The Apium P220 is a compact industrial FDM printer capable of 3D printing with high-temperature polymers. It can also successfully process materials containing higher proportions of CF or GF, like fiber-reinforced PEEK with up to 30% carbon fibre content.

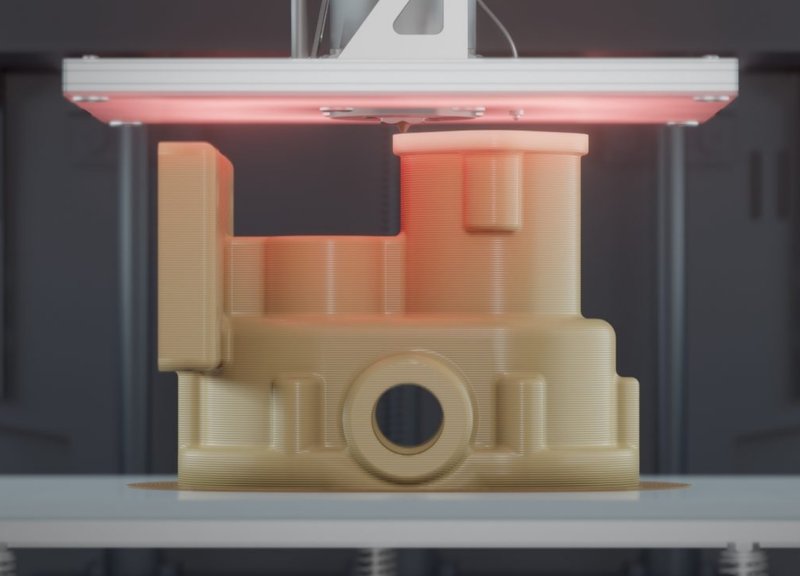

Equipped with an innovative adaptive zone heating system, the printer ensures time and energy saving and provides optimal 3D printing conditions for highly demanding industrial filaments, such as PEEK, PEKK, PEI, and others. The heater is integrated into the print head and the system precisely adjusts the heating power to achieve a complete part crystallinity, good layer adhesion, and excellent surface quality.

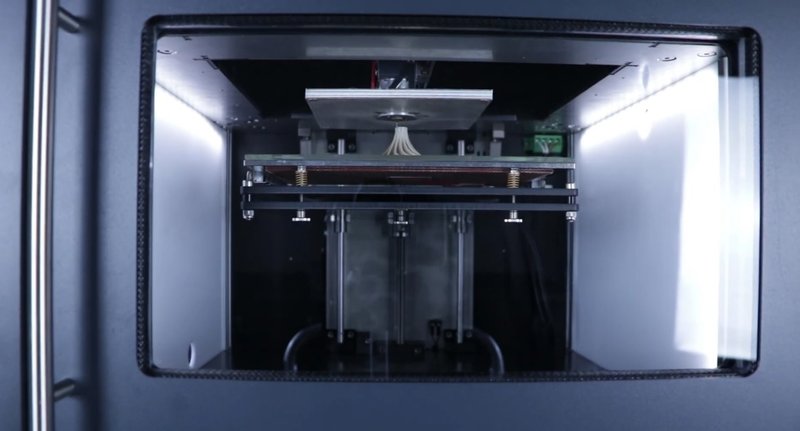

The advanced extruder with 4 times higher feeding force than that of the previous model allows printing with reinforced, compound materials as well as pure materials and metal-filled filaments with further debinding and sintering to get ready-to-use full-metal parts.

A sturdy construction with an industrial-grade threaded rod and two linear guides prevents vibrations and makes for print precision. The machine is easy to set up and use, and the integrated software guides the user through semi-automatic bed calibration or reminds about the necessary maintenance. With the built-in camera, the user can monitor the printing process, and the advanced parameter control enables varied print parameters for challenging geometries in a single part with automatic recording of all important settings in a PDF protocol. With the latter unique capability, the machine confidently overcomes most geometrical challenges and sets a new standard in high-performance polymer additive manufacturing.

The models below were printed with carbon-fiber reinforced PEEK.

The Apium P220 can print layers with a minimum height of 50 microns. Its high-performance 540 °C extruder with interchangeable nozzles of 0.2–0.8 mm diameters, a full-metal hot end, and adaptive zone heating system allow creating high-quality parts with excellent mechanical properties and smooth surface finish. For better print quality and convenient user experience, a specially designed filament guide automates the loading process.

