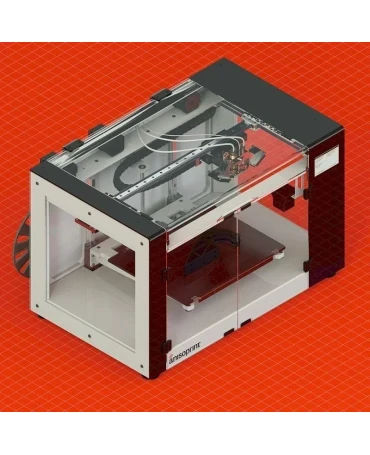

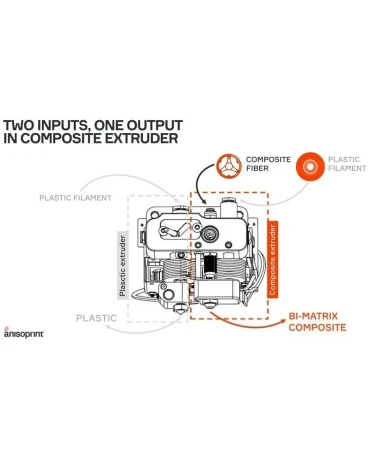

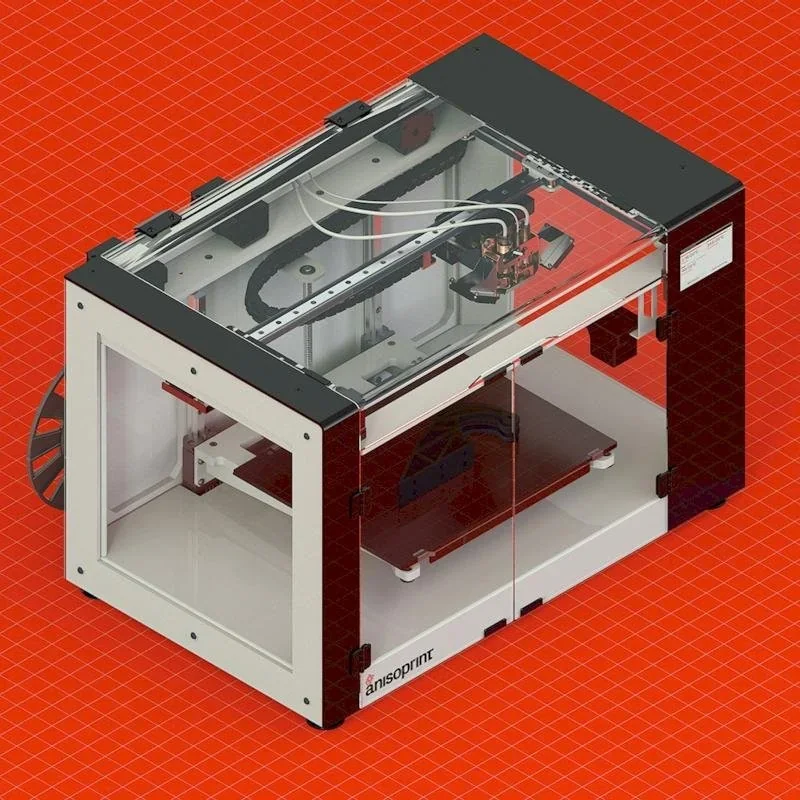

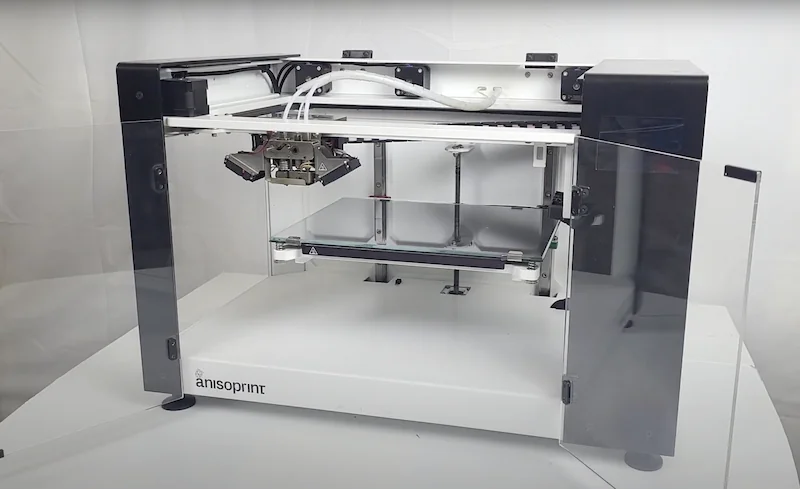

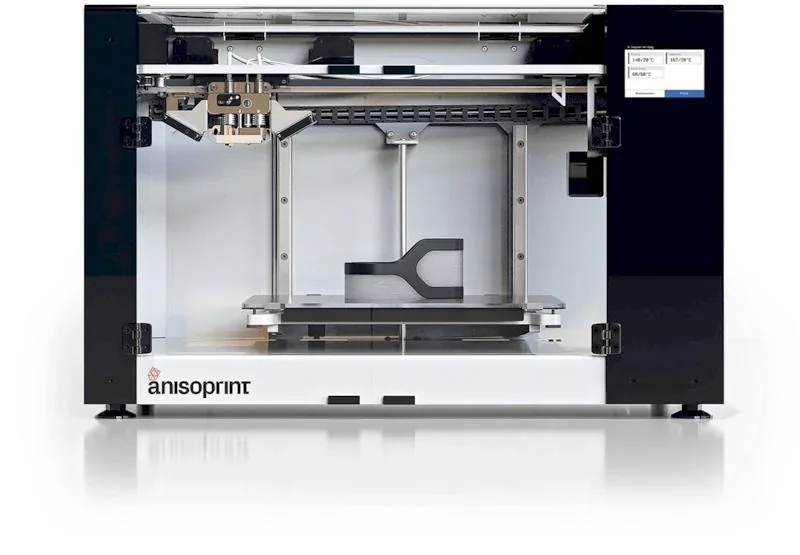

The Anisoprint Composer A3 is a large-format, desktop 3D printer that combines standard FFF with Composite Fiber Co-extrusion (CFC) to embed continuous fibers, producing parts 30× stronger than plastic and 2 times lighter yet stronger than aluminum. With a 460 × 297 × 210 mm build volume, it supports industrial applications like aerospace components and mechanical parts. Its dual-matrix system allows up to 60% fiber volume with complex reinforcement patterns, while an open material system handles thermoplastics up to 270°C. Printing at speeds up to 80 mm/s (FFF) and 10 mm/s (fiber) with 60-micron precision, it enables high-strength, professional-grade composite manufacturing.

Watch our in-depth review of the Anisoprint A4 to learn how its patent-pending composite fiber coextrusion technology works.

The Anisoprint Composer A3 prints with 60-micron precision, delivering smooth, detailed end-use parts using both FFF and CFC modules. The Composer A3 uses dedicated cooling fans to reduce stringing, while the enclosed chamber ensures stable temperatures to prevent warping, especially with high-temp materials. The Composer A3 prints up to 80 mm/s with FFF and 10 mm/s with CFC for precise fiber placement. Its heated glass bed reaches 120°C, ensuring strong adhesion for high-temp materials like ABS, PC, and Nylon, even in an open chamber.

