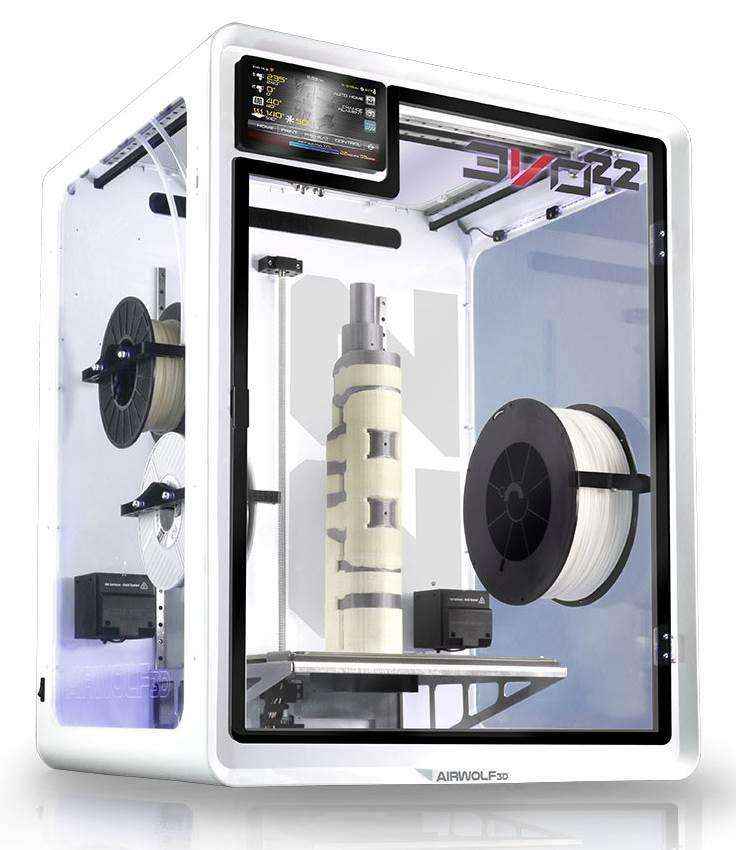

The EVO 22 Large 3D Printer/Additive Manufacturing Center is an FDM professional 3D printer. With a rugged unified frame made of aluminum and a sturdy CoreXY linear-guide-based motion system, the printer provides extreme precision and high print speed without requiring further maintenance. Despite its heavy-duty design, the EVO 22 can be easily transported thanks to its lightness. The printer is equipped with dual high-flow extruders and multiplied-force hotends able to speed up the printing process while ensuring an optimized material deposition rate. It shows an oversized, enclosed print area of 305 x 305 x 578 mm optimized for producing large, end-use parts. It offers industry-leading features, including auto-leveling and calibration, air filtration, print recovery, and more. The proprietary Tri-heat technology introduces two internal chamber heaters and a heatable bed, which can heat up to 160°C. The high-temperature hotend completes the offering allowing for complex material printing. In addition, an Integrated Filament Drying System favors optimal printing conditions. The EVO 22 can print with over 40 materials, from standard filaments to soluble and functional ones. The air cleansing system limits toxic emissions making the machine ideal for school and small spaces. The device is successfully used in prototyping and small-scale manufacturing to fabricate usable parts or production-ready components. For example, it was used to print jigs, fixtures, engineering prototypes, real-scale figures and sculpts. Read the review to find out more.

