3D scanning and 3D printing don’t just serve recreation or manufacturing — artists use them as full-fledged creative tools. For example, we recreated Vera Mukhina’s Worker and Kolkhoz Woman for the House of European History in Brussels.

These technologies help replicate existing 3D objects and also support the creation of entirely original artworks.

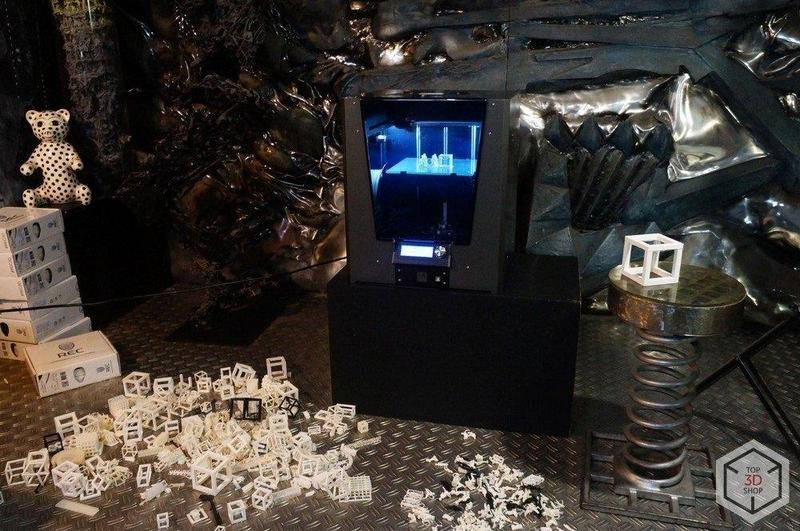

This is the story of one of our customers and how they create sculptures with an Epitum 3D printer they purchased from us.

The artist works with complex, multi-part sculptures and needed a way to produce many small, repeatable elements without spending all his time on molds and casting.

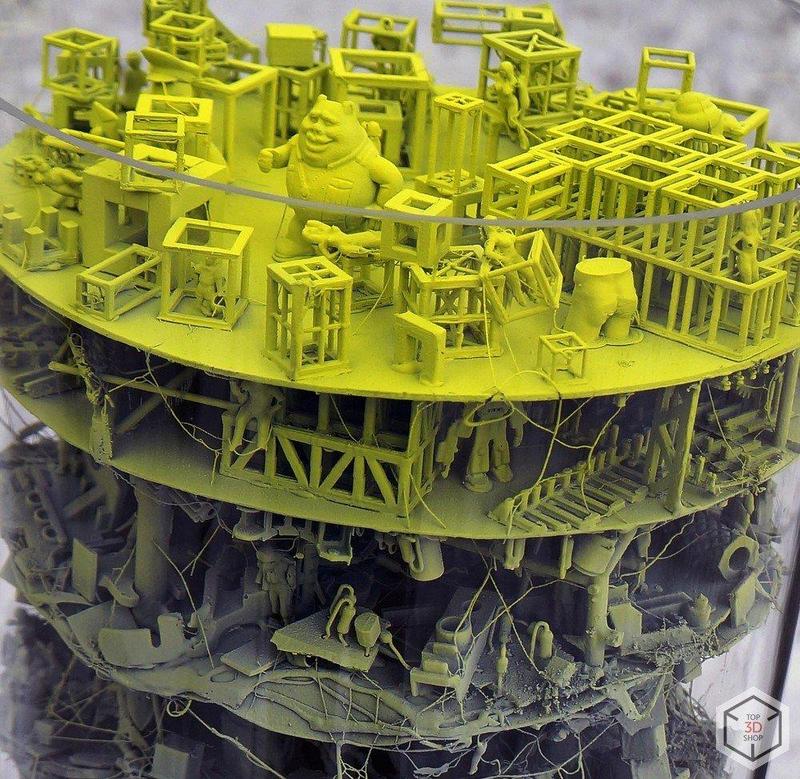

Example: Upper section of the sculpture “Paleogeomorphology. Core Sample #17”.

