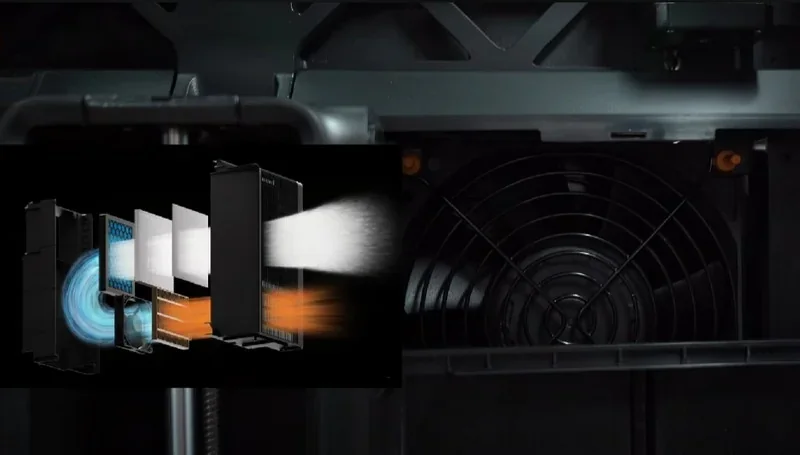

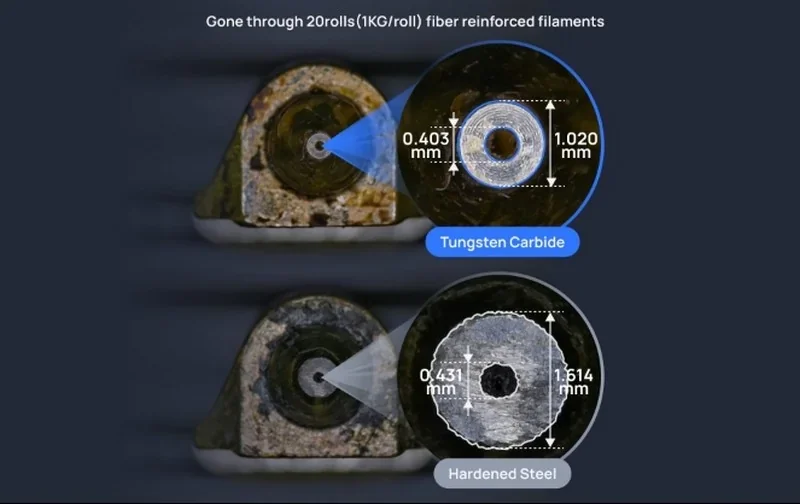

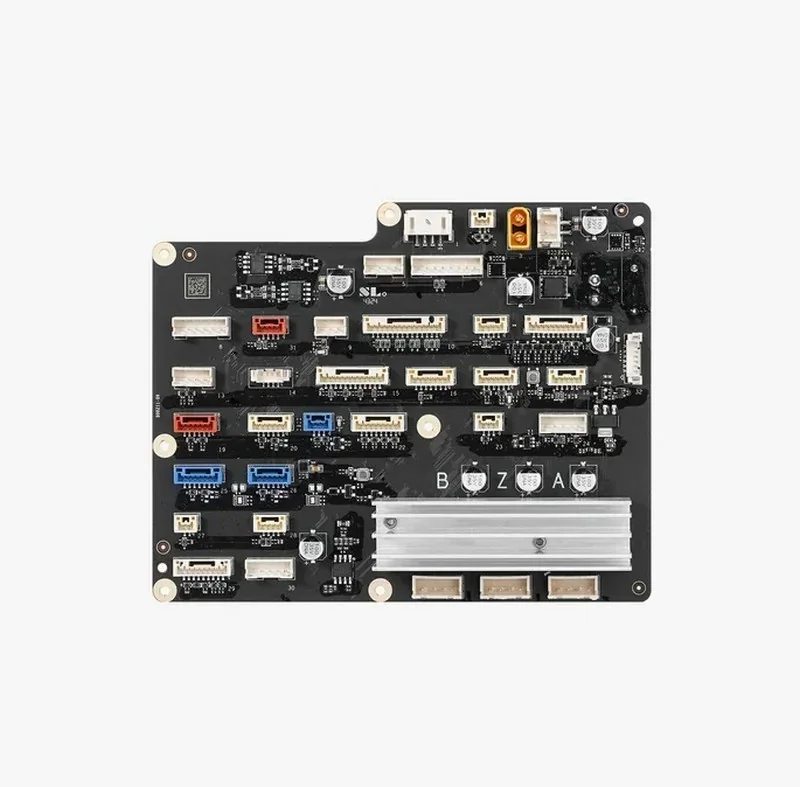

Bambu Lab H2D Pro is a professional dual-nozzle FFF 3D printer built for engineering-grade, multi-material production, combining a 350 × 320 × 325 mm total build envelope with 350 °C all-metal hotends (tungsten-carbide nozzles, a more powerful cooling system than on the H2D), a 65 °C actively heated chamber, and a standard Vision Encoder that delivers 50 µm motion accuracy across the plate — features that elevate dimensional fidelity on technical polymers and composites.

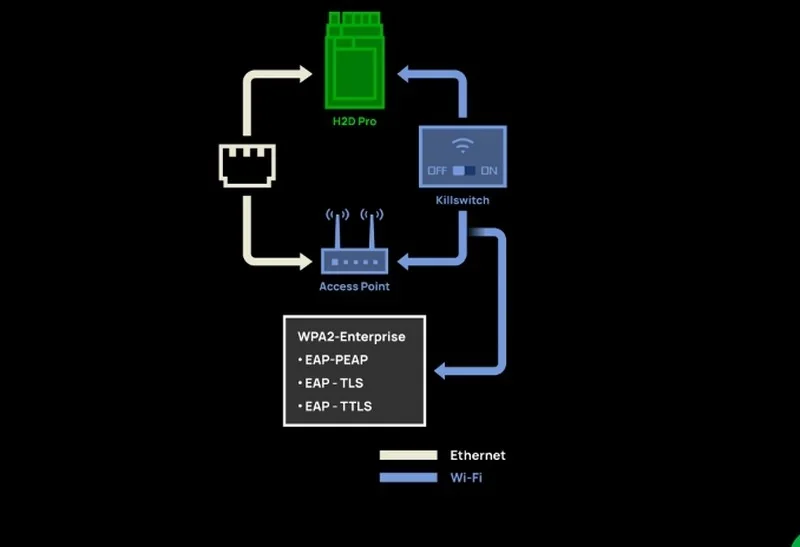

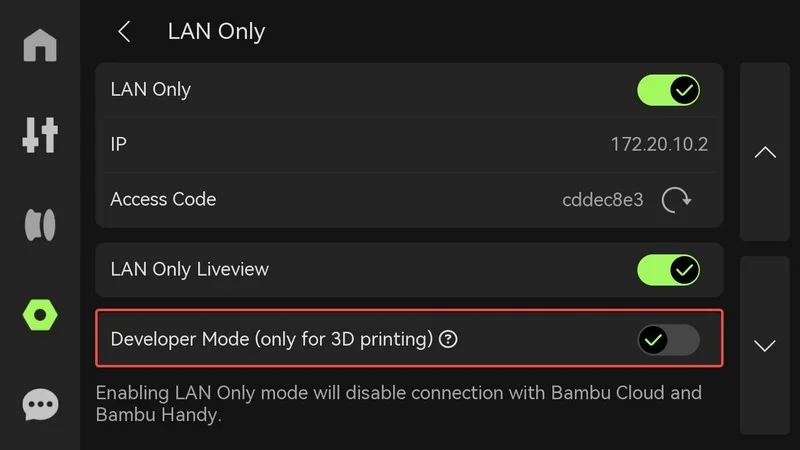

Distinctively, the H2D Pro adds enterprise-ready networking — Ethernet, WPA2-Enterprise (802.1X), hardware kill switches for Wi-Fi/Ethernet, and a removable network module for air-gapped deployment — while AMS 2 Pro and AMS HT ship in the box for moisture-controlled, RFID-assisted material handling, positioning the H2D Pro as a high-reliability desktop platform for professional environments.

