The Autodesk Fusion 360 Machining Extension expands the functionality of CAM programming tools inside Fusion 360 workspace. This extension is designed to prepare the model for machining. It allows for a flexible cost-effective way to make better use of your 5-axis CNC machinery and produce parts of higher quality.

The chart shows the extended capabilities of the Machining Extension compared to the original Fusion 360 software.

|

Fusion 360 |

Fusion 360 + Machining Extension |

||

|

Drilling |

Hole drilling (3-axis) |

✓ |

✓ |

|

Automatic hole recognition & drilling (3-axis and multi-axis) |

– |

✓ |

|

|

Milling |

2D and 2.5-axis milling |

✓ |

✓ |

|

3-axis milling |

✓ |

✓ |

|

|

3+1 and 3+2 axis positional milling |

✓ |

✓ |

|

|

Machine simulation |

✓ |

✓ |

|

|

Automated entire part machining (3-axis and multi-axis) |

– |

✓ |

|

|

4- and 5-axis simultaneous milling |

– |

✓ |

|

|

Multi-axis collision avoidance |

– |

✓ |

|

|

Turning |

2-axis turning |

✓ |

✓ |

|

Turn-mill machining |

✓ |

✓ |

|

|

Modifications |

Toolpath modifications – limit/split/delete sections |

– |

✓ |

|

Toolpath modifications – replace tool |

– |

✓ |

|

|

Inspection and part alignment |

Work Coordinate System (WCS) setup probing |

✓ |

✓ |

|

Manual inspection |

✓ |

✓ |

|

|

Geometry probing |

– |

✓ |

|

|

Surface inspection |

– |

✓ |

|

|

Part alignment |

– |

✓ |

|

|

Posts |

Post-processing of NC code |

✓ |

✓ |

Below are the main features the Machining Extension adds to your Fusion 360 software capabilities:

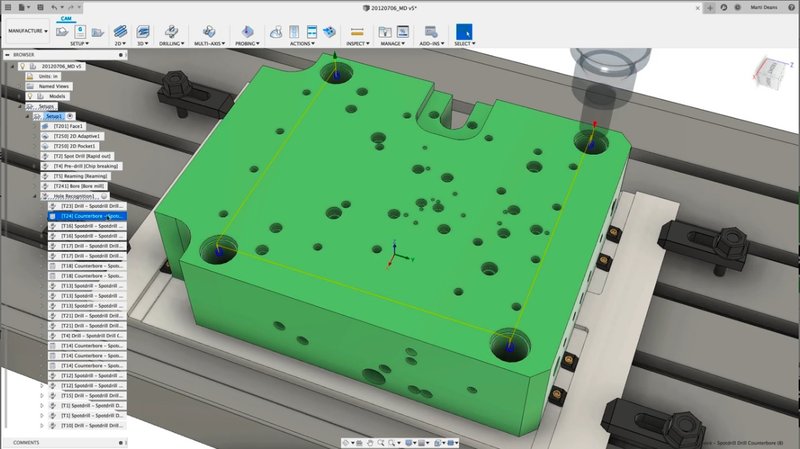

The function simplifies the drilling and milling of complex, feature-rich models with a range of intelligent toolpaths that can safely and efficiently process an entire part for faster CAM programming.

With automated 3+2 machining you get the access to additional strategies and tool axis controls that can use the rotary axes of your CNC machine to drill and mill entire parts.

