What is the print quality and performance of the Apium P400 3D Printer?

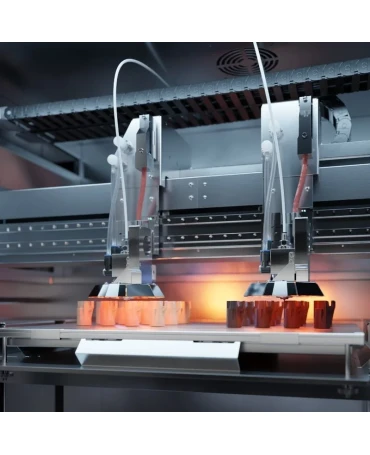

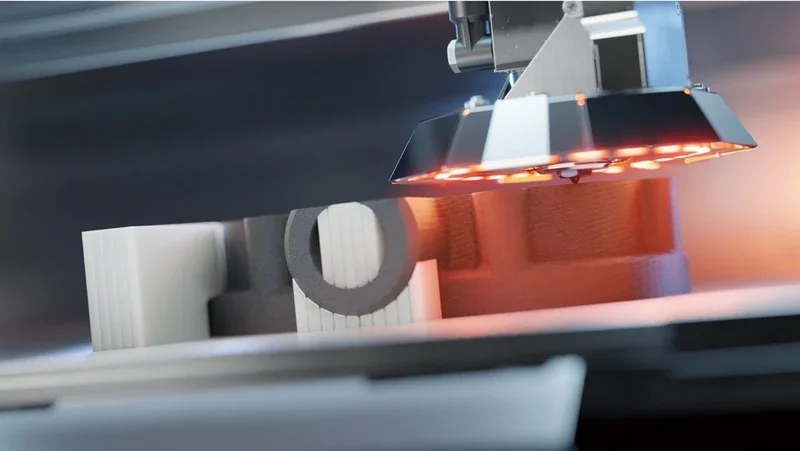

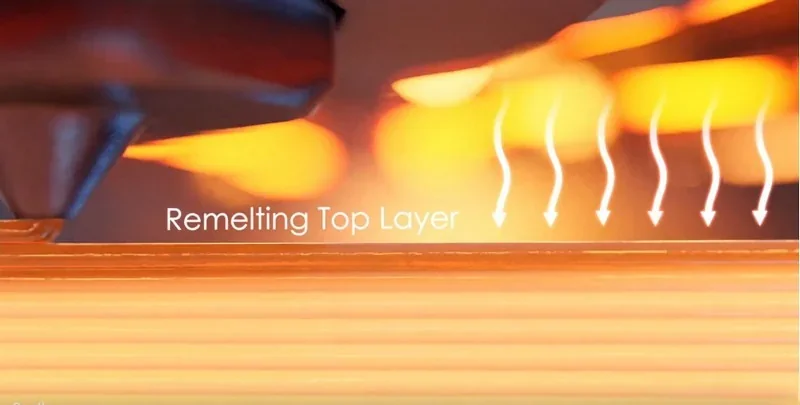

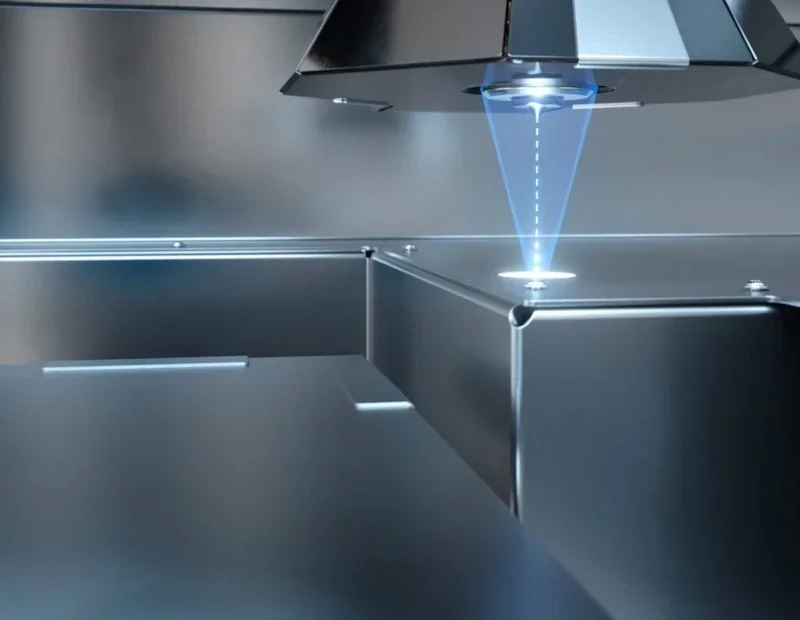

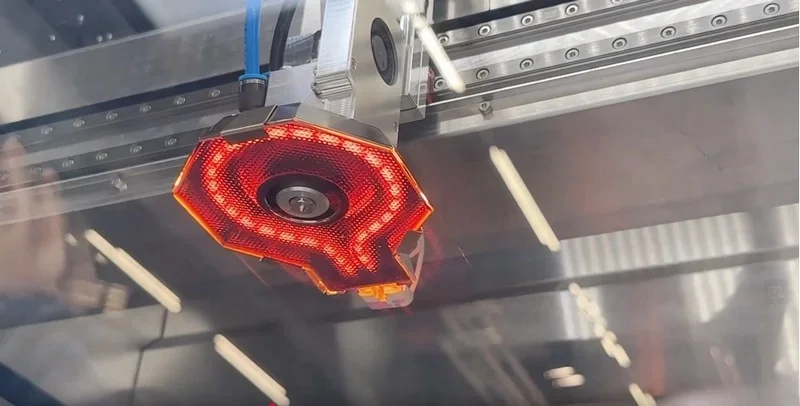