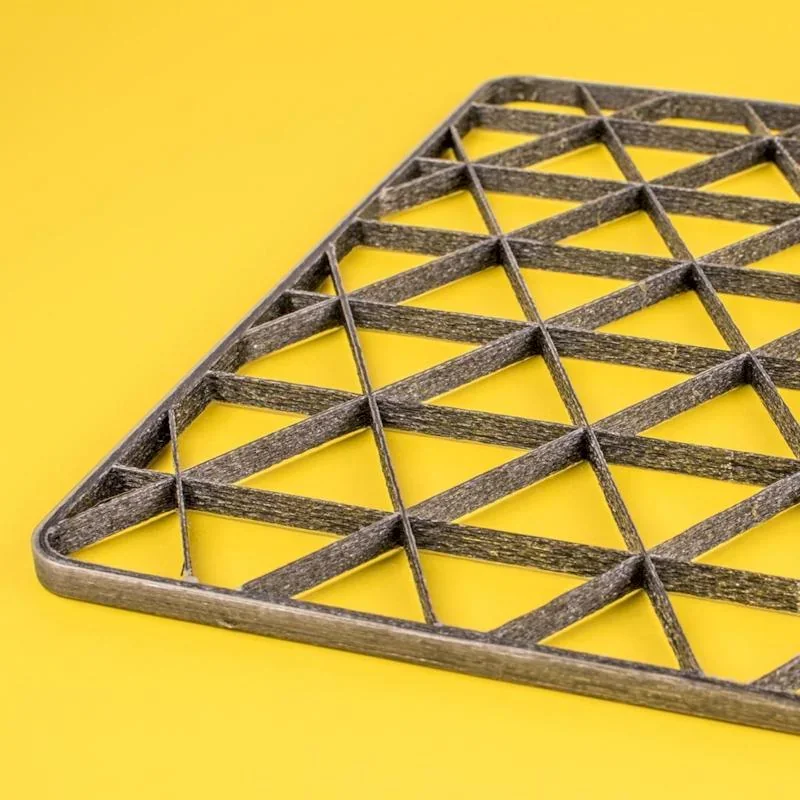

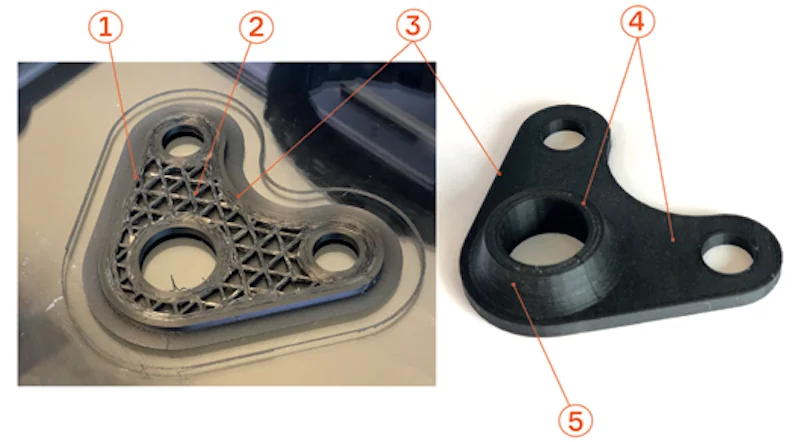

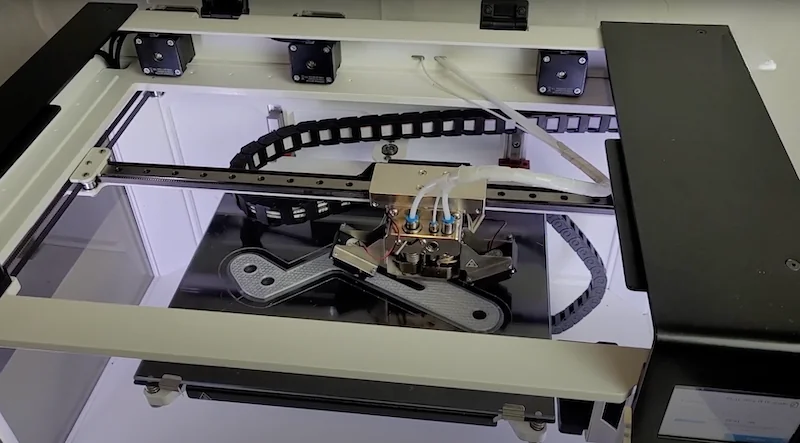

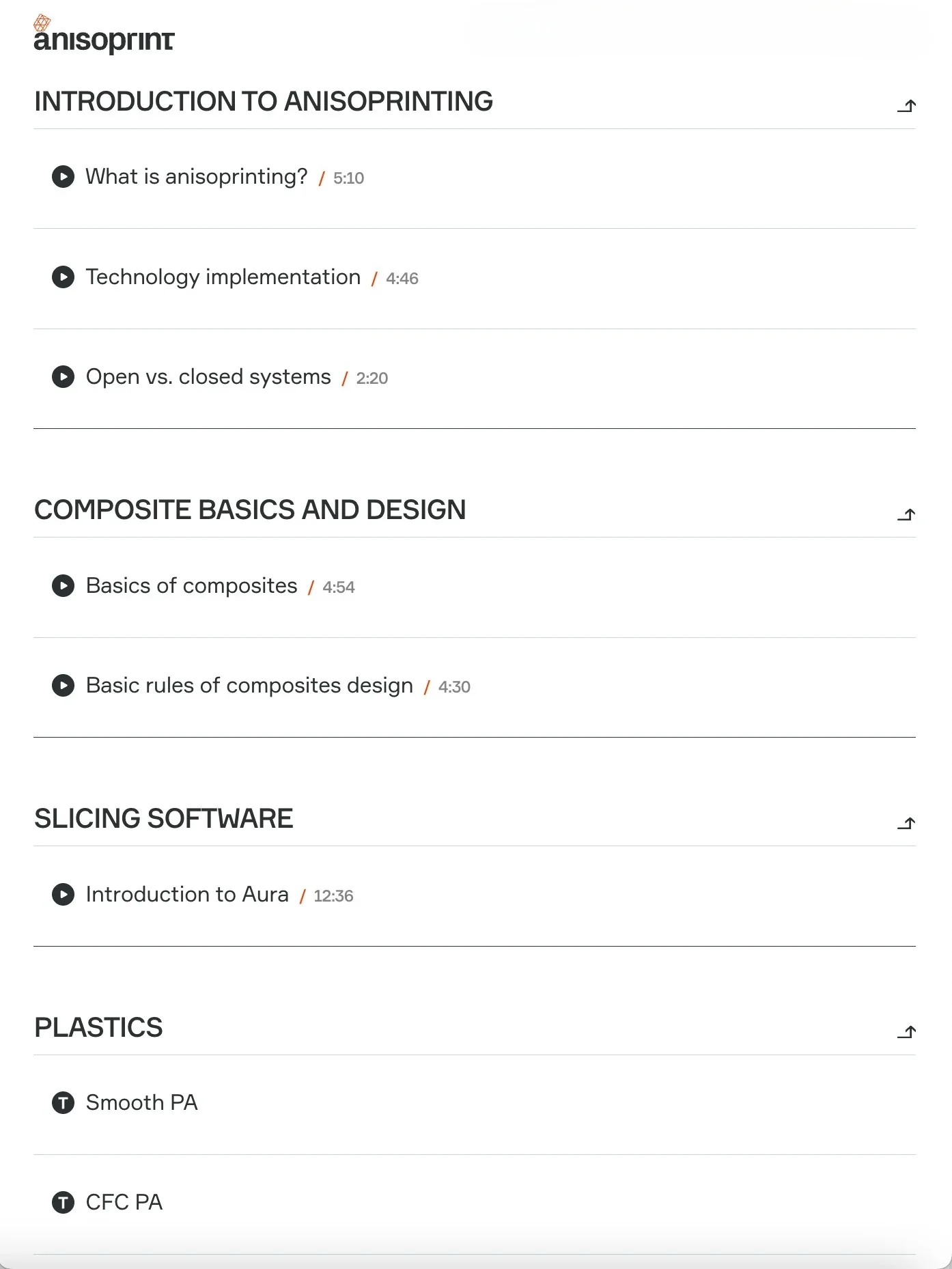

The Anisoprint Aura software gives full control over placement and trajectory of the reinforcing fiber, allowing users to design lattice structures, curvilinear paths, and variable layers for strong, high-performance parts. For example, TSURU Robotics redesigned a drone frame with anisoprinted continuous carbon fiber, cutting weight by 43%, costs by 48%, and boosting rigidity by 16% over their original design.

| Old frame | Anisoprinted frame | |

| Weight, gr | 32 | 18 |

| First fundamental frequency, Hz | 172 | 200.3 |

| Cost, $ | 60 | 31 |

Anisoprint produced HVAC spare parts with carbon fiber reinforcement for €24 versus €285 replacements, delivering higher strength and reliability at a fraction of the cost.

Clemens Schwöbel designed a 358 g, 420 mm bicycle handlebar using carbon fiber and Smooth PA with continuous fiber co-extrusion, optimizing fiber paths through truss design and finite element analysis.

Anisoprint produced an aircraft seat support on the Composer A4 that holds 1.5 tons, cut weight by 40% compared to a 400 g aluminum part, and saved 25 kg per aircraft with 100 supports.

Markforged’s pre-preg approach uses a single filament pre-impregnated with fiber and thermoplastic (e.g., nylon), while Anisoprint’s coextrusion desktop anisoprinting separately feeds fiber and thermoplastic into the print head, enabling adjustable fiber volume ratios and curved reinforcement aligned to stress, such as strengthening holes without added weight.

The Composer A3 supports an open material system up to 270°C, compatible with PLA, ABS, PETG, Nylon, TPU, PC, ASA, SBS, and fiber-filled filaments. Using standard 1.75 mm filament, it lets users choose materials based on strength, heat, flexibility, or chemical resistance.

The Composer A3 ships with Smooth PA and CFC PA, designed to work together. Smooth PA (PA12 with chopped carbon fiber) is used for unreinforced zones and surfaces, offering low moisture absorption and anti-warping. CFC PA, a low-viscosity matrix material, ensures strong fiber bonding. Both print reliably without a dryer.

The Composer A3 produces continuous fiber reinforced parts with Composite Carbon Fiber (CCF) for maximum strength, stiffness, and light weight, or Composite Basalt Fiber (CBF) for lower-cost, non-conductive applications.

Continuous fiber 3D printing embeds long, oriented fibers within a plastic matrix to significantly enhance strength by distributing stress along the fiber length, whereas chopped fiber additive manufacturing mixes short, randomly oriented fibers into thermoplastics like nylon or PLA, improving stiffness and heat resistance but offering limited strength gains.

The Composer A3 offers a 460 × 297 × 210 mm build volume—over 4× larger than the Markforged Mark Two and 60% bigger than the X7. This space supports both multiple small parts and large single builds, demonstrated by a 280 × 280 mm drone frame printed at 18 g in 10 hours.

The Composer A3’s build volume gives it a strategic edge in professional and industrial markets, surpassing comparable desktop and industrial systems.

| Printer Model | Build Volume (mm) |

|---|---|

| Markforged Mark Two | 320 x 132 x 154 |

| Anisoprint Composer A4 | 287 x 210 x 140 |

| Markforged X7 | 330 x 270 x 200 |

| Anisoprint Composer A3 | 460 x 297 x 210 |

| Anisoprint Prom IS 500 | 600 x 420 x 300 |

The A3’s large build volume supports advanced projects, such as a Scott Gambler bike rocker printed in 100 hours with 10 composite perimeters and 80% composite isogrid infill.

