Today we share how a local museum of contemporary art uses 3D printing in its workshop and how it replaced outsourced souvenir production with an in-house workflow.

The museum wanted to:

Produce miniature souvenir replicas of its sculptures

Keep proportions and details as close to the originals as possible

Reduce dependence on external contractors

Gain more control over production time and quality

To achieve this, the team decided to introduce a professional 3D printer into the museum workshop and build a repeatable process around it.

The museum workshop needed a 3D printer that could:

Print with two materials at once

Use soluble supports for complex geometry

Deliver high-quality surface suitable for molding and casting

Fit into the available space and budget

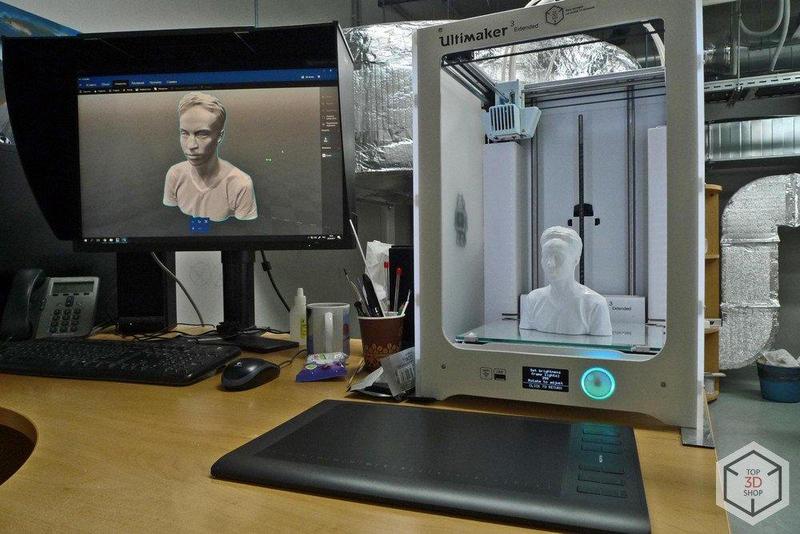

After a short search and team discussion, the museum chose the Ultimaker 3 Extended, a Dutch-made professional FDM 3D printer.

Technical Specifications

The museum acquired the printer primarily to produce miniature souvenir replicas of its sculptures:

“We bought the printer to start in-house souvenir production. Our first tests were scale models of museum sculptures, digitized with a handheld scanner to create 3D-printed masters. These were used to make molds for casting polymer souvenir models. We also offer custom portrait sculptures and hope the printer will serve us well long-term.”

The typical workflow now looks like this:

Scan original sculptures with a handheld 3D scanner.

Create high-quality 3D-printed masters on the Ultimaker 3 Extended.

Use these masters to produce molds.

Cast polymer souvenir models.

Offer custom portrait sculptures based on the same process.

Before 3D scanning and printing, the process looked very different:

A sculptor created master copies entirely by hand.

These masters often did not perfectly match the original sculpture’s proportions and fine details.

Each new souvenir type required significant manual labor, time, and artistic effort.

This slowed down production and made it harder to scale souvenir lines or test new ideas.

With 3D printing, the workshop can now:

Create scale copies that accurately reproduce the original’s proportions and forms.

Scan and prepare a small collection of sculptures in the time it used to take to handcraft a single master.

Maintain higher geometric accuracy and repeatability across batches.

Digitized models and 3D-printed masters allow the museum to:

Launch new souvenir items faster

Adjust scales and variants without re-sculpting

Keep a digital archive of forms for future use

The museum team described their experience with the Ultimaker 3 Extended as their first serious exposure to 3D printing:

"This is our first experience with 3D printing. While we can’t compare it to other models, we’re happy to share our impressions."

They noted several strong points:

Reliability:

“The printer has been reliable over 8 months of constant use.”

Ease of use:

Self-leveling build plate

Smooth integration with Cura software

Simple filament changes

Straightforward extruder cleaning

Efficiency and quality:

“It’s economical on filament without sacrificing quality. The filament itself is affordable, safe, and user-friendly. Despite no prior experience, we quickly learned the settings and were impressed with the print quality for the price.”

Overall, the team quickly built confidence with the system and integrated it into their daily work.

The museum also pointed out several challenges and limitations:

Initial calibration:

“We had to level the platform manually at first, as the auto-leveling didn’t work right away.”

Filament profiles:

Filaments differ by manufacturer.

Cura does not always provide presets for each brand.

This sometimes led to material waste and extra time during parameter testing.

Print time:

“High-quality prints are slow—some took 8 to 16 hours.”

Environmental factors:

Temperature fluctuations and drafts can affect support adhesion.

Failed supports can ruin long prints.

The printer requires a stable, draft-free environment for best results.

Post-processing:

“Support contact points also require cleanup after printing.”

These remarks reflect normal realities of professional FDM printing and helped the team adjust their workflow and workspace conditions.

By introducing the Ultimaker 3 Extended, the museum:

Switched from fully hand-made master models to digitized, 3D-printed masters

Gained better control over proportions, detail, and scale

Reduced dependence on external contractors

Learned to run in-house souvenir production based on scanning, 3D printing, and casting

For museums and galleries, this approach opens new opportunities:

Limited runs of miniature replicas

Custom sculptures and portraits

Fast experimental pieces for exhibitions and events

Buy 3D printers and handheld 3D scanners for museums, workshops, and studios at Top3DShop — our experts will help you choose the right equipment, set up a reliable workflow, and support you at every stage of your in-house souvenir and art production.

Update your browser to view this website correctly. Update my browser now

Write a comment