3D printing keeps proving its value across a wide range of industries — including the performing arts. This case shows how one creative team used the Raise3D N2 Dual 3D printer to produce elaborate stage costumes, running the machine almost nonstop for weeks at a time.

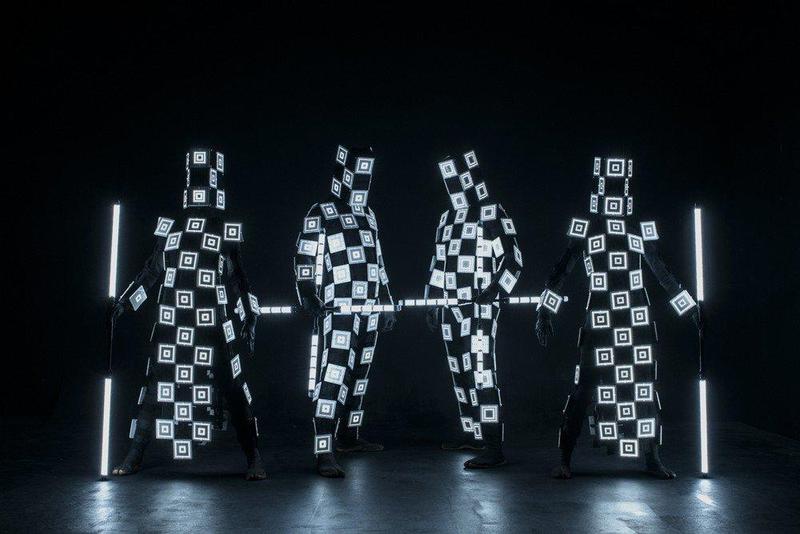

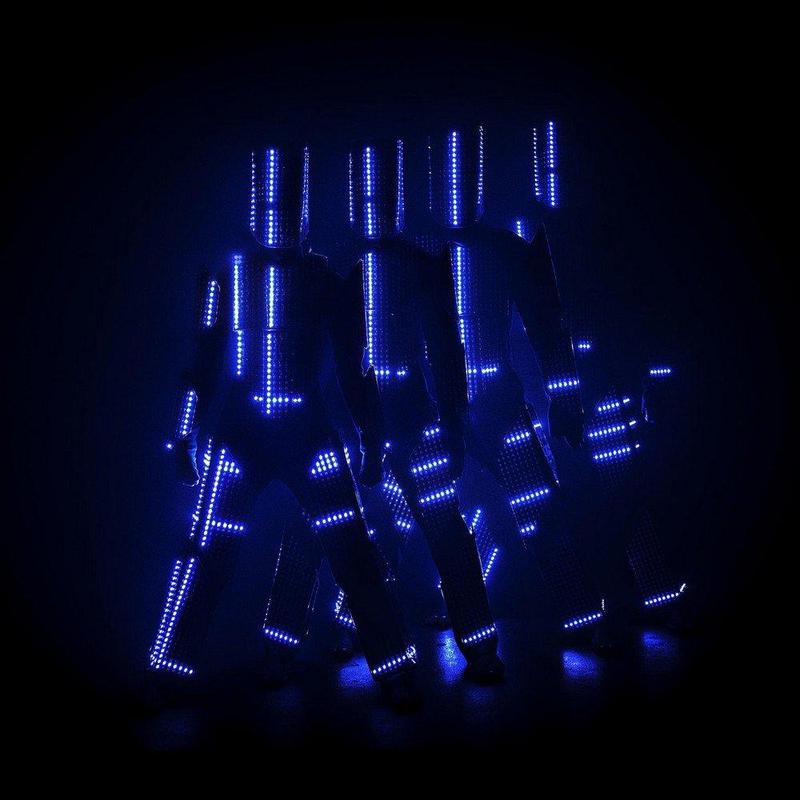

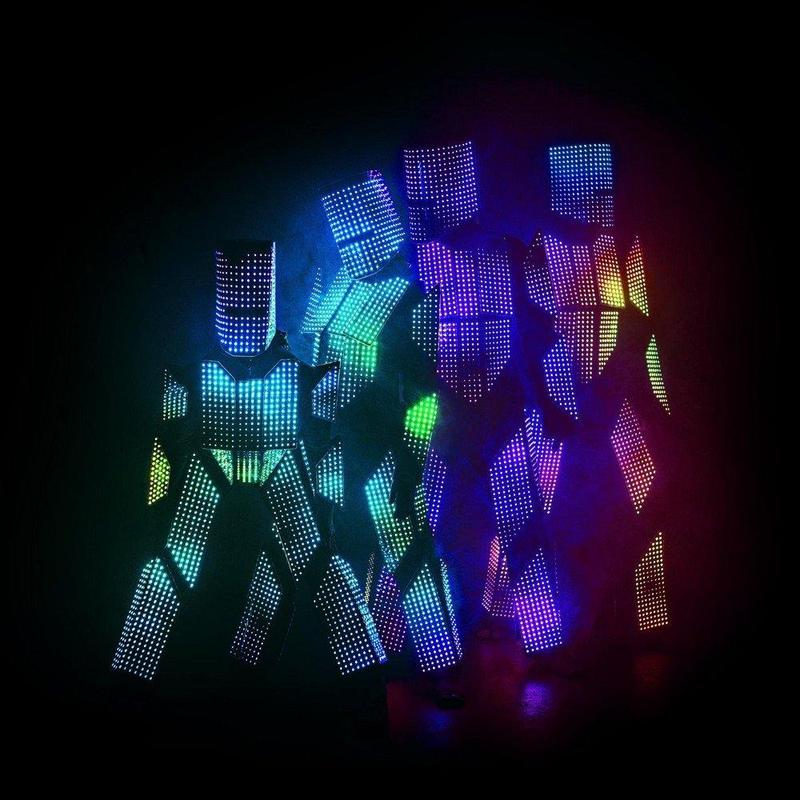

This show team is known for visually striking shows that combine light, mirrors, and fire. Their latest production required highly detailed, custom-made costumes with futuristic shapes and complex forms.

To turn these ideas into real objects, the team chose 3D printing instead of traditional fabrication.

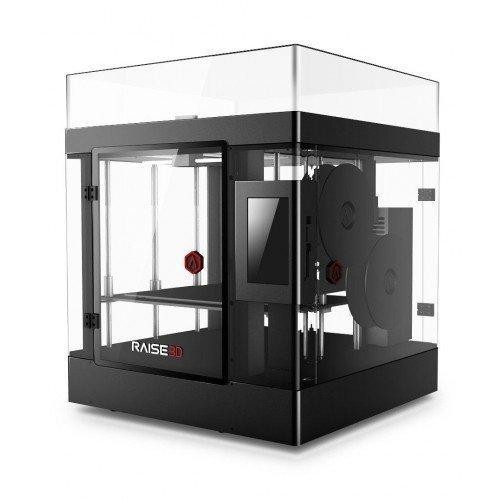

The team chose the Raise3D N2 Dual for its large build volume and high reliability. It allowed them to print complex masks and costume parts with good precision and minimal setup time.

Technical specifications:

Before 3D printing, the team either handmade props and costume parts or outsourced them to workshops. Both options often took a long time and cost a lot.

With in-house 3D printing, the process changed completely. Instead of cutting and combining 2D elements or carving shapes from blocks of material, the team designed parts digitally and printed them directly.

Large pieces still used a similar amount of material as outsourced parts, but the team saved time on delivery, fabrication, and revisions. Overall, 3D printing proved more efficient and gave them greater control.

When they searched for a printer, the team focused on:

Large build volume

Ease of use

Reliability

Strong local support

After consulting with experts at Top3DShop, they expanded their original budget and selected the Raise3D N2 Dual. They prioritized quality, reliability, and service over the lowest purchase price.

Even as beginners, they set up and started using the printer quickly. Its stable performance and print quality soon made it a key tool in their production workflow.

During intensive use, several advantages stood out:

Plug-and-play usability: Minimal setup and straightforward operation

Quiet operation: Can run continuously without disturbing work in the studio

Power loss recovery: Protects long prints from power outages