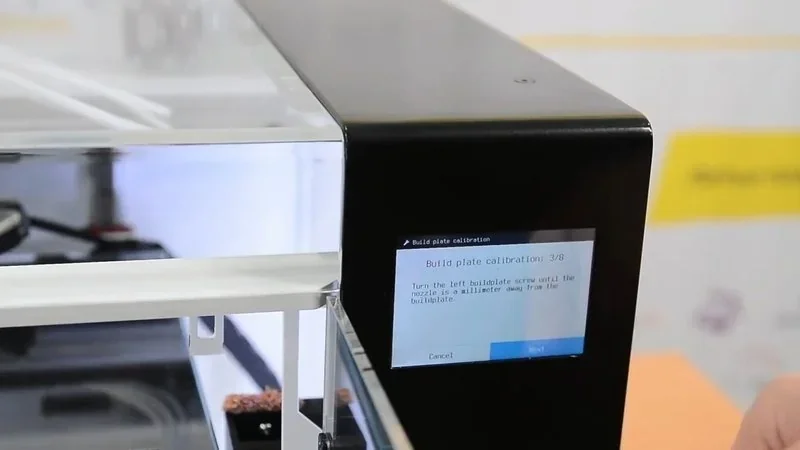

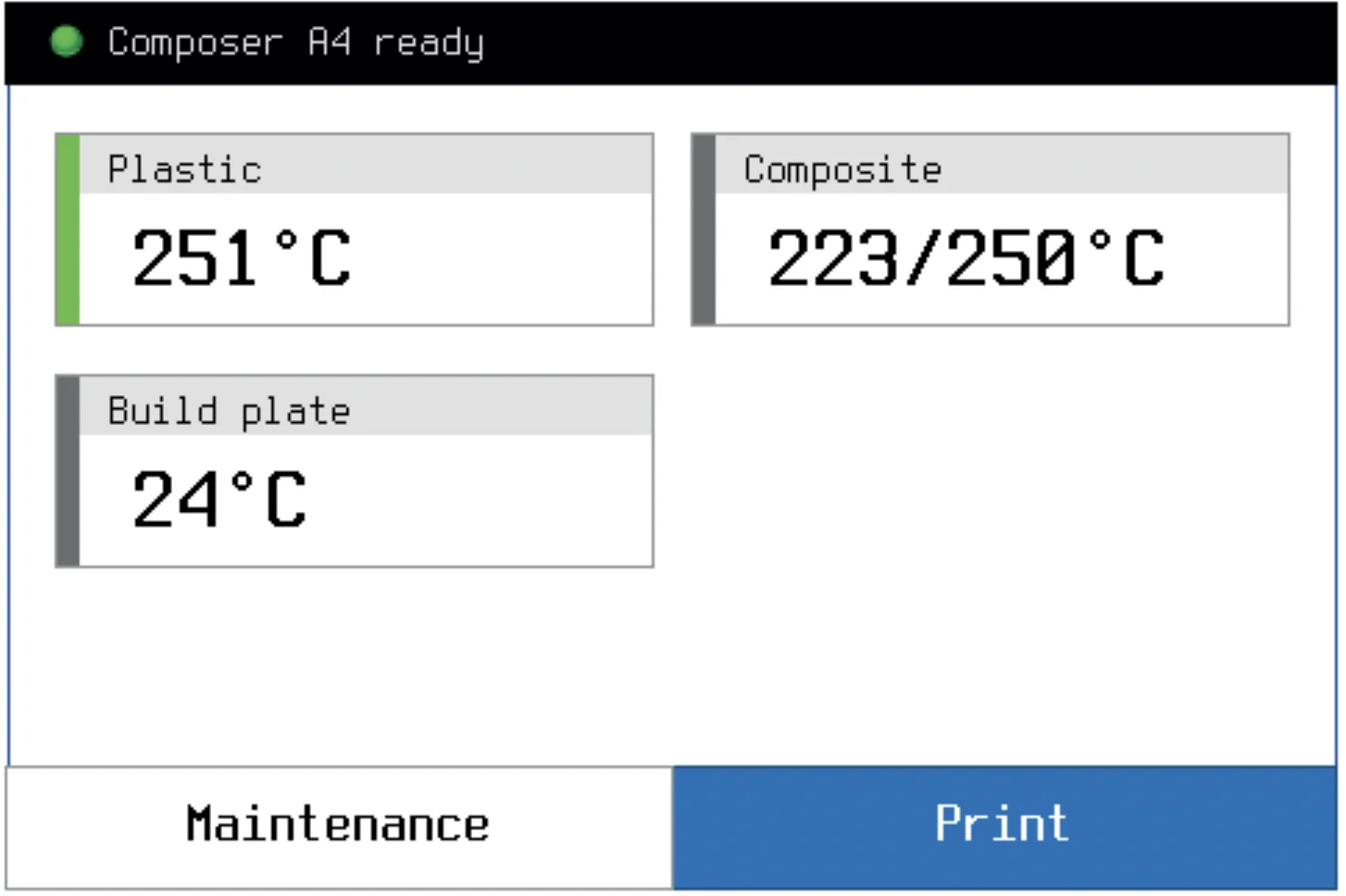

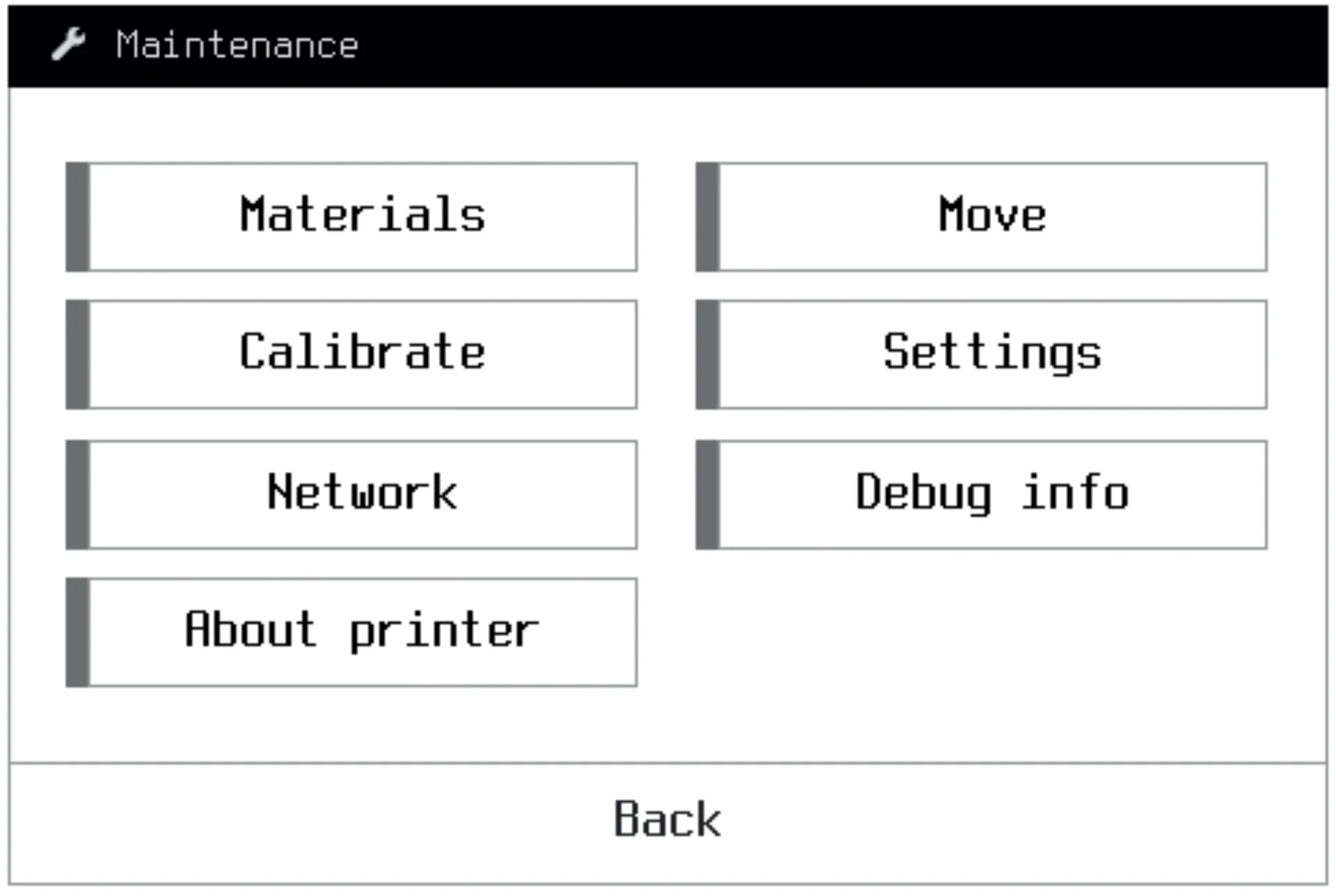

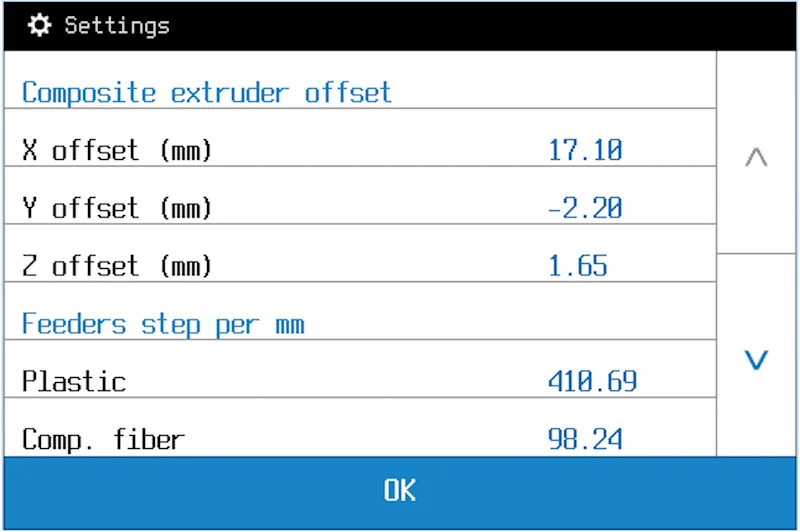

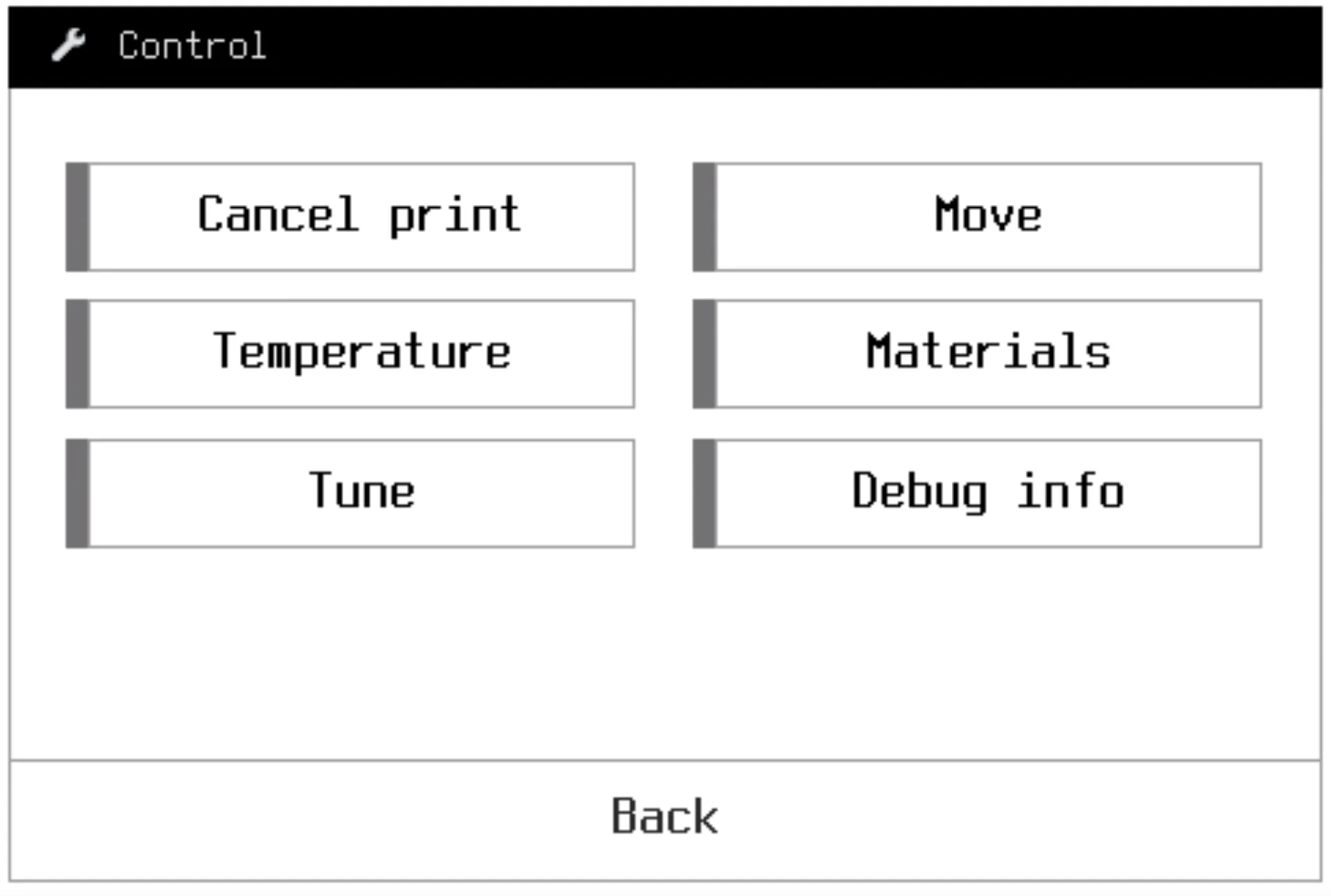

The Composer A3 provides 12 printer controls via its 4.3" touchscreen:

During the printing process, real-time controls allow feed rate (25–200%), plastic flow (25–150%), temperature (±100 °C), and fan power (±100%) adjustments. The Pause function repositions the printhead while keeping temperatures stable for inspection or changes.

The Move control includes an Extruders sub-menu for retracting or supplying filament, switching extruders, activating the fiber cutter, and controlling the nozzle fan.

