Rapid prototyping is a key concept of Industry 4.0. As production cycles shorten and efficiency becomes critical, more businesses turn to additive manufacturing, robotics, and digital fabrication tools to speed up product development.

Our client is a company specializing in electronics manufacturing. They recently upgraded their prototyping workflow with a range of 3D equipment and automation tools from Top3DShop. Their goal was clear: reduce development time from weeks to just a few days.

Here’s how they did it — and what tools made the biggest difference.

This company works across the full cycle of electronics production, from initial technical requirements to small-batch manufacturing. Their projects include:

Control systems and diagnostic tools

Augmented reality devices

Industrial cameras

Machine vision systems

To improve efficiency, they decided to bring prototyping in-house. Before this shift, external partners made most prototypes. The output quality was good, but the process often caused delays. Meeting tight deadlines that required prototypes in just 1–3 days became difficult.

By moving key stages of prototyping to their own facility, the company aimed to:

Cut waiting times

Increase the number of design iterations

Reduce dependency on subcontractors

Specifications

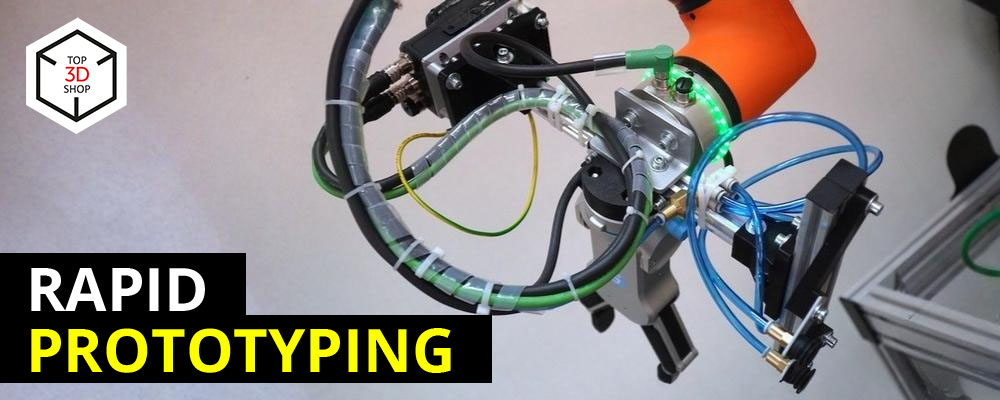

This 6-axis collaborative robot was introduced to test the feasibility of robotic integration into the company’s manufacturing and assembly processes. Engineers are still exploring its potential use cases and how it might be adapted to their workflows.

The company introduced this 6-axis collaborative robot to test how robotic automation could fit into their manufacturing and assembly processes. The engineering team is still exploring:

Which of the company’s tasks are suitable for robotic arms

How deeply they can integrate these cobots into planned technological processes

What kind of fixtures, grippers, and workflows will be most effective

The HCR-3 now works as a test platform for future automation scenarios.

The team uses this FDM printer for fast, low-cost production of early-stage prototypes and draft models. They chose the Pro2 Plus because it combines:

A large build volume for tall or bulky prototypes

Dual extrusion for multi-material or support-intensive parts

Reasonable purchase and operating costs

Good reliability for daily use

The printer can make both large parts and small components, which helps the company avoid buying several specialized FDM machines.

Specifications

When the client chose an FDM printer, the company considered financial factors alongside technical ones. They decided to invest in a universal solution that could:

Print large housings and enclosures

Produce small brackets, fixtures, and internal components

Support a wide range of filament materials

The company uses this SLS printer for functional prototypes and parts ready for pilot production. It provides:

High dimensional accuracy

Good mechanical strength

The ability to print complex geometries without support structures

This makes the Lisa Pro suitable for end-use components, small production runs, and mechanical parts that need real load-bearing capability.

Specifications

The team selected this model for its strong price-to-performance ratio at the time of purchase. It gave them industrial-level SLS capabilities without the cost and footprint of larger systems.

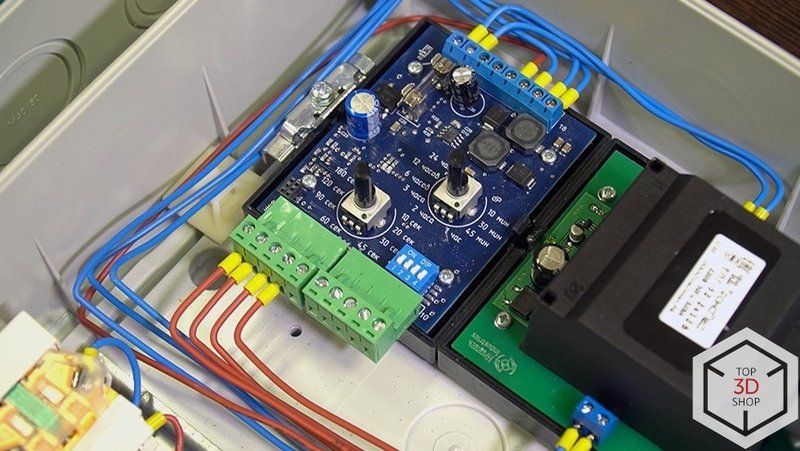

The team uses this laser system for cutting and engraving components, including parts for:

Non-standard equipment enclosures

Custom switchboards and control panels

Prototypes with tight internal layouts

The large working area supports:

Big panels and covers

Multiple smaller parts in a single job

Flexible nesting for different design requirements

Precision laser cutting helps the company maintain tight tolerances when mechanical constraints inside enclosures give them very little room to work with.

Specifications

By bringing prototyping in-house, the company significantly reduced the time between a new idea and a functional prototype. Engineers quickly mastered the new equipment and now achieve results comparable to previous subcontractor work, but in a much shorter time frame.

Main benefits:

Faster turnaround: Engineers no longer wait for third-party services to accept, produce, and ship prototypes.

Improved flexibility: They can modify a design, print or cut an updated part, and test it immediately.

Less manual handling: The team no longer needs to coordinate transport, pickups, or deliveries for each prototype iteration.

Lower costs over time: Investment in equipment pays off through higher productivity, reduced delays, and fewer external service fees.

Overall, the company moved from lead times measured in weeks to prototype cycles measured in days — often just 1–3 days from design to physical part.

When chosen carefully, 3D printers, laser cutters, and collaborative robots can significantly accelerate even complex electronics development cycles. In this case, a combination of FDM and SLS 3D printing, plus laser cutting and experimental cobot automation, reduced prototype production time from weeks to just a few days.

As hardware prices continue to fall, more companies can bring rapid prototyping and small-batch production in-house. This shift makes it easier to test ideas quickly, reduce risks before mass production, and build a more flexible, efficient development process.

Buy SLS 3D printers, large-format FDM 3D printers, collaborative robotic arms, and laser cutters at Top3DShop — our team of experts will help you choose the right equipment, integrate it into your workflow, and support you at every stage of implementation.

Update your browser to view this website correctly. Update my browser now

Write a comment