The H2D Pro delivers consistent, engineering-grade results at speed: independent testing measured repeatability deviations consistently <0.05 mm, and — after enabling Bambu Studio’s hole/shaft compensation — circular features reached a 0.044 mm mean deviation (σ = 0.021 mm), with stress tests confirming overhangs to 65° and bridges to 60 mm; the suite’s aggregate score placed the H2D Pro at the top end of desktop FFF performance.

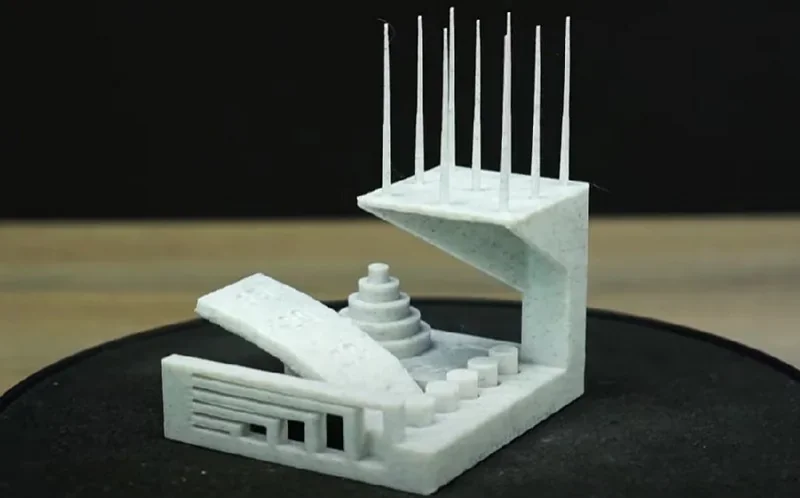

All-In-One test: clean layers, sharp spikes, accurate bridges; only minor overhang sag, fixable with slicer tweaks.

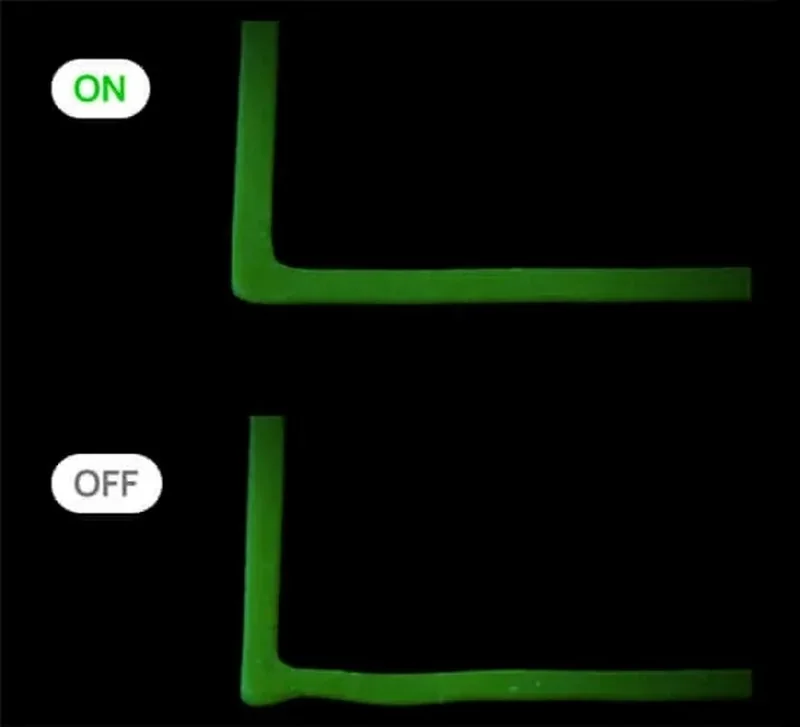

Mechanically, the platform sustains high throughput with a 1,000 mm/s toolhead limit, 20,000 mm/s² acceleration and 40 mm³/s rated flow, while its Vision Encoder uses 5 µm optical measurement to calibrate motion and hold 50 µm distance-independent accuracy across the plate; the 65 °C actively-heated chamber stabilizes layers on technical polymers to reduce warp and delamination.

Quality-driving features (impact on adhesion, accuracy, and surface finish):

In VFA, extrusion-consistency, and cooling tests, the H2D beat the X1C with smoother walls, lower ringing, and cleaner layers. Compared to the lighter H2C, it shows slightly more high-acceleration artifacts but delivers stronger cooling and better overhangs.

XYZ 20 mm cube in PLA, PETG, and ABS showed good dimensional accuracy. Surface finish was typical, with minor bubbles from undried filament — overall, standard FDM quality.

PLA Print Sample:

Dual-material print (PLA + Bambu Support-PLA): extremely clean overhangs, minimal sagging, and consistent layers—cleaner than the first layer.

Credit: Robert Silvers, Bambu Labs Facebook Community Group

Print Speed Test:

H2D printed a knitted PLA panda in 3h20m with clean surfaces and minimal purge waste — much faster than the P1S (8h36m) thanks to dual nozzles and an optimized multicolor workflow.

Credit: Alex Morales, Bambu Labs Facebook Community Group

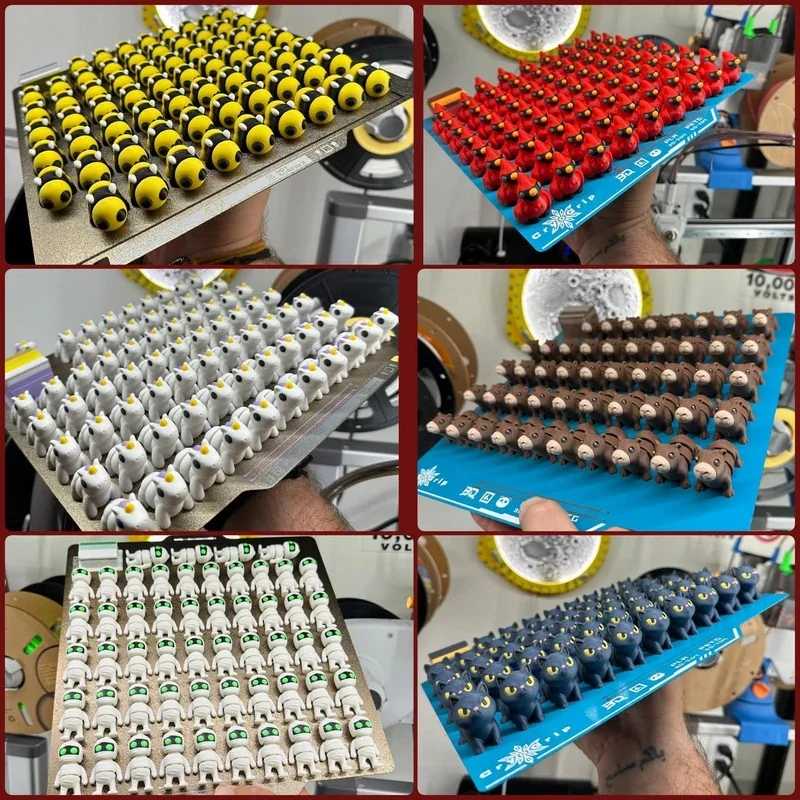

Batch Reliability:

Print Samples: Williams Industries uses the H2D to mass-produce high-quality, multicolor 3D prints in consistent batches for clients like Paramount, Nickelodeon, and HBO, and for special needs programs.