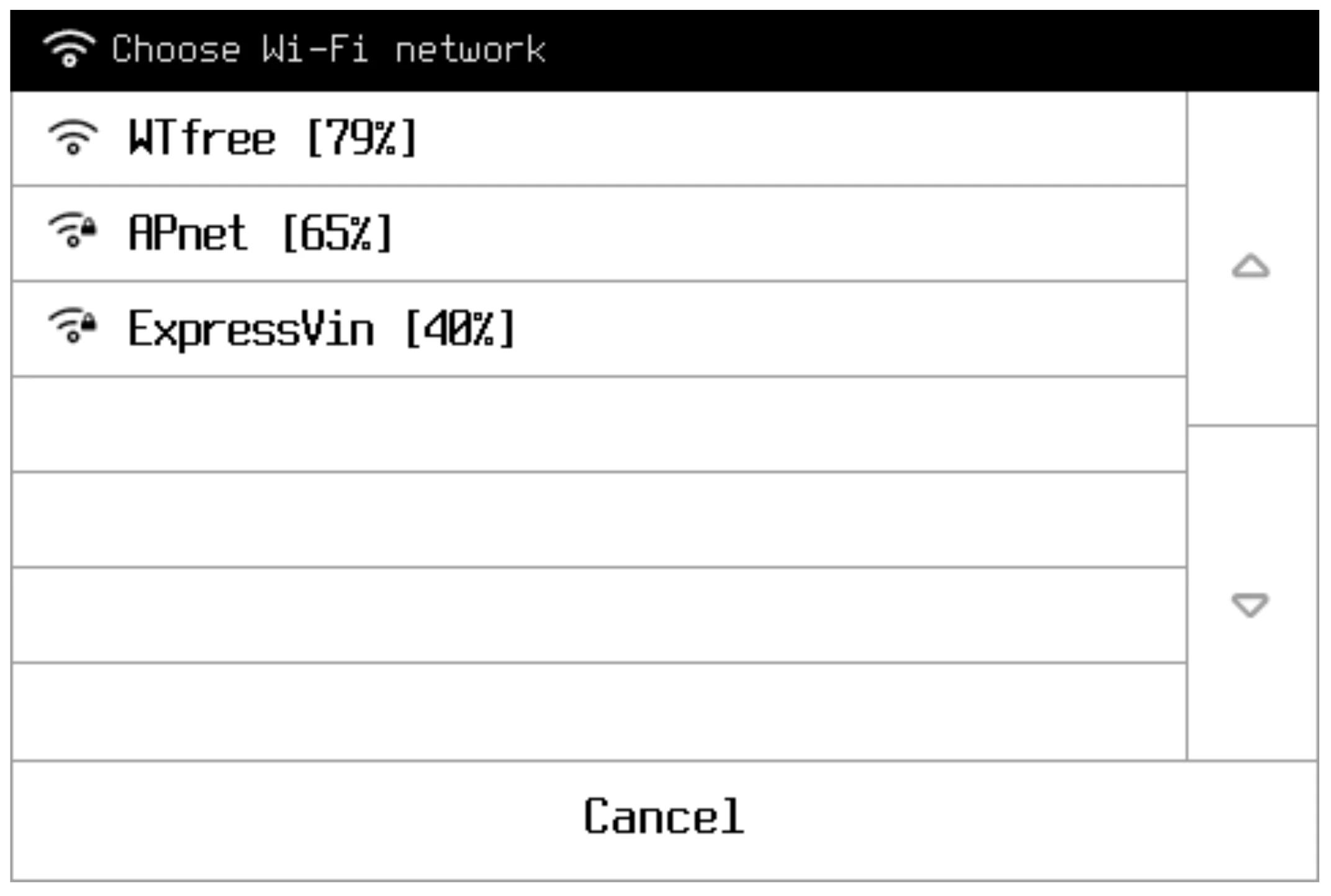

The Composer A3 connects via USB-B, SD card, or Wi-Fi. USB enables firmware updates and file transfer, while the SD slot allows standalone printing. A 4 GB SD card is included for immediate use.

The Composer A3 offers Wi-Fi and Ethernet for remote management and monitoring. Wi-Fi is set up via the touchscreen, and the network bridge updates automatically four times daily. The system supports Windows, MacOS, and Linux for cross-platform use.

The Composer A3 includes Anisoprint Aura, slicing software built for FFF and CFC printing. Aura enables full fiber control with linear, concentric, curvilinear paths and lattice structures (rhombic, isogrid, anisogrid). Features include masking for section-specific settings, adaptive layer thickness, and support generation. It handles STL, STEP, STP, 3DS, and OBJ files, runs locally on Windows, MacOS, and Linux, with model processing fully automated and executed using a local computer to ensure confidentiality and data safety, and requires minimal specs (DX10 GPU, 1080p display, i3/Athlon 64 CPU, 400 MB storage, 8 GB RAM).

The Composer A3 also supports third-party slicers like Cura and Slic3r for FFF printing. Firmware updates are handled via Aura with a USB connection, while bridge software updates install automatically when networked. Three software packages are offered: Basic (limited materials), EXT (extended profiles and warranty), and OPEN (full parameter control for custom materials).

The Composer A3 has an industrial desktop design with an 8 mm aluminum frame, enclosed acrylic panels, and dimensions of 720 × 630 × 490 mm. It weighs 65 kg, combining sturdiness with a compact desktop form.

The Composer A3 features dual front doors with magnetic locks and a hinged top cover, which can stay open for low-temp printing or closed for a passive heated chamber. An exhaust fan at the rear activates automatically above 60 °C.

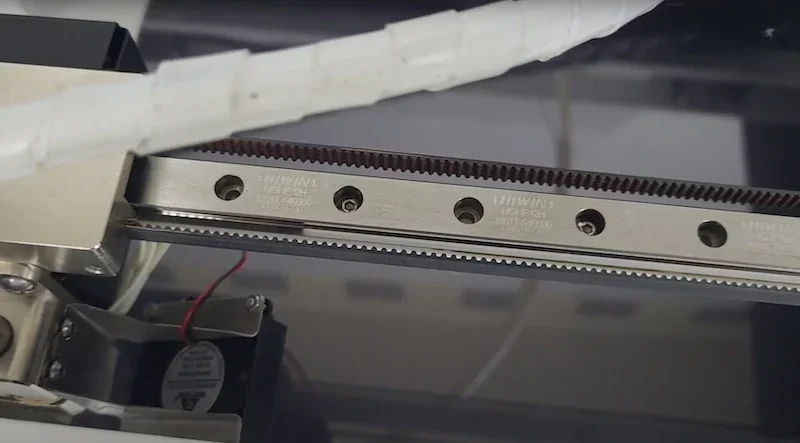

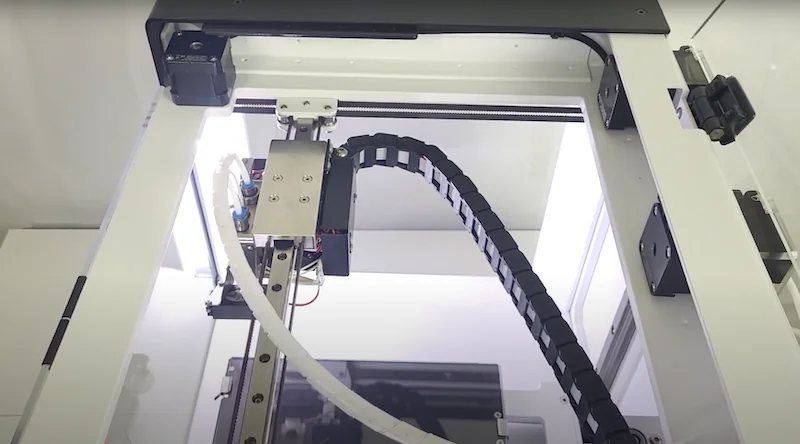

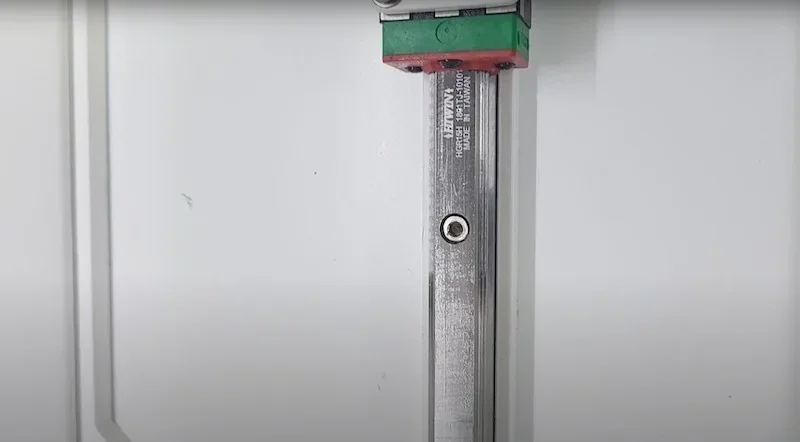

The Composer A3 professional 3D printer uses a CoreXY motion system with Gates 8 mm belts and NEMA 17 stepper motors. Its X and Y axes run on 12 mm Hiwin linear rails for precise, reliable movement.

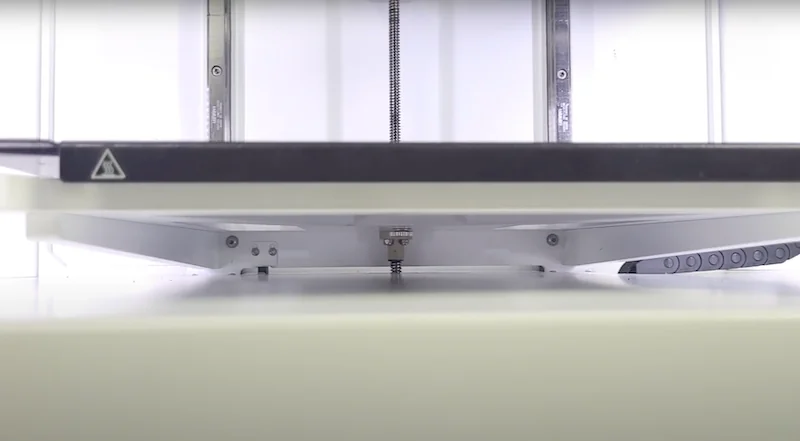

The Z-axis runs on dual 15 mm Hiwin rails with a direct-drive trapezoidal screw, eliminating couplings for stability and accuracy.

