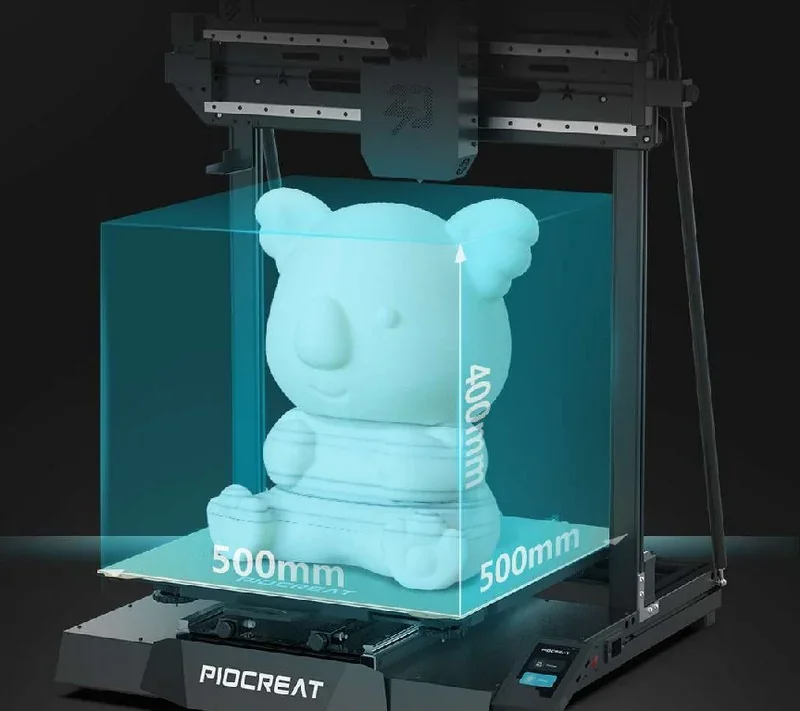

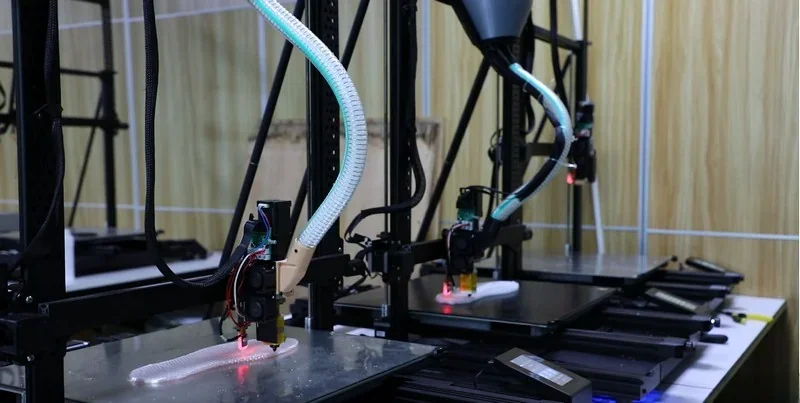

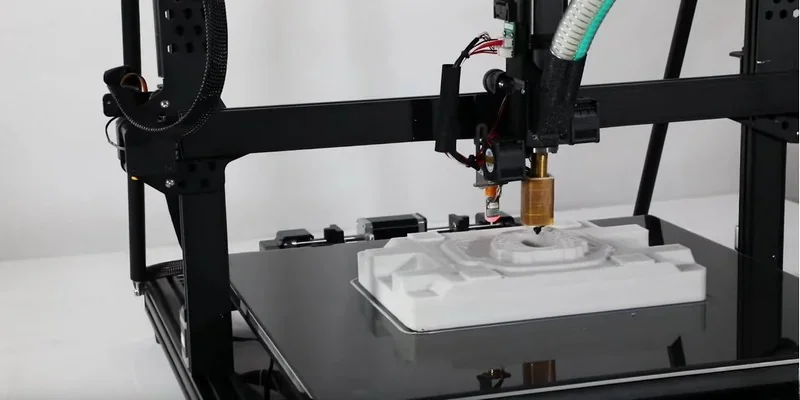

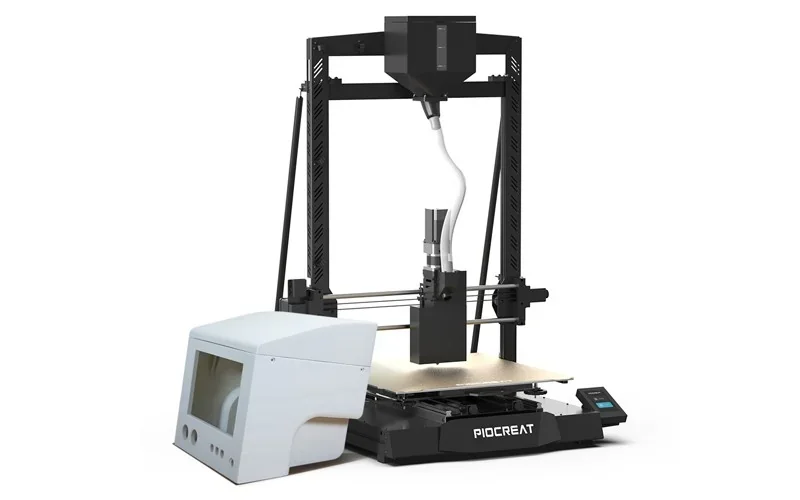

The Piocreat G5 Ultra Pellet 3D Printer uses Fused Granulate Fabrication (FGF) to print with plastic pellets, lowering costs, lead times, and environmental impact. Its screw-type extruder melts pellets from a 3-liter hopper, printing precise layers at up to 260 mm/s within a 500 x 500 x 400 mm build volume. With a 420°C extruder, 0.8 kg/h flow rate, clog-resistant design, auto-leveling, and a magnetic bed for easy part removal, it ensures reliable performance. Compatible with 2–5 mm thermoplastic pellets — including PLA, PETG, ABS, and recycled materials — the G5 Ultra suits architecture, design, mold making, education, and prototyping, with smart features like material sensing, pellet run-out detection, and power-loss recovery.

