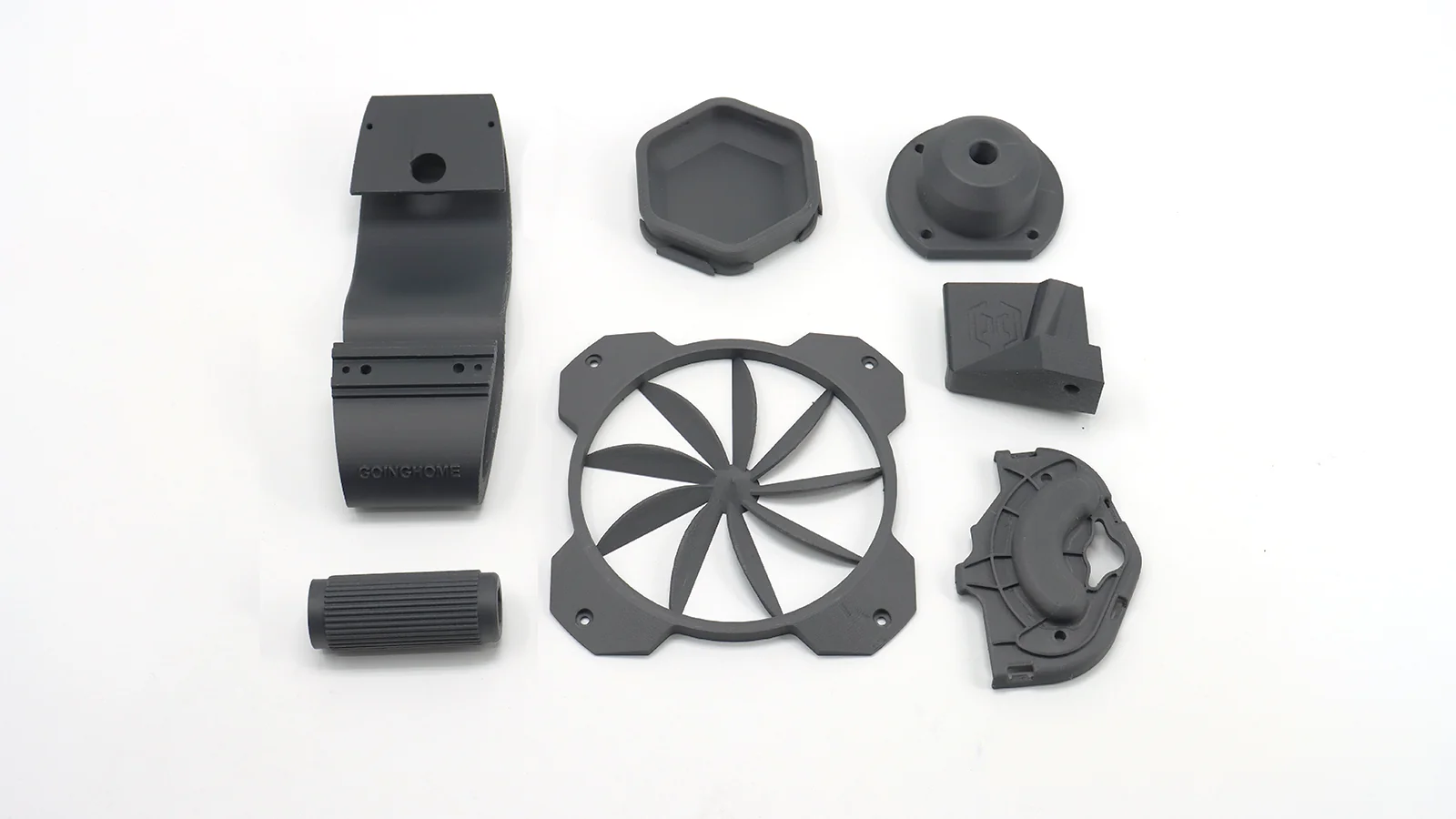

The QIDI X-Max 3 offers ±0.1 mm accuracy, 0.05–0.4 mm layers, and print speeds up to 250 mm/s. It delivers clean PLA prints, precise TPU at 40 mm/s, and warp-free ABS, supported by its CoreXY system, Klipper tuning (resonance compensation, pressure advance), 8×8 BLTouch leveling, and 65°C chamber. The X-Max 3’s performance is shown with a 3D Benchy printed in QIDI Rapido PLA at 0.2 mm layers and 250 mm/s. The model displayed clean overhangs, minimal artifacts, and consistent detail, proving the printer’s accuracy and reliability at high speeds.

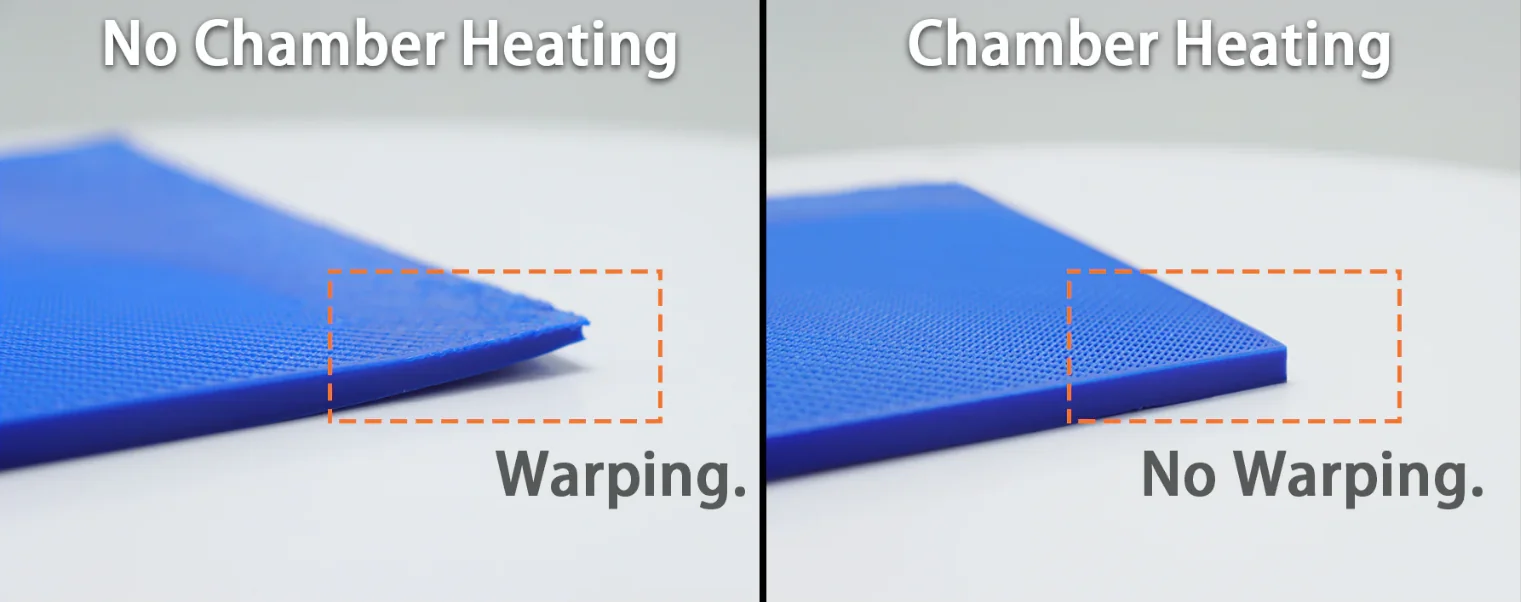

When printing high-temp materials, the 65°C heated chamber prevents warping, as seen in ABS prints with strong adhesion and stability. Without heating, edges warp noticeably, while chamber-heated prints stay flat and structurally sound.

The QIDI X-Max 3 handles flexible materials well, shown by a TPU95A-HF wallet printed at 40 mm/s. Despite challenges like stringing and deformation, the print achieved accurate dimensions, strong adhesion, and sharp details. This demonstrates Klipper’s pressure advance and the CoreXY system’s ability to maintain precision with soft filaments.