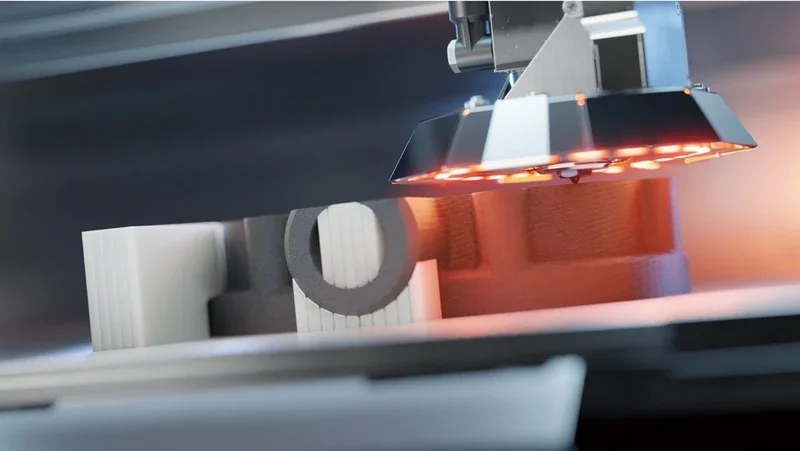

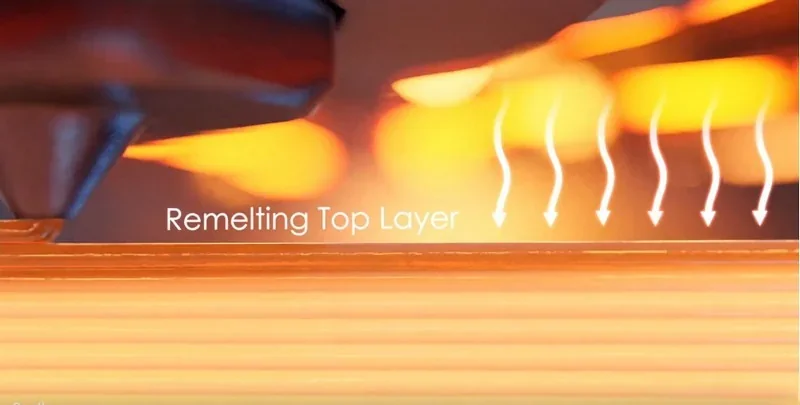

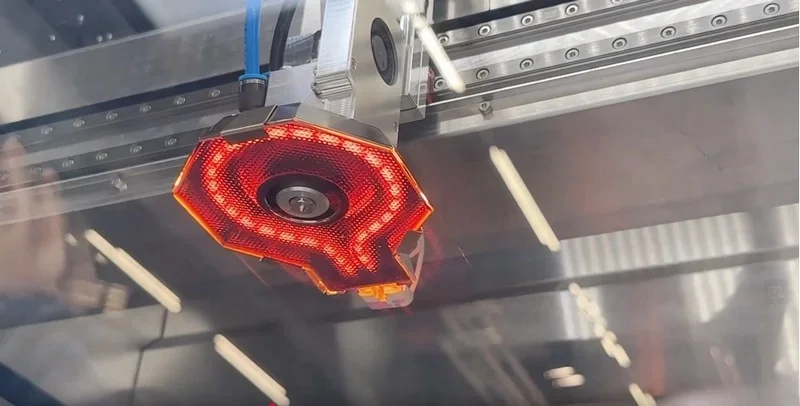

The Apium P400 delivers exceptional print quality through its next generation zone heater that applies temperatures exceeding 500°C directly to the printing zone.