The Z-axis motor sits in the lower compartment, and the motion system delivers the precision needed for both FFF and composite fiber printing.

The Composer A3 uses optical endstops on all axes for precise positioning before printing.

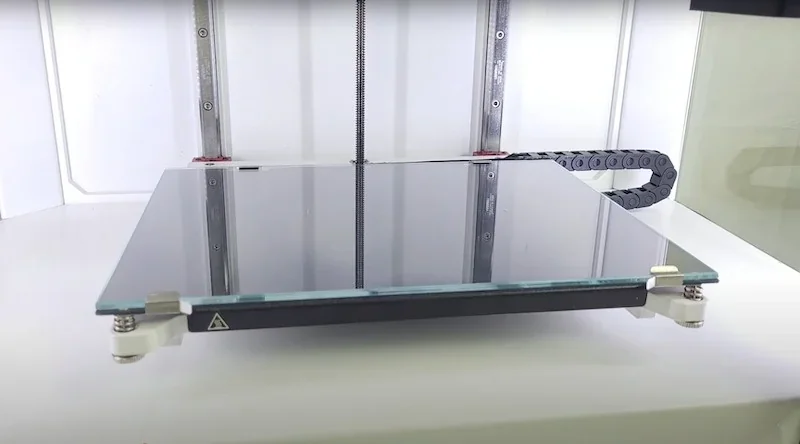

The Composer A3 has a cantilevered glass build plate (460 × 297 × 210 mm) on a rigid frame to prevent swaying. It heats to 60 °C in standard use and up to 120 °C when the chamber is open.

The Composer A3 build plate is mounted with two fixed rear brackets and two front hinges for easy removal. Manual calibration uses three adjustment points with software guidance, and the glass surface can be removed for part release and maintenance.