Credit: Mikal Williams

Multi-Assembly Projects Tests:

The H2D successfully printed a large, multicolor One Piece “Thousand Sunny” model in PLA, delivering vivid colors, sharp details, strong layer adhesion, and accurate textures on parts exceeding 30 cm. It completed over 100 components reliably within 2–3 weeks of continuous printing.

The H2D Pro supports 20 material types, including PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA (nylon), PET, PLA-CF/GF, PETG-CF/GF, PA-CF/GF, PET-CF/GF, PC-CF/GF, ABS-CF/GF, ASA-CF/GF, PPA-CF/GF, PPS, and PPS-CF/GF; its 350 °C hotends, 65 °C actively heated chamber, tungsten-carbide nozzles, and the included AMS HT dryer (up to 85 °C) broaden compatibility with engineering polymers and fiber-reinforced composites. Note that TPE and very soft TPU, as well as carbon/glass-fiber-filled filaments, are not supported through AMS feeding (load these via the side-mounted direct spool path); damp PVA/BVOH are also not supported. The system is open to standard 1.75 mm third-party materials, while RFID on Bambu spools enables automatic presets in Bambu Studio for convenience.

PLA 3D Print Sample:

PLA + PVA, PLA + PETG, PLA + PLA, PLA + PVA, PLA + PLA Silk Print Sample:

PETG + TPU Print Sample:

TPU Print Sample:

TPU 3D Print Sample:

ABS-GF 3D Print Sample:

PA6-CF with ABS/ASA Print Quality Tests:

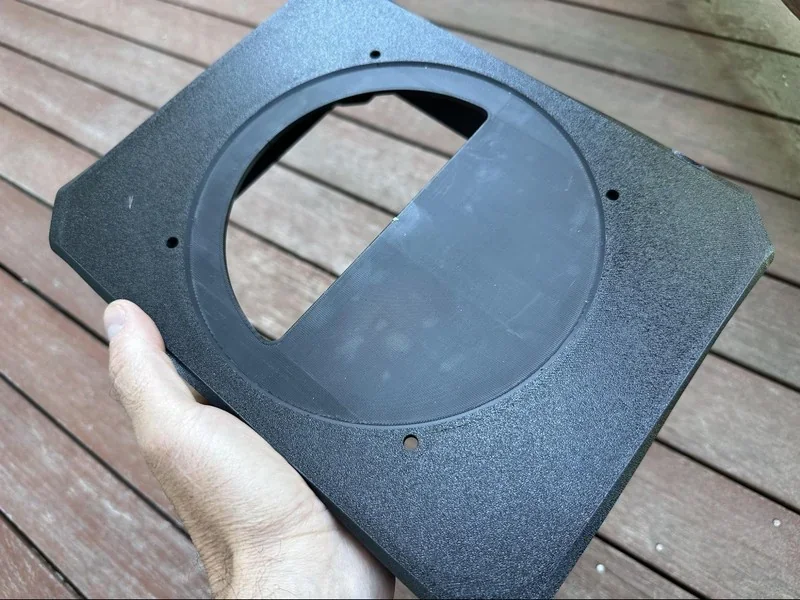

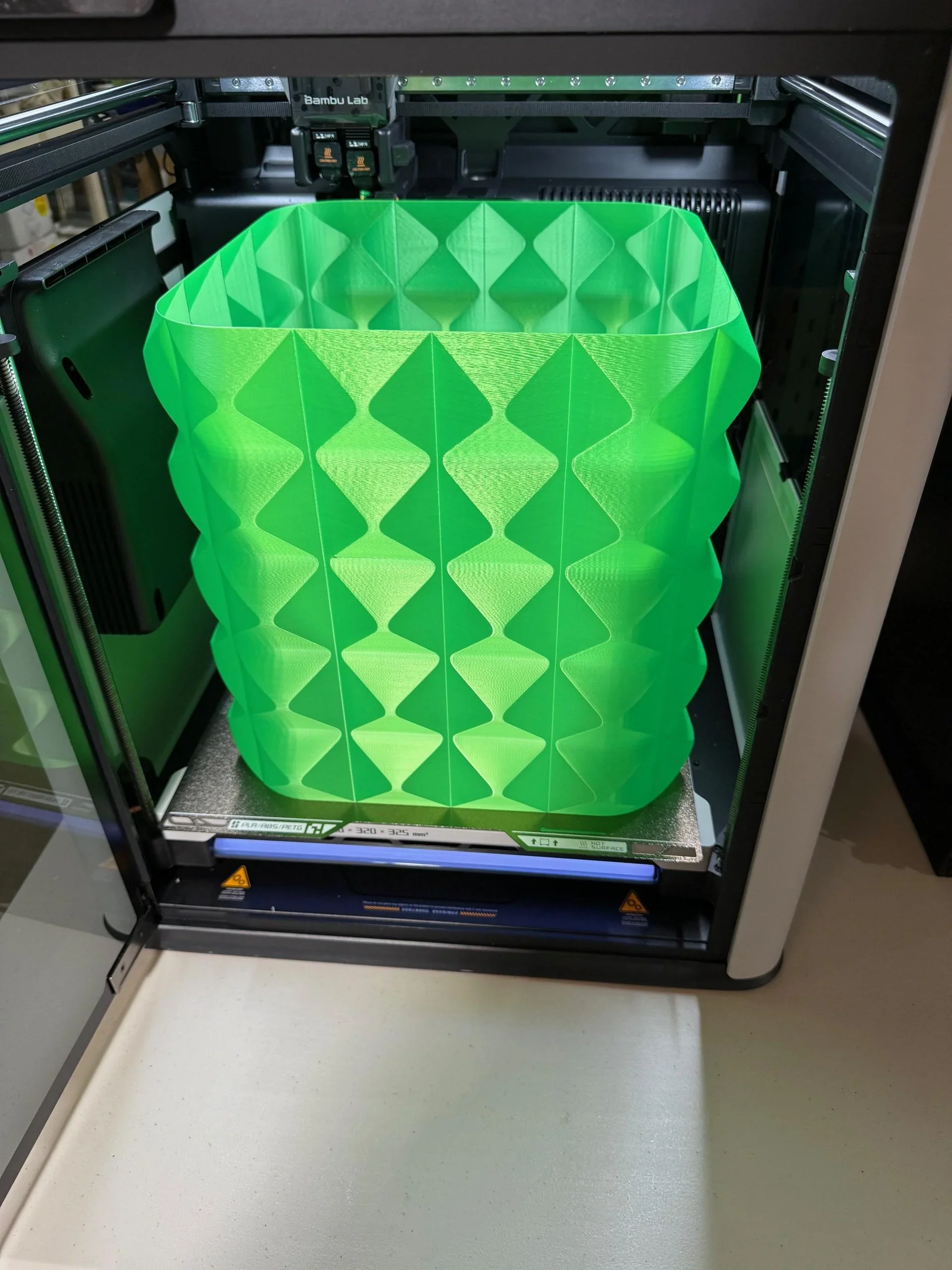

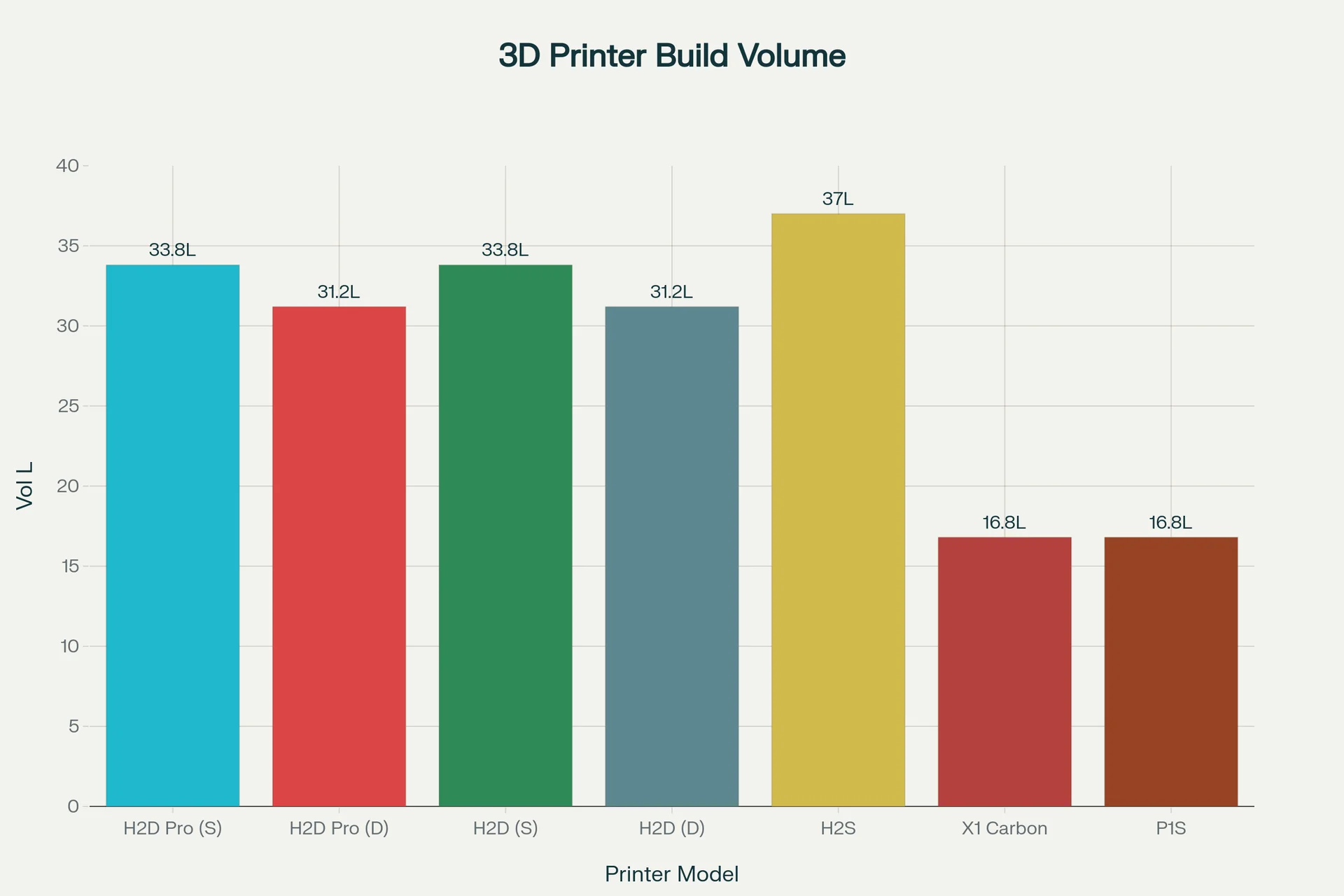

The H2D Pro provides a total build volume of 350 × 320 × 325 mm, with an effective area of 325 × 320 × 325 mm in single-nozzle mode and 300 × 320 × 325 mm in dual-nozzle mode due to the carriage clearance required for two hotends.

Credit: Reddit User https://www.reddit.com/user/separatelyrepeatedly/

The Bambu Lab H2D Pro refines the H2D platform for enterprise use by bundling key upgrades—Ethernet connectivity, WPA2-Enterprise support, a physical Wi-Fi kill switch, and a pre-installed Vision Encoder for 50 µm motion accuracy. It also features a durable tungsten carbide nozzle and enhanced toolhead cooling, improving high-temperature reliability and reducing clogs. Unlike the H2S, which trades dual extrusion for a lighter toolhead and marginally cleaner high-speed prints, the H2D Pro retains dual-material support for efficient multicolor and functional part production. Compared to the X1 and P1 series, which are limited to a 300 °C nozzle and 500 mm/s print speed, the H2D Pro offers a 350 °C nozzle and 1000 mm/s speed, along with a 65 °C actively heated chamber — enabling faster, more stable printing with advanced materials like PA, PC, and carbon fiber. With superior air filtration and dedicated enterprise support, the H2D Pro stands out as the most capable option for professionals needing speed, precision, and industrial-grade reliability.

