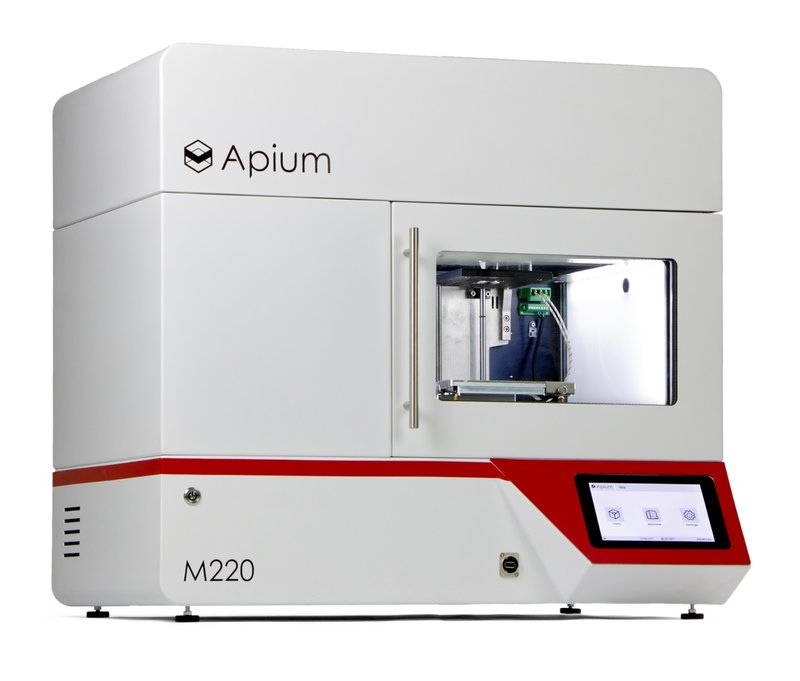

The Apium M220 is a high-temperature FDM printer capable of processing high-performance polymers and designed specifically for the medical industry. The machine meets all the requirements to produce patient-specific prostheses, biocompatible implants, and medical appliances and comes with convenient integrated service and maintenance functions. It is aimed at efficient researching, developing, and producing PEEK medical devices.

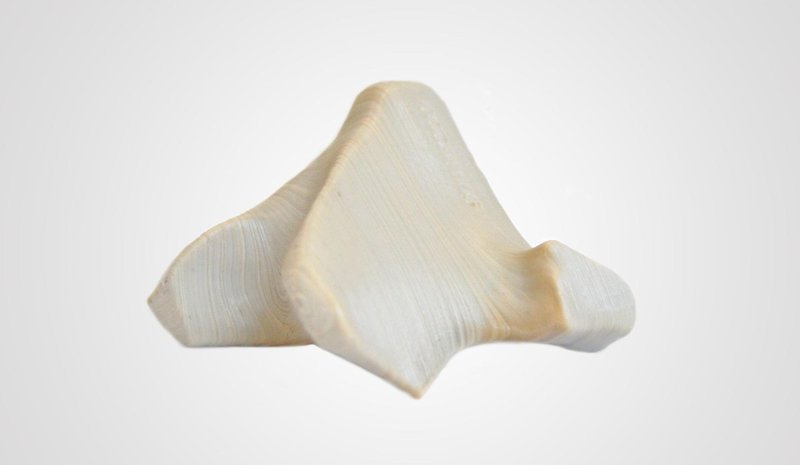

Based on the design freedom that comes along with Apium 3D printing technology, complex geometries can be created on your desktop using radiological imaging data as input. The digital implant model, generated from the patient-specific data, can be manufactured from PEEK within a few hours, sterilized then deployed for patient treatment.

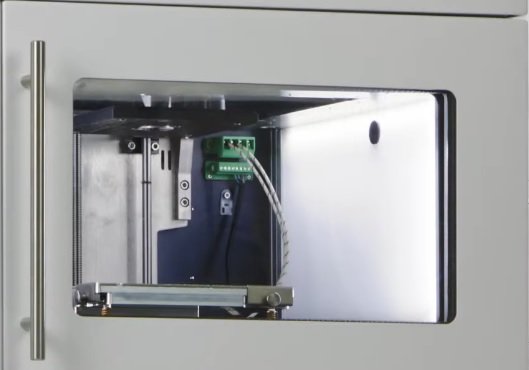

One of the most important M220 features is the hot-air filter system. It analyses the part geometry and adapts the heating power, ensuring optimum energy input as well as a sterile printing environment essential for medical device manufacturing. Apart from that, all the printer’s components that come into contact with the material being printed are made of medically compatible PEEK, titanium, 316L steel, or PTFE. The high-performance extruder provides precise material flow for consistent 3D printing.