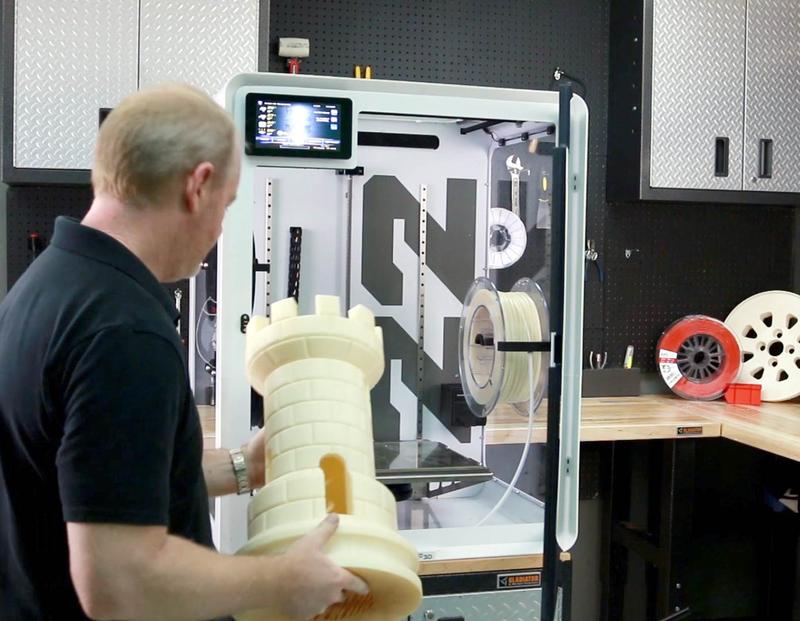

This large print is part of a cement hopper. It has been created using MG94 premium ABS filament. It is precise and flawless. No warps or strings are visible.

Credit: @airwolf3d / instagram

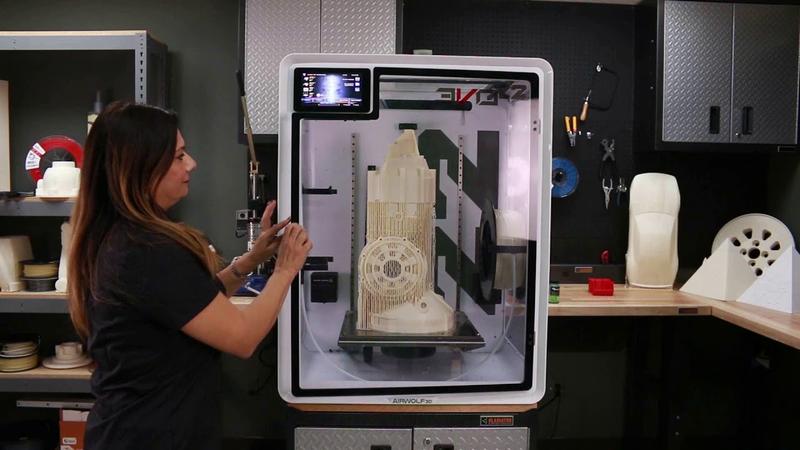

The Omega Skin pictured took more than 100 hours of printing. It has been made with 6 pounds of ABS filament and a precise setting. Look how neat it is.

Credit: @airwolf3d / instagram

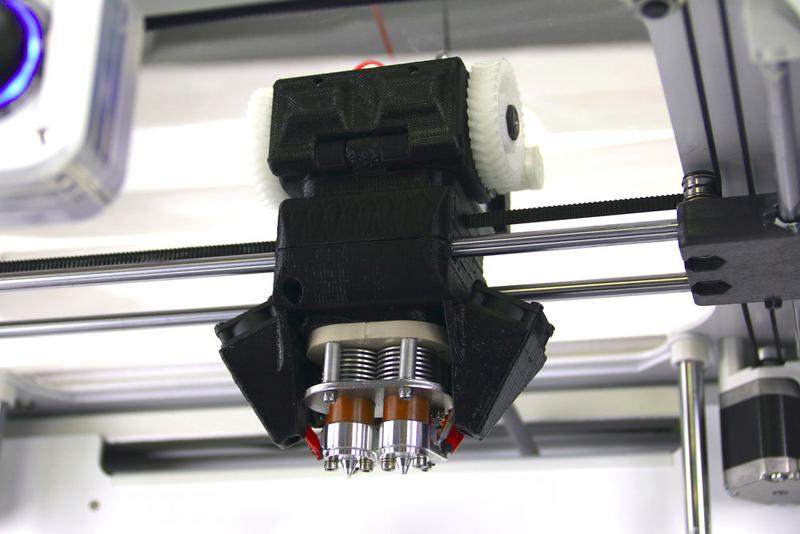

The EVO 22 Large 3D Printer/Additive Manufacturing Center is an FDM 3D printer that can print layers at 40 microns. This way you can produce parts with smooth exterior surfaces. The advanced thermal design creates the optimal conditions for the production of big-sized, robust, polished prints. Tri-Heat technology grants accurate heat and material management. The redesigned, cartridge planetary extruder prevents jams and clogs. Its advanced capacity allows for faster extrusion and precise material distribution rate. The printing capability and accuracy is also enhanced by the adoption of replaceable nozzles. The proprietary recovery systems, namely the Partsave and the Failsafe mechanisms, allows resuming printing with ease, reducing the risk of big print failures due to power outage, accidental unplugging, filament run-out, and more.