|

Model |

Build volume (mm) |

Chamber |

Max nozzle (°C) |

Max speed (mm/s) |

Price (USD) |

|

Bambu Lab H2D Pro |

325×320×325 (single); 300×320×325 (dual) |

Active to 65 °C |

350 |

up to 1000 |

From $3,799 . |

|

Bambu Lab H2D |

325×320×325 (single); 300×320×325 (dual) |

Active to 65 °C |

350 |

up to 1000 |

From $1,999. |

|

Bambu Lab H2S |

340×320×340 |

Active to 65 °C |

350 |

up to 1000 |

From $1,249. |

|

Bambu Lab X1 Carbon |

256×256×256 |

Enclosed (no active heat) |

300 |

up to 500 |

From $799 (printer) / $1,249 (Combo). |

|

Bambu Lab P1S |

256×256×256 |

Enclosed (no active heat) |

300 |

up to 500 |

From $549 (printer) / $749 (Combo). |

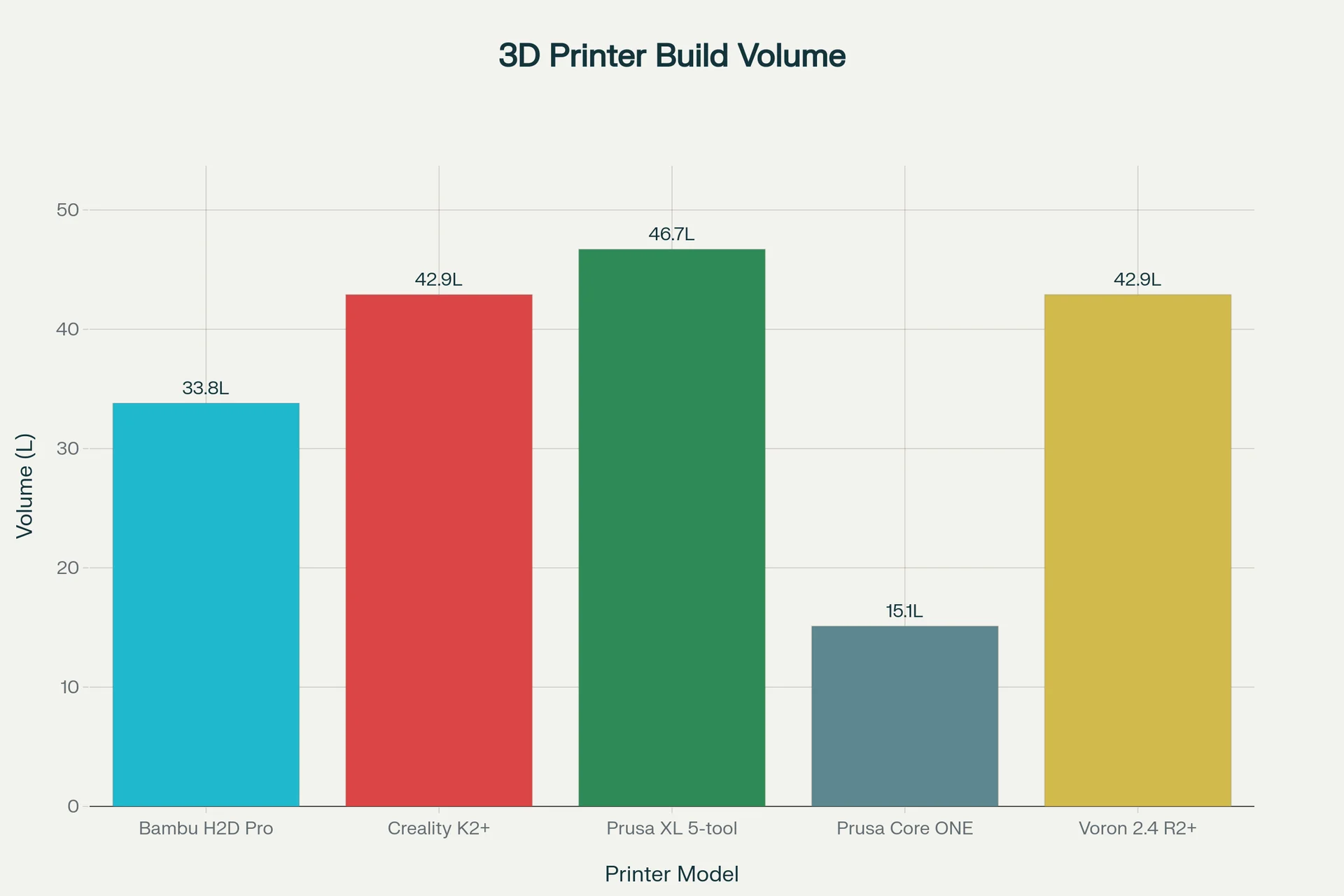

The H2D Pro emphasizes controlled high-temp, multi-material production: a 65 °C active chamber, 350 °C nozzle, up to 1000 mm/s with 20,000 mm/s² acceleration, 40 mm³/s flow, triple 1080p cameras, and enterprise networking (Ethernet, 802.1X, removable module, hardware kill switch). Creality K2 Plus matches the big-box size and adds an active chamber but is capped at ≤600 mm/s and relies on a desiccant-based CFS. Original Prusa XL trades active heating for a 5-tool toolchanger (zero-purge style workflow) but tops out at 290 °C. Prusa Core ONE targets compact precision (250×220×270 mm, 55 °C chamber ceiling, 290 °C nozzle), while Voron 2.4 R2 PRO+ is a kit in the 350³ mm class with 300 °C/110 °C thermals and no active chamber heat.

Bambu Lab and Prusa offer responsive support, fast part replacements, and consistent product quality. Creality's China-based support has delays, no phone line, language issues, and slow part delivery (3–8 weeks); reliability varies from batch to batch. Voron is DIY — performance depends on your engineering skills; all troubleshooting is done through the community forums.

| Category | Bambu Lab H2D Pro | Creality K2 Plus | Original Prusa XL (5-tool) | Prusa Core ONE | Voron 2.4 R2 PRO+ |

|---|---|---|---|---|---|

| Build volume (mm) | 325×320×325 (single); 300×320×325 (dual) | 350×350×350 | 360×360×360 | 250×220×270 | 350×350×350 |

| Max nozzle temperature / max bed temperature (°C) | 350 / 120 | ≤350 / ≤120 | 290 / 120 | 290 / 120 | 300 / 110 |

| Chamber heat (°C) | Active, up to 65 °C | Active, ≤60 °C | No active heater (enclosure optional) | Warm chamber ≤55 °C (no active heater) | Enclosed; no active heater stated |

| Max speed / acceleration (mm/s²) | 1000 mm/s / 20,000 mm/s² | ≤600 mm/s / ≤30,000 mm/s² | — (Input Shaper) | — (Input Shaper) | 250 mm/s (print) |

| Multi-material | Dual-nozzle; AMS 2 Pro / AMS HT (drying, odometry) | CFS 4-slot; ≤4 extensions (desiccant) | Toolchanger up to 5 heads (waste-lean) | MMU3 support | Single tool; community AFC optional |

| Networking | Ethernet + Wi-Fi, 802.1X, removable module, HW kill switch | USB / Ethernet / Wi-Fi | USB / LAN; optional Wi-Fi; Prusa Connect | Ethernet; optional Wi-Fi; Prusa Connect/App | Varies by build (DIY, Klipper stacks common) |

| Cameras / sensors | Triple 1080p (live/nozzle/toolhead); run-out, tangle; door; closed-loop fans | AI cam (monitoring & calibration); run-out; active belt/bed tilt | Loadcell first-layer; filament sensor; Power Panic | Loadcell; dual filament sensors; door | Tap leveling; ADXL345; run-out |

| Support & reliability | Timely support, quick parts, consistent units; low “lemon” risk | China-based; response delays (US/EU), no phone line, language barrier; parts 3–8 weeks; unit quality varies (“lottery”) | Timely support, quick parts, consistent units; low “lemon” risk | Timely support, quick parts, consistent units; low “lemon” risk | DIY kit; no official support—community forums; outcome depends on builder skill |

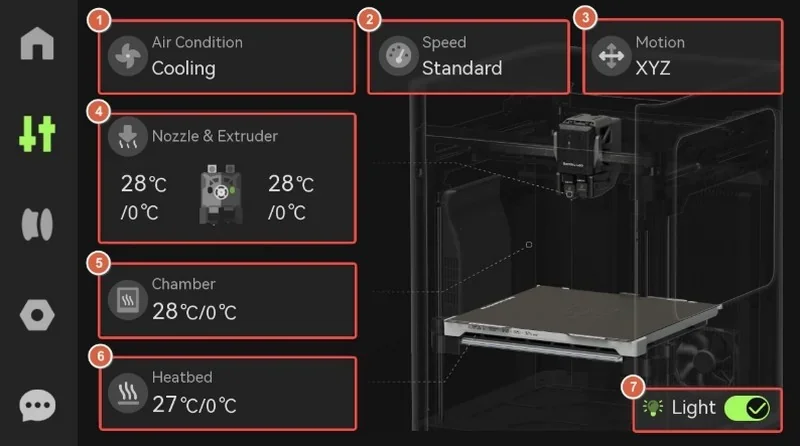

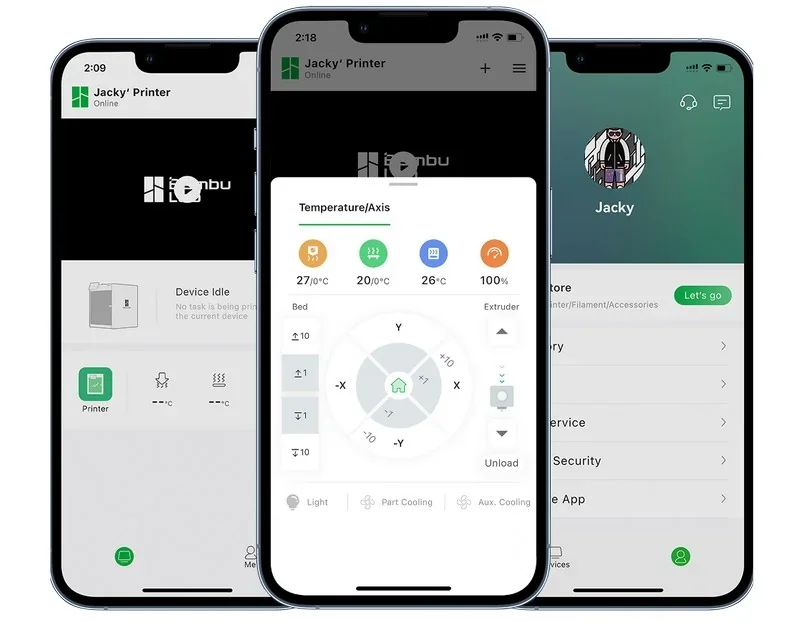

The H2D Pro uses an on-printer 5-inch, 720 × 1280 capacitive touchscreen with a left rail of primary tabs—Homepage, Controls, Filaments, Settings, and HMS — plus quick tiles for Print Files, Nozzle Temp, Filament, and Status. This layout centralizes job launch, calibration, and routine adjustments directly on the device without a computer.

