In 2018, Top 3D Shop supplied five 3D printers and two scanners to a national agricultural research institute. The equipment included FDM, SLA, and SLS 3D printers, along with handheld and structured light 3D scanners. By 2020, the lab reported increased reliance on additive manufacturing across its R&D efforts.

The institute advances agricultural engineering and modernizes production by collaborating with a nationwide network of universities and businesses to develop machinery, automation, and robotics.

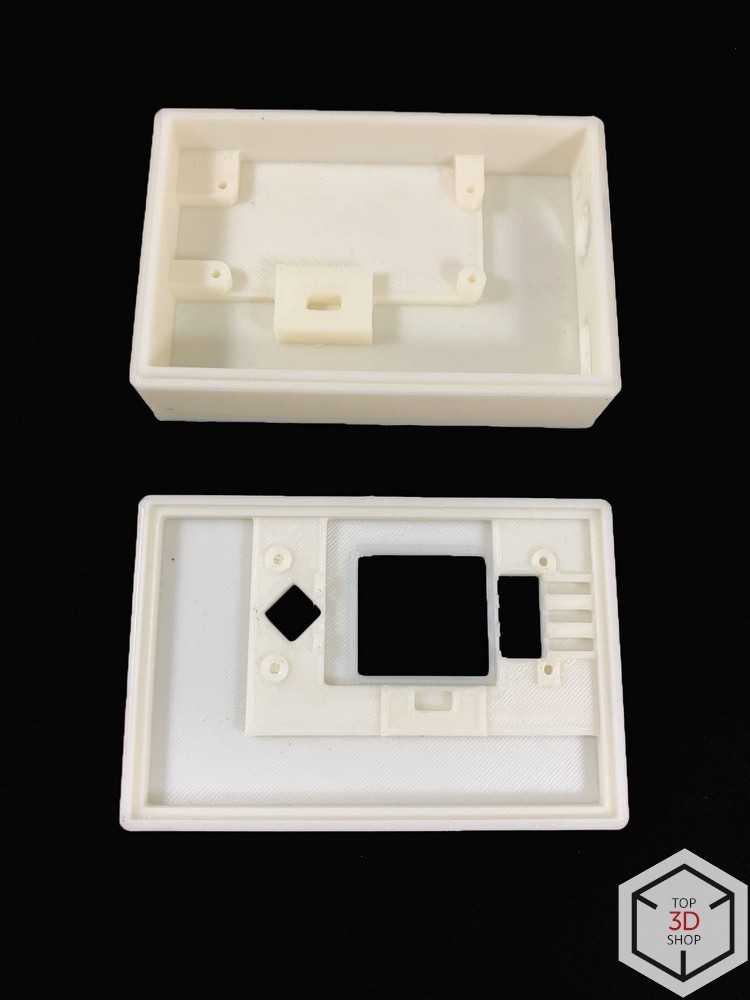

Its core work includes prototyping, diagnostics, repair, electrification, and digital modeling — enabling faster innovation and the creation of components like sensor mounts and precision farming enclosures.

The center also researches materials, surface coatings, and performs functional testing to develop durable agricultural machines. It offers integrated solutions and consulting in mechanization, livestock, crop production, and resource efficiency to support sustainable agriculture.

The center has long focused on prototyping agricultural machinery. Until a decade ago, it relied on metalworking and woodworking, with limited use of polymers. Producing complex polymer parts, such as lids and custom enclosures, was often impractical.

By 2017–2018, the team began exploring new production methods, building on limited experience with small parts and externally made master models later refined in-house.

Several technologies were evaluated, and equipment compatible with durable polymers was chosen due to the need for UV and weather resistance in agricultural machinery.

After thorough market research, the team selected three widely available methods: FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

For rapid manufacturing and prototyping, the team chose two FDM 3D printers: a custom industrial model co-designed with Top 3D Shop and the Epitum 3D printer.

The custom 3D printer was selected for its large build volume (over 500 mm), ability to handle high-temperature polymers, ease of use, and lower cost compared to industrial alternatives like Stratasys Fortus.

It features dual extrusion: one 1.75 mm extruder for standard and high-performance materials (e.g., polycarbonate, PPSU, PEEK, PEKK, Ultem), and a 2.85 mm extruder for faster printing with common plastics like ABS and PETG.

The dual-extrusion Epitum 3D printer was added for small models and prototypes, with a build volume of 200 × 200 × 210 mm.

