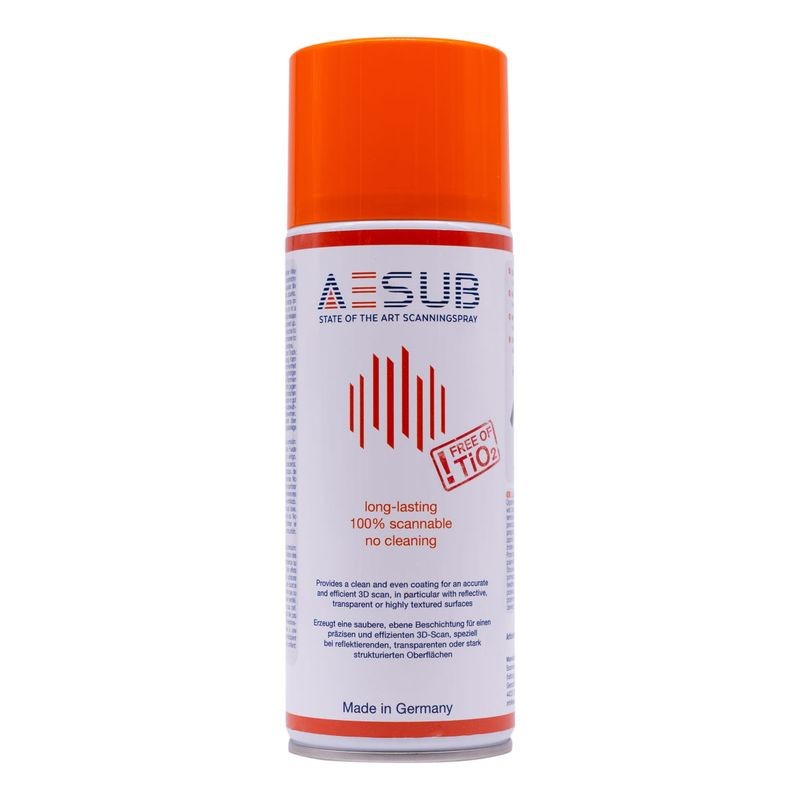

The AESUB company offers a line-up of scanning sprays that greatly add to the efficiency of the 3D scanning process. Most 3D scanners have problems capturing challenging surfaces, such as reflective, transparent, or dark-colored objects. In such cases using mattifying spray is the best solution. All AESUB sprays are free of TiO₂ which is a common additive for such products but can be potentially harmful to health.

The AESUB Orange is a vanishing type of scanning spray with much longer sublimation time than the universal AESUB Blue. Combined with the layer thickness of only 2–6 microns, this allows using the AESUB Orange for scanning projects requiring high precision and in cases when a longer time is needed to capture the object. The spray is applied to the surface to be scanned from a 15–20 cm distance in even, back and force strokes. After complete drying which usually takes up to 2 minutes, a white, matte coating is formed, and you can start scanning. The use of mattifying spray significantly improves scan quality and allows reducing scanning time. Within 12–24 hours the coating vanishes, leaving no residue and eliminating the need for tedious clean-up. There are several factors influencing the sublimation time, such as the ambient temperature, airflow, surface material and structure, and the thickness of the layer applied.

The AESUB Orange does not contain pigments which allows it to be used anywhere without the risk of contaminating the scanning area and equipment. Another advantage of using the spray is the possibility to stick reference markers on the coating. The application range of the AESUB Orange scanning spray is extremely wide, including metrology, reverse engineering, or surface inspection in numerous industries, such as automotive, aerospace, architecture, art and design, and a lot more. The spray is perfectly fit for highly precise 3D scanning of various-sized objects.

Update your browser to view this website correctly. Update my browser now