Job control & monitoring

Launch prints from Print Files; during jobs, the screen provides Pause/Stop and real-time status.

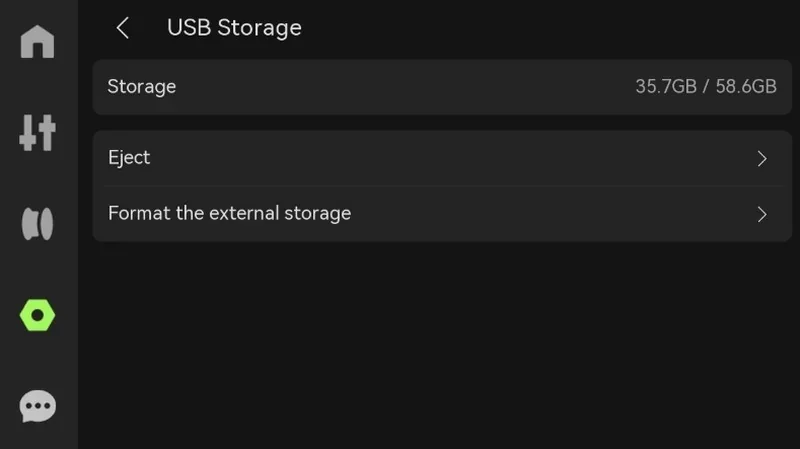

The system includes 32 GB eMMC for internal print storage, so models can run directly from the printer without external media.

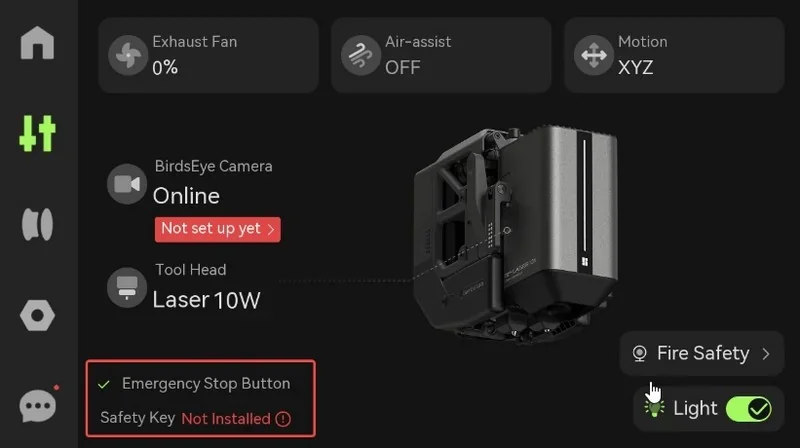

Safety & hard controls

The printer includes an Emergency Stop button (in-box) and a safety key interlock that must be inserted for operation—adding industrial-grade safety beyond the standard H2D.

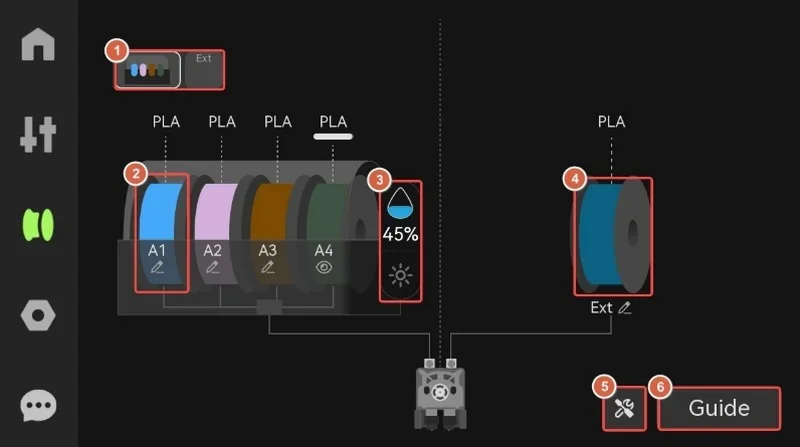

Filament & AMS setup

Filaments / AMS pages present slot selection and Load actions for automatic feeding.

In addition, H2D Pro adds a guided AMS setup wizard for configuring AMS 2 Pro / AMS HT, simplifying material routing and multi-material use.

Visual & environmental controls

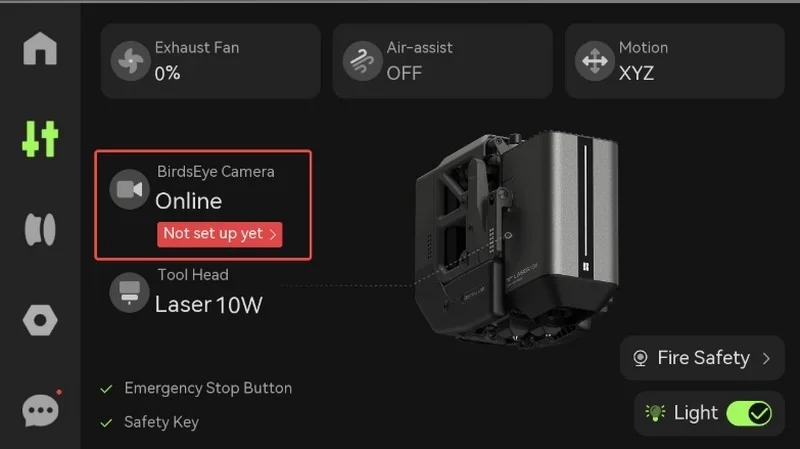

One-touch light control and optional BirdsEye camera tile appear in Controls for on-device visibility and time-lapse recording.

A USB drive is required for time-lapse saving and log export.

Air & motion control

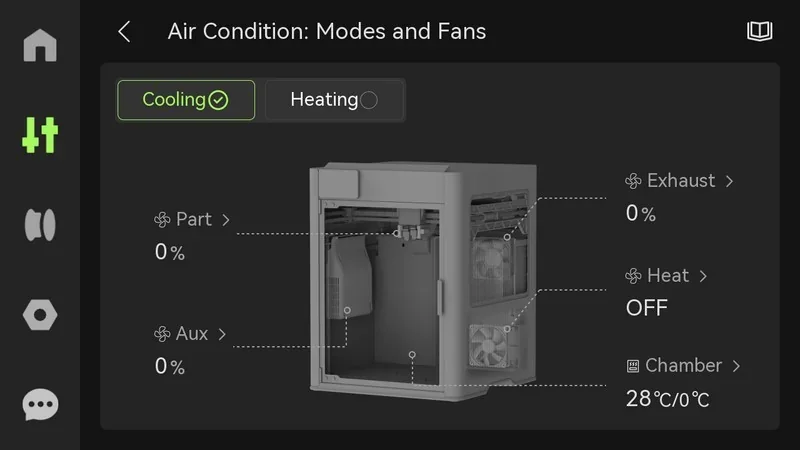

Controls → Air Condition manages chamber Cooling/Heating, part-cooling, auxiliary cooling, exhaust, and circulation fans to stabilize print quality.

