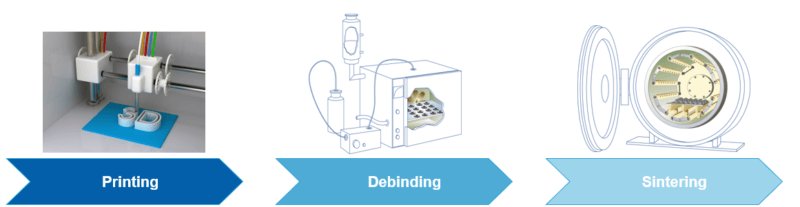

The Forge1 from Raise3D is a professional large-format metal 3D printer. It is a part of the new MetalFuse solution offered by the company that also includes the D200-E debinding device and S200-C vacuum sinter. The system is aimed at high performance, better repeatability, smooth post-processing, and environmental safety.

The machine boasts a large print area of 300 x 300 x 300 mm providing you with freedom of design. The dual extruding system with electronic lifting and precise kinematics ensures high speed and accuracy of printing. Apart from this, the device has a number of smart features optimizing the working process, such as the automatic bed leveling, filament run-out sensor, HEPA filter with activated charcoal, and more. The Raise3D Forge1 prints high-end metal filaments from BASF that contribute to simplicity, efficiency, and safety of the printing process as well as top quality of the outputs. All these features make the Forge1 a reliable tool for small scale production of end-use parts with outstanding mechanical properties.

Credit: raise3d.com

It is recommended to use the Forge1 3D printer with special equipment from the MetalFuse series. Thus, the polymer will be removed from the model during the catalytic debinding process, which will result in a pure metal with residual binder. The sintering process will further remove the binder due to the temperatures below the melting point of the metal. That way, the product achieves its final hardness and strength properties.

The Raise3D Forge1 prints layers from 0.25 to 0.1 mm, which makes for mass printing of parts with smooth exterior surfaces. The new catalytic debinding method not only leads to 60% off in processing time but also allows increasing the density of produced parts to up to 97% of wrought iron’s level.

Credit: raise3d.com

The machine features a silicone heat bed engineered with an automatic leveling system, which guarantees accurate calibration.

The Forge1 comes with 0.4 (default), 0.6, and 0.8 mm nozzles for all your printing needs.

The Forge1 from Raise3D utilizes the BASF Forward AM’s metal filaments Ultrafuse 316L and Ultrafuse 17-4 PH. With these materials, the MetalFuse system is capable of better printing repeatability and a greater yield rate.

Credit: ultrafusefff.com

Credit: raise3d.com

The build area varies depending on the number of extruders employed. It is 11.8 x 11.8 x 11.8 in (300 x 300 x 300 mm) for the single extruder print mode and 10 x 11.8 x 11.8 in (255 x 300 x 300 mm) for the dual extruder print mode. The massive volume like this allows producing complex end-use parts with improved mechanical properties in batches, which will definitely meet the requirements of small-scale manufacture.

