The ProM IS 500 is an industrial 3D printer powered by Anisoprint Composite Fiber Co-extrusion (CFC) and standard Fused Filament Fabrication (FFF) 3D printing technologies. This versatile device sports up to 4 swappable print heads, which make it capable of either continuous fiber 3D printing and filament 3D printing. The interchangeable print heads will let you print with both composites and pure filaments. Also, they allow reinforcing various zones of a part using different composites.

ProM IS 500 has been specifically designed for printing high-temperature fiber-reinforced plastics. It has a large print area of 600 x 420 x 300mm. It features an industrial quality design composed of industrial CNC components and safety systems. It is equipped with an optical filament sensor and a drying chamber that can hold up to two material coils.

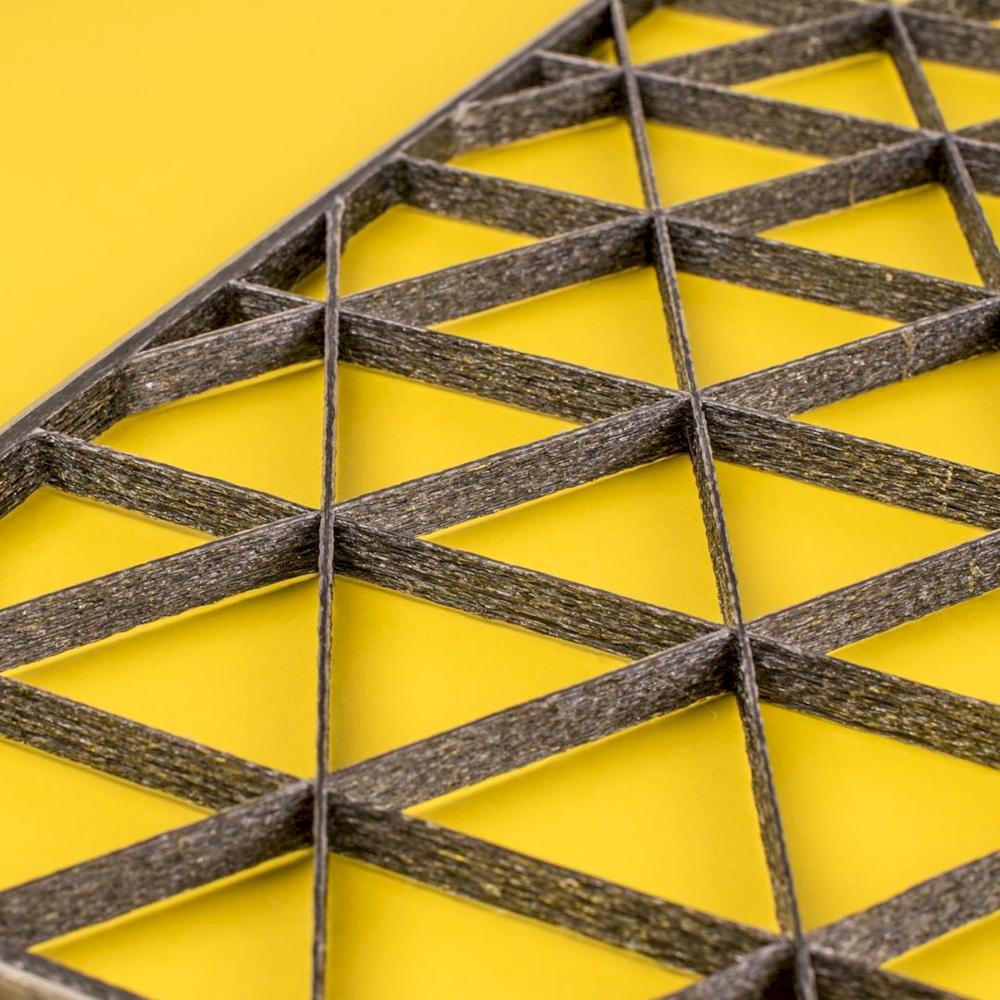

Reliable and safe, ProM IS 500 lets you print composite lattices granting optimal structures and mechanical properties. It delivers light performance parts reducing printing costs and production times. It can be used to produce a variety of strong yet lightweight fiber-reinforced composite 3D models, including spare parts, end-use tools, functional prototypes, and more. Continue reading for a deeper review.