An integrated camera system, temperature recording, and servomotors enable constantly monitored printing process and autonomously adjust it in case of any deviations. All important printing parameters are saved as a PDF protocol.

Below you can see a Cheekbone implant printed with PEEK.

The Apium M220 can print layers with a minimum height of 50 microns. The maximum nozzle temperature of 540 °C and hot-air filter system that can heat up to 280 °C and adapt the heating power, ensure optimal 3D printing conditions for creating biocompatible patient-specific implants and medical devices from high-temperature PEEK filament.

Together with the Evonik company, Apium has developed the medical-grade PEEK filament based on VESTAKEEP® i4 G, a high-viscous polymer from Evonik. The medical PEEK is biocompatible, biostable, and x-ray transparent, which makes it an ideal material for medical devices and implants. Among other advantages of medical 3D printing are cost-effectiveness and greatly reduced production time, as well as the ability to create highly customized models of any complexity that would have been impossible to make using other methods.

The M220 build volume of 130 x 130 x 120 mm is perfectly suitable for printing implants and medical appliances.

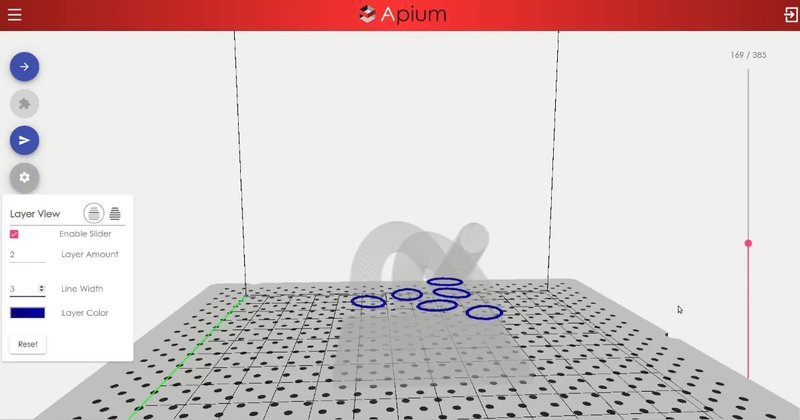

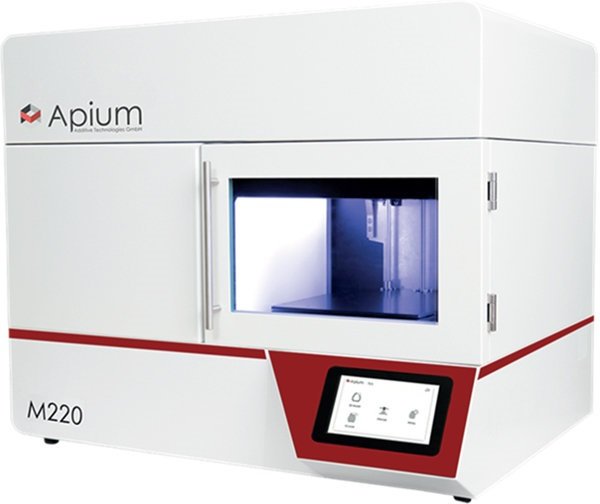

The Apium M220 series is equipped with a built-in LCD touchscreen with integrated control software featuring intuitive user interface. One can adjust printing parameters, manage print jobs, or check the printer status. Apart from basic functionality, the software automatically informs about incoming maintenance operations and guides step-by-step through the procedures. Its integrated calibration routines guarantee consistent component quality.

Apium web interface allows for remote control of the machine via Ethernet. The user can visualize models in the 3D viewer, arrange the 3D printing queue, or check the printer status.

For some items, package content may change. In case of any questions, please get in touch.

The Apium M220 inductrial FDM printer is available in white with red trimmings. Its compact design makes it ideal for any hospital, clinic, or medical lab.

The machine dimensions are 33.5 x 27 x 26.6 in (850 x 685 x 675 mm). It weighs approximately 147.7 lb (67 kg).

To learn the current price of the Apium M220 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now