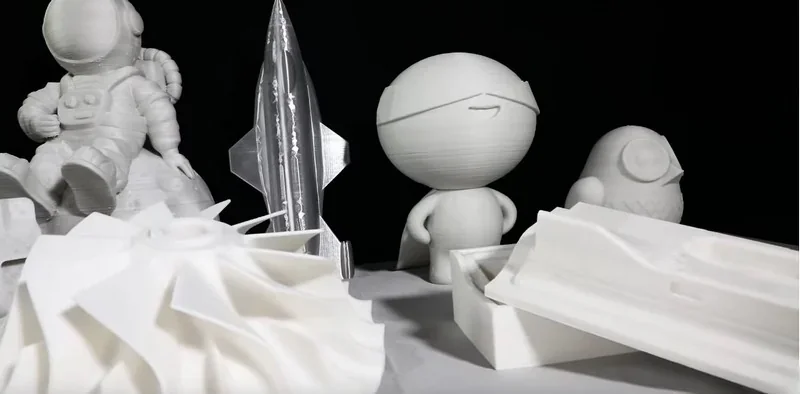

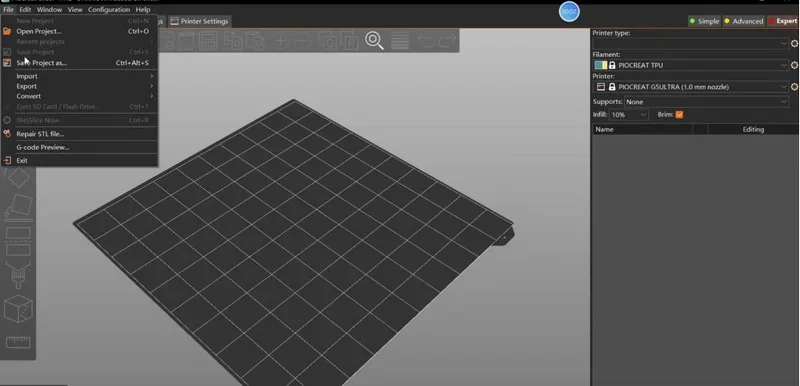

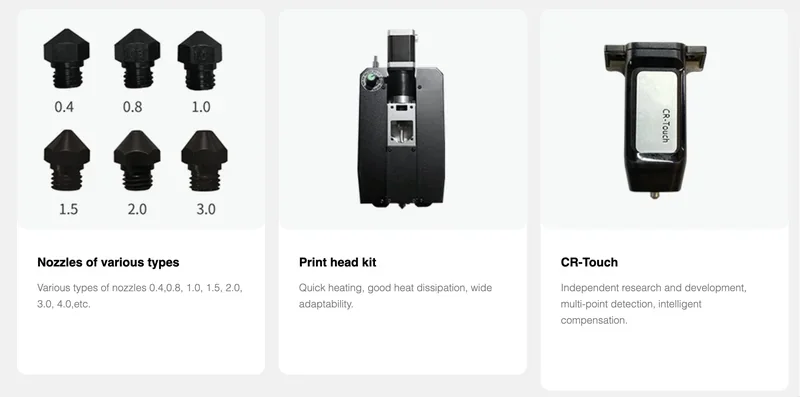

The Piocreat G5 Ultra delivers high print quality with layer thicknesses from 0.2 to 1.0 mm, suitable for detailed work or fast production. Its extruder ensures stable 0.8 kg/h material flow with consistent force. Interchangeable nozzles from 0.4 to 2.0 mm (optional 3.0 mm) offer flexibility between precision and volume. The below example show the shoe slicing and manufacturing process on the Piocreat G5.

The G5 Ultra prints up to 260 mm/s, a major improvement over the original G5’s 100 mm/s. Its dual Z-axis lead screws, tie rods, and metal frame ensure stability and precision at high speeds. Running on Klipper firmware, it also supports advanced features like WiFi for remote monitoring.

The G5 Ultra ensures consistent print quality with automatic and auxiliary bed leveling, a heated bed up to 120°C for ABS materials, and a detachable magnetic steel platform for easy part removal. Its material level sensor detects low pellet levels and resumes printing after refills, preventing interruptions during long jobs.

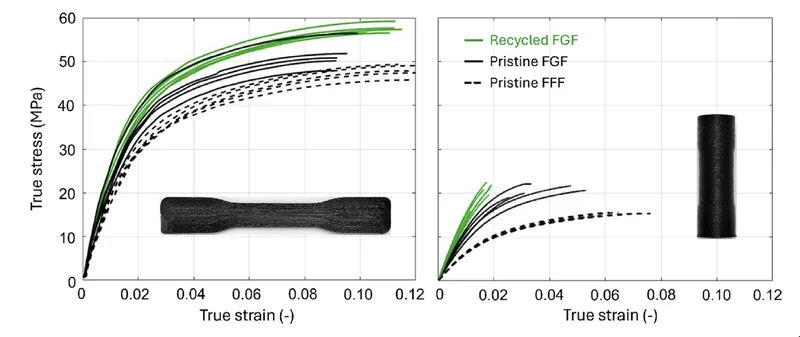

Research Study: Researchers at Politecnico di Torino found that printing PA12 with 10% short carbon fibers using a PioCreat G5 Pro (FGF) from pellets or recycled flakes results in denser microstructures, less porosity, and up to 20% higher tensile strength than comparable filament-based parts.