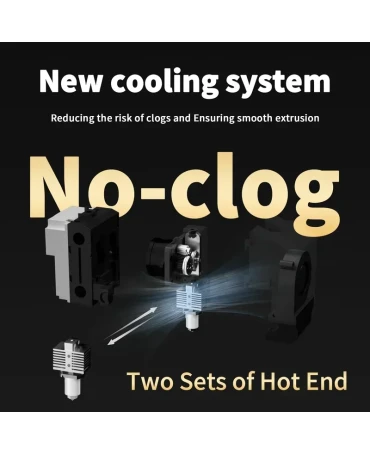

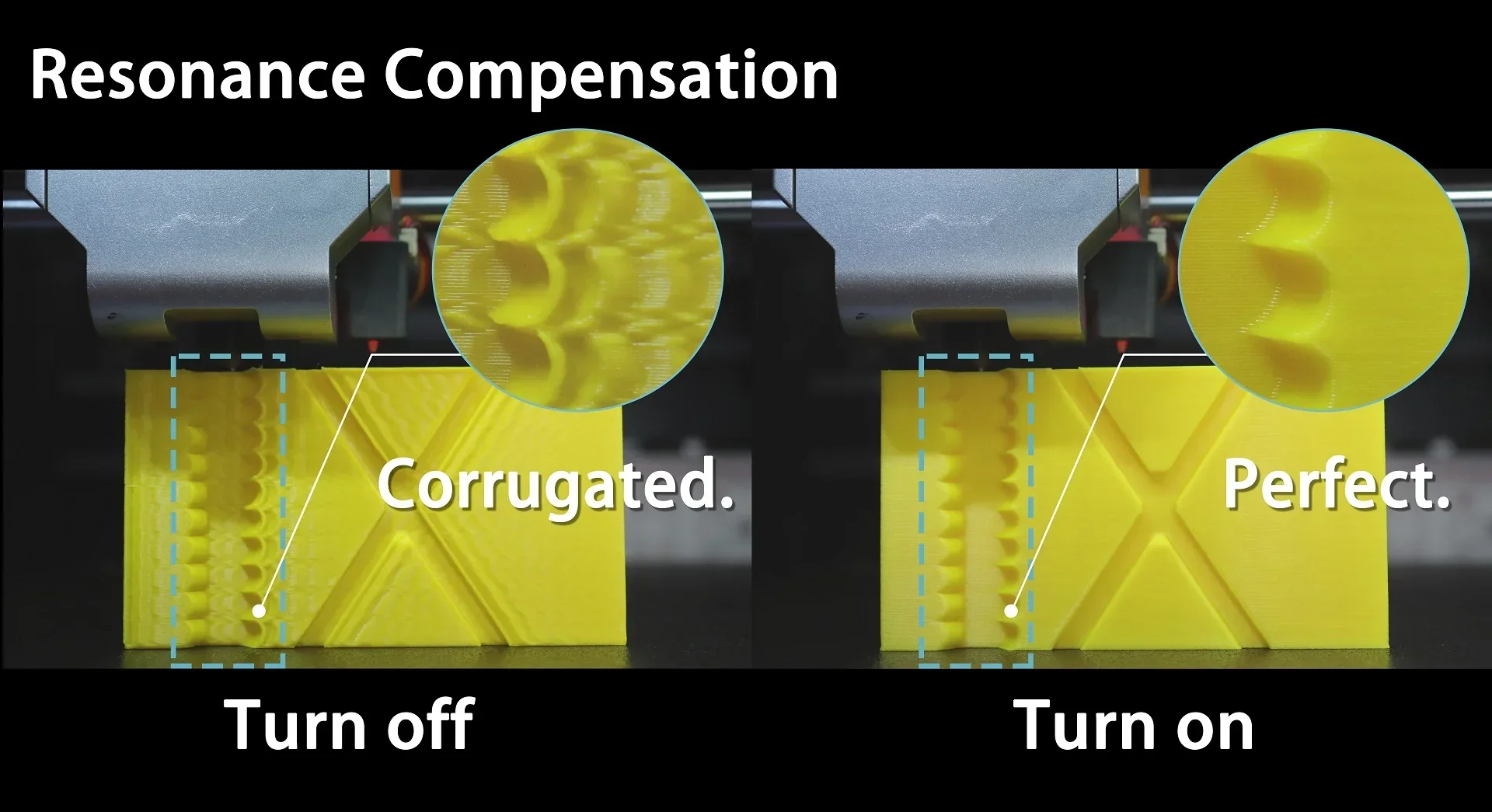

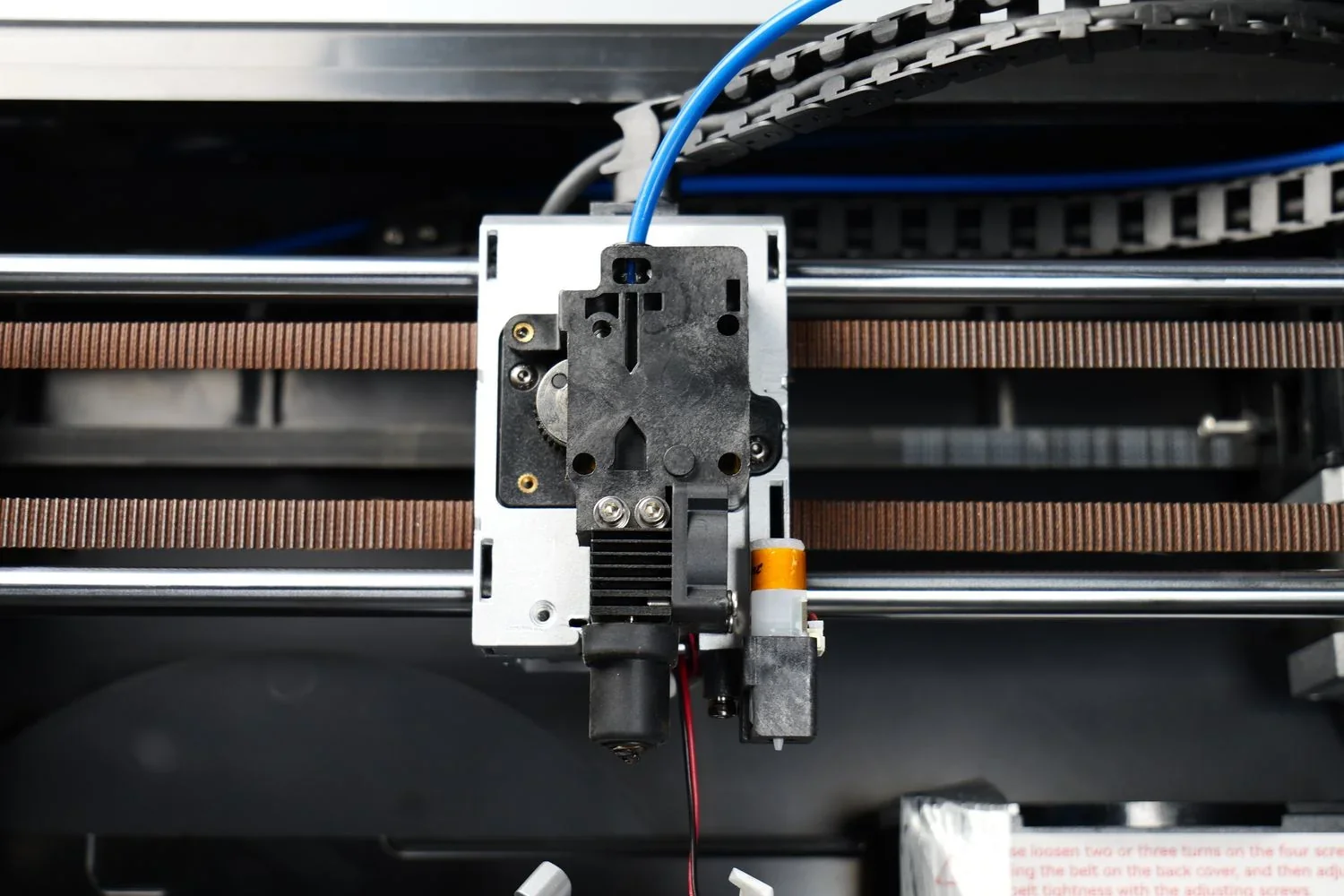

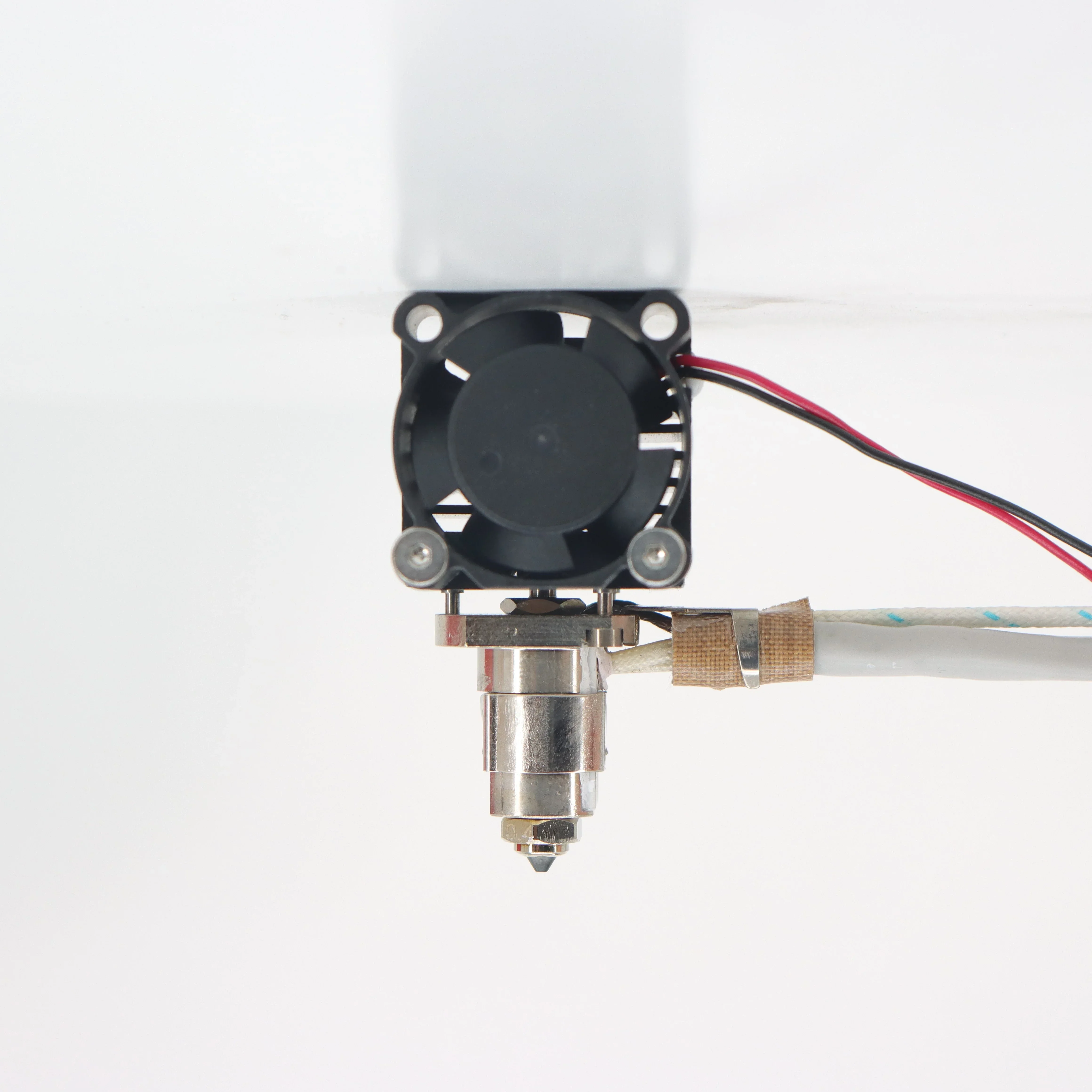

The QIDI X-Max 3’s dual cooling system uses a 5015 fan for part cooling and an auxiliary fan for chamber airflow, supporting high-speed printing. Its high-flow hotend handles 35 mm³/s extrusion, with a ceramic ring heater heating to 300°C in under 2 minutes for quick material changes. Resonance compensation reduces vibration distortions, ensuring smooth, precise layers at high speeds.

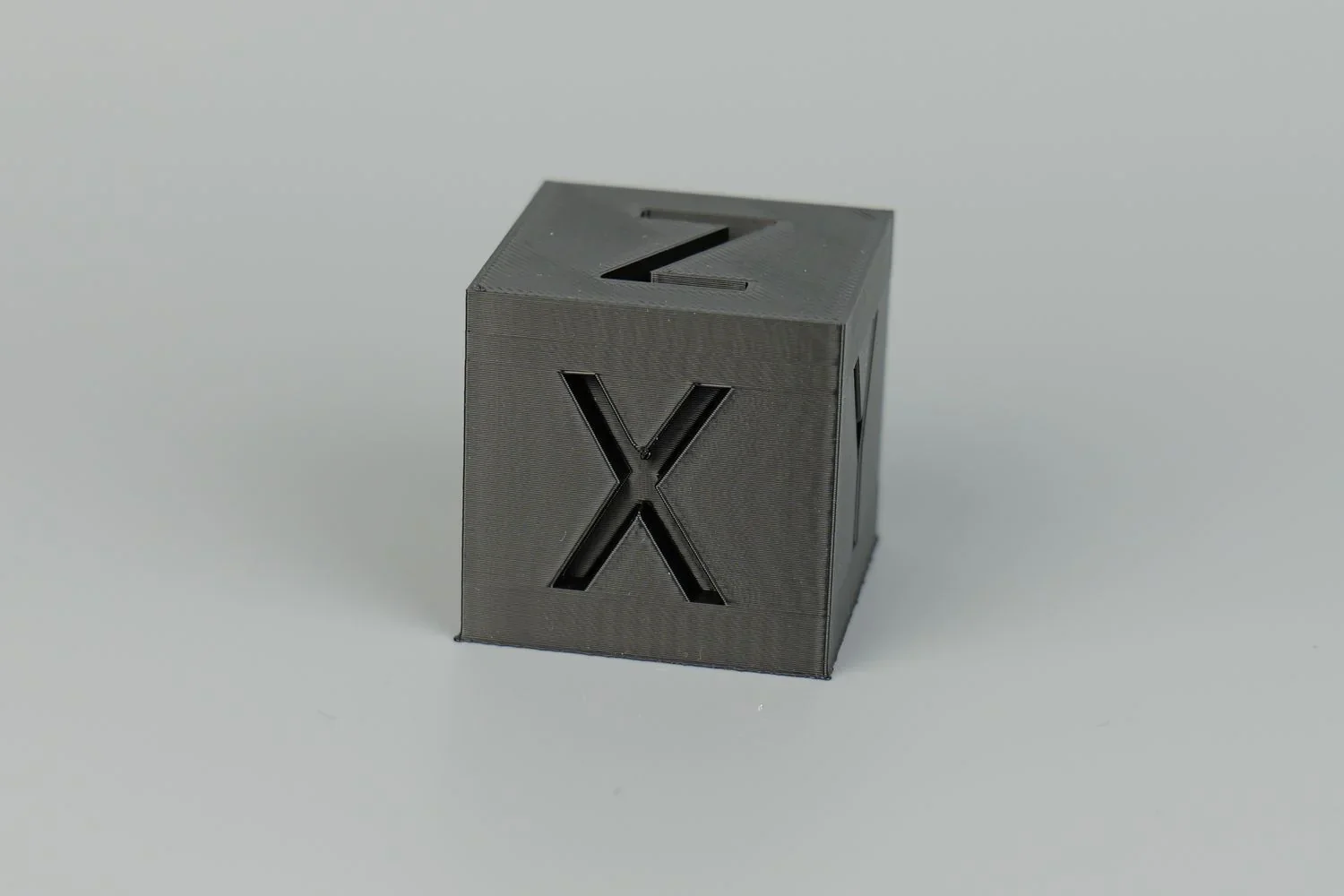

An XYZ Calibration Cube printed at 0.2 mm layers and 250 mm/s showed sharp edges, uniform walls, and cleanly rendered letters without warping or shifts. This confirms the X-Max 3’s precise axis calibration and high geometric accuracy across the build volume, making it suitable for applications requiring tight tolerances.