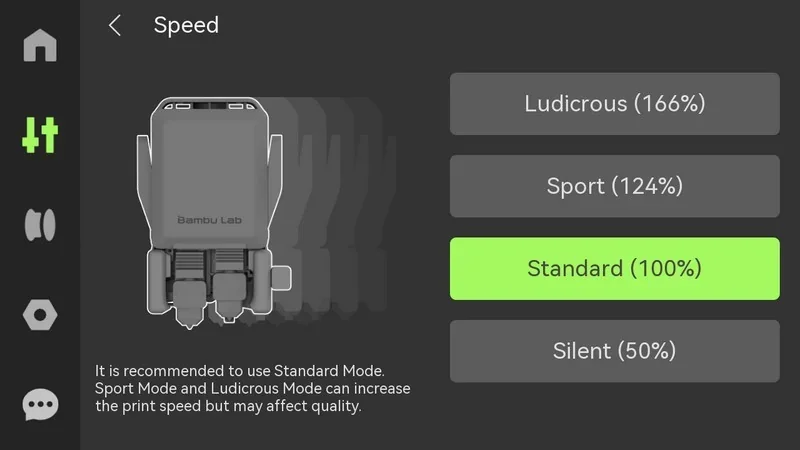

Controls → Speed offers Silent / Standard / Sport / Ludicrous motion presets balancing quality and throughput.

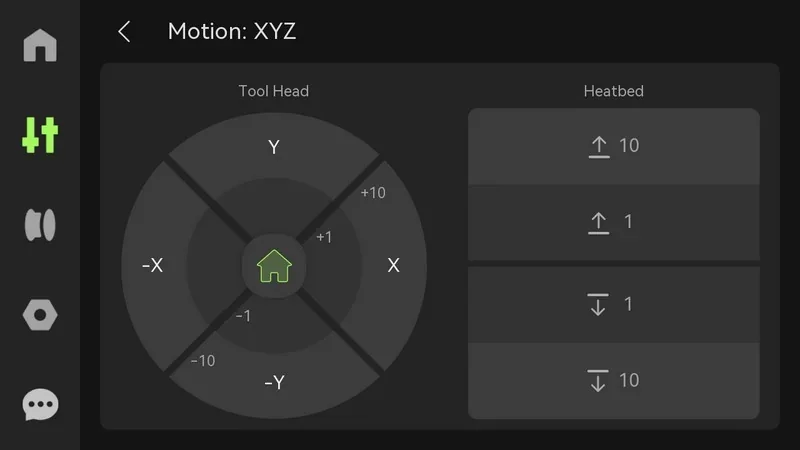

Controls → Motion jogs XY toolhead and Z bed for setup or recovery.

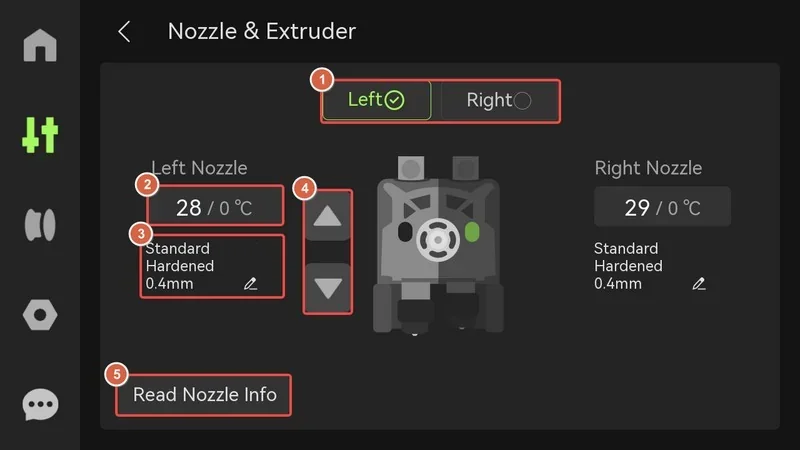

Controls → Nozzle & Extruder selects left/right nozzle, sets nozzle type/diameter, temperatures, and manual load/unload; Read Nozzle Info automatically detects installed nozzle metadata.

Calibration & maintenance

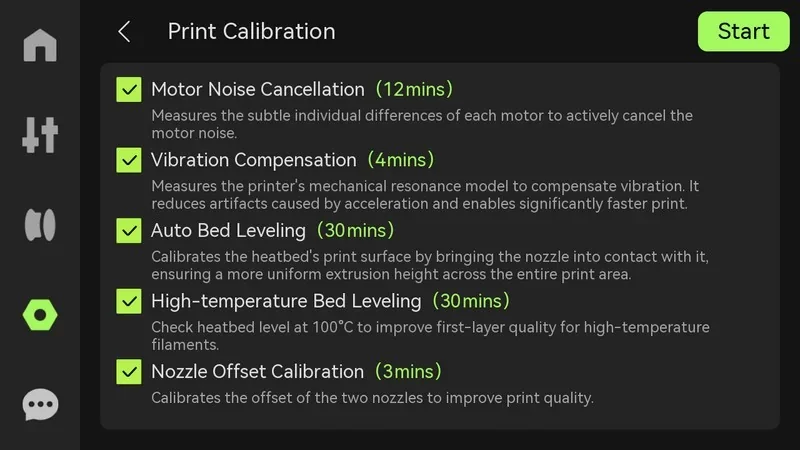

From Settings → Calibration / Print Calibration, the H2D Pro runs built-in adjustment routines—motor noise cancellation, vibration compensation, auto bed leveling, high-temperature leveling, and dual-nozzle offset calibration.

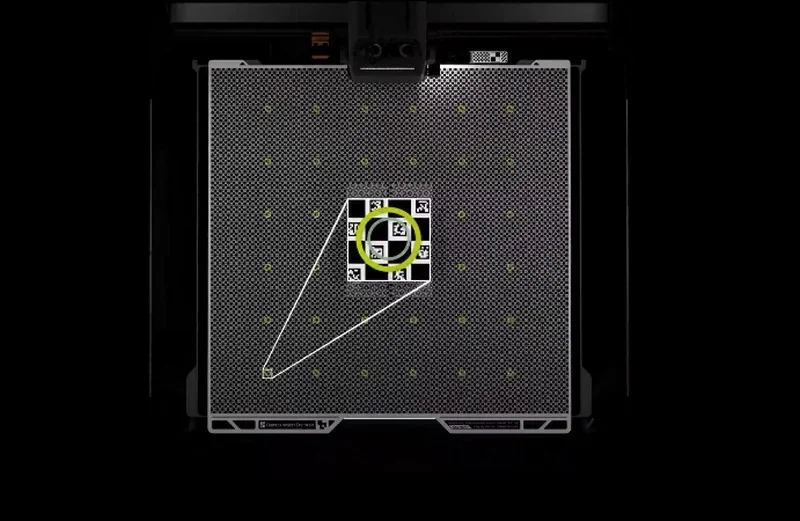

On the H2D Pro, this menu expands to include Motion Accuracy Calibration, running the Vision Encoder plate routine for precision gantry alignment and XY motion checks across the full bed.

Guided 8×8 / 22×22 probing routines and dual-nozzle offset wizards remain, with the UI noting when high-temperature leveling should be rerun after hardware changes.