Study: “Recycling a carbon fiber-reinforced polyamide through 3D printing: A mechanical and physicochemical analysis.” Bandinelli, F.; Tito, E.; Parisi, E.; Peroni, L.; Scapin, M. (2025)

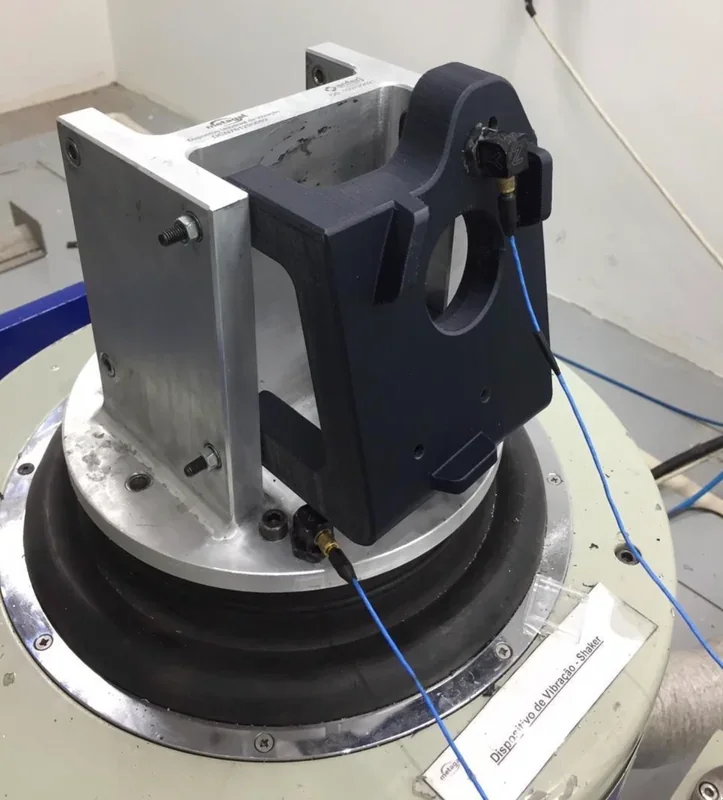

Research Study: Researchers at Universidade Federal de Itajubá (UNIFEI) showed that a PioCreat G5 (FGF) can pellet-print PA6 + 20% CF and ePA6 + 25% CF mirror-adapter prototypes that are far cheaper (≈ 89–93% cost reduction) than machined Al 6061-T6 and exhibit first modal frequencies of ~827–879 Hz (vs. ~1105 Hz for aluminum), though still ~12–17% below a >1 kHz target.

Study: “Análise de viabilidade estrutural e financeira para a troca de peças usinadas por impressas em um dispositivo de retrovisão.” Pereira, M. C.; Barbosa, T. T.; Papandréa, P. J. (2023). Journal of Open Research (ISSN 2675-293X).

Bending Tests on the TPU, PP and PA Parts:

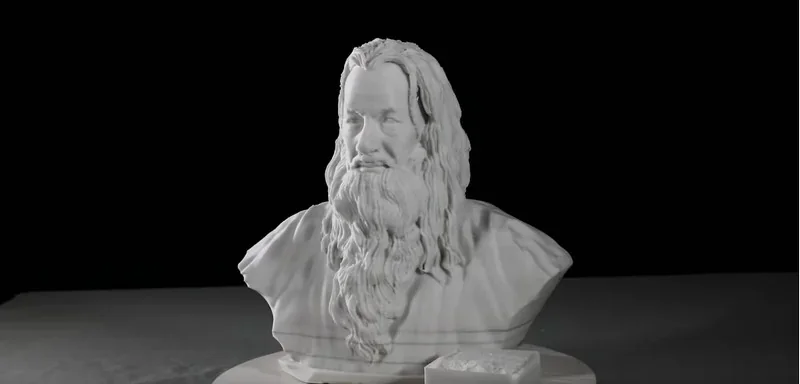

3D Printed Sample:

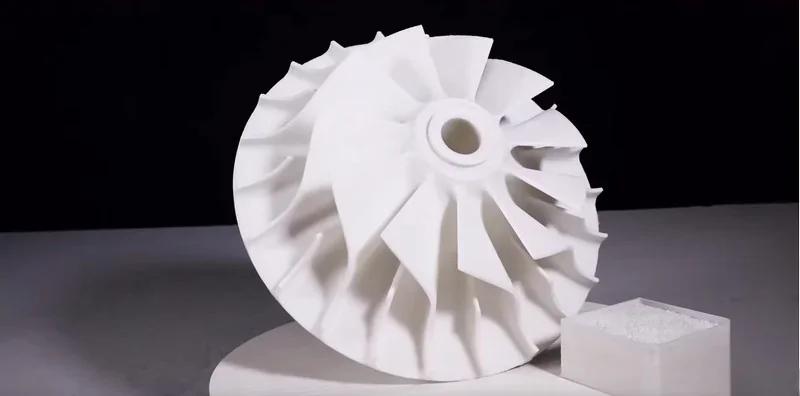

3D print sample: Impeller

The Piocreat G5 Ultra FGF 3D printer supports 2–5 mm plastic pellets, handling both standard and engineering-grade materials with its 420°C high-temperature extruder. Compatible pellets include PLA, rPLA, PETG, ABS, PP, TPU, TPE, and fiber-reinforced composites like PA-CF, PC-CF, PLA-CF, PETG-GF, PP-GF, GPPS. Piocreat 3D handles both brand-new and recycled plastic.