This technology ensures outstanding layer adhesion by remelting the previous layer, creating strong bonds between layers that result in printed parts with isotropic properties comparable to injection-molded components, i.e. you will get equal material properties in all directions, as in conventionally manufactured parts.

The printer delivers high precision with 7.5 µm XY and 1 µm Z accuracy, enabling detailed, dimensionally accurate prints.

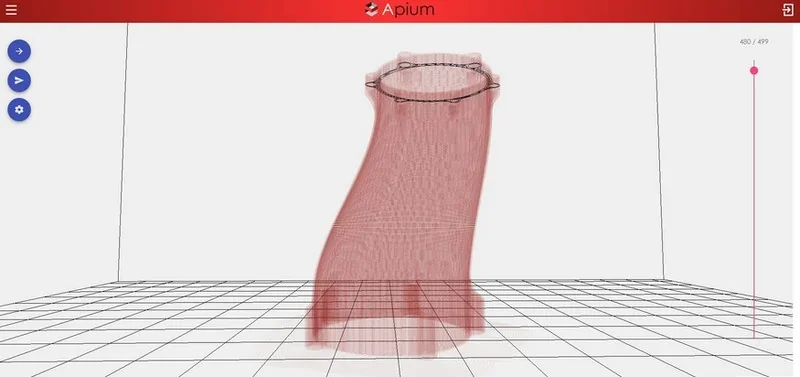

Example: This liquid channel, 3D printed in 3 h 07 min using 7.2 g of PEI 9085 filament, features a glossy surface suitable for visible applications due to its high-quality component texture.

Print performance is enhanced by the Apium P400's ability to produce layers ranging from 50 to 600 microns in thickness, accommodating both fine detail work and faster production runs. The printer supports nozzle diameters between 0.2 and 1.0 mm, providing flexibility for different applications and filament types.

High-quality linear rails and servo motors ensure consistent movement and minimal vibration during additive manufacturing, contributing to superior surface finish and dimensional stability across the entire 400 x 300 x 300 mm build volume.

Example:

Example: This downhole connector, 3D printed from 201.3 g of PEEK GFR, is used for cable routing in oil and gas drill holes. It provides high electrical insulation, chemical resistance, and compressive strength. Print time: 27 h 24 min.