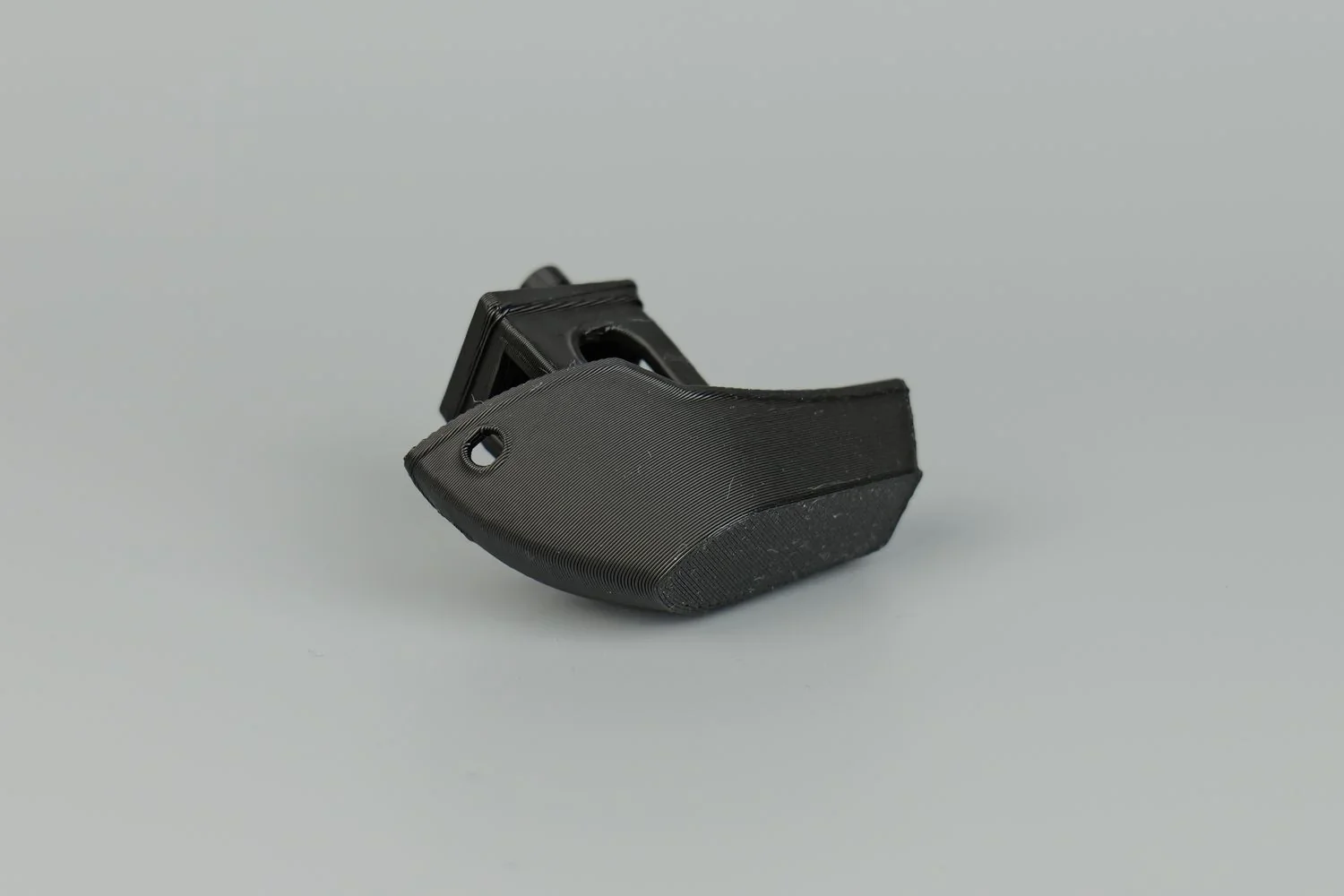

The QIDI X Max 3’s sheet metal frame and dual Z-axis deliver excellent print accuracy and finish. In the 5-hour “Torture Toaster” test, it produced working parts with tolerances down to 0.3 mm. Smooth gear movement and precise sliding fits highlight its dimensional accuracy and mechanical reliability.

Large-format prints, like a full-size Flexi Fox in PETG, showed consistent wall quality over 10 hours. The 9.5:1 direct drive extruder provided precise filament control, delivering clean surfaces and minimal stringing, even with flexible materials.

The QIDI X-Max 3 large-format 3D printer handles PLA, ABS, ASA, PETG, TPU, and high performance materials such as Nylon, PC, and carbon fiber composites with dual 350°C hotends (one hardened steel), a 120°C bed, 65°C chamber, and a 9.5:1 direct drive extruder for reliable printing of standard, flexible, and abrasive materials.

PETG Print Sample: A full-size Flexi Fox was printed at 0.16 mm layers, 250°C nozzle, 80°C bed, and 250 mm/s speed. The 10-hour print showed strong adhesion and structural integrity throughout.

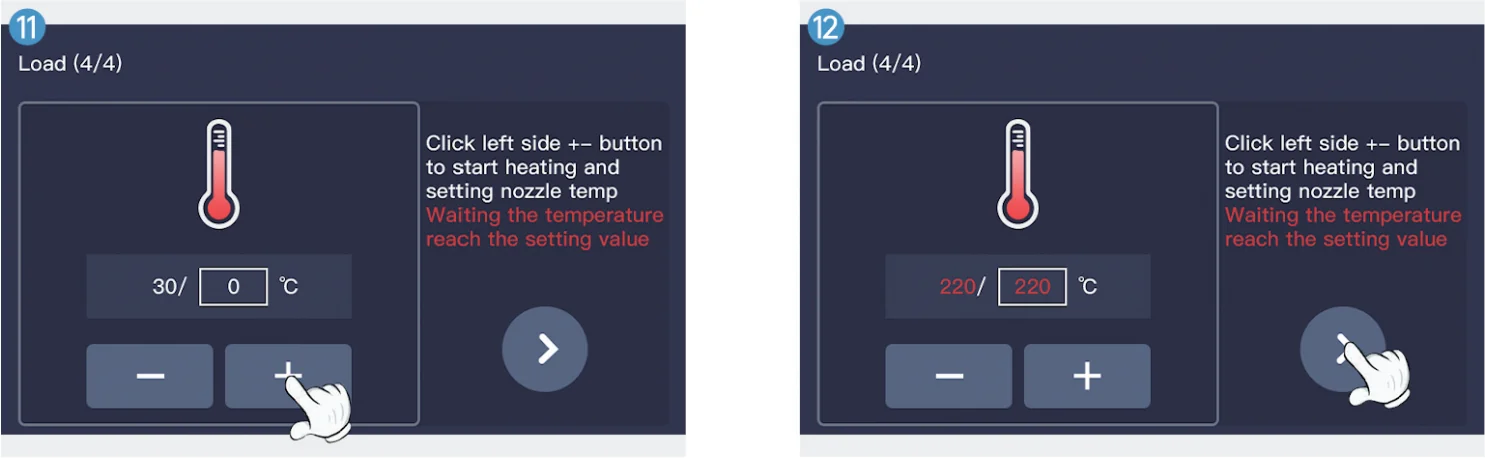

PLA Print Sample: The Phil-A-Ment model printed at 0.2 mm layers, 220°C nozzle, 60°C bed, and 250 mm/s showed excellent surface detail, with only minor flaws under the gloves.

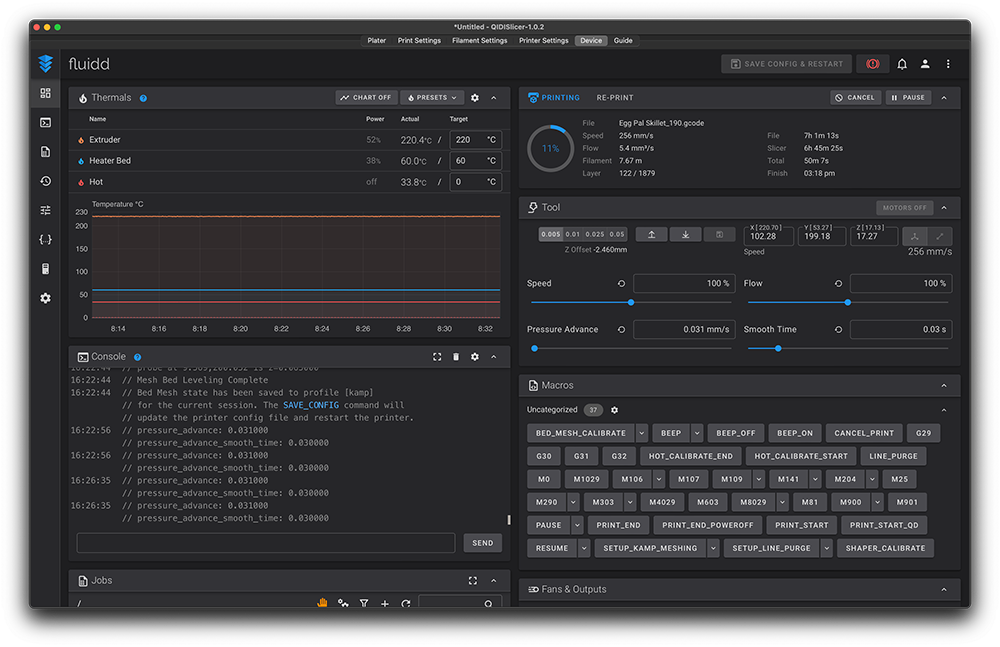

PLA Print Sample: The Egg Pal model, printed in multiple PLA colors at 0.16 mm layers, 220°C nozzle, 60°C bed, and 250 mm/s, was scaled to frying pan size with accurate dimensions and strong layer bonding.

ABS Print Sample: The Pirate and His Rat model printed at 0.16 mm layers, 250°C nozzle, 100°C bed, and 250 mm/s (without chamber heating) showed high surface quality and fine detail throughout.

ASA Print Sample: The Rugged Box printed at 0.2 mm layers, 260°C nozzle, 100°C bed, and 55°C chamber (using an ABS profile) showed strong layer adhesion and minimal warping across the full build volume.

The X-Max 3’s dual hotends boost material compatibility: a copper-plated nozzle for standard filaments and a hardened steel nozzle for abrasives. Both reach 350°C, allowing high-temp engineering plastics.

The 9.5:1 direct drive extruder ensures precise control of both rigid and flexible filaments.

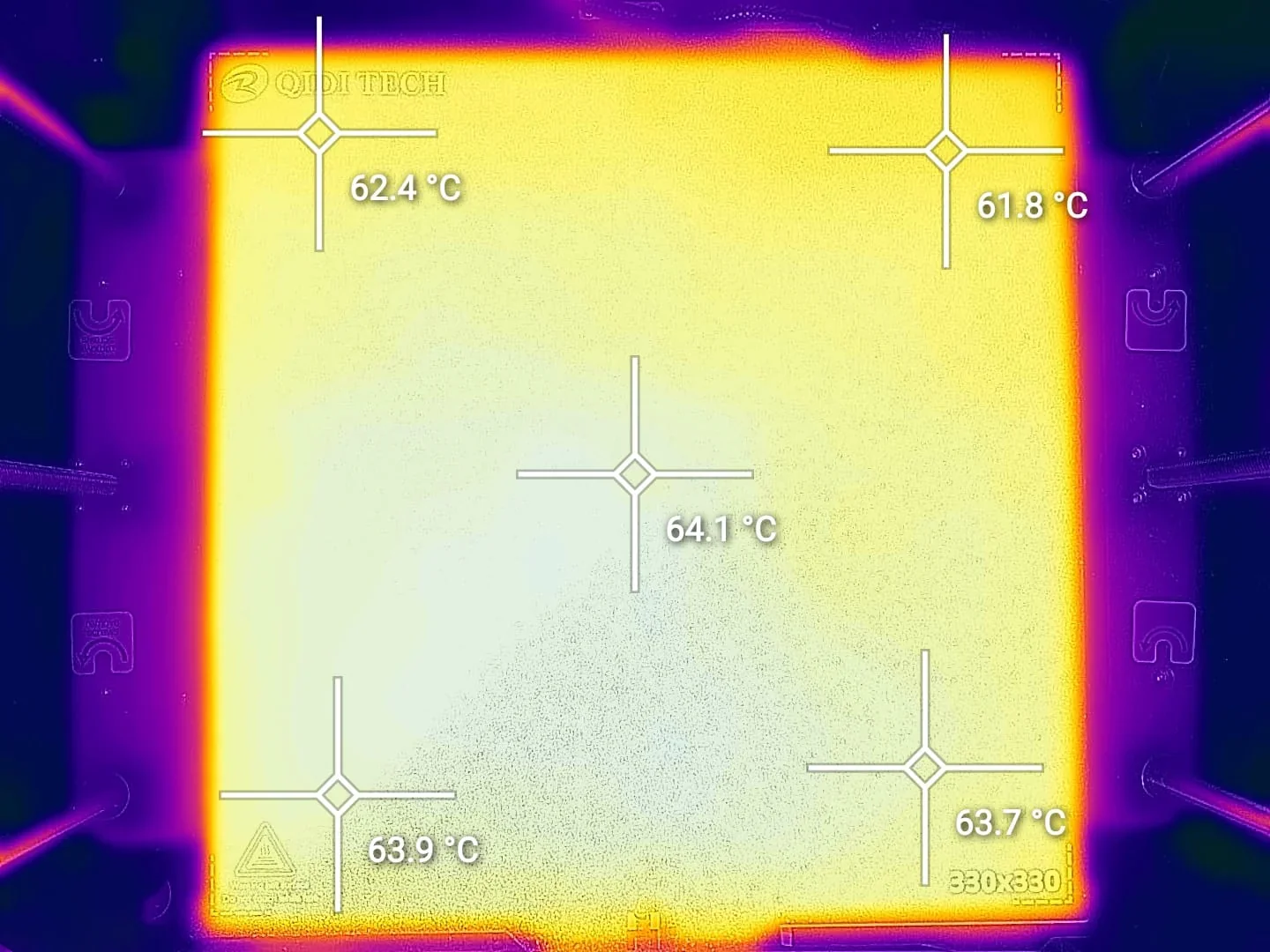

The 6 mm aluminum heatbed heats to 120°C, paired with a 300W chamber heater that maintains 65°C for warp-prone materials like ABS, PC, and Nylon. A thermal image shows less than 2.3°C variation across the bed, ensuring consistent adhesion, accuracy, and reliable prints.