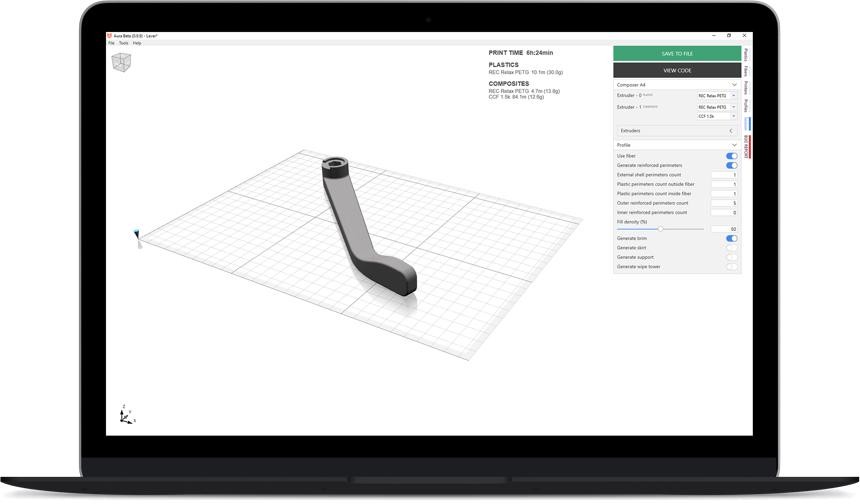

Continuous fiber 3D printing has been used by the team of Dmitry Pavlenko, a world-record-holder para-athlete diver, to produce a special buoyancy compensation lever. The lever has been printed with a component made of carbon-fiber-reinforced PETG on an Anisoprint 3D printer. Here is the final result.

The ProM IS 500 is a professional continuous fiber 3D printer that can print layers at 60 microns. This way you can produce parts with smooth exterior surfaces. The printer can reach up to 60 cm3/hour in CFC mode granting rapid print times.

For example, this drive fixture has been produced using PETG as a matrix.

The ProM IS 500 supports a variety of nozzle diameters from 0.4 to 1.5mm, giving you plenty of choices.

The print head features a liquid cooling system for accurate prints.

ProM IS 500 can print with all plastics with processing temperatures of up to 270°C, namely PLA, ABS, PETG, PA(Nylon), TPU, PC, ASA SBS, and CF/GF filled filaments.

It comes standard with an extruder that can reach up to 270°C and a heated platform that heats up to 160°C.

Credit: @anisoprint / Instagram

It can be equipped with an optional high-temperature FFF print head (400°C), a high-temp extruder (400°C), and a heated build chamber (160°C). This additional equipment lets you print with either PEEK and PEI (ULTEM) as a matrix.

Credit: @anisoprint / medium.com

The ProM IS 500 prints with 1.75mm filaments. Anisoprint supplies 1.5k and 3k Composite Carbon Fiber and Composite Basalt Fiber. These reinforcing fibers can be used with PLA, ABS, PETG, PA, TPU, PC, ASA, fiber-filled and glass fiber-filled filaments.

The build area is 23.6 x 16.5 x 11.8 inches (600 x 420 x 300 mm). It lets your print medium-to-large parts in one go.

The printer comes with an integrated touch screen for seamless operation. Also, it provides USB and Ethernet connectivity for easy file transfer.

Anisoprint ProM IS 500 works with the proprietary Aura slicer software. Specifically developed for composite 3D printing, the program allows preparing both 3D models for CFC- and FFF-printers. It is simple to use and intuitive. It provides a variety of useful features for easy print management. It lets you generate support structures and see a real-time preview of the final print. For each layer, it generates reinforcing fiber trajectories. Also, it lets you easily regulate the reinforcement scheme to increase the final strength of the part. The software runs on Windows 7+.

For some items, package content may change. In case of any questions, please get in touch.

ProM IS 500 is available in a white and black design. Its stylish look makes it ideal for industrial production of end-use high-performance parts.

The printer dimensions are 74.8 x 47.2 x 74.8 inches (1,900 x 1,200 x 1,900 mm).

To learn the current price of the 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now