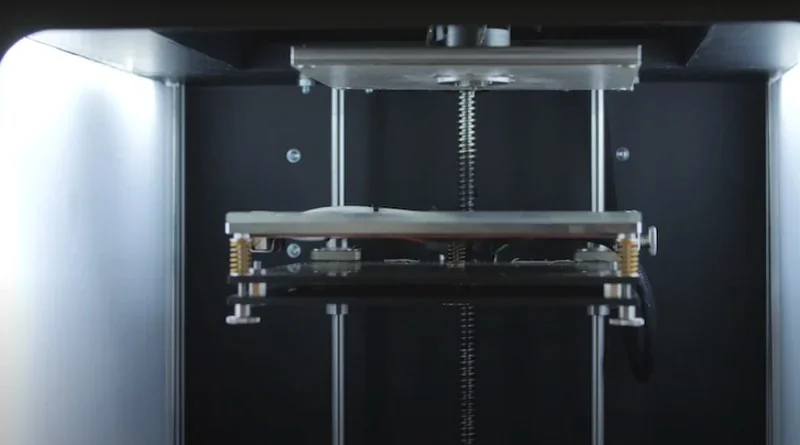

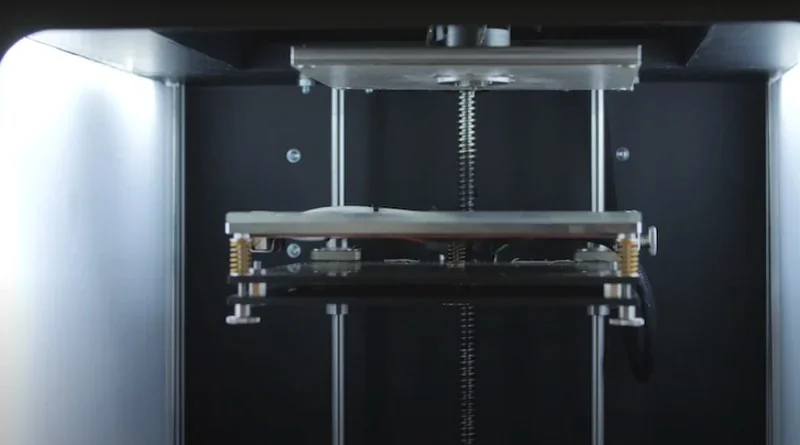

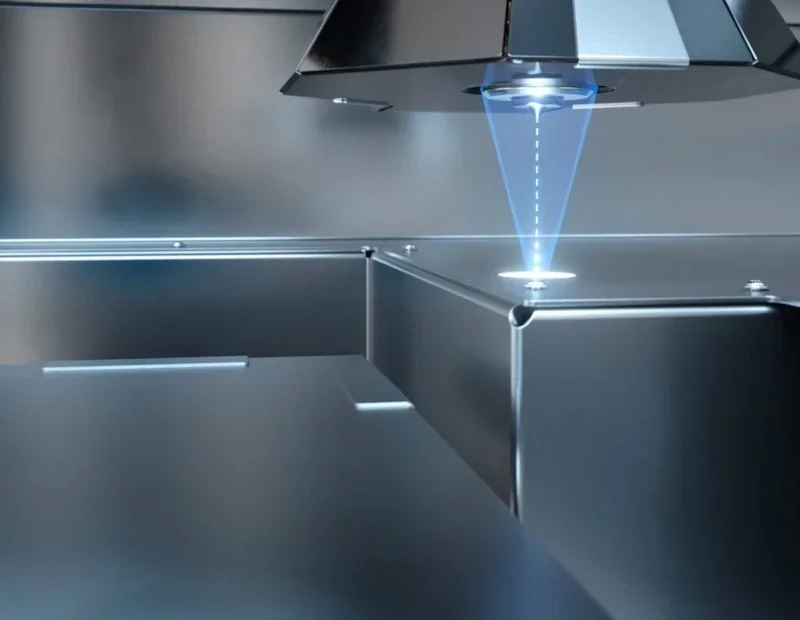

The Apium P400 incorporates automatic bed leveling and an integrated optical calibration system for the print heads, ensuring precise alignment and consistent first-layer adhesion. These automated features maintain print quality consistency across jobs without manual intervention.

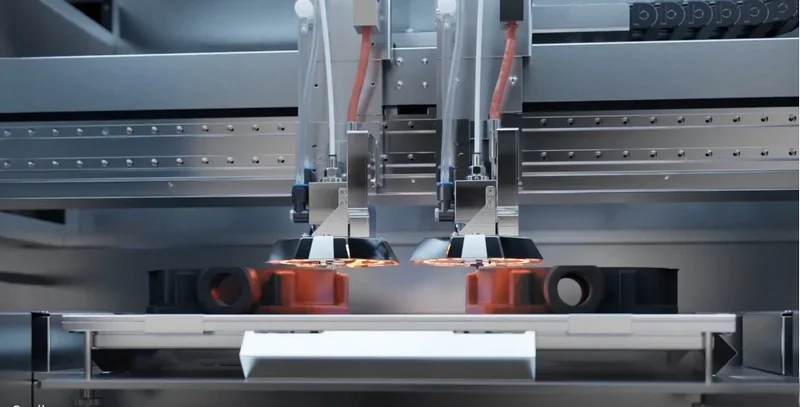

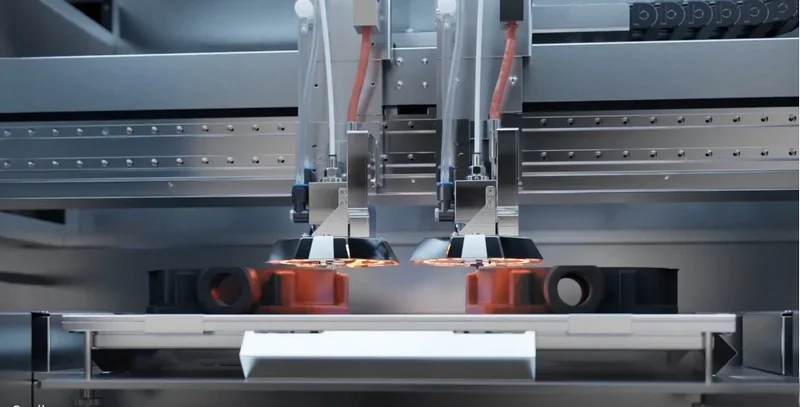

The independent dual extrusion system (IDEX) not only increases production capacity but also maintains filament integrity when printing with multiple filaments, as each extruder operates independently with its optimal temperature settings.