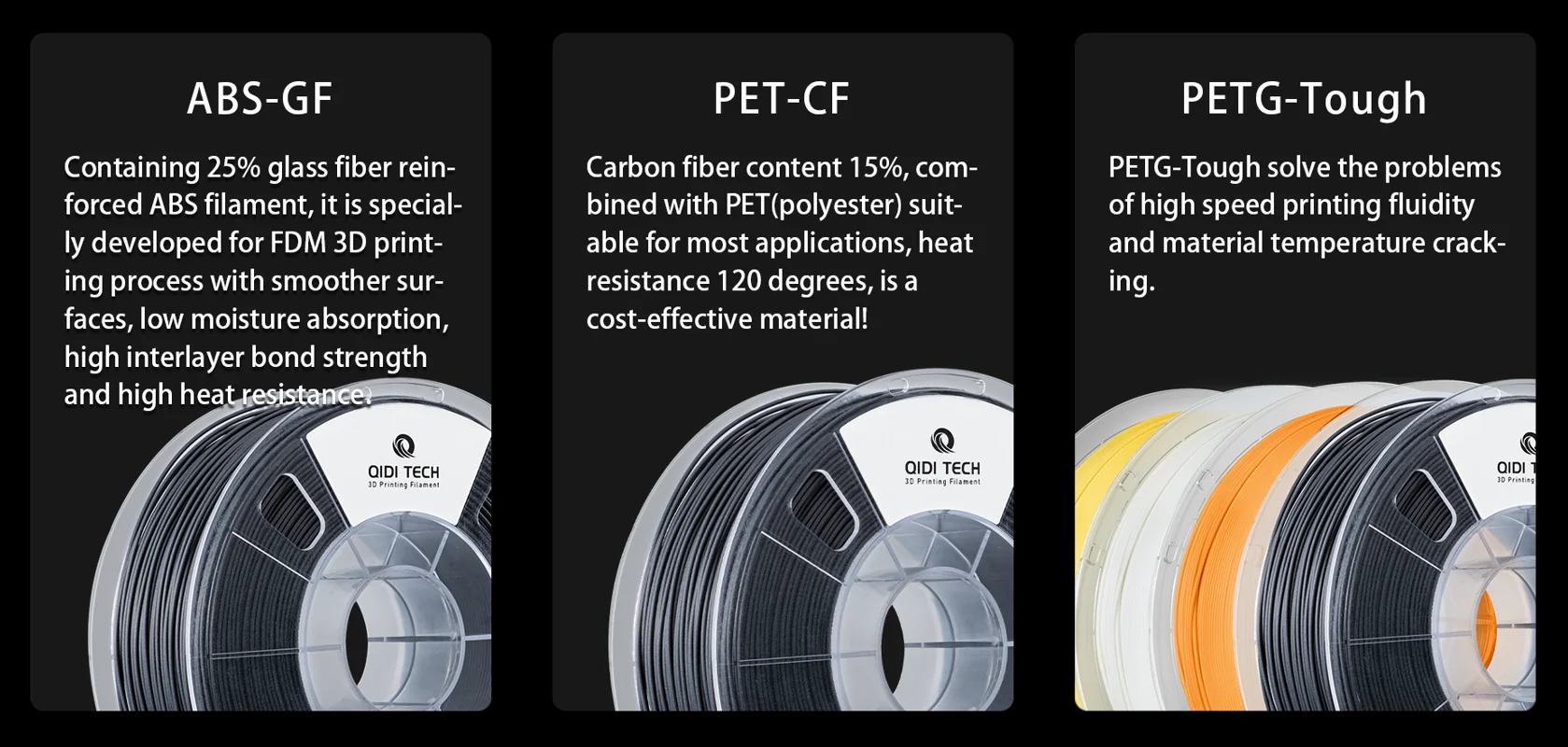

The X-Max 3 is an open-material system using 1.75 mm filament from any brand. QIDI provides optimized options like PLA Rapido, ABS Rapido, and PAHT-CF, but users can also print third-party materials, including composites such as ABS-GF, PET-CF, and PETG-Tough.

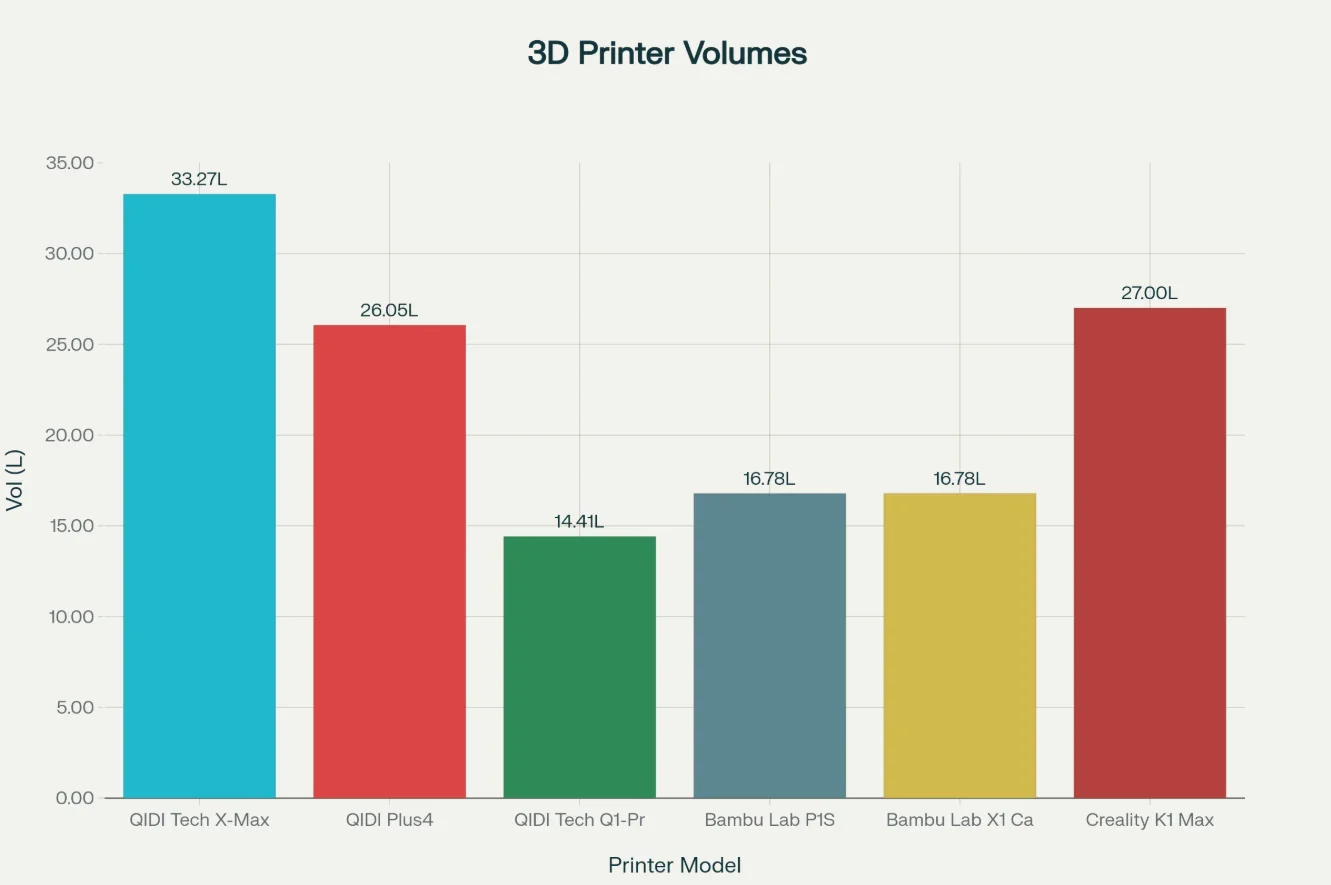

The X-Max 3 offers a 325 × 325 × 315 mm build volume (33.3L), larger than most desktop printers. Its enclosed design maintains chamber temperature while accommodating oversized parts or multiple prints at once.

In the $699+ range, the QIDI X-Max 3D printer competes with 2 FDM 3D printers: the Bambu Lab P1S and Creality K1 Max. It has the largest print size (33.27L vs. 27L and 16.78L), a 65°C heated chamber and a removable dry box, ideal for technical filaments. The P1S and K1 Max rely only on bed heat, limiting chamber temps. Unlike them, the QIDI X Max 3 lacks a camera and LiDAR. While less polished in design and software, it delivers strong hardware and capacity at its price. The X-Max 3 suits users prioritizing large build area and chamber heat, while the P1S and K1 Max excel in ease of use and smart features at higher cost.

| 3D Printer Model | Build Volume (mm) | Build Volume (liters) | Price (USD) |

|---|---|---|---|

| QIDI Tech X-Max 3 | 325 x 325 x 315 | 33.27 | $699+ |

| QIDI Plus4 | 305 x 305 x 280 | 26.05 | $799+ |

| QIDI Tech Q1-Pro | 245 x 245 x 240 | 14.41 | $449+ |

| Bambu Lab P1S | 256 x 256 x 256 | 16.78 | $549+ |

| Bambu Lab X1 Carbon | 256 x 256 x 256 | 16.78 | $1249+ |

| Creality K1 Max | 300 x 300 x 300 | 27.00 | $649+ |

The X-Max 3 has use a 7-inch touchscreen, 800 × 480 color touchscreen for direct control, offering the following printer functions:

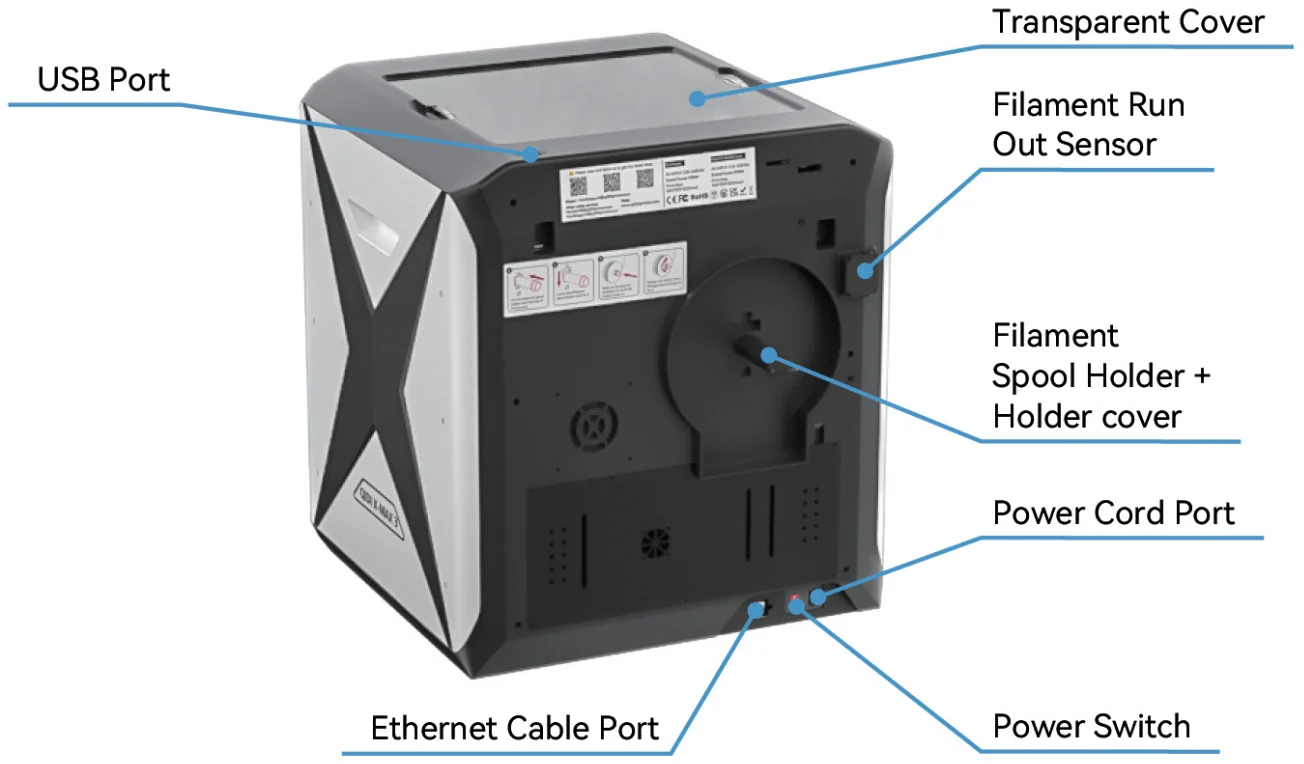

The QIDI Tech X-Max 3 supports USB, Ethernet, and 2.4G Wi-Fi for offline or remote printing through the Fluidd interface, with external USB webcam support but no built-in camera.