Cultivator sweep with ripper attachment

Sensor mounting brackets for tractors

Filtering device caps

Sensor brackets and caps

Flow meter mounting lids

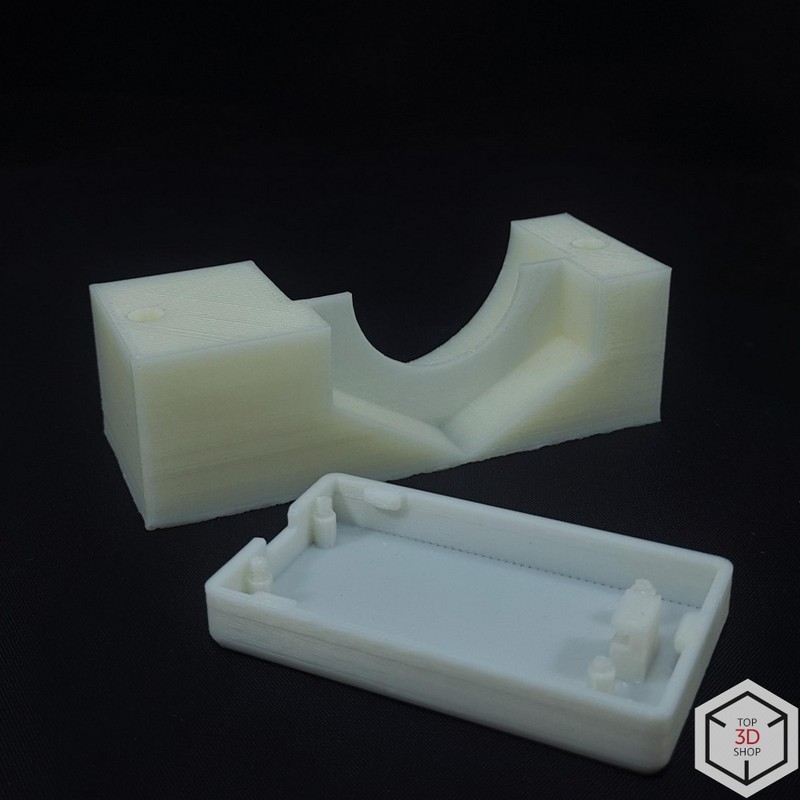

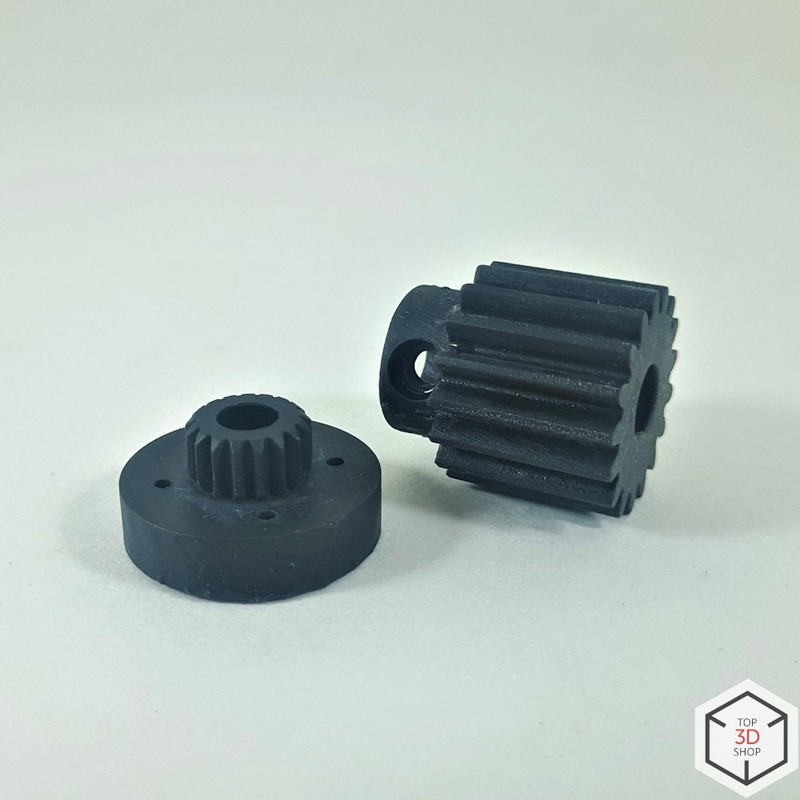

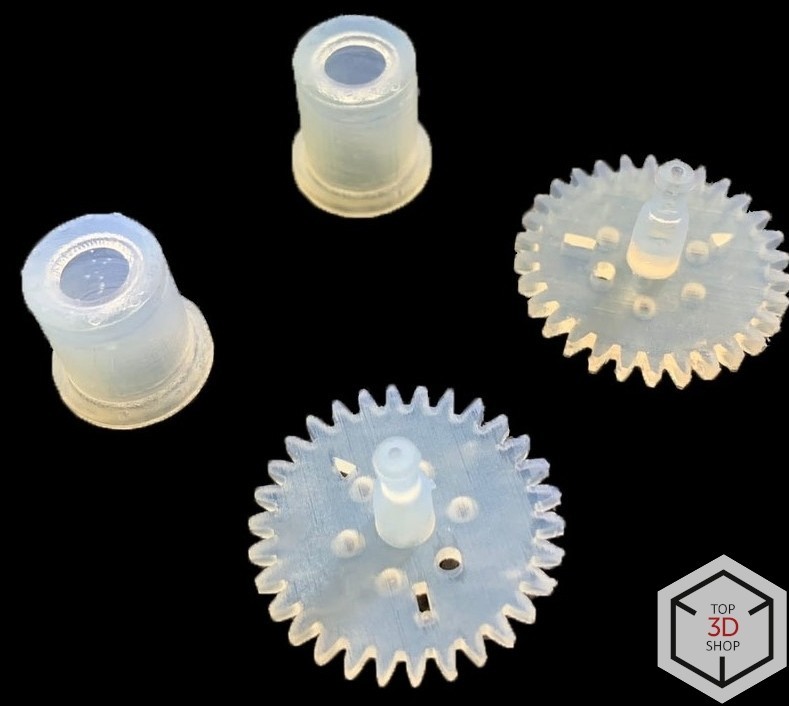

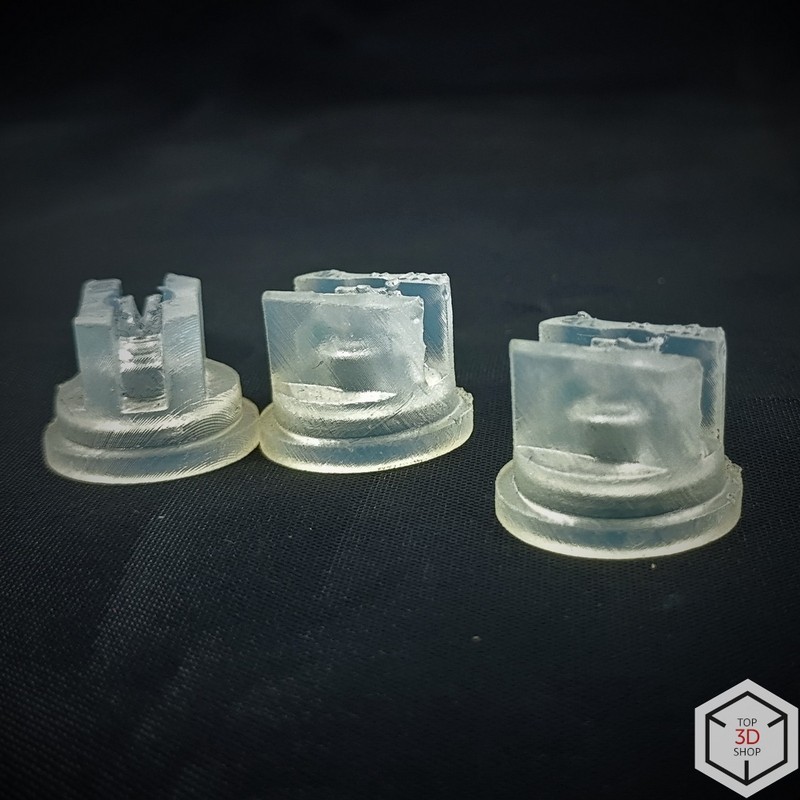