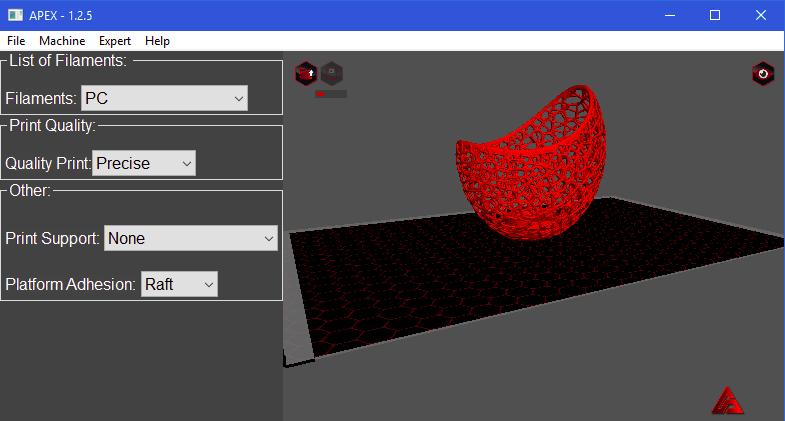

Sliced with the dedicated APEX software, this ukulele is 22.75-inch tall. It has been printed in one piece with ABS filament and took 30 hours to print.

Credit: @airwolf3d / instagram

The EVO 22 Large 3D Printer/Additive Manufacturing Center supports extended-life, swappable nozzles of 1.0, 0.8, 0,5, and 0.35 mm in diameter. These ultra durable components let you save money and time ensuring high precision, speed, and efficiency.

The print head runs on rods with linear bearings, making the design more simple, lightweight and effective, all characteristics that are desirable in a 3D printer. The Z-stage adopts a self-developed coupling that connects the ball screw with the stepper motor. It is really powerful and precise and provides high accuracy.

EVO 22 can print with over 40 types of filament, including metal, ABS, PC, PP, Nylons, TPE, TPU, and other materials.

The extruder comes with a fan for printing with PLA-type materials. By cooling the model down, it reduces warping, stringing and, generally, makes for higher quality prints.

Unlike many FDM printers, the EVO 22 Large 3D Printer has a heated print bed and closed print chamber, which means it can reliably print with ABS-type and temperature-sensitive materials.

The extruder has a maximum working temperature of 599 °F (315 °C), which means it can print high-temperature materials like PEEK, ABS/PC, PEI, carbon fiber, and glass fiber.

The EVO 22 Large 3D Printer/Additive Manufacturing Center prints with generic 2.85 mm filaments, providing you with a wide choice of materials.

The build area of 12 x 12 x 22.8 inches (305 x 305 x 578 mm) lets you print large, real-scale parts safely. In case of accidental power interruptions, you'll only have to turn the printer back on and resume printing where you left off.

The printer can be controlled via PC or via the built-in, 7-inch LCD touchscreen. The responsive display gives you the possibility to manage the printing settings in one touch. You might even write and execute g-Code on the fly through the on-screen keyboard.

3D models can be printed from computer via Ethernet, USB Cable, and USB Drive.

The printer software, APEX, works with 3D models in AMF, GCODE, STL formats, and is available for Mac OS and Windows. Linux users will have to install a virtual machine or other software.

For some items, package content may change. In case of any questions, please get in touch.

EVO 22 Large 3D Printer/Additive Manufacturing Center is available in white with black trims. Its stylish look makes it ideal for professional use and end-use production.

The printer dimensions are 36 x 28 x 24 inches (914 x 711 x 609 mm). It weighs 75 lb (34 kg). The spool holder is mounted on the inside.

The price of the EVO 22 Large 3D Printer/Additive Manufacturing Center is $11,995.00, which is reasonable considering its functionality, large printing capacity, and smart features.

Update your browser to view this website correctly. Update my browser now