The capability of printing with PEEK and other engineering filaments allows using the P220 for a variety of applications in different industries, including automotive, aerospace, engineering, and others.

These parts were printed on the Apium P220 using PEEK filament.

And this is an example of printing with Smart ABS.

The Apium P220 is an open material system which means it can print with almost any filament in the market no matter the manufacturer. The machine is compatible with high-performance polymers, including carbon and glass fiber-reinforced composites with high fiber content. The list of compatible filaments includes PEEK, PEEK-CFR, PP, PEI ULTEM, Smart ABS, and others. In addition, the machine is capable of printing with metal-containing compounds, such as 17-4PH or 316L, to create green parts that are debinded and sintered afterwards.

Due to the smart material management system, the system running on the Apium P220 recognizes the material type and tracks the amount used. When the Apium P220 identifies that an Apium material is loaded, it automatically adjusts the printing parameters according to Apium's material profile and allows you to use the optimal process parameters for high quality results.

The P220 build volume of 205 x 155 x 150 mm allows printing small-to-medium parts and using the machine for functional prototyping and end-use parts manufacturing.

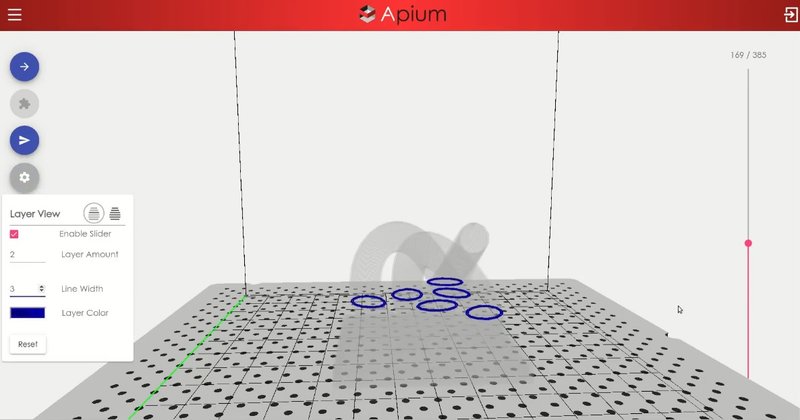

The P220 is operated via a built-in LCD touchscreen with integrated control software including optimization of varied print parameters, a process control system, and a maintenance system. With the open software system, the user is free to choose any slicer for print preparation.

Wi-Fi and Ethernet connectivity options allow controlling the printer remotely via Apium web interface. The user can visualize models in the 3D viewer, arrange the printing queue, or check the printer status.

For some items, package content may change. In case of any questions, please get in touch.

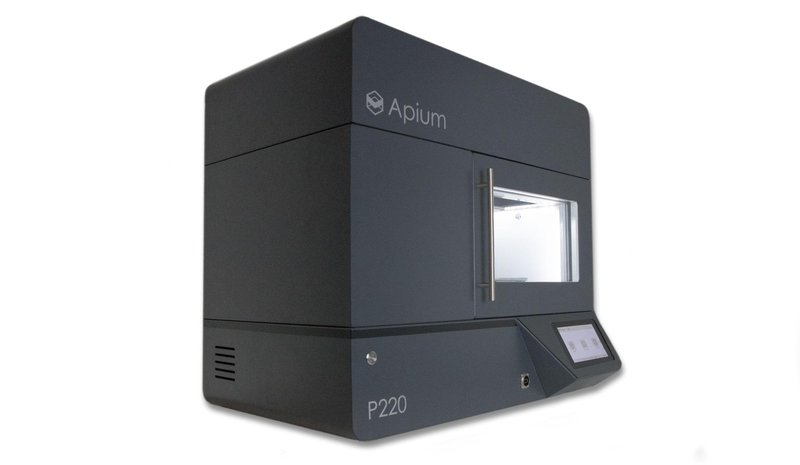

The Apium P220 is available in black. Its compact design and quiet operation make it ideal for any engineering or research lab.

The machine dimensions are 33.5 x 27 x 26.6 in (850 x 685 x 675 mm). It weighs approximately 143.3 lb (65 kg).

To learn the current price of the Apium P220 industrial FDM printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now