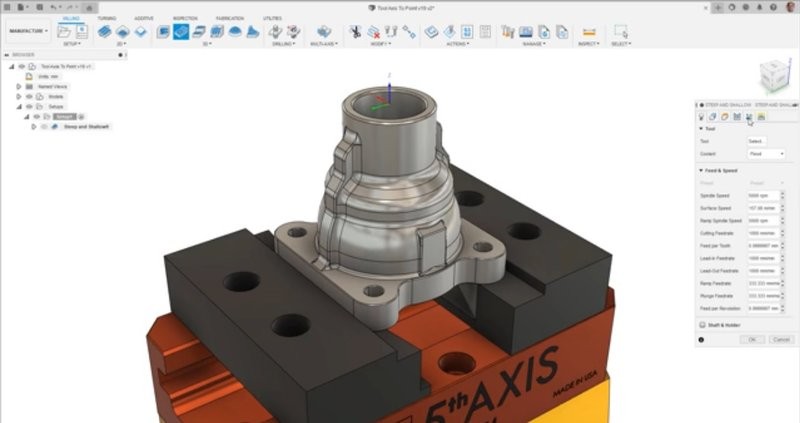

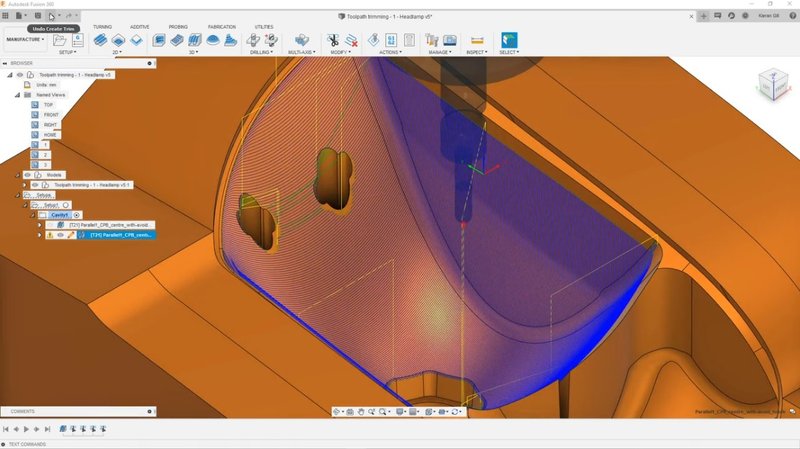

Advanced multi-axis strategies and tool axis options allow you to drive the linear and rotary axes of your CNC machine simultaneously to improve surface finish, use fewer parts setups, and produce the most complex shapes safely and efficiently with automatic collision avoidance.

You can take advantage of powerful modification tools to make global or local edits to toolpaths without wasting time on a complete recalculation. For greater flexibility you can edit modifications themselves.

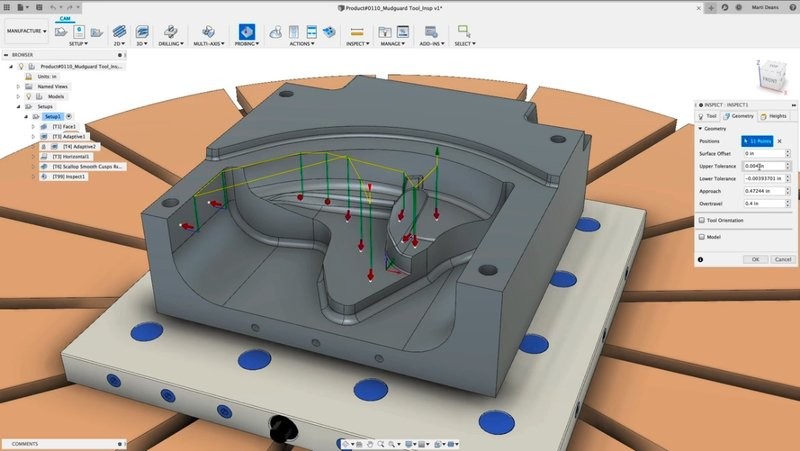

This function allows you to measure features in-process with the probing cycles on your machine. You can verify dimensions and positions of critical geometric features, update tool wear parameters, and pause or stop your programs to address out-of-tolerance features.

With CAD-based probing capability you can measure and improve the accuracy of complex surface geometry with a spindle-mounted probe. Intelligent part alignment automates the setup and machining of non-prismatic parts, like forgings and castings, thus helping save time and increase product quality.

The Fusion 360 Machining Extension is an indispensible set of powerful tools for any enterprise employing CNC machining. The extension allows for workflow automation which helps the user speed up programming, eliminate repetitive tasks, and minimize possible errors. It greatly adds to your CNC machines’ performance and ensures production of high-quality parts.

The system requirements for the Autodesk Fusion 360 software are as follows:

|

OS |

Apple macOS:

Microsoft Windows:

|

|

CPU |

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported |

|

RAM |

4 GB (integrated graphics recommend 6 GB or more) |

|

Hard disk |

3 GB of storage |

|

Display |

1366 x 768 (1920 x 1080 or greater at 100% scale recommended) |

|

GPU |

DirectX11 (Direct3D 10.1 or greater); dedicated GPU with 1 GB or more of VRAM; integrated graphics with 6 GB or more of RAM |

|

Pointing device |

HID-compliant mouse or trackpad, optional Wacom® tablet and 3Dconnexion SpaceMouse® support |

|

Internet |

2.5 Mbps or faster download; 500 Kbps or faster upload |

|

Dependencies |

SSL 3.0, TLS 1.2+, .NET Framework 4.5 or newer required to submit crash reports |

To learn the current price of the Autodesk Fusion 360 Machining Extension, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now