Print quality is further optimized by the integrated filament dryer that heats up to 150°C, eliminating residual humidity from hygroscopic filaments before printing. It holds up to four spools. This pre-conditioning process significantly improves surface quality and structural integrity of printed parts, particularly when working with engineering-grade filaments such as PEEK, PEEK-CFR, PEI 9085, or other high-performance polymers.The combination of these features makes the Apium P400 particularly effective for functional prototyping and small-series production of components requiring high mechanical strength and excellent surface quality.

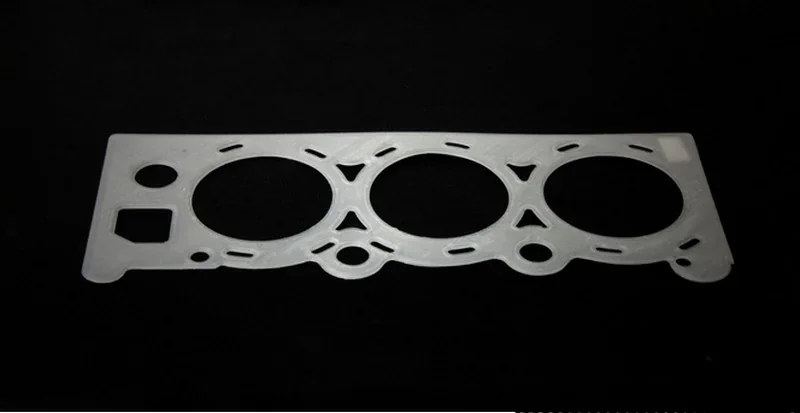

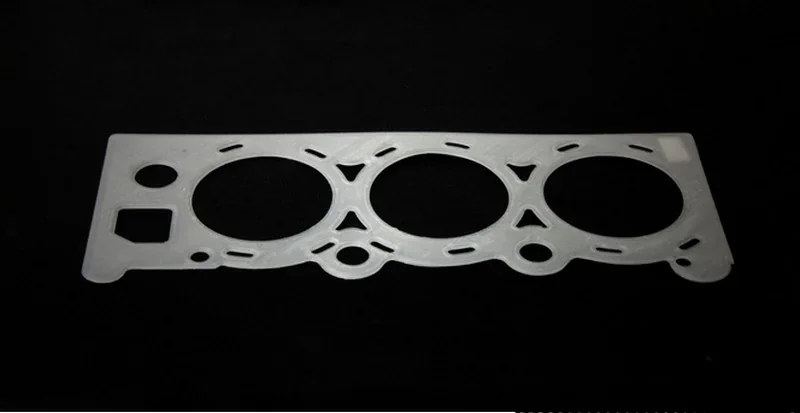

Example: This flat gasket, 3D printed in 5 h 36 min using 11.2 g of PVDF filament, features thickness through 50 μm layer resolution.

Which filaments can you use with the Apium P400 Additive Manufacturing System?

The Apium P400 supports demanding filaments with high-temperature capabilities: a 540°C extruder, 200°C heated bed, and zone heating over 500°C. Its 150°C filament dryer removes moisture from hygroscopic filaments, improving print quality and part integrity. The Apium P400 features an open filament system compatible with 1.75 mm filaments from any manufacturer.

PVDF 3D Print Sample: A 16.3 gram pipe cooling unit printed in 3h 01 m

Polypropylene 3D Print Sample: This 11.3 g bottle was printed in 10 h 17 min using 3.55 m of PP filament for 1.33 €, offering chemical resistance and low cost for material storage.

PEEK 3D Print Sample: An 11 gram gear wheel with arrow gearing printed in 1 h 47 m.

PEI 3D Print Sample: A 30 gram pump impeller printed in 4 h 05 m.

PEEK-CFR Print Sample: A 32.54 gram component for CNC-machining printed in 7 h 13 m.

PEEK GFR 3D Print Sample: This gearbox housing was 3D printed in 17h 44min using 116.7 g of PEEK GFR filament, costing 79.36 €. It’s used in mechanical engineering for its high dimensional stability and resistance to chemical, physical, thermal, and biological stress.

What is the build volume of the Apium P400?