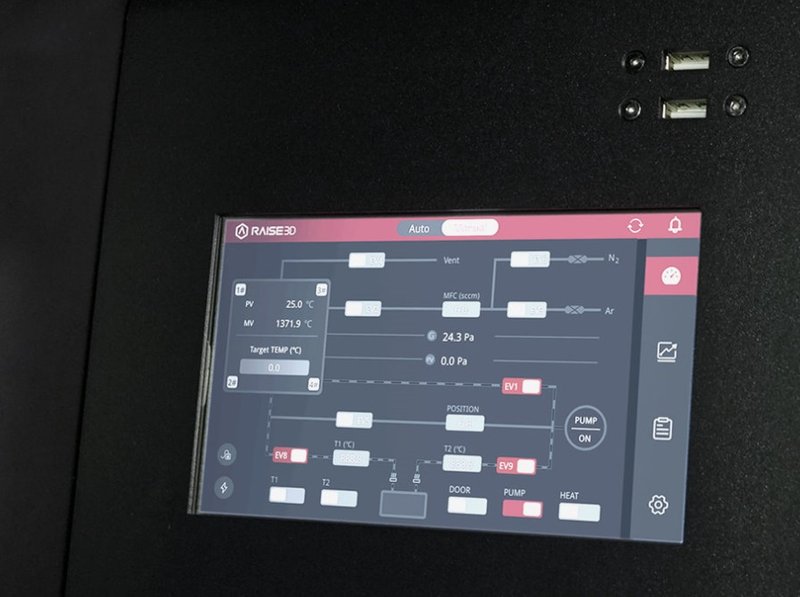

The Raise3D Forge1 is equipped with a 7" sensitive touchscreen for comfortable control, with its intuitive interface allowing users to easily manage the printing process. The built-in camera provides remote monitoring options.

Credit: raise3d.com

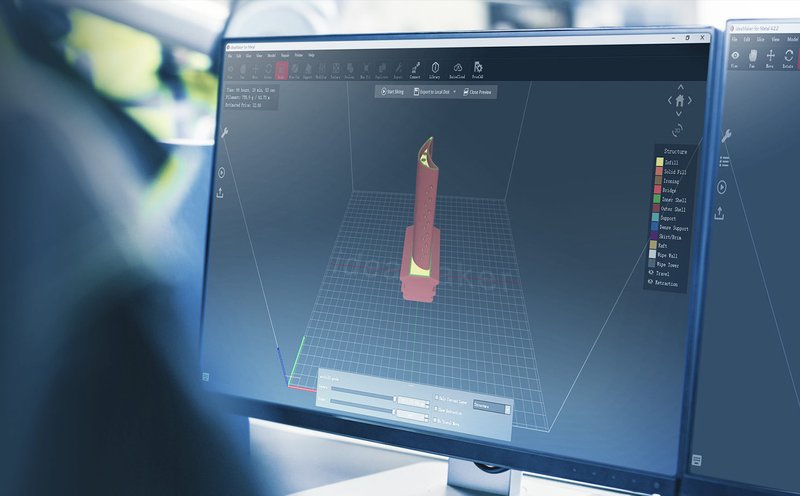

The printer comes bundled with a special edition of the ideaMaker software that offers templates optimized for this kind of printing. Apart from this, the program ensures a smooth sintering and debinding process that are an essential part of the MetalFuse system. The special edition of the ideaMaker also features simplified slicing algorithms.

Credit: raise3d.com

The Raise3D Forge1 is available in black with red trimmings. Its stylish look makes it ideal for any workshop or maker lab.

Credit: raise3d.com

Credit: raise3d.com

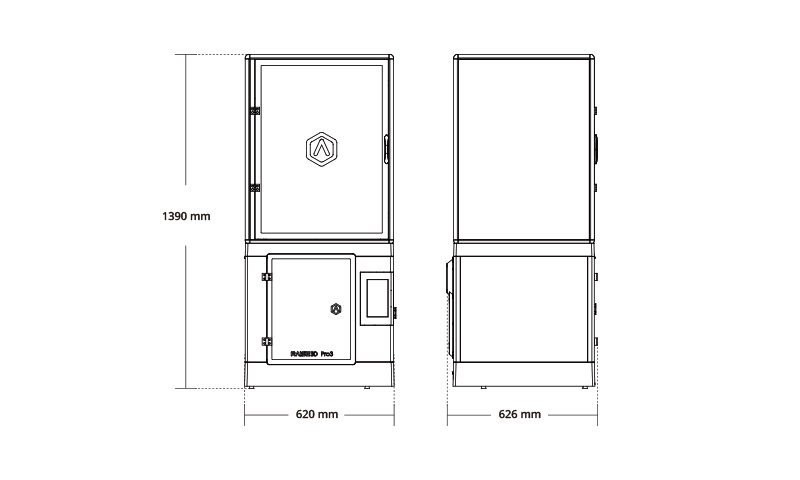

The printer dimensions are 24.4 x 24.7 x 54.7 in (620 x 626 x 1390 mm). It weighs 165 lb (75 kg).

To learn the current price of the Raise3D Forge1, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now