The G5 Ultra prints with both virgin and recycled pellets, including flakes and regrind, supporting sustainable, circular manufacturing. By skipping filament production, it cuts material costs by 60–90% and reduces environmental impact through spool-free printing and plastic waste reuse.

The G5 Ultra’s pellet system enables fast material changes and multi-material printing within a single project. Users can customize colors by adding masterbatch to pellets. Its 3-liter hopper ensures steady supply, while a material sensor pauses printing when pellets run low and resumes seamlessly after refilling, preventing waste and print failures.

PLA 3D print sample: 250 x 185 x 295 mm Koala 3D printed in 15 hours (with a 0.8 mm nozzle)

PLA 3D Print Sample: Pumpkin

TPU 3D print sample: Shoe sole

TPU 3D Print Sample: A Plastic Bag

ABS + 20% CF 3D print sample: Arm splint

Polypropylene 3D Print Sample: 617g Arm Protector produced in 90 minutes.

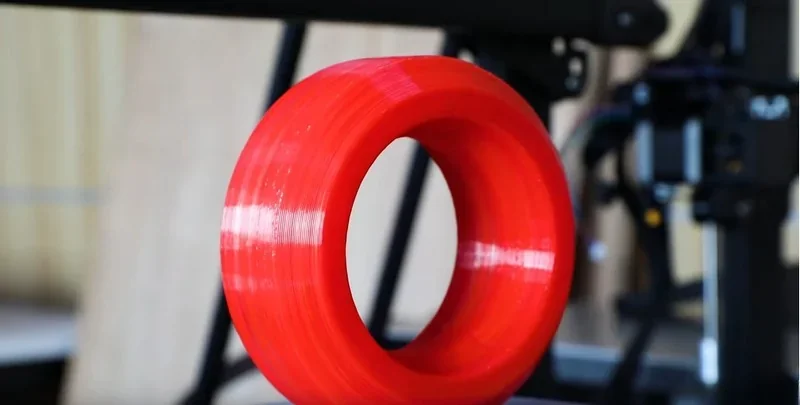

TPU 3D print sample: V-wheel

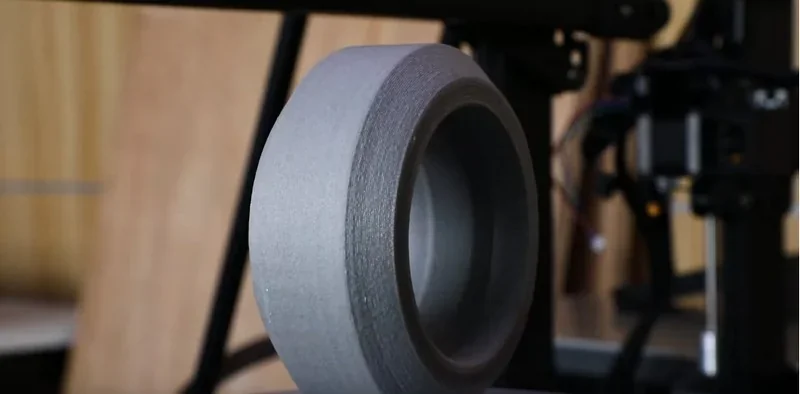

PP 3D print sample: V-wheel

PA 3D print sample: V-wheel

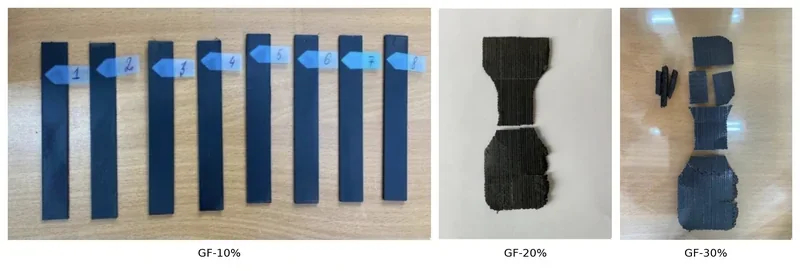

Research Study: Satbayev University researchers found that 10% glass-fiber composite printed well on a PioCreat G5 FGF system, while 20–30% GF led to defects due to increased solids and reduced binder, which weakened matrix-filler adhesion. GF-10% parts reached ~81 MPa tensile strength at 270 °C, 0.3 mm layers, and 100% infill.

Study: “The influence of technological factors of 3D printing on the strength of standard details made of glass-filled polymer composite.”, Abilezova G., et al (2024)

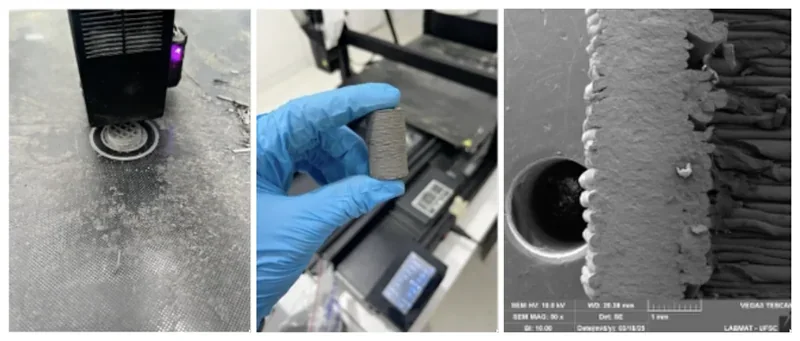

Research Study: Researchers at Universidade Federal de Santa Catarina used a Piocreat G5 with a screw extruder and metal-MEX process to print carbonyl-iron feedstock with PP/EVA/paraffin binders. After debinding and sintering, they produced dense, hermetically sealed metal parts with stable, closed cavities.