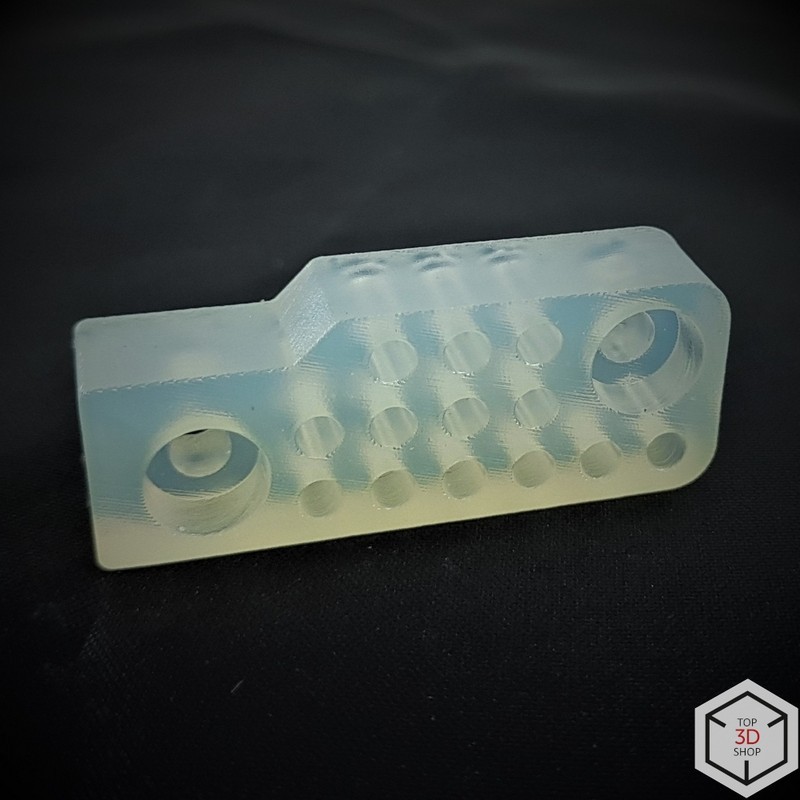

Engineers selected the Formlabs Form 2 SLA 3D printer to produce precise small parts and master models for molding. Its smooth surface finish often eliminates the need for polishing. Examples include worm shafts, fine-module gears, and small cases.

Toothed gears (SLA 3D printed)