On the back panel, the USB port sits above the power switch and the Ethernet port below it. The built-in Wi-Fi has no external antenna and is set up through the printer menu.

A limitation is the lack of a built-in webcam. However, standard USB webcams can be added and configured via Klipper for remote monitoring. Installation guide: https://wiki.qidi3d.com/en/X-Plus3/manual/camera-install

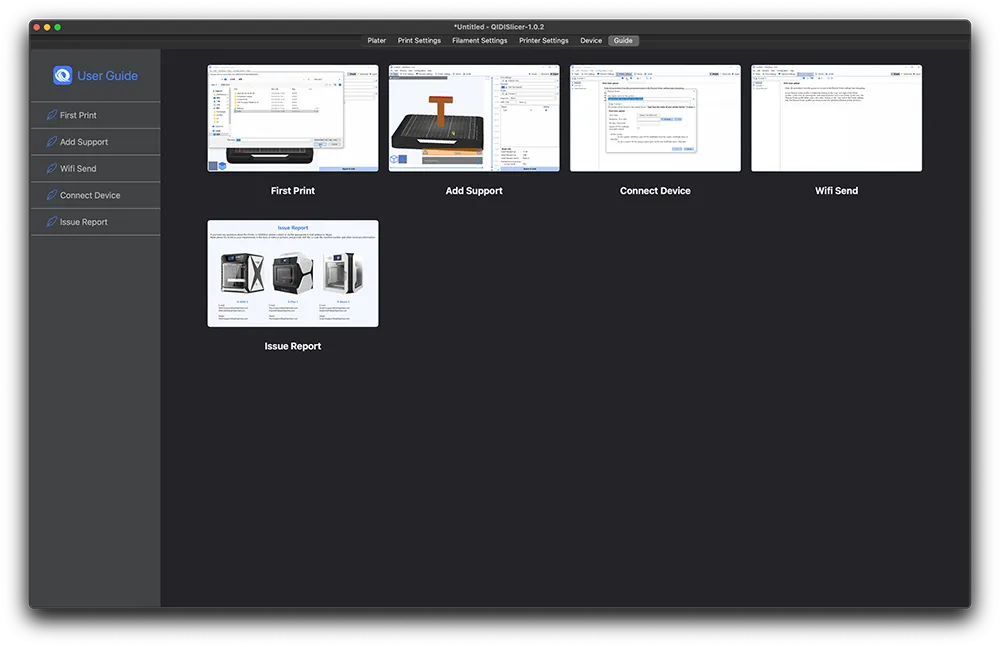

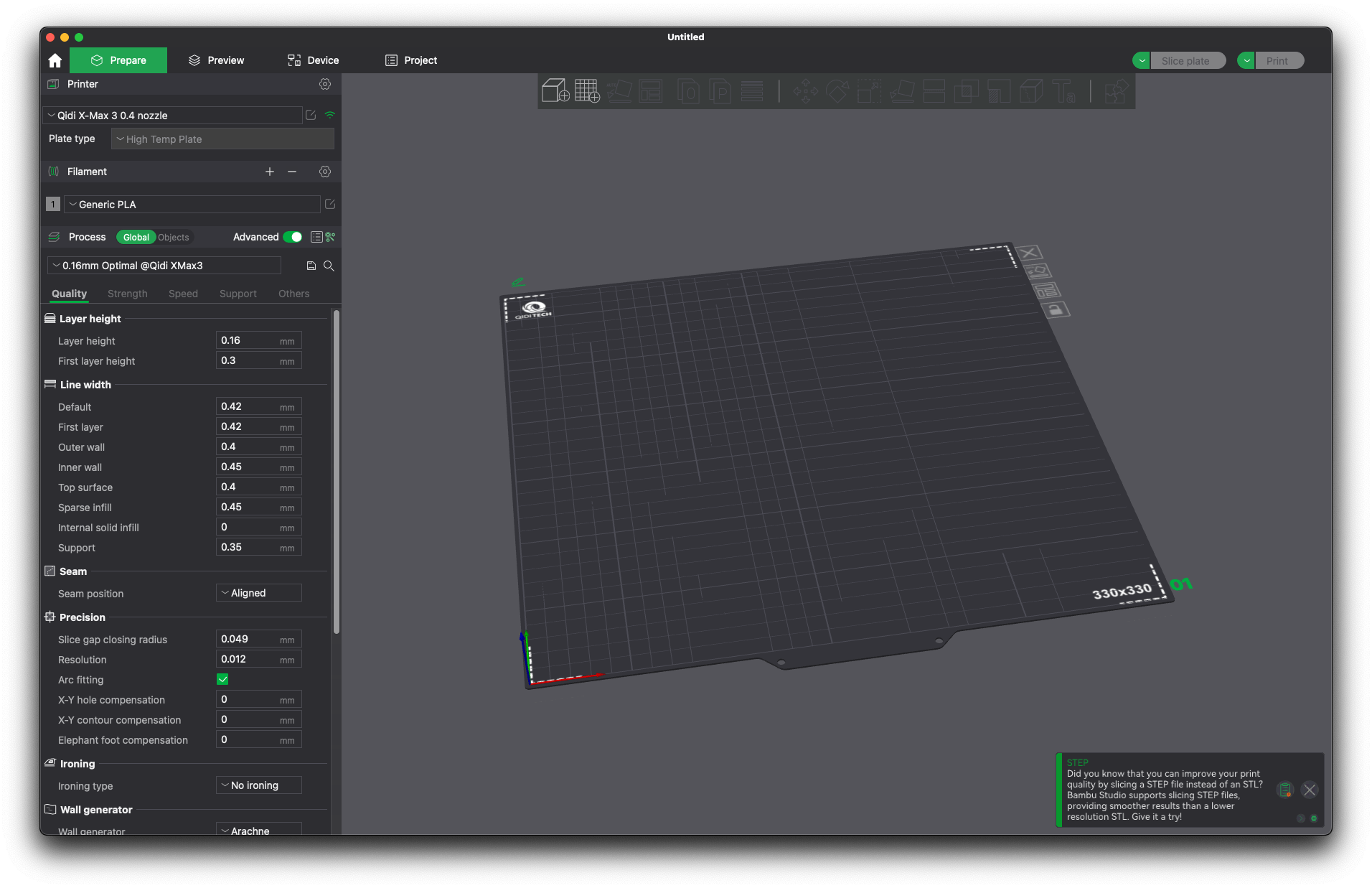

The X-Max 3 includes QIDI Print slicer software, a Prusa Slicer variant with optimized profiles. It adds two extra tabs, including Device, which embeds the Fluidd web interface for direct printer control.

The Guide tab features animated printer operation tutorials.

QIDI Print slicing software allows full control of speed, temperature, and layer settings, with presets for QIDI filaments. The X-Max 3 also works with third-party slicers like Cura, Simplify3D, PrusaSlicer, Bambu Studio, and Orca Slicer, all offering dedicated profiles.

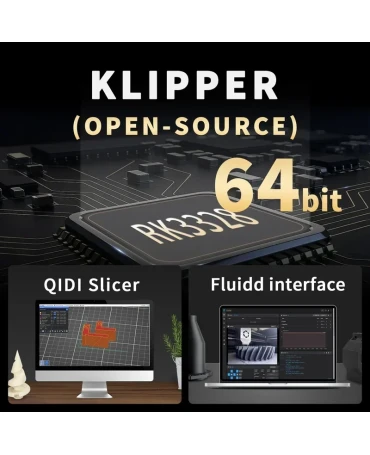

The X-Max 3 runs Klipper with Fluidd, offering features like resonance compensation and pressure advance. It includes KAMP for faster, area-specific bed probing. Firmware runs on an 8GB EMMC with 1GB DDR3 RAM for real-time high-speed control. Users have full access to Klipper via Fluidd, though major version upgrades require QIDI support to ensure compatibility.

For those not using QIDI Slicer, Bambu Studio and Orca Slicer now include a 0.4 mm nozzle profile for the X-Max 3.

Full user manual: https://wiki.qidi3d.com/en/X-Max3/Manual

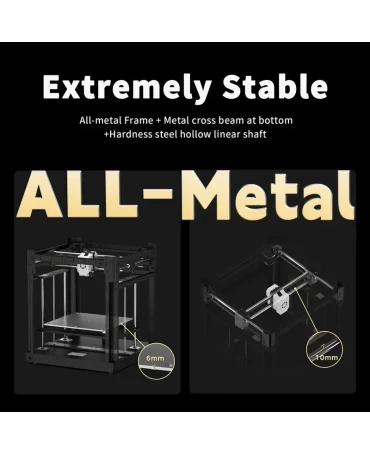

The QIDI X-MAX 3 large 3D printer has a fully enclosed design measuring 553 × 553 × 601 mm (21.77 × 21.77 × 23.66 inches) and 38 kg (83.78 lbs) weight. Its reinforced sheet metal frame and plastic panels form the enclosure, with a clear front door and removable top for monitoring. Reviewers note the plastic sides may rattle and look less premium than glass alternatives.

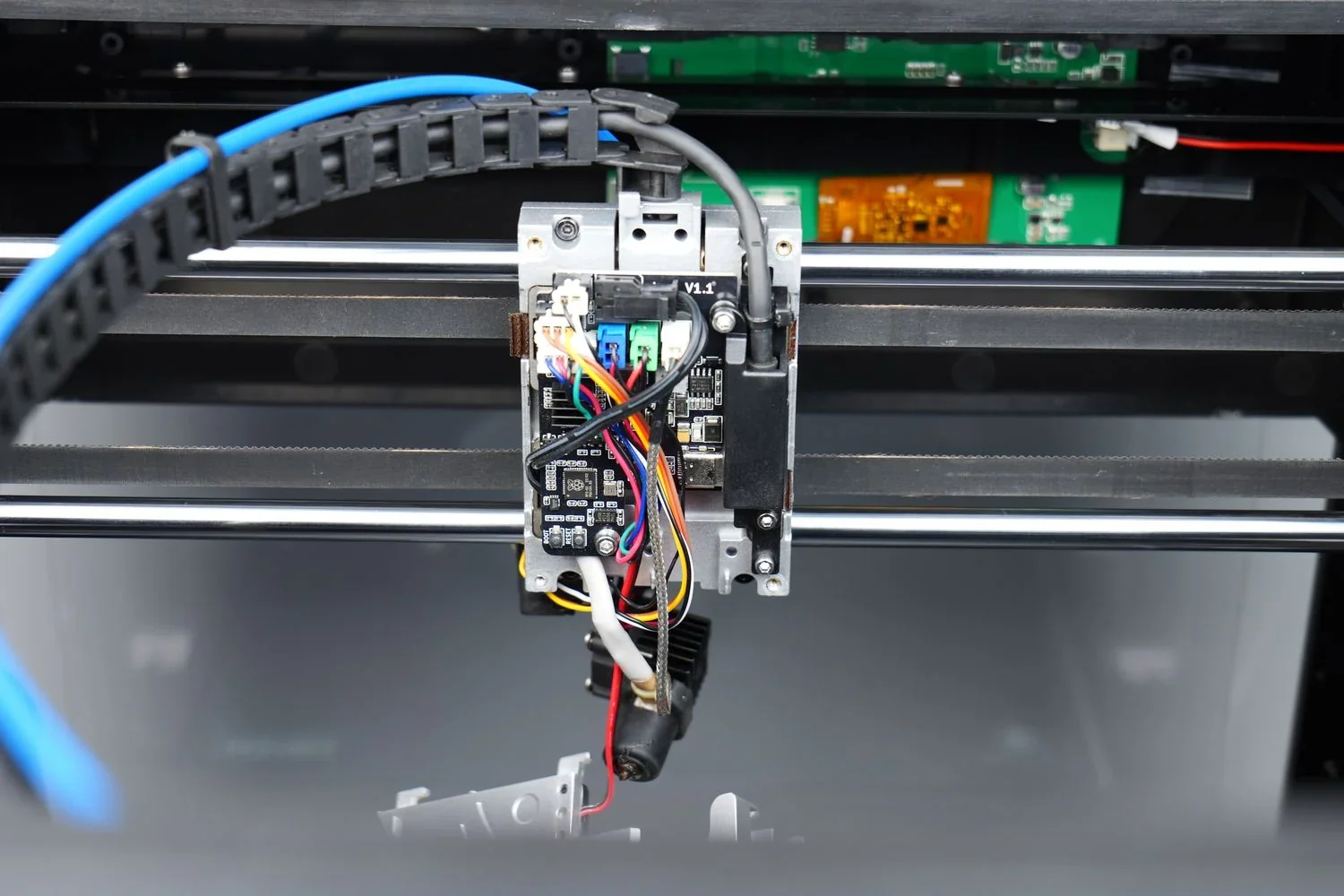

The X-MAX 3 large-size 3D printer uses a CoreXY motion system for reduced inertia and faster speeds. The X-axis runs on 10 mm hollow stainless steel rods with self-lubricating brass bushings (greased by QIDI), while the Y-axis uses 10 mm rods with LMU10UU bearings, adding slight noise. It features 10 mm GATES belts, though the belt path isn’t perfectly straight, which may affect accuracy. TMC2209 drivers keep operation quiet.