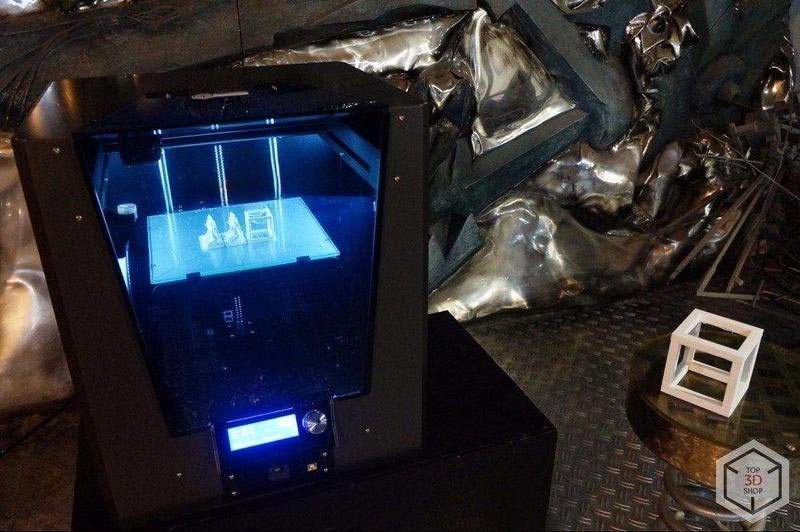

After careful comparison of different options, the client chose the Epitum 3D printer as a reliable tool for turning digital ideas into physical objects. The 3D printer’s build volume, resolution, and supported materials gave the artist enough flexibility to experiment with different forms and textures.

Key specifications of the Epitum 3D printer

The artist uses the Epitum printer to create a wide variety of small sculpture components, including:

Structural parts with straight, sharp lines

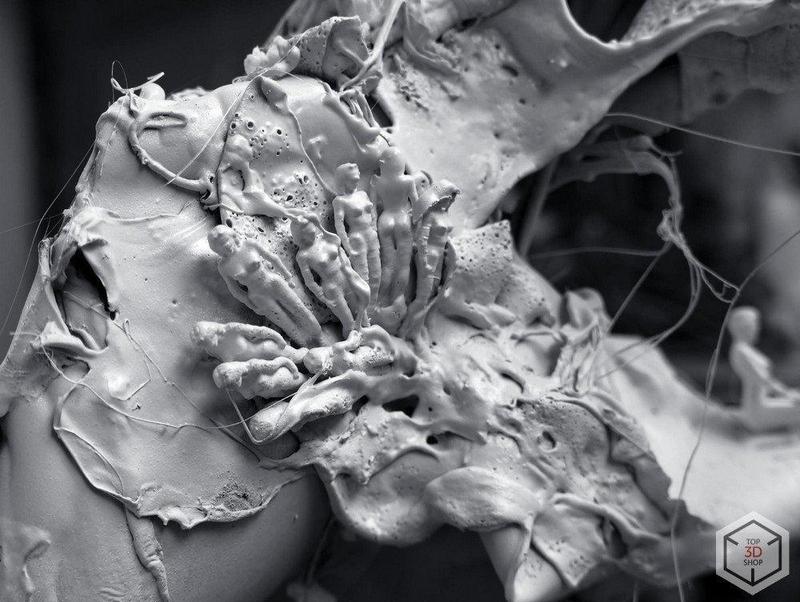

Organic, biomorphic shapes

Human and animal figurines

Many other small, repeatable elements

3D printing now handles the bulk production of these parts, while the artist focuses more on composition, finishing, and final details.