TR sprayer caps and toothed gears for pressure regulator drive

Pilot batch of slot sprayers

Master model for polyurethane connector casting

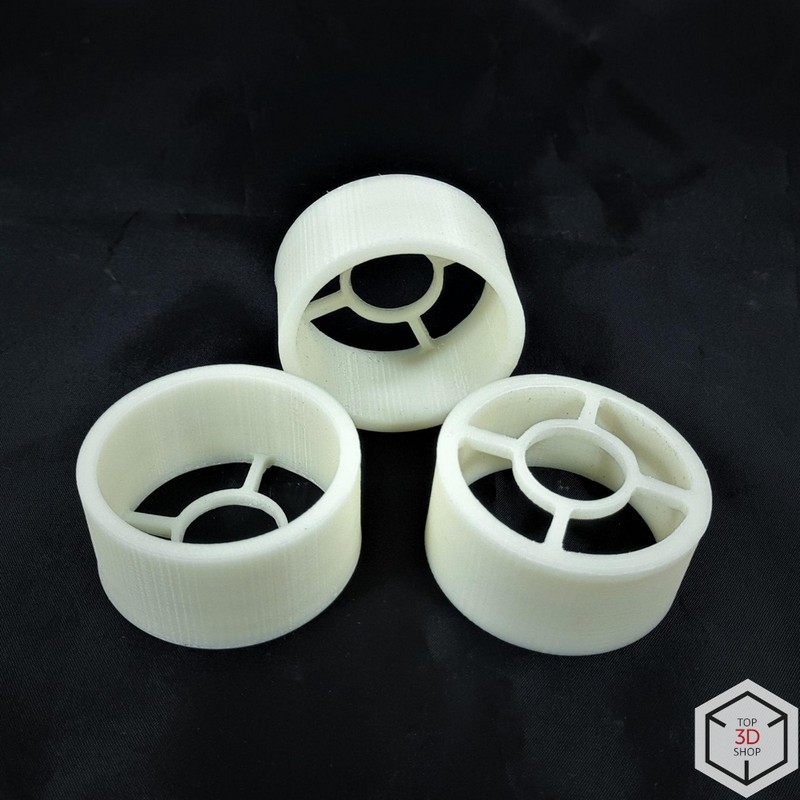

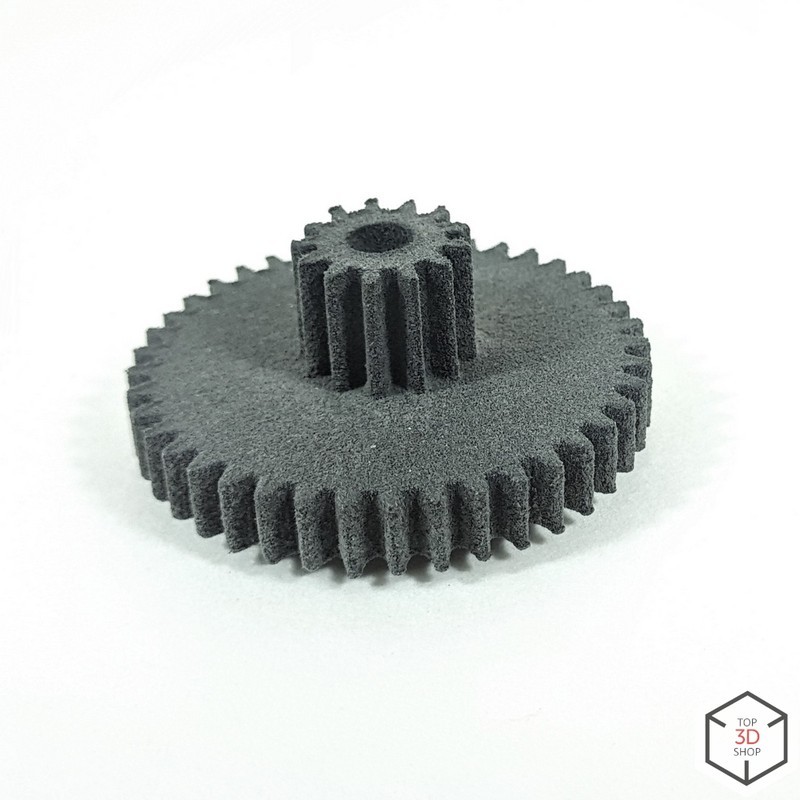

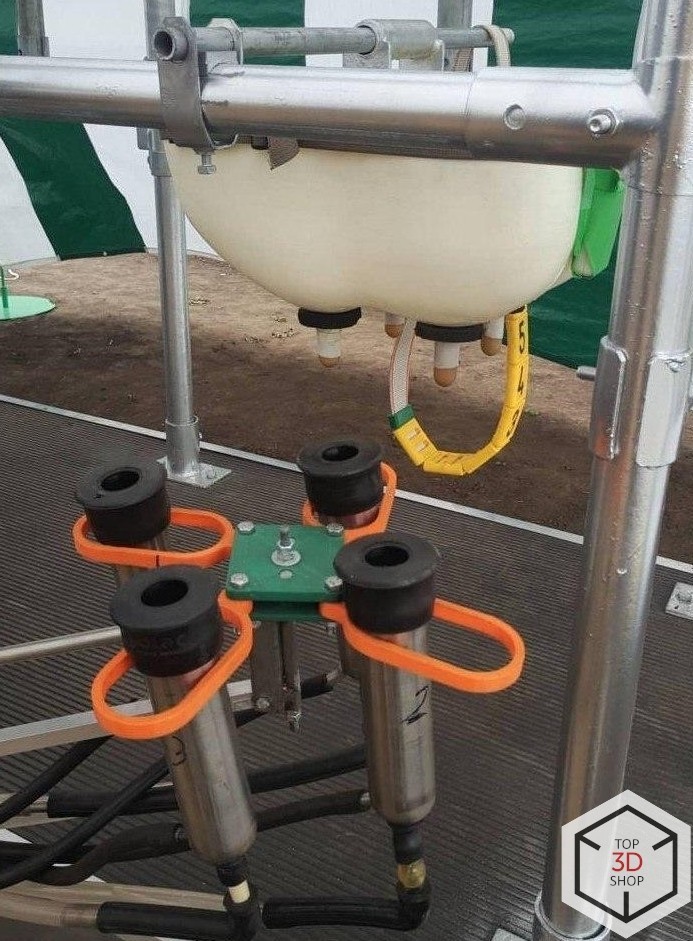

The team chose the Sinterit Lisa SLS (Selective Laser Sintering) printer for its build volume and affordability, selecting it over options like the EOS Formiga. It’s mainly used for functional prototypes of small parts, such as brackets and enclosures that can withstand mechanical loads.

Toothed gear for pump drive

Experimental batch of proximity sensor enclosures

Worm shafts for manipulator hand drive

Engineers estimate that 90% of the lab's work uses FDM, with SLA and SLS each at 5%. SLS usage is rising, with the Sinterit Lisa increasingly used for small pilot batches of functional parts in research testing.

The lab purchased an FLD-35 extrusion line to produce print-ready filament from low-cost granules sourced directly from chemical suppliers. It meets the lab's filament needs and is also used to produce filament for external clients. Engineers have tested it with ABS, SBS, and flexible materials, and plan to produce polycarbonate next.