The X-MAX 3 is quiet at ~45dB while printing and ~60dB idle (one foot from the rear). Noise varies with setup—XY motors can reach ~70 °C and generate extra heat-related noise when the enclosure is closed.

The 5015 radial fan cools effectively but produces a sharp whine that some users find annoying.

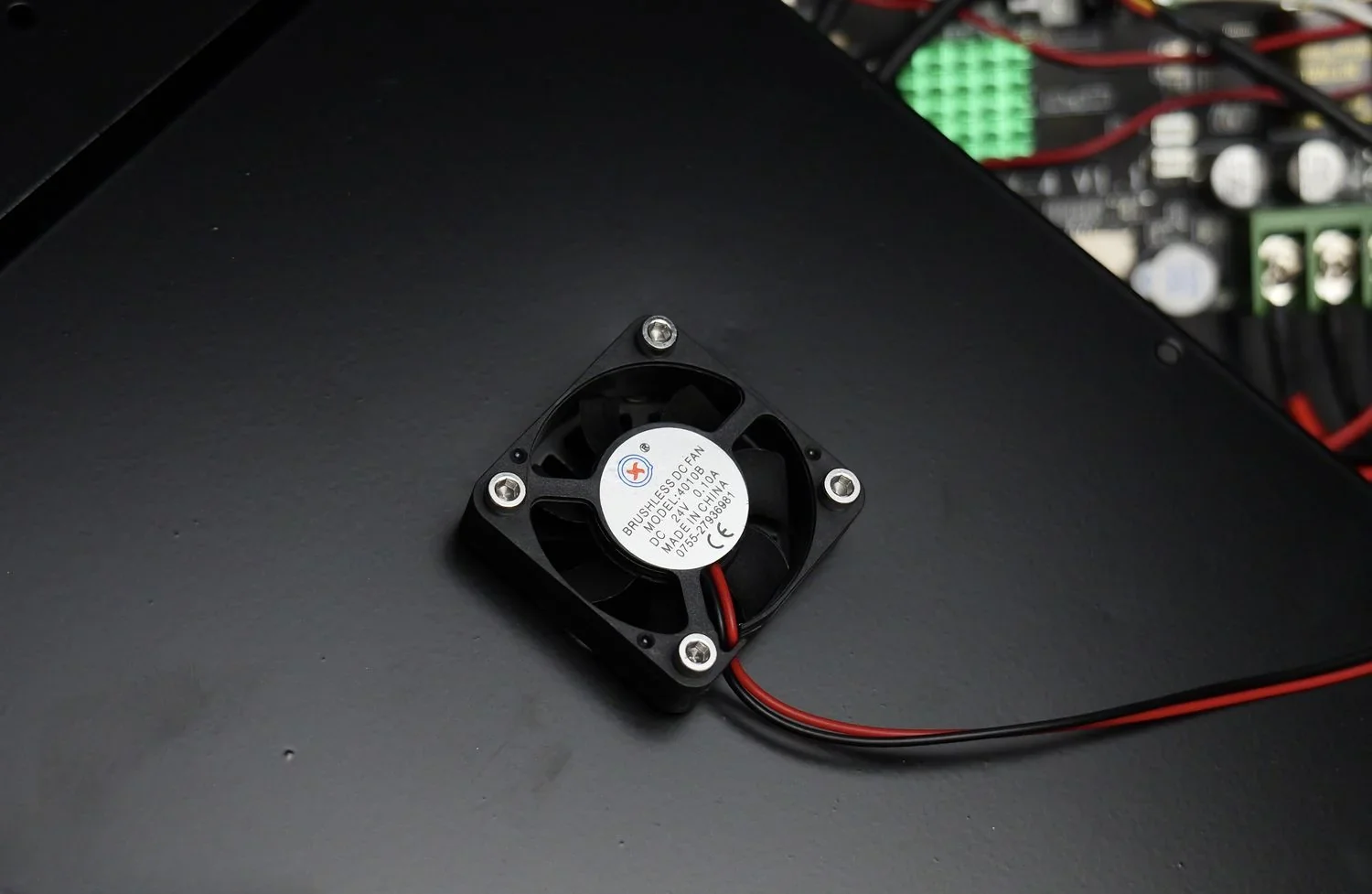

A 4010 fan prevents control board and driver overheating but creates audible noise during standby.

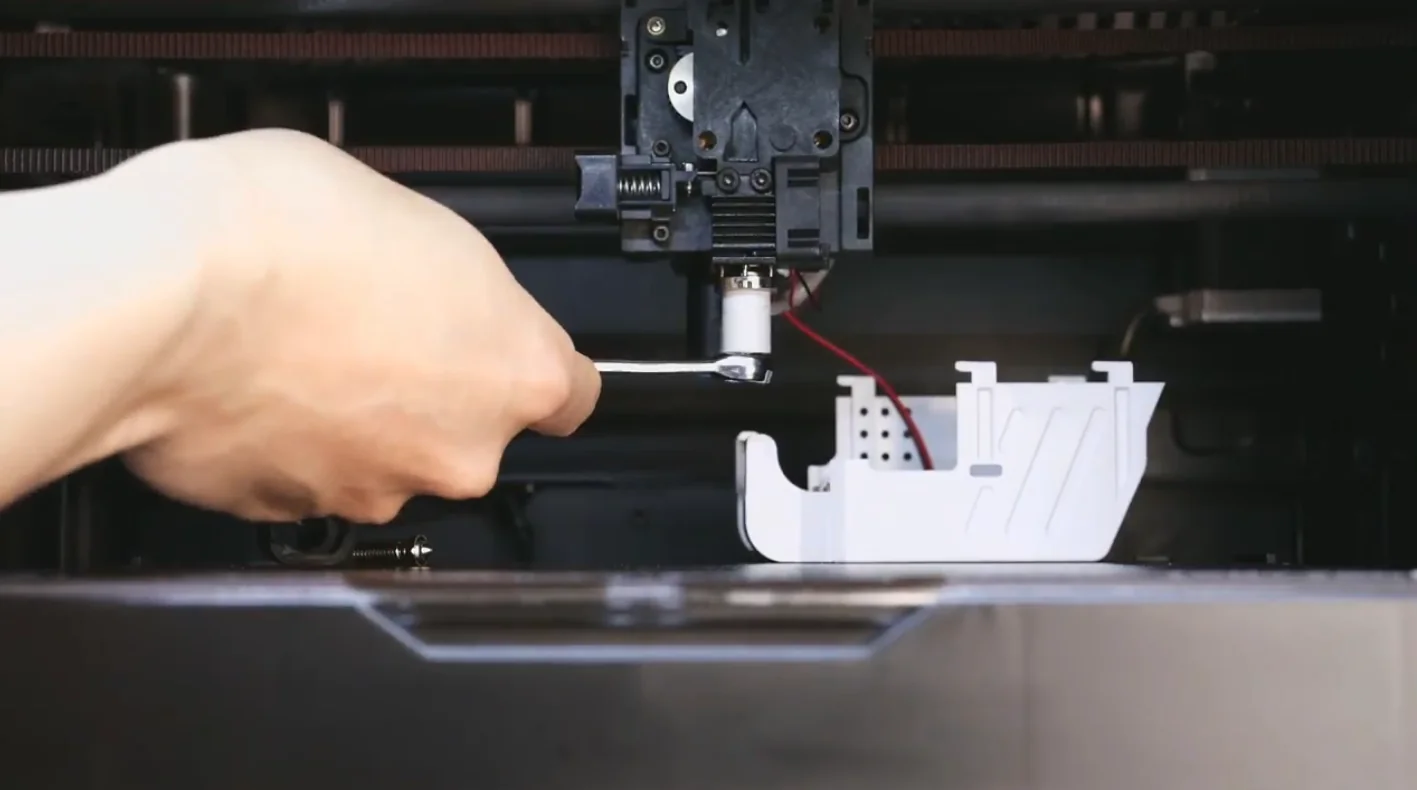

The X-MAX 3 large format 3D printer has a 6 mm aluminum heated bed with integrated magnets, reaching up to 120°C.

The print bed uses a double-sided textured PEI flexible magnetic plate. The print surface offers strong adhesion for most materials.