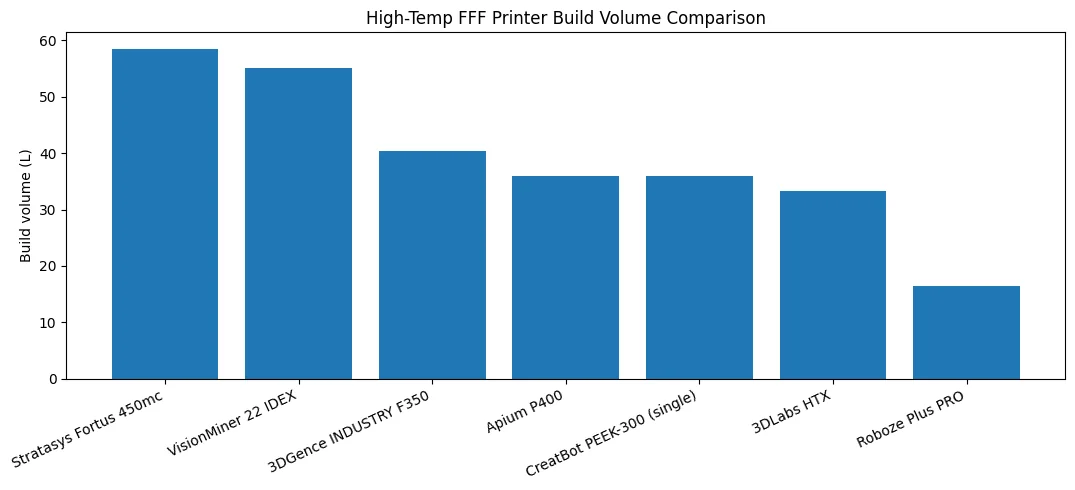

The Apium P400 offers a 400 x 300 x 300 mm (15.7 x 11.8 x 11.8 in) build volume. This medium-to-large industrial FDM printer balances capacity and footprint, with overall dimensions of 1060 x 705 x 1941 mm (41.7 x 27.8 x 76.4 in).

PEEK-GFR 3D Print Sample: Down-hole connector for oil & gas cable connections, printed in 27 h 24 min using 201.3 g / 58.11 m of filament (material cost €120.78), leveraging PEEK-GFR’s electrical insulation, chemical resistance, and compressive strength.

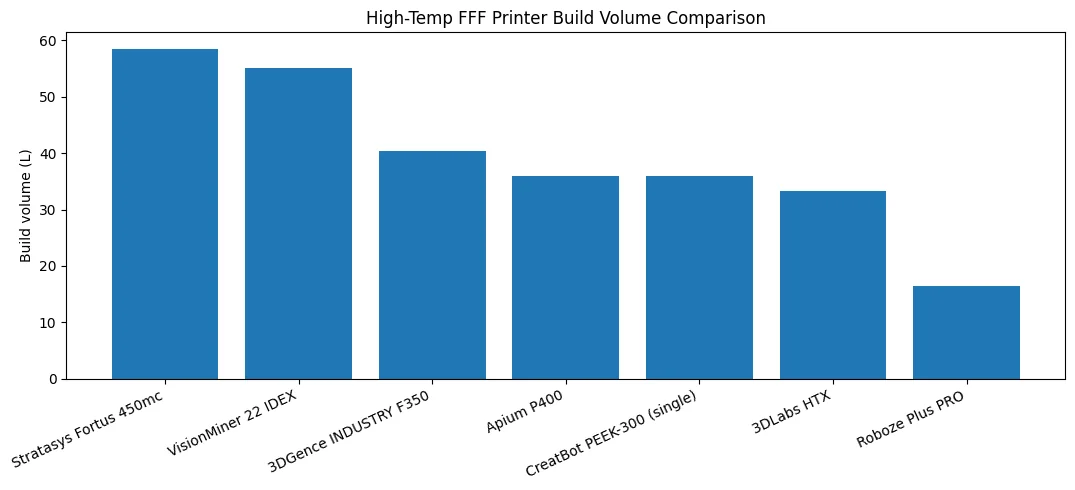

What is the difference between Apium P400, CreatBot PEEK-300, VisionMiner 22 IDEX, 3DLabs HTX, Roboze Plus PRO, 3DGence INDUSTRY F350 and Stratasys Fortus 450mc?

Apium P400 — high-temp, precision PEEK/PEI platform with a 540 °C extruder, 200 °C bed, and adaptive zone heating > 500 °C that performs in-situ annealing during printing (no separate post-anneal step), delivering fine 7.5 µm XY / 1.0 µm Z resolution across a 400 × 300 × 300 mm build at the premium tier ($125,000+).