The filament produced on the FLD-35 extrusion line

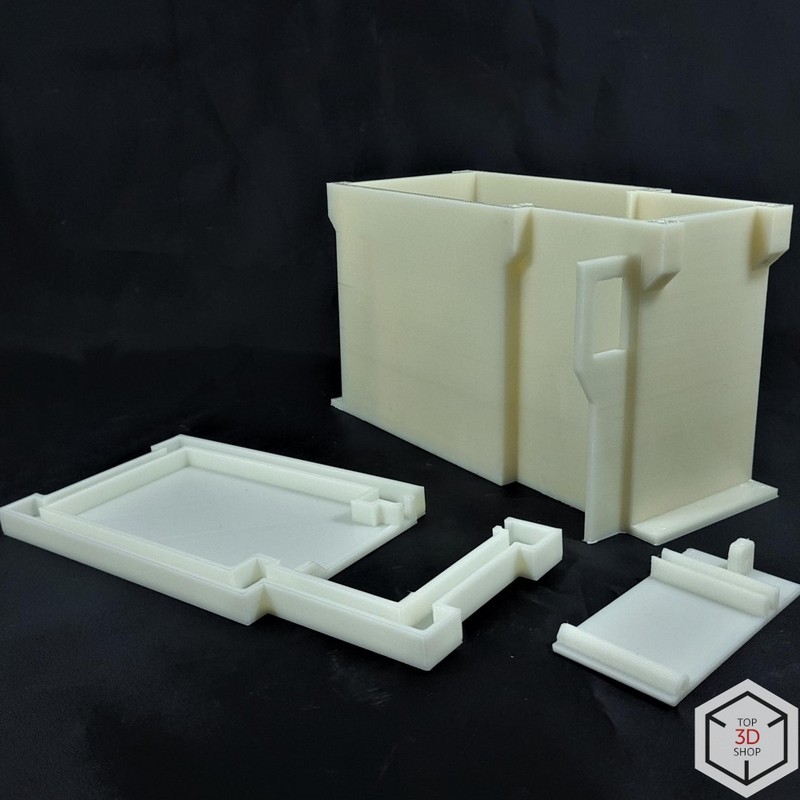

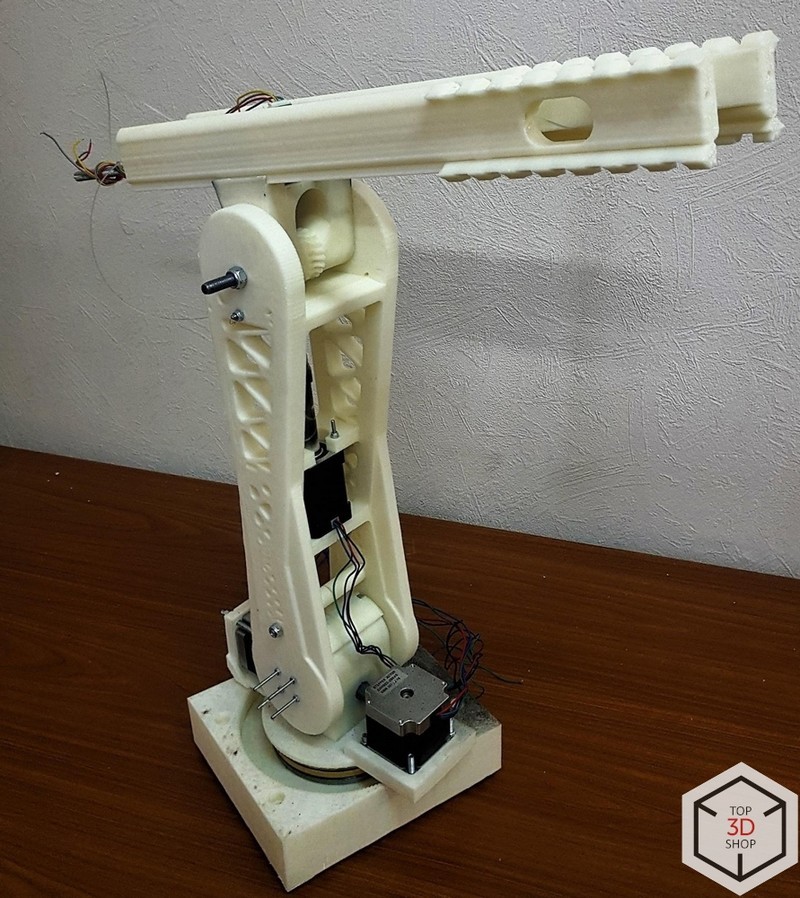

The custom high-temp FDM printer runs 24/7, with a months-long print queue. A second unit was later added. Applications include parts for milking systems, hydrocyclones, and humidifier enclosures.