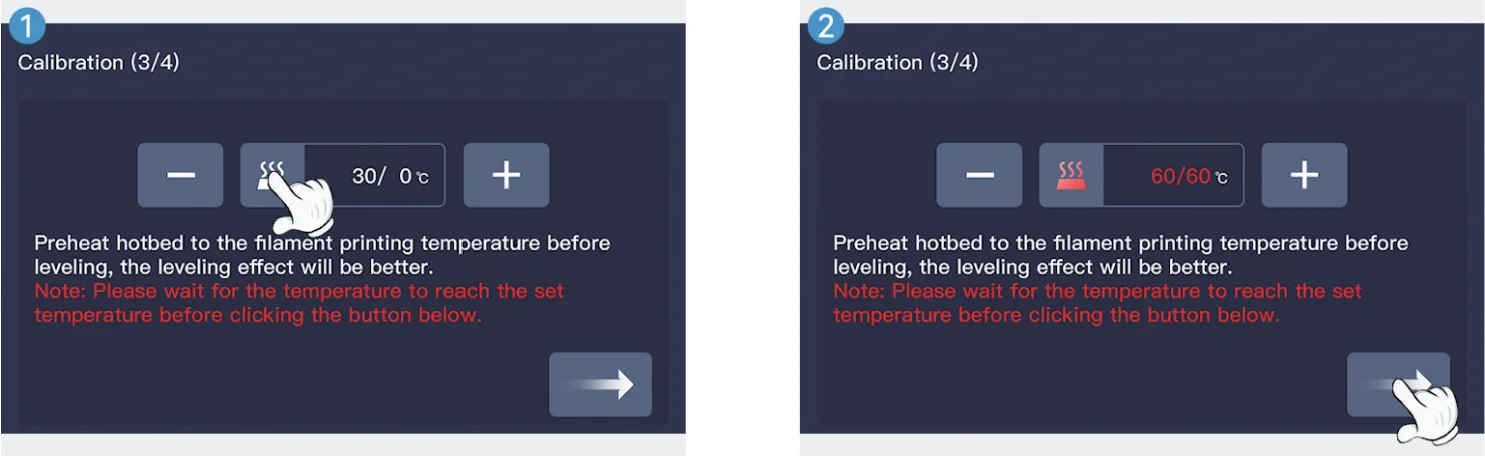

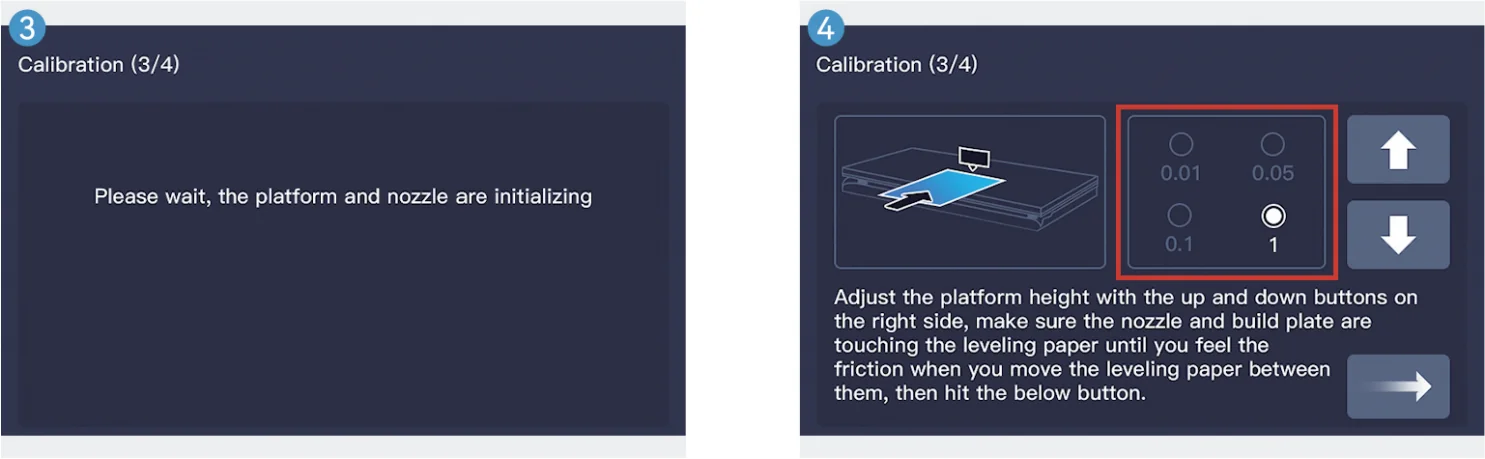

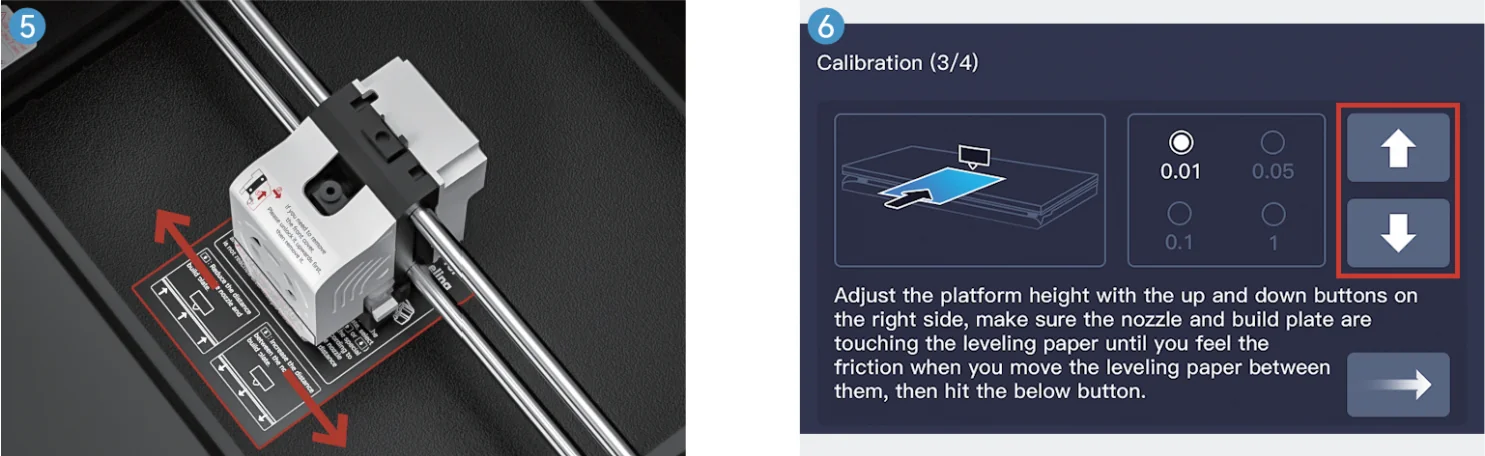

The large print bed maintains uniform temps, usually a few degrees higher than displayed. Its plastic support structure feels less sturdy for a large printer. Bed leveling uses a BLTouch probe with 16-point mesh compensation.

The X-MAX 3 uses a high-flow direct drive extruder with a 9.5:1 gear ratio for stronger extrusion.

The X-MAX 3’s high-temperature extruder uses dual large gears like Bondtech LGX Lite for strong filament grip and easy maintenance. It includes two hotends: a copper alloy nozzle for standard filaments and a hardened steel nozzle for abrasives, both heating to 350°C with ceramic cores. The hotend mounts with two bolts (Bambu-style), though wiring access requires removing the rear cover. Flow rates reach up to 35 mm³/s, with typical use around 20–22 mm³/s.

The X-MAX 3 has a rear-mounted filament drying box that keeps a roll of filament dry with desiccant and an airtight seal, feeding filament via PTFE tubing. A runout sensor pauses prints when spools empty. While effective, the rear placement makes filament handling less convenient near the front touchscreen. A filament run-out sensor pauses prints when spools empty. While effective, the rear placement makes filament handling less convenient near the front touchscreen.

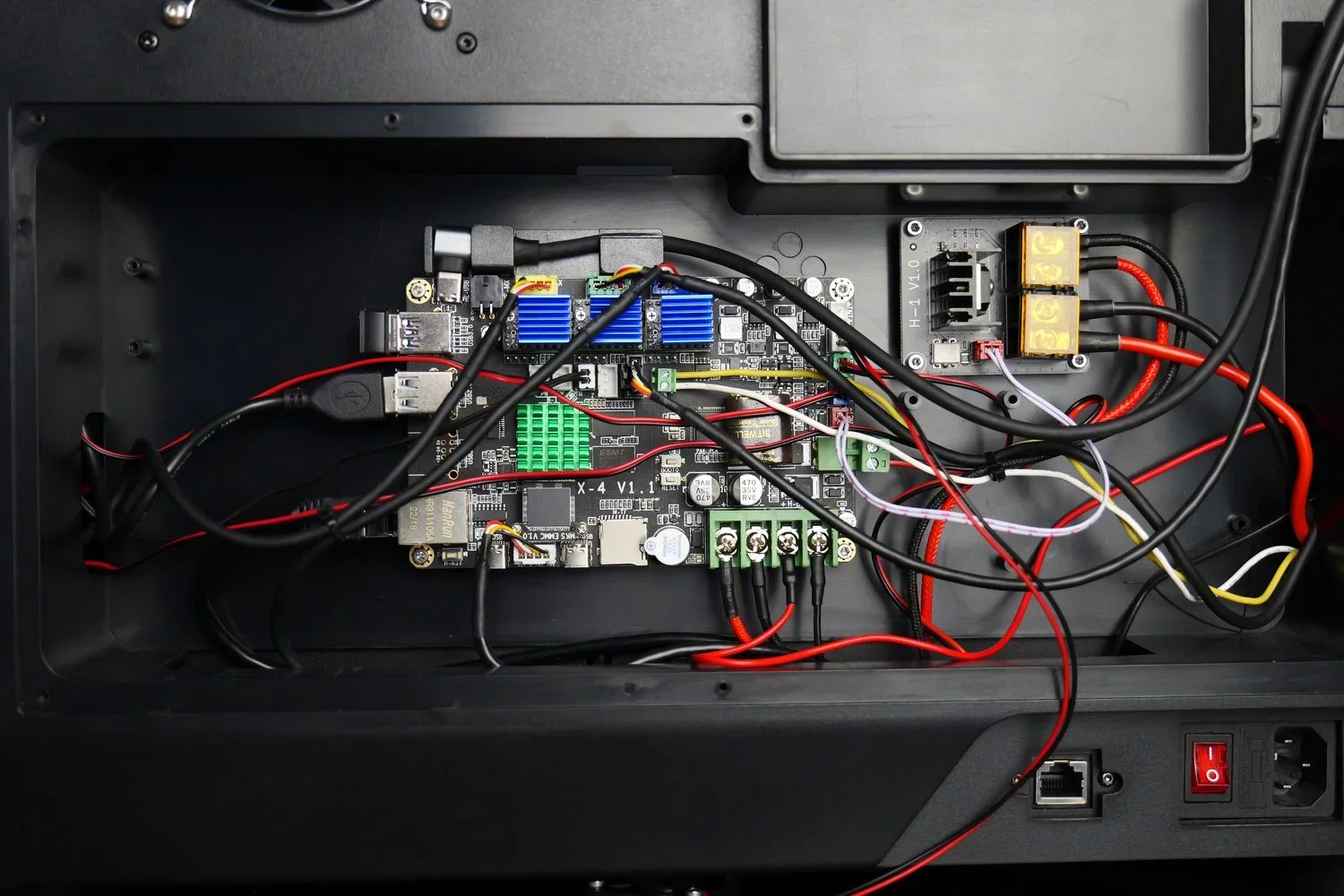

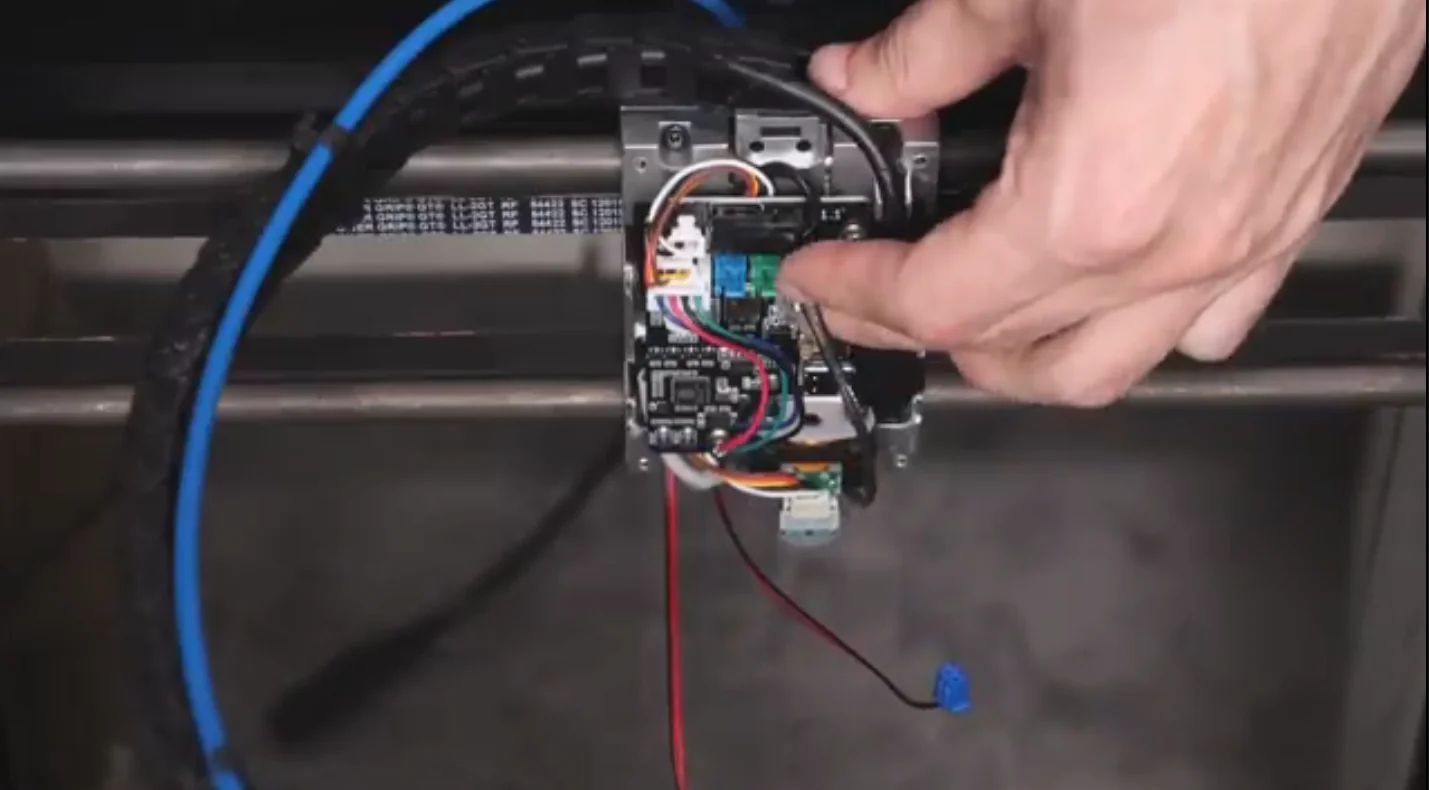

The X-MAX 3 uses a 32-bit X4-V1.1 mainboard (likely MKS) with a Cortex-A53 64-bit processor at 1.5GHz, 1GB DDR3 RAM, and 8GB EMMC storage.

The mainboard has three removable TMC2209 drivers, while a CAN BUS daughter board on the print head handles additional motor control.

The mainboard runs Klipper natively, enabling Input Shaper and Pressure Advance. A 4010 fan cools the board and stepper drivers.

The X-MAX 3 uses dual 450W, 24V power supplies with a 900W max rating and ~20W idle draw. Heating uses ~400W, rising to ~720W with the 300W chamber heater. Compatible with 100–240VAC, the system powers the bed, hotends, chamber heater, and high-speed motion reliably.