Study: “Controle de Porosidade Comunicante em Peças Metálicas Ocas Produzidas via Manufatura Aditiva (MEX).”, Dorneles, L. C. (2025).

The G5 Ultra offers a large 500 x 500 x 400 mm build volume for printing big models or multiple parts at once. Despite its capacity, it has a compact 765 x 890 x 1040 mm footprint, making it suitable for workshops, labs, and home studios.

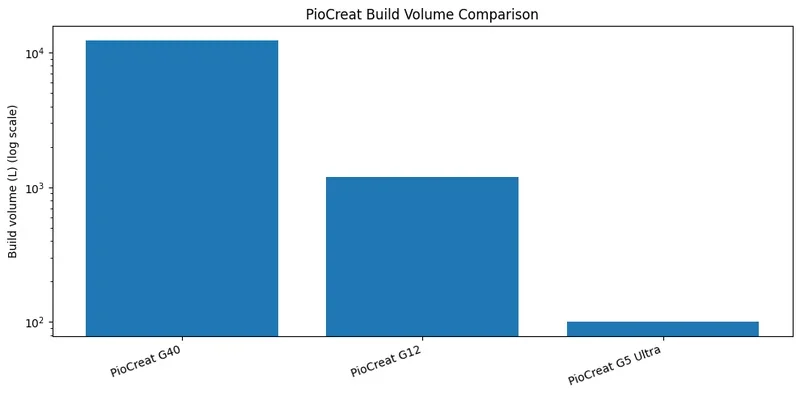

All support high-temp printing (420–450 °C nozzles, 120–130 °C beds) and 2–5 mm pellets. Key differences lie in size, throughput, and power: choose G5 Ultra for agile R&D, G12 for serious scale-up, and G40 for monolithic builds with in-line finishing.

| Feature | PioCreat G5 Ultra | PioCreat G12 | PioCreat G40 |

|---|---|---|---|

| Build Volume | 500 × 500 × 400 mm | 1200 × 1000 × 1000 mm | 3725 × 2500 × 1330 mm |

| Material Flow Rate | ~0.8 kg/h | ~3 kg/h | ~25 kg/h |

| Max Nozzle Temp | ≤ 420 °C | ≤ 450 °C | ≤ 450 °C |

| Bed/Workbench Temp | ≤ 120 °C | ≤ 130 °C | ≤ 120 °C |

| Nozzle Diameter Range | 0.4–2.0 mm (kits: 0.8/1.0/2.0) | 0.6–4.0 mm | 3–8 mm |

| Layer Height | 0.2–1.0 mm | 0.2–1.5 mm | 0.2–1.0 mm |

| Printing Speed | up to 220 mm/s | 80–100 mm/s | — |

| Pellet Size | 2–5 mm | 2–5 mm | 2–5 mm |

| Rated Power & Voltage | 1450 W, AC100–240 V | 7000 W, AC220 V | 65 kW, — |

| Machine Size | 765 × 890 × 1040 mm | 2135 × 1775 × 2305 mm | 5962 × 4220 × 4800 mm |

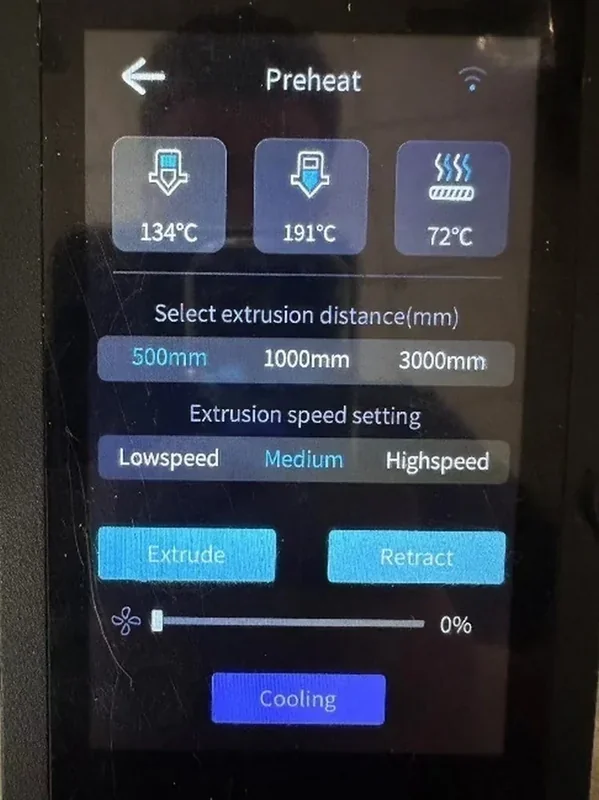

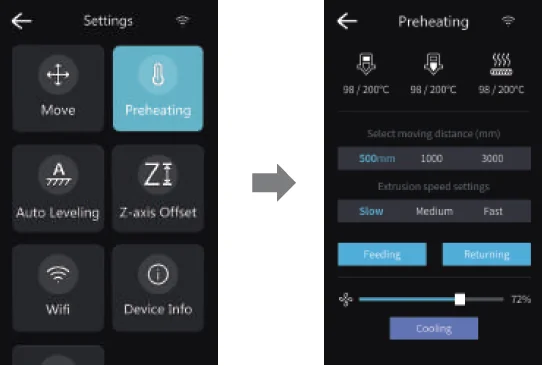

Physical Controls (3 categories):