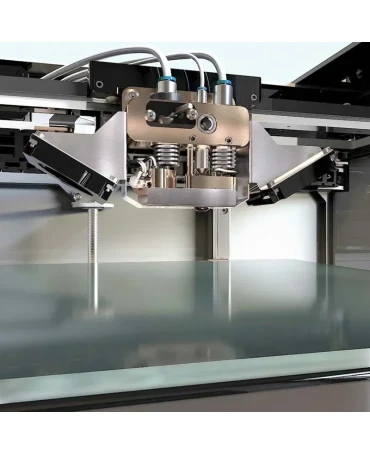

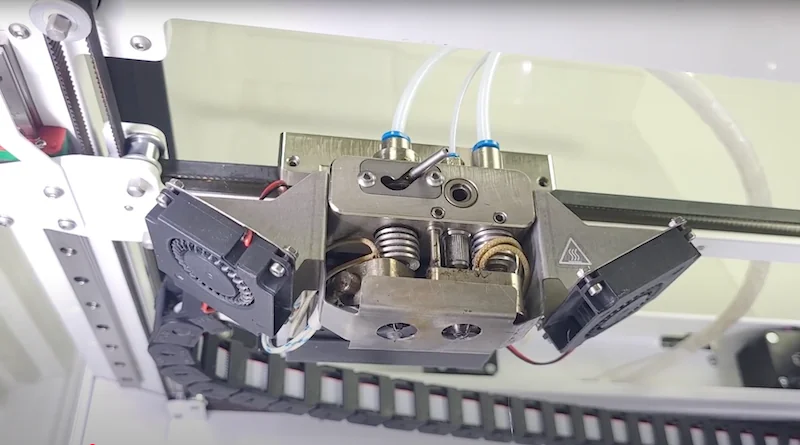

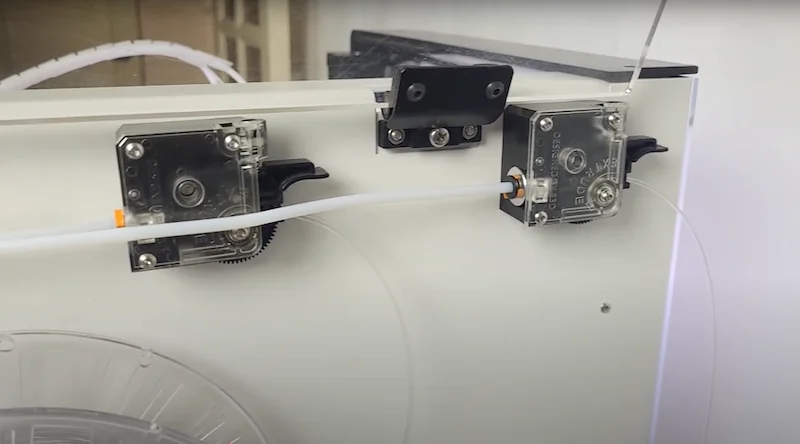

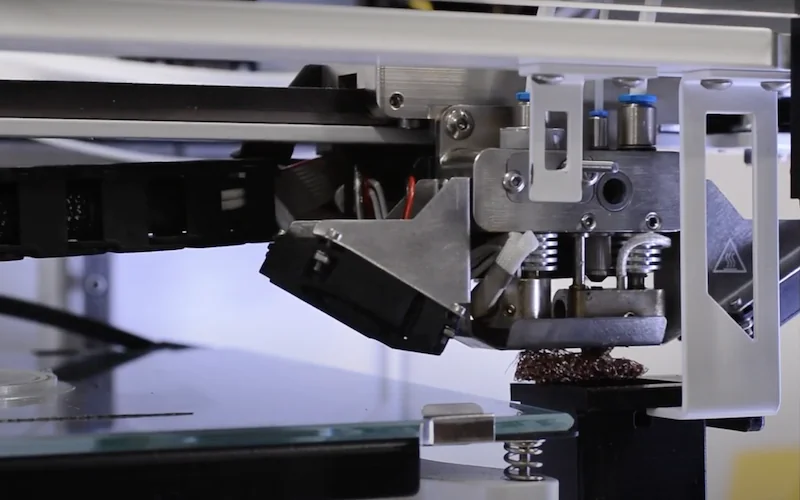

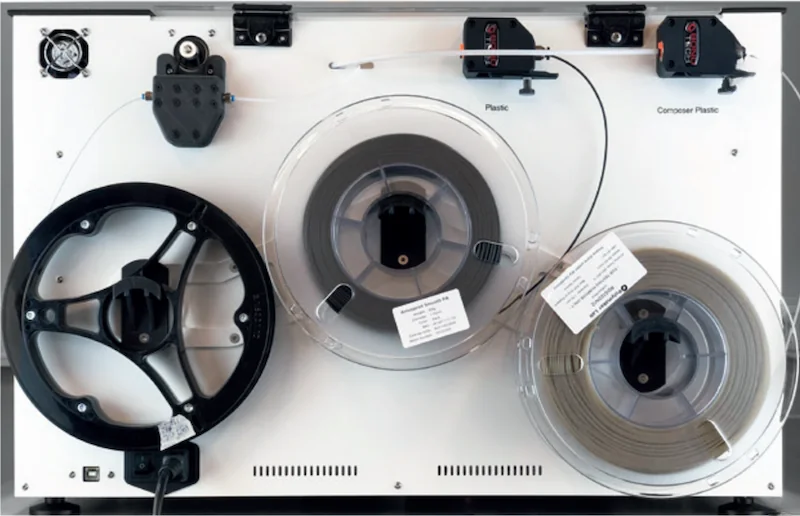

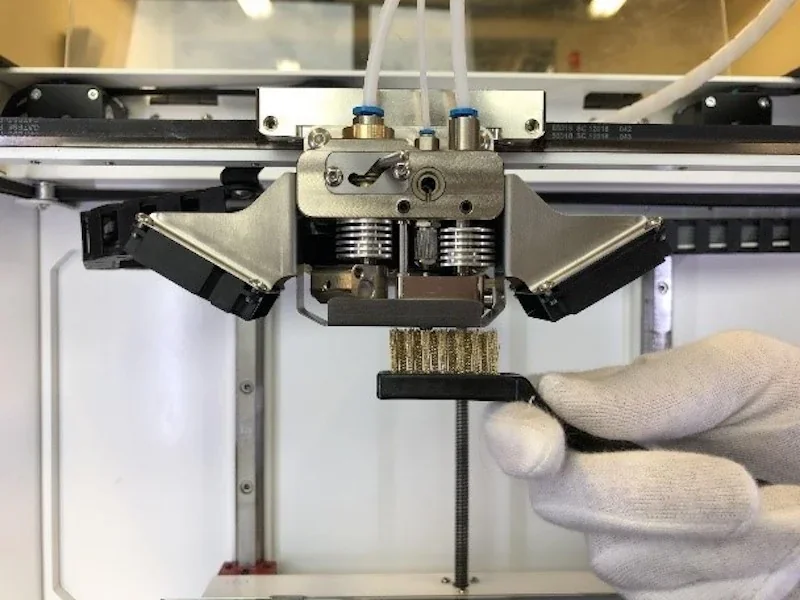

The Anisoprint Composer A3 features a right extruder with a custom 0.8 mm nozzle combining polymer and fiber in a dedicated chamber. Both Composer A3 extruders use Bowden setups with feed mechanisms mounted on the rear wall.

The Composer A3 uses a Titan-style geared feeder for plastic filament.

The Composer A3’s composite fiber feeder uses a proprietary dual-belt design that prevents slipping without damaging the fiber.

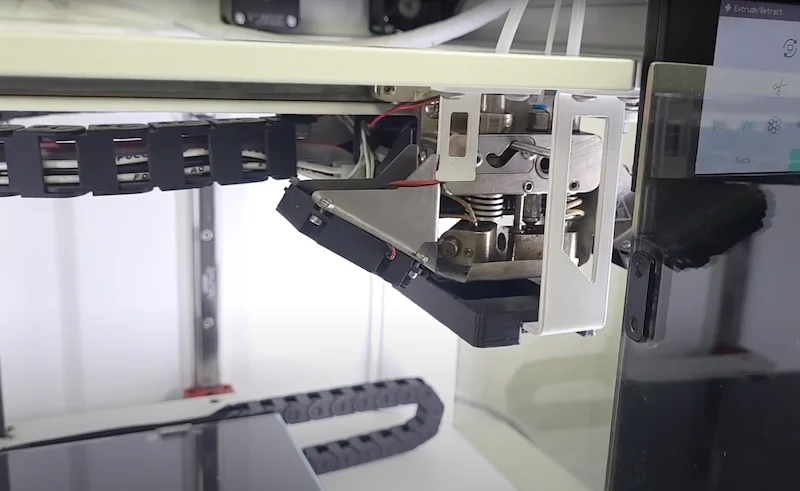

The Composer A3 switches extruders with a mechanical lift system: the print head engages a side lever in a V-notch to raise or lower the plastic extruder, eliminating the need for extra motors or servos.

Both extruders use GDSTime 4010 fans for quiet, low-vibration cooling.

The Composer A3 stores materials on rear-mounted external spool holders for three spools: center for the left extruder, right for composite filament, and left for fiber. Feeding is routed through PTFE tubes to the hotends.

The Composer A4 runs on 220–240 V AC with optional 100–120 V support at 50/60 Hz, consuming up to 1000 W.

The Composer A3 ships partially assembled for quick setup and includes two plastic filament spools and one CCF-1.5k fiber spool for immediate printing. A tool kit (hex keys, 7 mm wrench, brass brush, cleaning needles) supports maintenance, while PPE ensures safe fiber handling. A spare parts kit, 4 GB SD card with sample files, and a detailed user manual are also included.

Note: Package contents may vary by manufacturer without notice. Confirm current inclusions with a Top3DShop sales representative before ordering.

The Anisoprint Composer A3 offers three software packages: Basic for proprietary PA12 materials, EXT for broader partner materials and extended warranty, and OPEN for full system access including custom fibers like copper.

| Package | Description | Features | Target User |

|---|---|---|---|

| Basic | Locked system for simplicity | Proprietary materials only (PA12, fiber-PA12, PETG) | Beginners, plug-and-play use |

| EXT | Broader compatibility | Partner materials, extended warranty, extra slicing settings | Professionals needing flexibility |