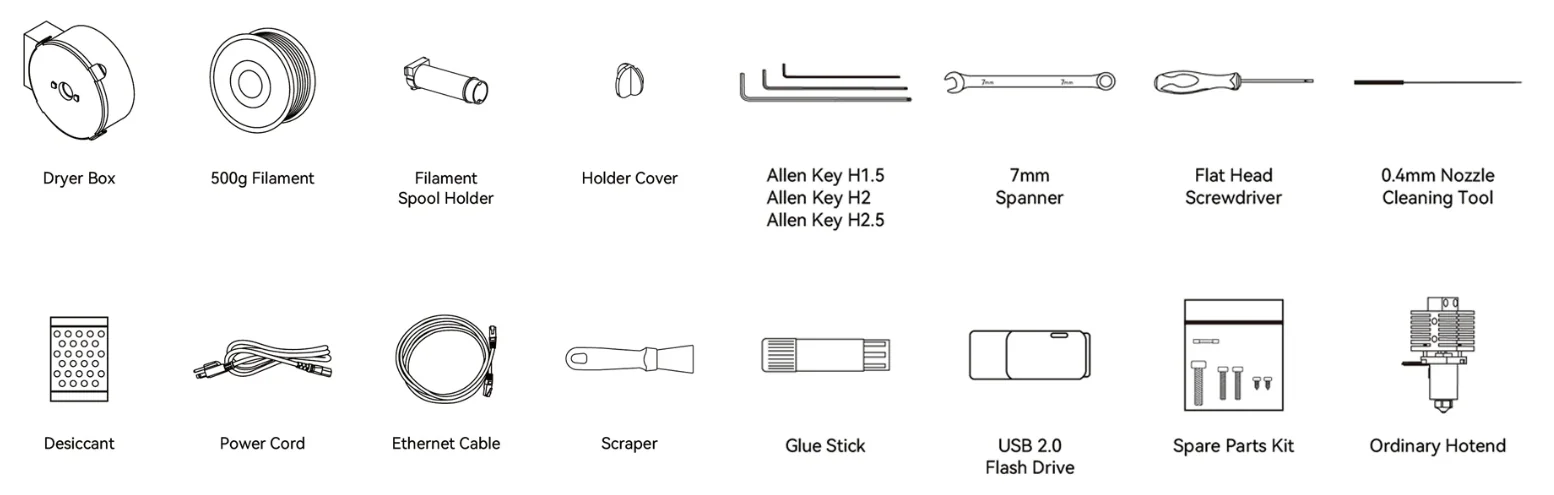

What's included in the Box:

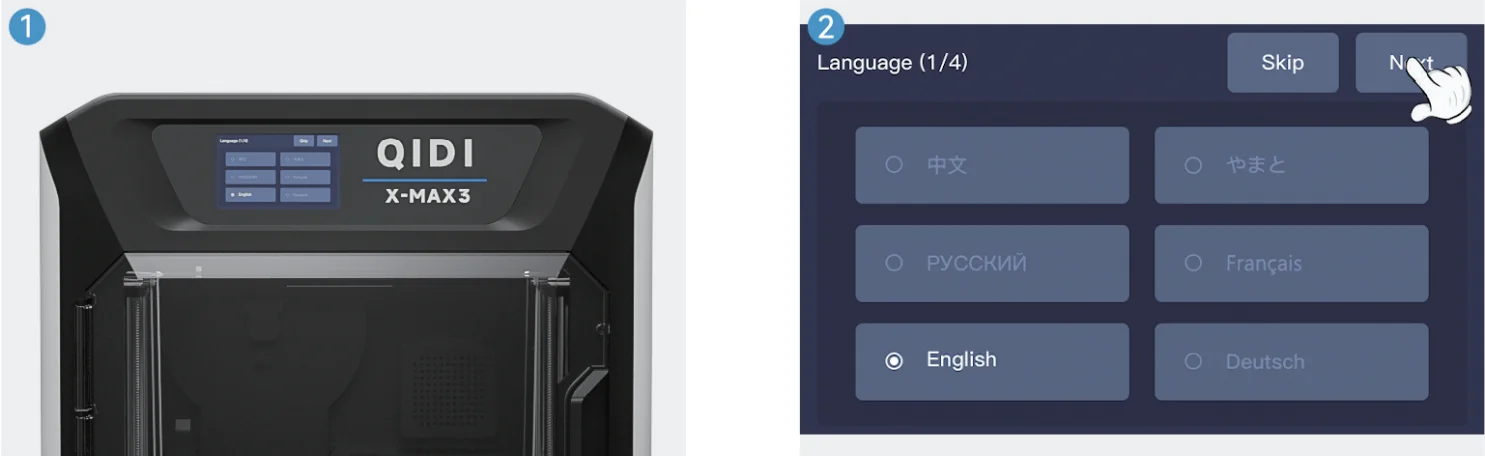

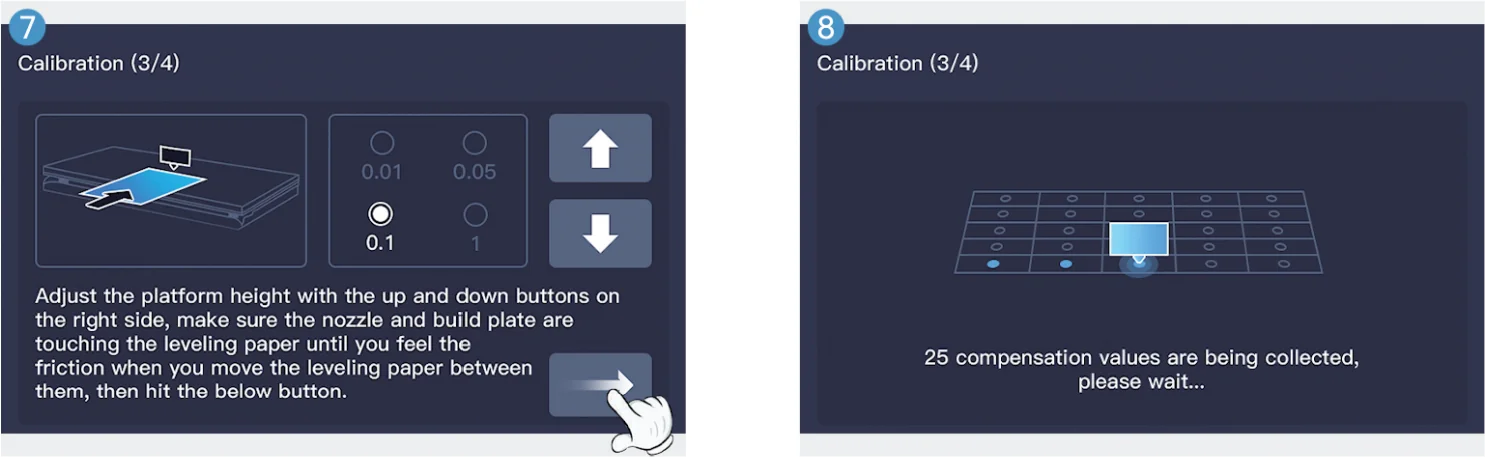

The X-MAX 3 is ready to print with minimal setup (~10 minutes). It includes two hotends (copper-plated for standard, hardened steel for abrasives), a filament drying box with direct feed, and a USB drive with pre-configured profiles. Setup is guided on-screen, using only the included toolkit.

Note: Package contents may vary. Confirm current items with a sales representative before ordering.

The X-MAX 3 supports accessories and upgrades like spare hotends, nozzles, and extra flexible PEI build plates. Dual-sided textured plates are especially useful for switching between standard and engineering materials without adhesion sprays.

QIDI offers hardened steel nozzles in 0.2 mm, 0.6 mm, and 0.8 mm sizes in addition to the standard 0.4 mm. Smaller nozzles suit fine detail, while larger ones boost speed and strength. All are compatible with both standard and high-temp hotends, keeping the X-MAX 3 versatile.

The X-MAX 3 lacks a built-in camera, but users can connect a USB webcam with simple Klipper setup for remote monitoring—useful for long engineering prints.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| Qidi filament dryer box | Keeps spools dry for moisture-sensitive filaments | For moisture-sensitive filaments (PA12-CF, UltraPA, ABS, PETG) | $40+ |

| Bimetal Nozzles (2pcs) | Heat- and wear-resistant for durable printing | For advanced users needing durable nozzles | $30+ |

| Tungsten Carbide Bimetal Nozzles (1pc) | Ultra-durable for abrasive materials | For industrial or heavy-use with abrasive materials | $50+ |

| Double-sided gold PEI plate | Strong adhesion, easy print removal | For all 3D printer users (PEI plate) | $50+ |

| Hot end V2.5 | Replacement/ upgrade hotend | For maintenance and upgrade needs (hotend) | $35+ |

| Extruder (without hot end) | Replacement extruder assembly | For repair and replacement (extruder) | $30+ |

| Automatic leveler | Simplifies plate leveling | For easier setup (auto-leveler) | $40+ |

The QIDI Filament Dryer Box uses a PP cover, ABS body, and VMQ seal to create a sealed, moisture-proof chamber. With desiccant inside, it keeps hygroscopic filaments like PA12-CF, UltraPA, ABS, and PETG dry, preventing stringing, clogs, poor adhesion, and layer shifts. It improves print stability, extends filament life, and protects against dust. Compatible with spools up to 210×85.5 mm and works with QIDI printers including X-PLUS, X-MAX, X-CF Pro, I-Fast, X-SMART3, X-PLUS3, and X-MAX3.

The QIDI Bimetal Nozzle fits the Q1 Pro hotend and V2.5 hotends on MAX3, PLUS3, and SMART3 models only. Available in 0.2–0.8 mm sizes, it provides precise extrusion, good heat transfer, and abrasion resistance for reliable, high-quality prints. QIDI advises using one filament type per nozzle to reduce clogging from material changes.

The QIDI Tungsten Carbide Bimetal Nozzle, built with a tungsten carbide tip and brass body, offers extreme wear resistance and heat stability. It is compatible only with the Q1 Pro and V2.5 hotends on MAX3, PLUS3, and SMART3 printers. Designed for single filament use per nozzle to avoid clogs, it excels at printing abrasive materials like carbon- and glass-fiber filaments while maintaining accuracy and long service life.

The QIDI Double-Sided PEI Gold Textured Board for the X-Max 3 provides strong adhesion on both sides for various filaments. It should be cleaned with hot water and dish soap, kept free of dust/grease, and never exposed to acetone. Let prints cool before removal for easier release. Designed for the X-Max 3, it improves stability and surface finish.

The QIDI Hot End V2.5 for MAX3, PLUS3, and X-Smart3 supports multiple nozzle types for durable, precise printing. It includes a protective cover and requires filament-specific settings, such as PA 0.042/210℃ for PLA and PA 0.035/260℃ for ABS. Its unique heating method demands parameter adjustments for stable extrusion, making it best suited for advanced users.

The QIDI extruder uses dual hardened steel gears for stronger, slip-free filament feeding and wear resistance. It handles carbon- and glass-fiber filaments like PA12-CF, PET-CF, PAHT-CF, and ABS-GF, ensuring durable, precise extrusion. Designed for demanding applications, it suits advanced users of the X-Max 3, X-Plus 3, and X-Smart 3 printers.

The QIDI Automatic Leveler for the X-Max 3 ensures consistent first-layer adhesion by compensating for bed irregularities. It probes multiple points on the build plate for precise height adjustments, improving print quality, reducing manual calibration, and supporting stable printing across the X-Max 3’s 325 × 325 × 315 mm build volume.

The QIDI X-Max3 needs regular maintenance to stay reliable and last longer. Full tutorials: https://wiki.qidi3d.com/en/X-Max3/Maintenance

As-Needed Maintenance

Monthly (Heavy Use) / Quarterly (Normal Use)

Regular Maintenance (3–6 Months, Usage Dependent)

The QIDI Tech X-Max 3 has a one-year warranty for the printer body and electronics. The extruder (excluding gears) and hotend assembly carry a three-month warranty. Consumables like nozzles, gears, build plates, and PTFE tubes are excluded but replaced if defective on arrival.

QIDI offers model-specific support via dedicated emails. For the X-Max 3:

Specialized support ensures faster resolutions, replies within one business day, and quick replacement part shipping to reduce downtime.

The X-Max 3 includes a USB drive with assembly guides, maintenance instructions, and troubleshooting videos. QIDI’s website provides firmware updates, slicer downloads, and educational resources: https://qidi3d.com/pages/software-firmware. The QIDI Slicer’s onboard Guide tab adds animated tutorials for common tasks. This layered support gives users help throughout ownership.

Full warranty terms: https://qidi3d.com/pages/warranty-policy-after-sales-support, https://qidi3d.com/pages/warranty-statement

The QIDI Tech X-Max 3 is priced at $699.00 with a large build volume and fast printing. It features a CoreXY structure, automatic leveling, a 65 °C heated chamber, and Klipper firmware on a 64-bit Cortex-A53 processor. A high-flow direct drive extruder supports high-performance printing filaments.

Update your browser to view this website correctly. Update my browser now