Touchscreen Controls (6 main interfaces):

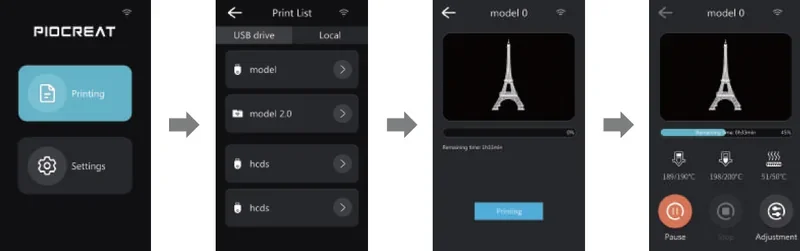

Starting a Print Job Interface:

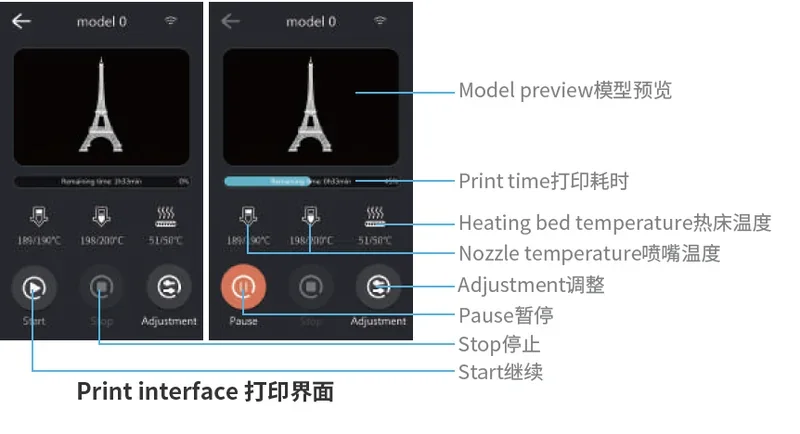

Print Interface Overview:

Adjustment Panel During Printing

Z-axis Offset:

Print Speed:

Extrusion Flow:

Fan Speed: Adjustable via slider at the bottom.

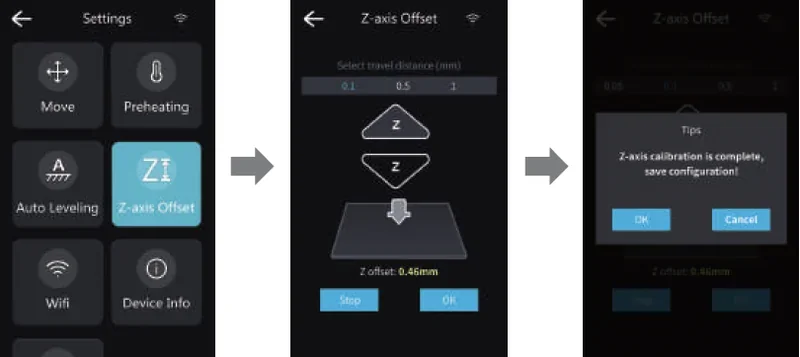

Z-Axis Offset Adjustment Interface

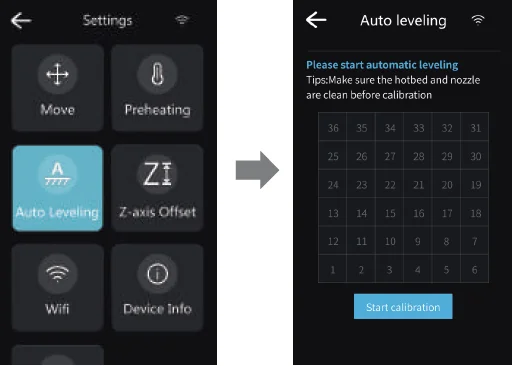

Auto-Leveling Interface

Preheating Menu Interface

The G5 Ultra offers USB, WiFi, and Ethernet for file loading and networked printing. Files can be loaded via USB without a computer. Built-in WiFi supports wireless transfers and real-time monitoring.

The G5 Ultra includes Piocreat Slicer (supports STL, OBJ, AMF) with essential editing tools and is compatible with Cura and Simplify3D. Now powered by Klipper, it offers wireless transfers, real-time monitoring, and better performance than the original G5. A Dragon slicer license is also included, enabling simulation-based slicing, auto speed adjustment, and access to 40+ material profiles for reliable pellet printing.