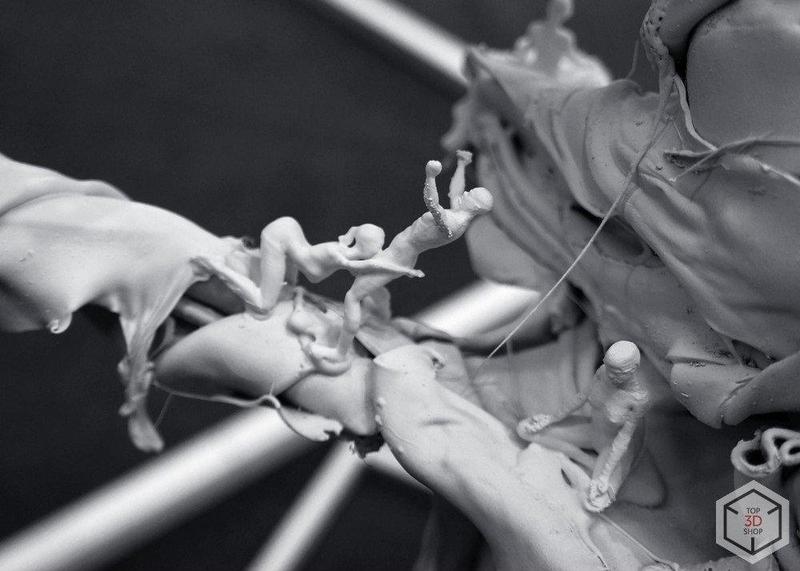

Example: Middle section of the sculpture “Paleogeomorphology. Core Sample #17”.

Before switching to 3D printing, producing these components was a slow and monotonous process:

“Before getting a 3D printer, I would make each piece by hand and then make a mold from it. I would then use the mold to cast copy after copy after copy until I got sick of casting copies, and then I would still have to cast the same amount again. The quality was good enough, but not everything can be cast like that, not even in a high-quality rubber mold.”

This workflow delivered acceptable quality, but:

Required a lot of time

Limited the complexity of shapes

Depended heavily on mold durability and casting technique

Like in other industries, 3D printing opened new creative and practical possibilities for sculpture.

“Have I opened up a new frontier for myself? Yes, you could say that. I’ve spent so much time working at those little details, and that’s a big chunk of my life that I’ll never get back, but now I can just churn them out on my 3D printer. It doesn’t get tired, it doesn’t complain, it doesn’t ask to be fed and it works three times faster than I do.”

Key benefits for the artist:

The printer steadily produces repeated parts without fatigue

Small, detailed elements no longer consume most of the artist’s time

Complex shapes that were difficult or impossible to cast now become feasible

Like any tool, 3D printing in art also brings new challenges and temptations:

“There is a downside, a big one. Getting a 3D printer has radically pushed back the limits of what I can create, and now I need a couple more printers and a 3D scanner to bring all my new ideas to life."

As soon as the production bottleneck disappeared, the scale of ideas increased. Now the artist plans to expand their setup with:

More 3D printers

A 3D scanner for capturing existing objects and textures

Sculpture “Inhabited Sculpture for Birds”, 2017:

This client’s experience shows how 3D printing helps in projects that require many small elements, but it also scales to much larger works.

If a sculpture exceeds the print chamber, you can:

Print it in parts

Assemble the sections into a single composition

Use post-processing to hide seams

Thanks to the precision of 3D printing, correctly prepared component parts fit together so well that seams become invisible after sanding, priming, and painting.

Creating physical objects from digital models is still not standard practice for most artists, even in contemporary art. However, it already works as an avant-garde tool — a way to turn complex, digital fantasies into real, solid forms.

A 3D printer now serves not only makers and engineers, but also sculptors and visual artists who want new ways to build and reproduce their ideas.

The Top3DShop online store offers a full range of 3D printers, 3D scanners, materials, and accessories. Our experts will gladly advise you and help you choose technologies, materials, and special features that match your budget and artistic requirements.

Update your browser to view this website correctly. Update my browser now

Write a comment