In contrast:

- CreatBot PEEK-300 — Wins: far lower price ($13,000+) and taller Z 400 mm. Loses to P400: lower temps (480 °C nozzle, 120 °C chamber), coarser accuracy (12.7 µm XY / 1.25 µm Z), limited connectivity (USB/USB disk), and no in-situ annealing.

- VisionMiner 22 IDEX — Wins: larger 350 × 350 × 450 mm volume, higher bed (250 °C), IDEX, and modern connectivity; much cheaper ($14,900+). Loses: cooler process window (500 °C nozzle, 100 °C chamber), and coarser resolution (10 µm XY / 7 µm Z) vs Apium’s 7.5/1.0 µm; no in-situ annealing.

- 3DLabs HTX — Wins: lower price ($15,500+), solid 370 × 300 × 300 mm volume, 500 °C nozzle, 220 °C bed. Loses: 100 °C chamber, coarser 12.45 µm XY / 1.25 µm Z, and no in-situ annealing.

- Roboze Plus PRO — Wins: substantially cheaper ($50,000+). Loses: smaller 300 × 250 × 220 mm volume, lower temps (500 °C nozzle, 150 °C bed), coarser 15 µm XY / 25 µm Z, chamber not specified, and no in-situ annealing.

- 3DGence INDUSTRY F350 — Wins: strong 140 °C active chamber, competitive 340 × 340 × 350 mm volume, and much lower price ($30,000+). Loses: lower thermal ceiling (500 °C nozzle, 160 °C bed) and looser stated tolerance (±0.125 mm or 0.0014 mm/mm) vs Apium’s finer resolution; no in-situ annealing.

- Stratasys Fortus 450mc — Wins: larger 406 × 355 × 406 mm build and proven enterprise ecosystem. Loses: highest price ($185,000+), lower temps (450 °C nozzle, 140–160 °C bed), chamber not listed here, and tolerance spec (±0.127 mm or 0.0015 mm/mm) rather than fine-resolution metrics; no in-situ annealing.

What printer controls are available on the Apium P400?

The Apium P400 has a built-in color LCD touchscreen with an intuitive interface for managing print jobs, monitoring printer status, and tracking nozzles linked to specific filaments. It also provides access to automatic bed leveling and optical calibration for accurate print alignment. On-device controls include sensor-based monitoring of consumables and maintenance parts. The system also manages the integrated dryer, allowing filament preconditioning up to 150 °C to remove humidity from hygroscopic materials.

What connectivity options are available on the Apium P400?

The Apium P400 printer supports WiFi and Ethernet connectivity options. The WiFi module is optional and can be removed if needed. In addition, the Apium P400 supports remote monitoring — the printer status can be accessed and checked both on-site and via remote access using the integrated software.

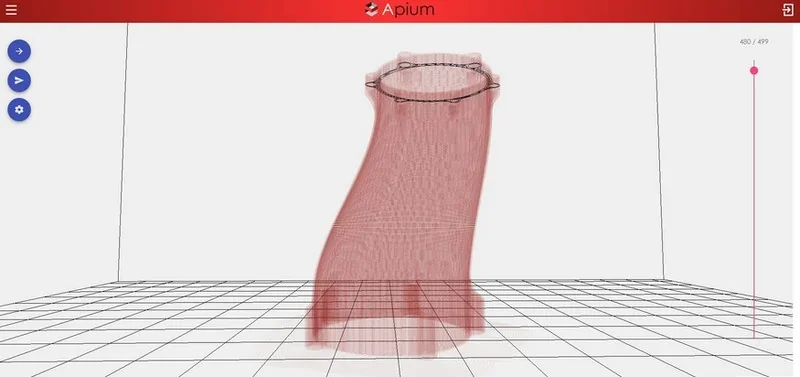

What slicing software is offered with the Apium P400?