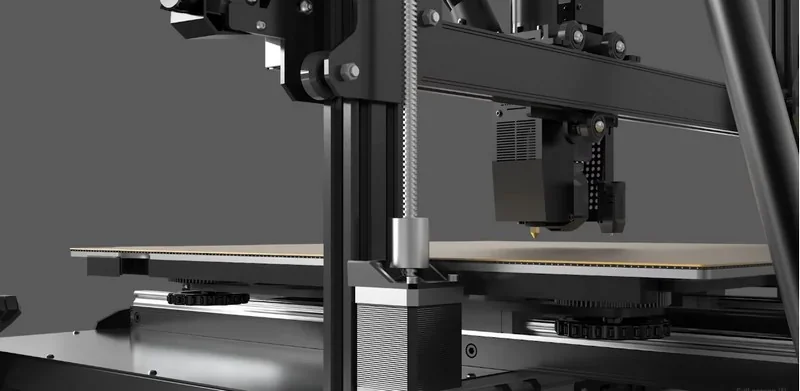

The G5 Ultra has an open-frame gantry made of sheet metal and aluminum, with tie rods and support feet, but no full enclosure. It offers a 500 x 500 x 400 mm build volume.

The G5 Ultra uses a Cartesian bedslinger motion system: belt-driven X and Y (the bed moves in Y), with two Z motors driving T-type lead screws to lift the gantry; guidance uses X- and Z-axis sliding-roller carriages with an X-axis beam guide, and the machine includes linear slides that require periodic lubrication.

The G5 Ultra features a heated glass build platform with a max temperature of 120°C. It can be manually leveled using knobs and supports automatic leveling via the CR-Touch Auto Leveling Kit.

The G5 Ultra uses a single-nozzle FGF extrusion system with a screw motor to process 1.0–5.0 mm pellets. Its hotend has upper and lower heating zones reaching 360°C and 420°C. Standard nozzle sizes include 0.8 mm, 1.0 mm, and 2.0 mm.

The G5 Ultra features a 3L hopper for a steady material supply and a sensor that alerts users when to refill. If pellets run out, printing pauses, sounds a warning alarm, and resumes from the same point after refilling. Pellets are loaded into a hopper on the print head and fed to the extruder via a tube.

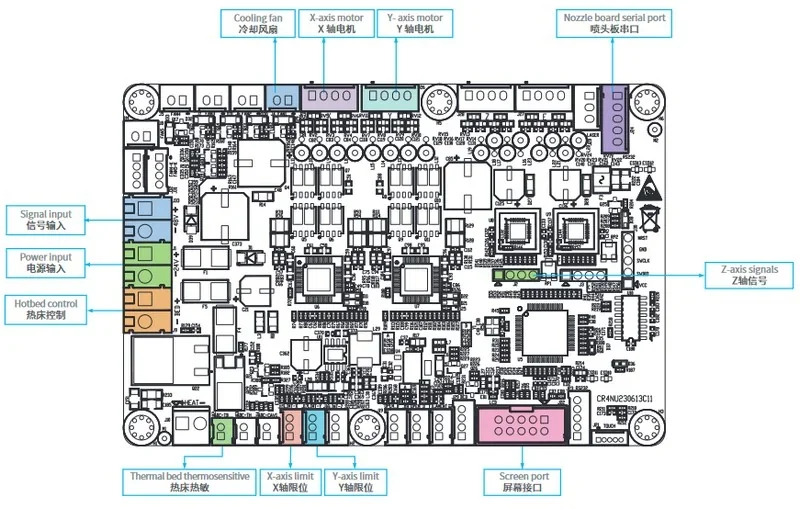

The G5 Ultra's electronics are enclosed in a motherboard power box. The manual does not specify the mainboard model, manufacturer, MCU type, or expansion features.

he G5 Ultra uses a 1450 W power supply with an input of AC 100–240 V, 50/60 Hz and a DC 24 V output. It requires a grounded three-prong outlet and the included power cord.

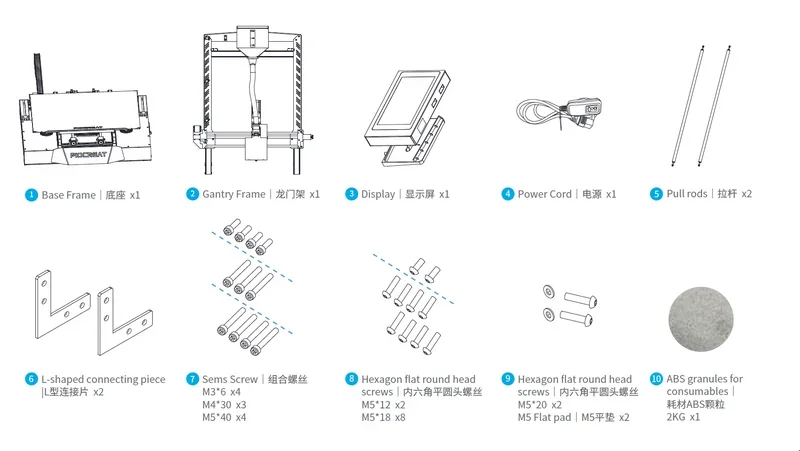

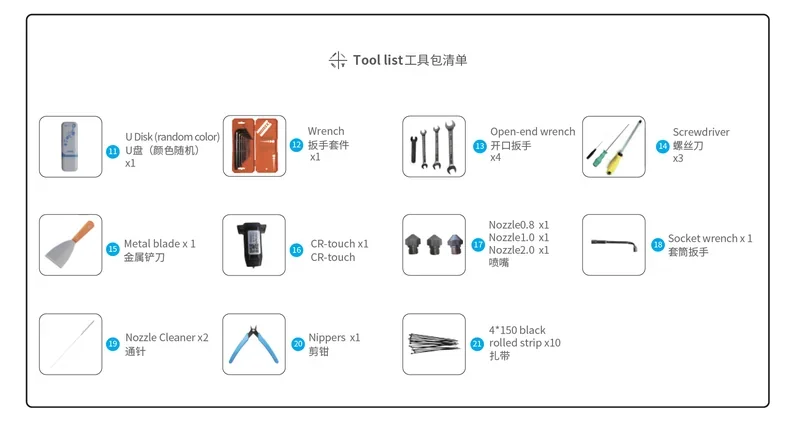

Assembly state: Partially assembled kit — you assemble the gantry to the base, mount the display and feed tube, install the two side pull-rods, and connect the cables before use.