Professional build quality: Rigid, industrial-grade hardware that inspires confidence

The printer didn’t just produce parts — it also changed how the team worked and learned.

The project director explains:

“To begin with I thought it only had one job — to print stuff — but after a couple of months I realized that it had pushed me to learn 3D modeling and had even become a source of motivation. You see, when your printer is working round the clock for two months straight, you kind of feel like you can’t just laze around and slack off at home. It’s like it’s looking at you the whole time, saying, ‘Hey, buddy, I work day and night and I don’t even get to sleep, so what are you complaining about?’ That’s another big bonus.".

3D printing didn’t just upgrade their costumes; it also encouraged new skills and a stronger production mindset.

No machine is perfect, and the team faced a few issues:

No filament sensor: Once, the feed wheel chewed through the filament while the printer continued to run, resulting in 10 hours of “printing air.”

Build surface wear: The BuildTak sheet wore out quickly. After cleaning it and adjusting bed temperature, adhesion returned to normal.

Despite these minor problems, the Raise3D N2 Dual has remained a dependable tool in daily use, even under near-continuous workloads.

This case shows that 3D printing is not limited to manufacturing or engineering. It fits naturally into performance and entertainment workflows as well.

The team can now:

Produce one-of-a-kind, show-ready costume components

Iterate quickly on complex shapes and fits

Experiment with bold visual ideas without long lead times

Additive manufacturing opens new options for stage design, costume creation, and visual storytelling. With the right 3D printer, even a small creative team can deliver high-impact results on tight schedules.

If you want to bring the same flexibility to your shows, studios, or design projects, consider adding a professional FDM 3D printer to your workflow.

You can explore and purchase reliable 3D printers — including models like the Raise3D N2 series — at Top3DShop, where you get expert guidance, official warranty, and full support for your creative production setup.

Update your browser to view this website correctly. Update my browser now

Write a comment