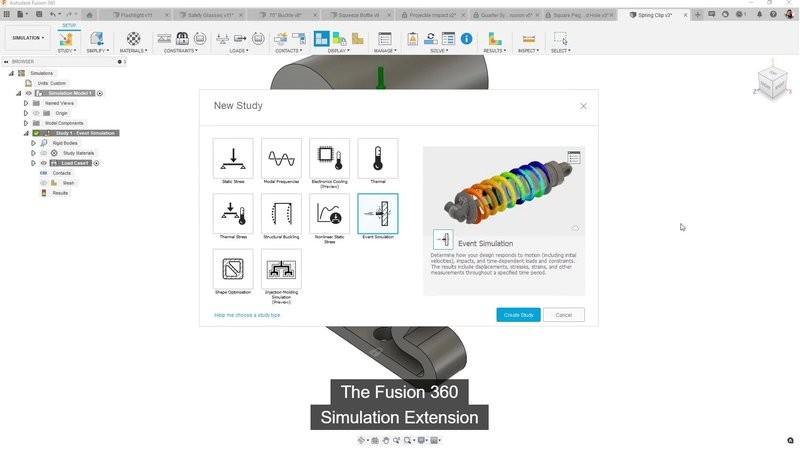

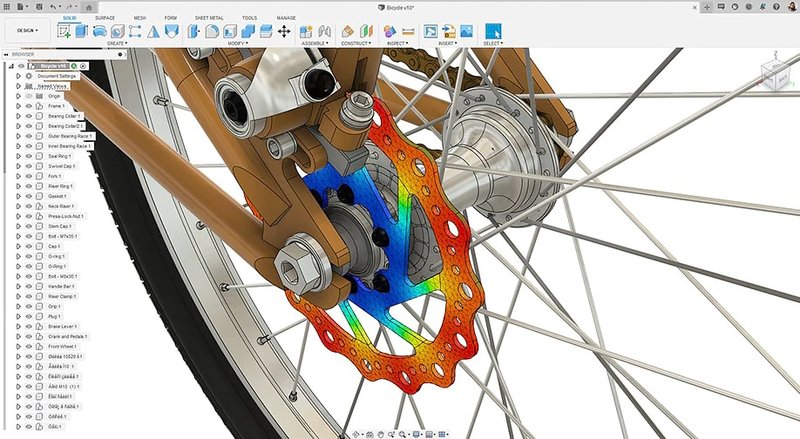

The Autodesk Fusion 360 Simulation Extension further expands the 3D simulation capabilities of the Fusion 360 software and provides designers and engineers with the opportunity to analyze performance and processability of the product under development. A variety of study types allows for the deep insight into the model design and helps improve its performance in real-life conditions without the need of spending time and money on prototyping.

The extension grants access to professional-grade simulation tools and numerous cloud solutions for advanced study types, meeting the requirements of the most demanding analysts.

This feature provides the engineers with a heads-up look into the molding process and allows them to test the manufacturability of the part to prevent such common issues as sink marks, air entrapments, warpage, shrinkage, and weld lines.

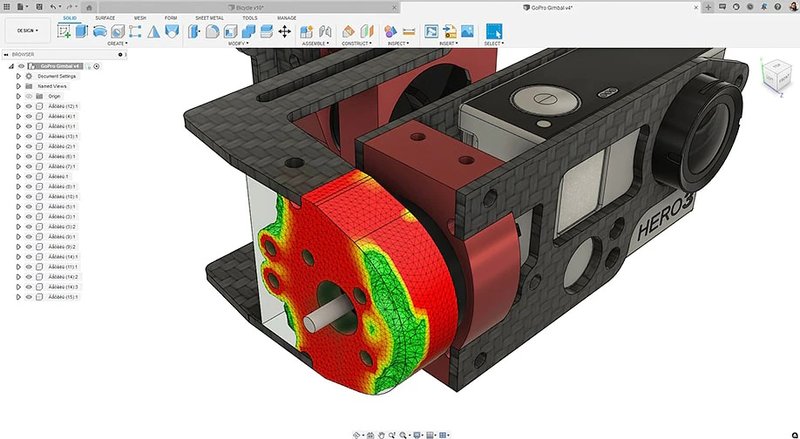

Non-linear static stress simulation allows the user to stimulate and quickly produce the result of complex nonlinear boundary conditions, like large deformation, motion, contact, and load change.

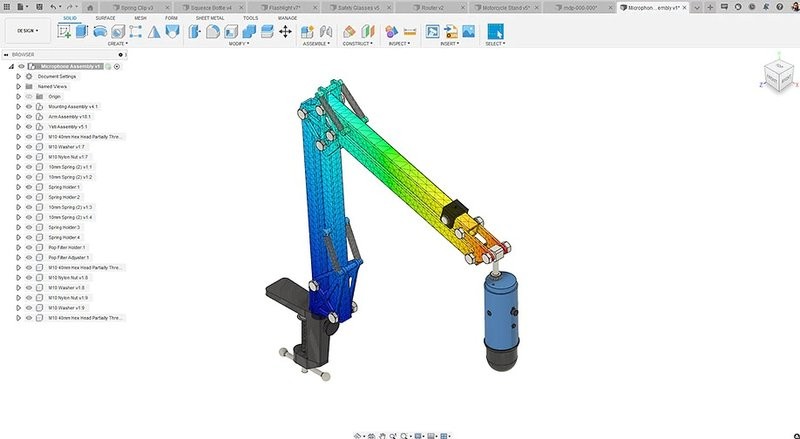

This study type examines how time-dependent non-linear loads, such as collisions or accelerations, influence the part performance. It predicts the model’s behavior from drop tests, ballistics impacts, or compliant and flexible structures, like living hinges and snap closures.

Thermal steady state simulation offers the opportunity to test the thermal management of the model and its ability to absorb, deflect, or shed thermal energy through conduction, reflection, and radiation.

This study shows how the product can be affected by natural free vibrations. This will help realize if your 3D model design needs to be modified.

This analysis helps determine the critical buckling multiplier to prevent structural failure.

You can simulate your model’s behavior under the temperature-induced stresses and determine the critical values at which the design can deform.

This feature allows you to determine the final shape of the model and make it as lightweight as possible. You only need to specify certain conditions, such as weight and material type, to identify and remove the excessive material from your product.

Simulations use a mathematical representation of a physical system. The simulation workflow consists of the following steps:

The Fusion 360 Simulation Extension is a powerful instrument for designers and engineers that allows for ultimate product testing in real-life conditions. It provides the opportunity to examine the model performance at the development stage, thus preventing possible manufacturing failures and reducing development and production costs.

The system requirements for the Autodesk Fusion 360 software are as follows:

|

OS |

Apple macOS:

Microsoft Windows:

|

|

CPU |

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported |

|

RAM |

4 GB (integrated graphics recommend 6 GB or more) |

|

Hard disk |

3 GB of storage |

|

Display |

1366 x 768 (1920 x 1080 or greater at 100% scale recommended) |

|

GPU |

DirectX11 (Direct3D 10.1 or greater); dedicated GPU with 1 GB or more of VRAM; integrated graphics with 6 GB or more of RAM |

|

Pointing device |

HID-compliant mouse or trackpad, optional Wacom® tablet and 3Dconnexion SpaceMouse® support |

|

Internet |

2.5 Mbps or faster download; 500 Kbps or faster upload |

|

Dependencies |

SSL 3.0, TLS 1.2+, .NET Framework 4.5 or newer required to submit crash reports |

To learn the current price of the Fusion 360 Simulation Extension, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now