Assembly state: Partially assembled kit — you assemble the gantry to the base, mount the display and feed tube, install the two side pull-rods, and connect the cables before use.

Note: Package contents may vary. Contact a Top3DShop sales representative to confirm included items before ordering.

Piocreat supplies over 7 additional parts.

| Name | Functionality |

|---|---|

| Additional Nozzle Sizes | Expands nozzle diameter options beyond standard set |

| Print Head Kit | Replacement/upgrade for hotend assembly |

| CR-Touch Enhanced | Advanced multi-point bed detection system |

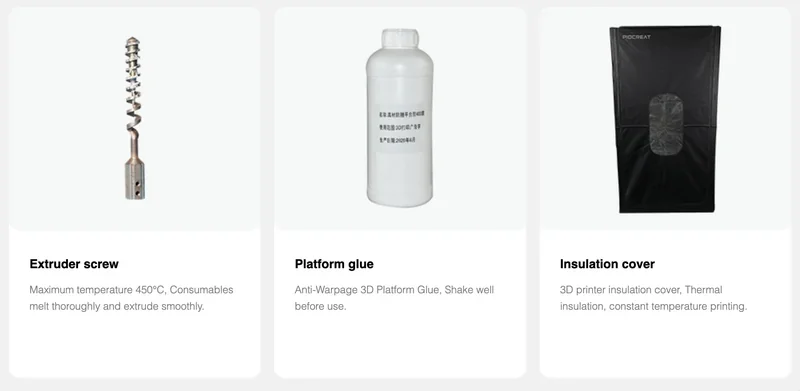

| Replacement Extruder Screw | Spare/replacement screw for material extrusion |

| Additional Platform Glue | Extra adhesive for bed preparation |

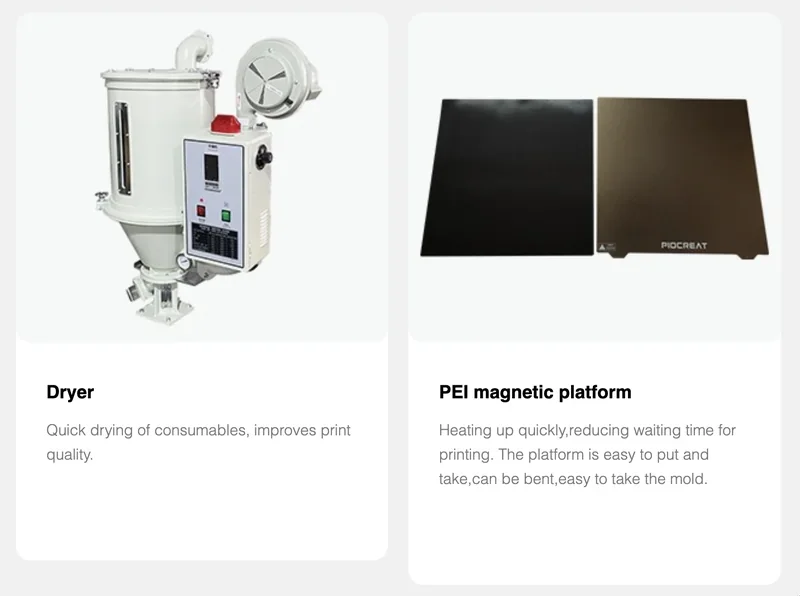

| Material Dryer | Pellet moisture removal for improved print quality |

| PEI Magnetic Platform | Flexible sheet to lift, bend, and pop prints off |

Adds nozzle sizes beyond the standard 1.2mm–4.0mm, including 0.4mm, 0.8mm, and 1.0mm for finer detail.

Replacement printhead with fast heating, efficient cooling, and broad material compatibility for consistent extrusion.

Advanced bed leveling uses independent multi-point detection and smart compensation for higher accuracy than standard methods.

High-temp extruder screw rated for 450°C, ensuring full material melting and smooth, consistent extrusion.

Anti-warpage adhesive for large prints, improves bed adhesion on tough materials; shake well before use.

Dedicated drying system for removing moisture from thermoplastic pellets, improving print quality by eliminating moisture-related defects such as bubbling and poor layer adhesion.

PEI build plate heats quickly to cut wait time. The removable, flexible sheet lets you lift, bend, and pop prints off easily.

The G5 Ultra requires 4 main maintenance procedures to ensure smooth operation and extend component lifespan.

Every 3 months:

As needed during or after use:

Piocreat 3D includes a 1-year limited warranty covering workmanship defects from the purchase date, with proof of purchase and serial number required for claims. Piocreat offers lifetime technical support, including USB setup videos, online resources, and direct help via after@piocreat3d.com or Top3DShop’s support team.

Support guide: https://www.piocreat3d.com/3d-printer-user-guide/

The Piocreat G5 Ultra is is priced at $5,499.00. It offers industrial-grade pellet 3D printing with a 500×500×400 mm build volume, 420°C nozzle temperature, and 0.8 kg/h material flow rate, supporting engineering thermoplastics like PA-CF, PC-CF, and recycled pellets. Contact Top3DShop for a personalized quote.

Update your browser to view this website correctly. Update my browser now