| OPEN | Full system access | Custom profiles, full slicing control, alternative fibers (e.g., copper) | Advanced users, material developers |

Available consumables include CCF-1.5k carbon fiber for maximum strength and stiffness, and CBF basalt fiber for lower-cost, non-conductive reinforcement. Matrix materials include Smooth PA for the plastic extruder and CFC PA for the composite extruder, both optimized for the Composer A3.

Maintenance supplies for the Composer A3 include replacement nozzles with copper washers, cleaning needles, brass brushes, lubricants, and a barbed needle tool for composite channel cleaning. Regular upkeep prevents clogging and ensures print quality. For bed adhesion, Magigoo Original is recommended for PETG and Magigoo PA for Nylon.

For continuous fiber printing on the Composer A3, material-specific adhesives are essential for strong first-layer bonding and to prevent part detachment. These specialized adhesives outperform general-purpose options, ensuring reliable results with reinforced parts.

Before Each Print

Weekly

As Needed (Calibration)

Component Replacement

Semi-Annual

The Composer A3’s accessible design includes removable fan brackets and extruder assemblies for easy maintenance. Built-in heaters allow thermal cleaning, while the touchscreen guides calibrations. The package provides cleaning tools (barbed needles, brass brushes, tweezers) and lubricants tailored for its mechanics.

The Composer A3 includes a 1-year manufacturer warranty covering material and workmanship defects under normal use, provided it is operated according to the user manual.

Anisoprint supports Composer A3 owners with an online portal (support.anisoprint.com) offering documentation, troubleshooting, and firmware updates. A detailed user manual is included, and technical help is available via email at support@anisoprint.com

Top3DShop, an authorized reseller of the Composer A3, offers pre-purchase consultation, setup assistance, and after-sales support. Buyers can extend coverage with the EXT package warranty—ideal for professionals needing guaranteed production uptime.

The Composer A3 is available with three software options: Standard (basic use), EXT (extended materials and warranty), and OPEN (full parameter control for custom development). For pricing on software, material bundles, or volume orders, contact Top3DShop for a tailored quote.

Update your browser to view this website correctly. Update my browser now