Projects using FDM include cladding panels and cabinets for environmental chambers.

Parts of the cow milking stanchion

Environmental chamber humidifier enclosure

Hydrocyclone parts

Humidity and pressure control unit enclosure

UAV sensor bracket

Experts print models and prototypes of devices for livestock and crop production. Examples include parts for a milking stanchion test stand and the enclosure for a robotic manipulator.

Parts of the cow milking stanchion

Robotic manipulator hand for crop harvesting

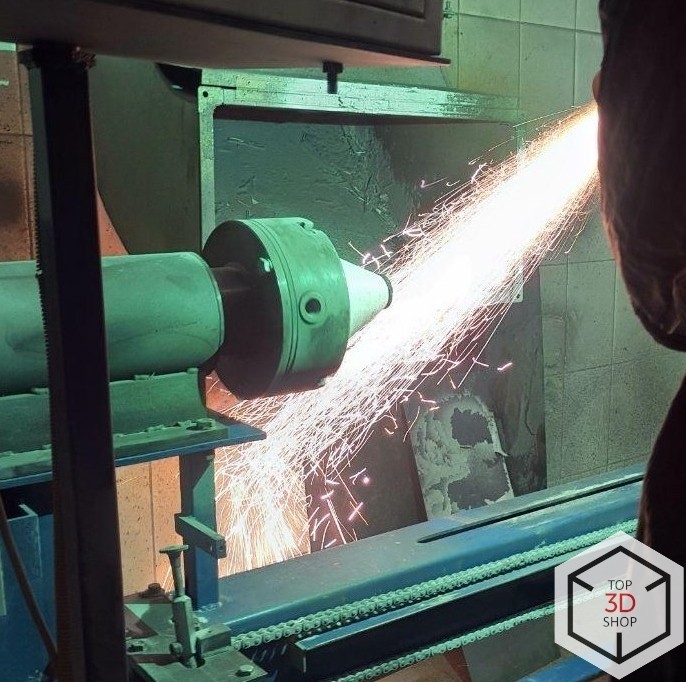

The lab also conducts extensive R&D. One achievement is applying metal coatings to ABS prints from FDM printers, enabling sensor enclosures that block interference.

Shielded sensor enclosure for tractor installation

Metal coating process

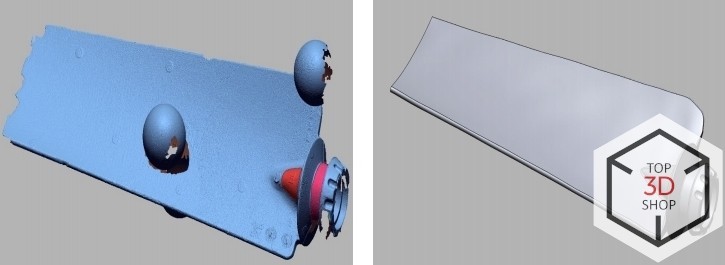

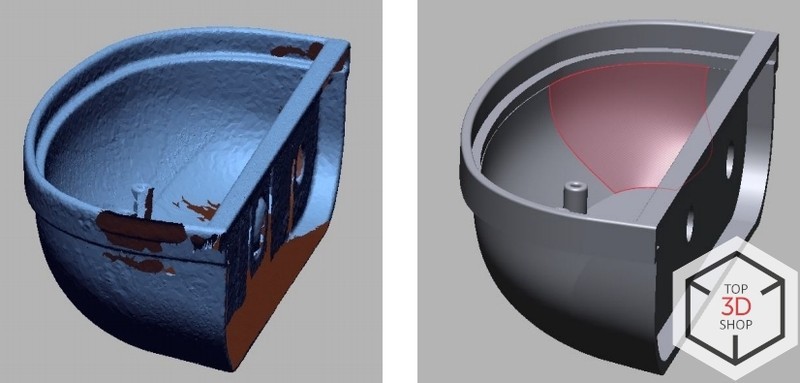

The lab uses the EinScan Pro 2X Plus (SHINING 3D) 3D Scanner for reverse engineering complex parts from older equipment that no longer has design documentation.

