The Sinterit Lisa Set is a bundle consisting of the Sinterit Lisa professional SLS 3D printer and a number of accessories to facilitate the printing process and perfect the outputs. The add-ons are meant to provide the user with all the benefits needed for both improved experience and streamlined operation.

The Sinterit Lisa is a high-performance SLS 3D printer for quality prototyping and small-scale manufacturing. It combines user accessible functionality and affordable price in terms of the SLS technology. The machine is capable of precise and support-free printing of large prints. Its delicate hardware allows making high-resolution objects of intricate shapes and complex structures, which can be used in many spheres.

The Sinterit Lisa boasts a friendly UI and automated operation. Due to its simplicity and reliability, the device is great for small businesses and independent makers creating prototypes and functional parts in the engineering, automotive, and other areas with similar needs.

Credit: @filament2print / Instagram

The Sinterit Platform is an adjustable structure with rubber wheels that is designed to provide ergonomic workspace by giving access to all the essential devices in the printing process. Stable and robust, the platform ensures reliability and convenience coupled with the easy transportation of the bundle’s components.

The Sinterit ATEX Vacuum Cleaner will be of great use when having to clean and collect unsintered powder. The device has a compact size yet rather a large capacity of 12 liters, which makes it extremely convenient. Thus, powder cleaning and recovery become easy, fast, and highly effective.

The set includes a sifting station for used SLS powder, ensuring reuse and hence great savings of the material. The device filters out contaminants and removes lumps and impurities — all you need to do is press the button and wait 18 minutes for the material to be ready for being mixed with fresh powder and subsequently re-used for producing new objects.

The Sinterit Sandblaster is a post-processing tool for cleaning and polishing parts printed on an SLS 3D printer. It uses compressed air and little glass balls to cover the whole surface of your model and highlight every line and angle. In addition, the device is equipped with a HEPA filter which, along with full sealing, ensures a dustless environment. Other features to mention include a large working area of 410 x 310 x 200 mm and a built-in pressure meter providing for exceptional accuracy of tiny details.

This essential toolkit is meant to make working with SLS powders simpler, cleaner, and safer. The set includes tools and accessories associated with personal protection, powder management, and post-processing. It includes a variety of spatulas and brushes, a scoop, measuring cup, trowel, IO box, foldable tray, funnel, binder, a service kit, and other tools, as well as protective glasses, gloves, a mask, and even a T-shirt.

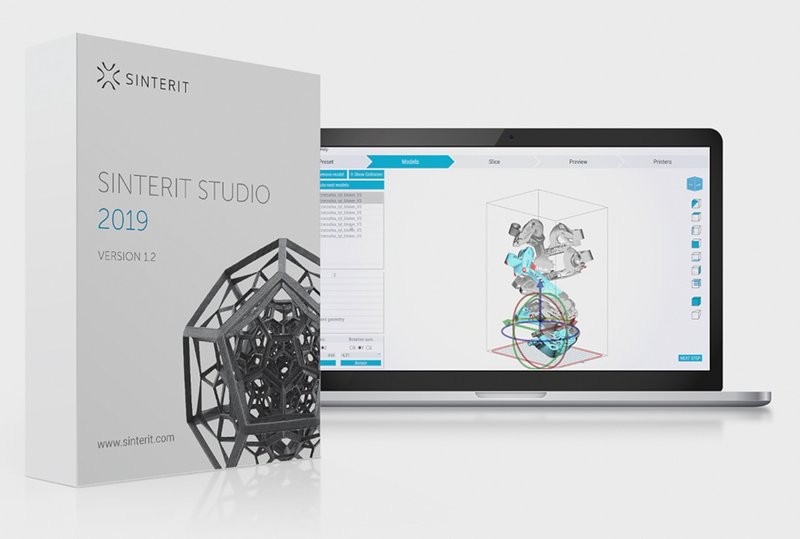

The bundle comes with the proprietary Sinterit Studio software — a highly efficient tool for slicing and preparation of 3D models for printing. The program features a plethora of smart functions such as auto nesting, collision detection, scale and temperature modification. It also has pre-defined profiles for PA12 Smooth and Flexa Grey Sinerit materials.

|

Technology |

SLS |

|

Connectivity |

USB cable |

|

Display |

4 inches, LCD |

|

Laser Class |

Class IV infrared laser, 5w, 808nm |

|

Max heated bed temperature |

190 °C |

|

Operating systems |

Windows, macOS, Linux |

|

Outer dimensions |

650 x 550 x 400 mm |

|

Printable materials |

PA12 powder, TPU powder |

|

Slicing |

Sinterit Studio |

|

Weight |

35 kg |

|

Build volume |

150 x 200 x 150 mm |

|

Min layer thickness |

75 μm |

|

Dimensions |

550 x 740 mm |

|

2 leg heights |

240 / 440 mm |

|

Weight |

25 kg |

|

Max. load capacity |

100 kg |

|

Wheels |

50 mm rubber wheels with brakes |

|

Material |

Powder-coated steel |

|

Dimensions |

440 x 420 x 780 mm |

|

Weight |

25 kg |

|

Power |

1.1 kW |

|

Voltage |

230 V AC, 50/60 Hz or 110 V AC 50/60 Hz |

|

Noise level (EN ISO 3744) |

77 dB(A) |

|

Max. air flow (rate) |

215 m³/h |

|

Suction inlet |

50 mm |

|

Filter type |

Star, M class filtration |

|

Capacity of the collection unit |

40 L |

|

ATEX zones |

Z22 or INTERTEK certification |

|

Type |

Automatic |

|

Working time |

18 min |

|

Dimensions |

600 x 340 x 330 mm |

|

Weight |

22.5 kg |

|

Maximum capacity |

5 L |

|

Power Supply |

12 V / 2 A |

|

Maximum power consumption |

24W |

|

Dimensions |

480 x 370 x 360 mm |

|

Weight |

15 kg |

|

Working area |

410 x 310 x 200 mm |

|

Power supply |

6W |

|

Max pressure |

125 [psi] | 8.62 [bar] |

|

Abrasive material |

glass balls 200 μm |

|

Abrasive material container capacity |

5.44 kg |

|

Input voltage |

230 V / 50 Hz | 120 V / 60 Hz |

|

Air consumption |

290 l/min |

|

Compatible with |

ATEX Vacuum Cleaner |

|

OS |

Windows 7+ (64-bit Edition) |

|

RAM |

2 GB or more |

|

Hard disk |

1 GB or more |

|

GPU |

Compatible with OpenGL 3.0 or higher |

The price of the Sinterit Lisa Set is $17,990.00, which is reasonable considering its functionality, smart features, and efficient tools.

Update your browser to view this website correctly. Update my browser now