The Apium P400 uses Apium CS, allowing users to choose their slicing software while offering integrated control software tailored to the printer. It features an intuitive interface for job management, printer monitoring, and tracking of consumables and maintenance. The software also auto-generates PDF protocols of key print parameters for quality assurance. The software accepts standard G-code files, ensuring compatibility with all major slicing applications on the market

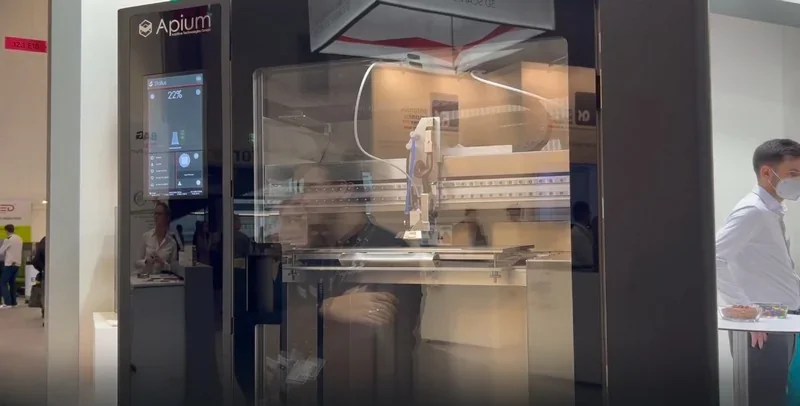

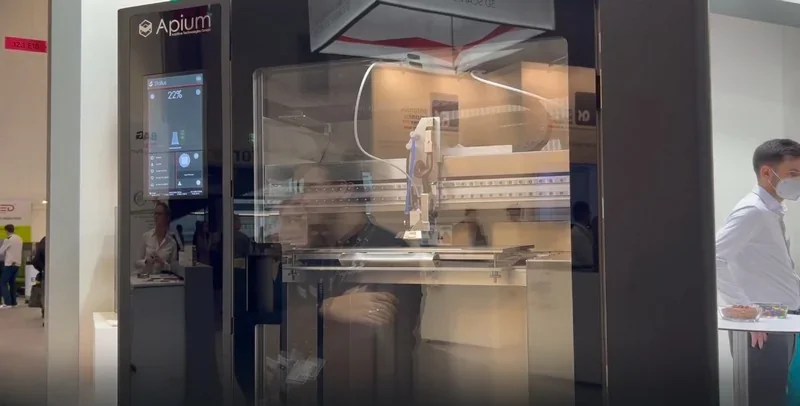

What is the design and build quality of the Apium P400?

What is the design and form factor of the Apium P400?

The Apium P400 is an industrial-grade 3D printer with an enclosed build chamber. Its overall dimensions are 1000 x 705 x 1941mm. The Apium P400 weighs 280kg.

What is the noise level of the Apium P400?

The Apium P400 emits less than 55dB(A) during operation.

What are the build platform specifications of the Apium P400?

The Apium P400 has a build volume of 400x300x300mm. The print bed heats to 200°C and is constructed from borosilicate glass and stainless steel. The Apium P400 features automatic table levelling.

What is the hotend and extruder system of the Apium P400?

The Apium P400 features a high-temperature extruder with a 540 °C nozzle and a patented adaptive zone heating system using infrared heating above 500 °C. It includes an IDEX system, interchangeable nozzles (0.2–1.0 mm), and an optical calibration system for precise alignment.

How does the Apium P400 handle filament storage and feeding?

The Apium P400 includes an integrated filament dryer that holds up to four spools and heats to 150°C.

What are the power supply specifications of the Apium P400?

The Apium P400 has a maximum power consumption of 3600W. The Apium P400 operates on a 230V, 50Hz power supply.

What comes included in the box with Apium P400?

What's in the box:

• 1x Apium P400 3D printer (fully assembled)

• 1x Built-in filament dryer

• 1x Tool set for maintenance and setup

• All necessary cables for power and connectivity

• 1x User manual with setup and operation instructions

The Apium P400 arrives fully assembled and ready to use after minimal setup. Its built-in filament dryer enables immediate processing of high-performance polymers without extra equipment. A complete tool set and user guide are included for setup, maintenance, and basic troubleshooting.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

What support and warranty come with the Apium P400?

The Apium P400 includes a 1-year warranty covering filament and workmanship defects under normal use. Backed by nearly a decade of expertise, Apium provides technical support to ensure reliable operation of its high-performance printing systems.

Apium offers comprehensive support options, including on-site installation, training, maintenance guidance, software updates, application support, and remote or on-site repairs by Apium engineers. These services aim to ensure uptime, print quality, and user proficiency.

How much does the Apium P400 cost?

The Apium P400 is available from Top3DShop by request for a personalized quote. As an industrial 3D printer, it offers key features like adaptive zone heating, IDEX, 540 °C printing, and an integrated dryer for processing polymers such as PEEK and PEKK. Each purchase includes delivery, a 1-year warranty, local support, and complimentary training. For pricing, contact Top3DShop, an official reseller of Apium Additive Technologies.