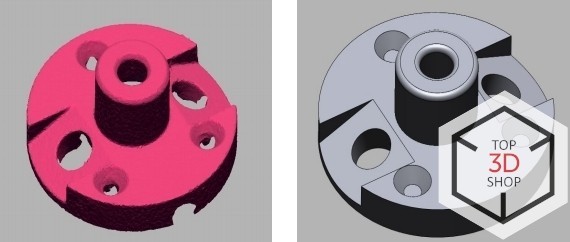

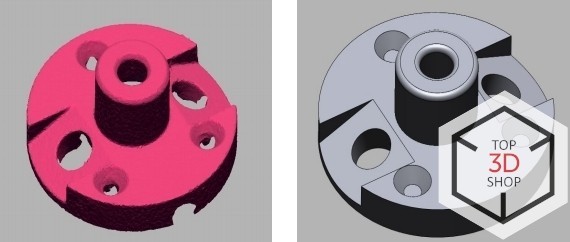

Half of a hub: reverse engineering to create a 3D model from a physical sample (part size up to 0.5 m)

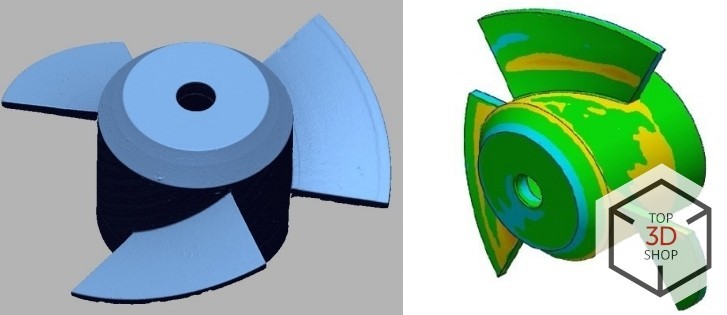

Rotor: geometry inspection and casting-geometry analysis (part size up to 0.5 m)

Metallizer component: reverse engineering to create a 3D model from a physical sample (part size up to 0.5 m)

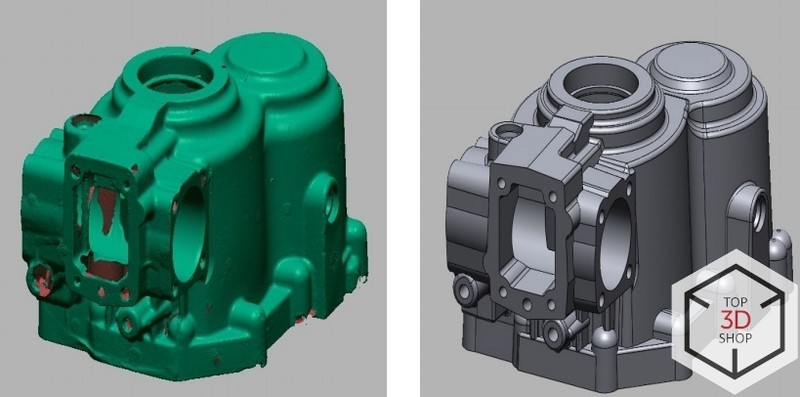

Gearbox enclosure: reverse engineering to create a 3D model from a physical sample (part size up to 0.5 m)

Blade: reverse engineering to create a 3D model from a physical sample (part size up to 0.5 m)

Headlamp enclosure part: reverse engineering to create a 3D model from a physical sample (part size up to 0.5 m)

Lab experts say the scanners are used regularly but infrequently, mainly to recreate drawings for part production. They’re also occasionally used for quality control.

Over two years, the lab reported no major issues with the 3D equipment. Minor problems were resolved in-house or with support.

The Epitum required adjustment due to non-standard nozzles, and initial PLA issues were resolved with manufacturer advice. The custom large-format FDM printer from Top 3D Shop also had minor issues, quickly addressed with quality support.

The Formlabs Form 2 ran problem-free for two years. The Sinterit Lisa required trial and error due to a lack of documentation at purchase.

Vacuum forming will be added soon. The machine supports 1–16 mm plastic sheets, has dual heating zones, and three forming area options (1×2, 2×2, 2×3 meters). It operates in manual and automatic modes. It will be used for commercial and research projects, including large tractor parts like kits and roofs. The lab is also considering a vacuum casting machine.

Additive manufacturing has become integral to the lab’s research. Equipment usage has multiplied, and its capabilities now support core programs. The technology appeals to both seasoned engineers and younger researchers, reflecting its growing role in modern agriculture.

Explore large-format 3D printers and high-accuracy 3D scanners at Top3DShop!

Update your browser to view this website correctly. Update my browser now

Write a comment