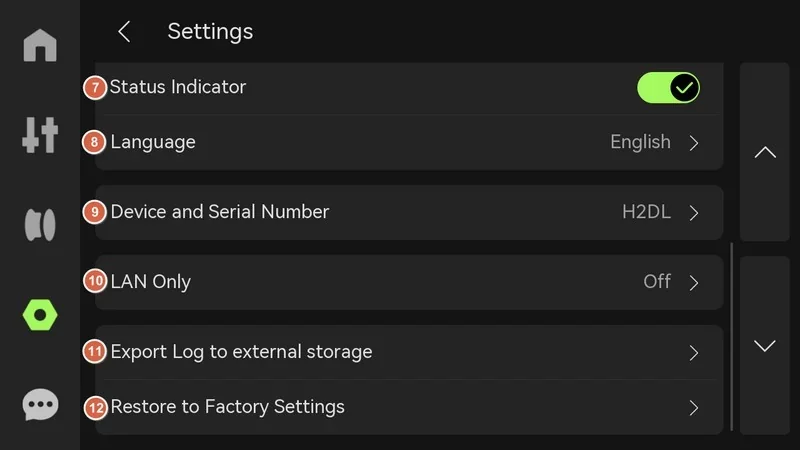

System settings

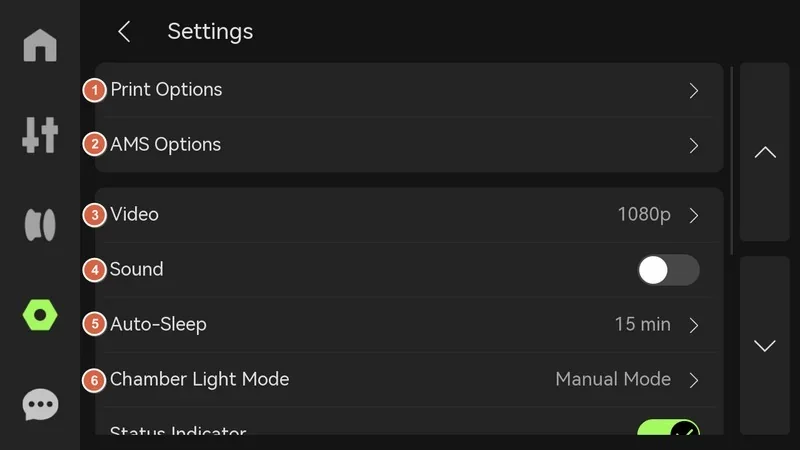

The Settings page includes UI preferences (sounds, sleep, chamber light, language), device info, safety key status, status indicator, export logs to USB, and factory reset options.

Software offered with the Bambu Lab H2D Pro: Bambu Studio, Bambu Handy, and Bambu Suite.

Full Video Tutorial Playlist:

https://www.youtube.com/playlist?list=PLFUVS59deIm2mawl3Zjk1XI9yp7H7955J

CoreXY kinematics with up to 20,000 mm/s² toolhead acceleration and three-point Z-axis. A standard Vision Encoder (5 µm optical measurement) provides closed-loop motion calibration to maintain 50 µm motion accuracy across the build area.

The Z-axis moves on linear rods with lead screws, the Y-axis uses linear rods, and the X-axis uses a rail.

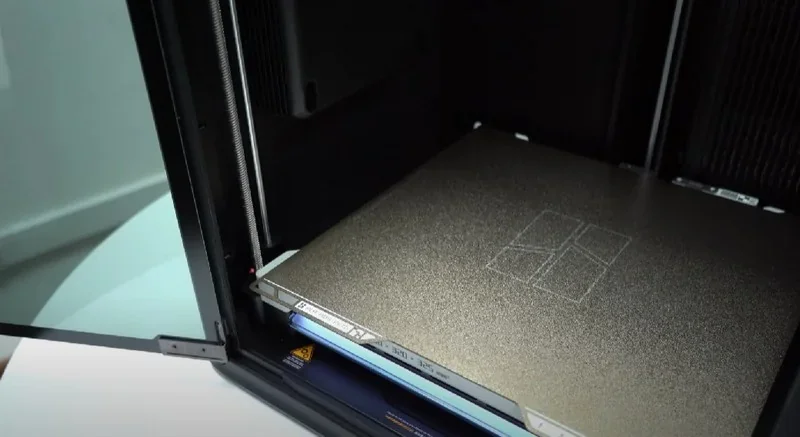

Flexible spring-steel build plate (textured PEI included; smooth PEI supported) on a 120 °C heated bed with the bed size of 325 × 320 × 325 mm. Automatic mesh leveling is supported.

The toolhead adds an enhanced cooling fan and auxiliary part-cooling under closed-loop control.

Extruder motor: Bambu Lab high-precision PMSM.

Ships standard with AMS 2 Pro and AMS HT: sealed, actively dried storage (up to 85 °C on AMS HT), RFID support, and automated switching.

Chaining supports up to 4× AMS 2 Pro and 8× AMS HT (max 25 colors when combined with an external spool on the second hotend).

A side-mounted external spool holder provides a direct path for flexible filaments (e.g., TPU).

H2D Pro supports the first-generation AMS (no drying); AMS Lite is not supported.

Tool/Accessory Box (1× set):

|

Name |

Specific functionality / problem it solves |

Price |

|

AMS 2 Pro |

Automatic Material System enabling multi-material/color printing with active drying |

From $359.00 USD |

|

AMS HT |

High-temperature filament dryer/feeder with up to 85 °C drying and airtight storage |

From $159.00 USD |

|

Bambu High Flow Hotend – H2 Series |

Quick-swap high-flow hotend/nozzle (to 350 °C) for higher volumetric flow and shorter print times |

From $51.99 USD |

|

Bambu Smooth PEI Plate – H2 Series |

Smooth PEI-coated build plate for glossy first layers and reliable adhesion |

From $61.99 USD |

|

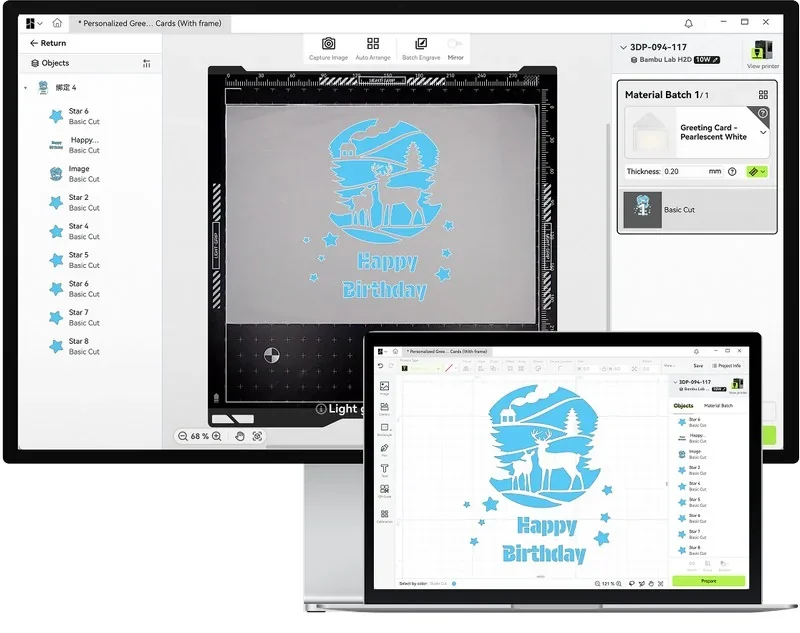

H2 Series Laser Upgrade Kit |

A diode-laser head with integrated mounts and electronics adds cutting and engraving capabilities to H2-series printers. |

From $349.00 USD |

|

H2 Series Cutting Upgrade Kit |

Adds digital cutting and pen-drawing on the H2 platform with cutting module and dual-grip mats |

From $89.00 USD |

|

Laser Protective Goggles |

OD5+ at 200–460 nm and OD6+ at 900–1100 nm eyewear for safe laser operation |

From $39.99 USD |

|

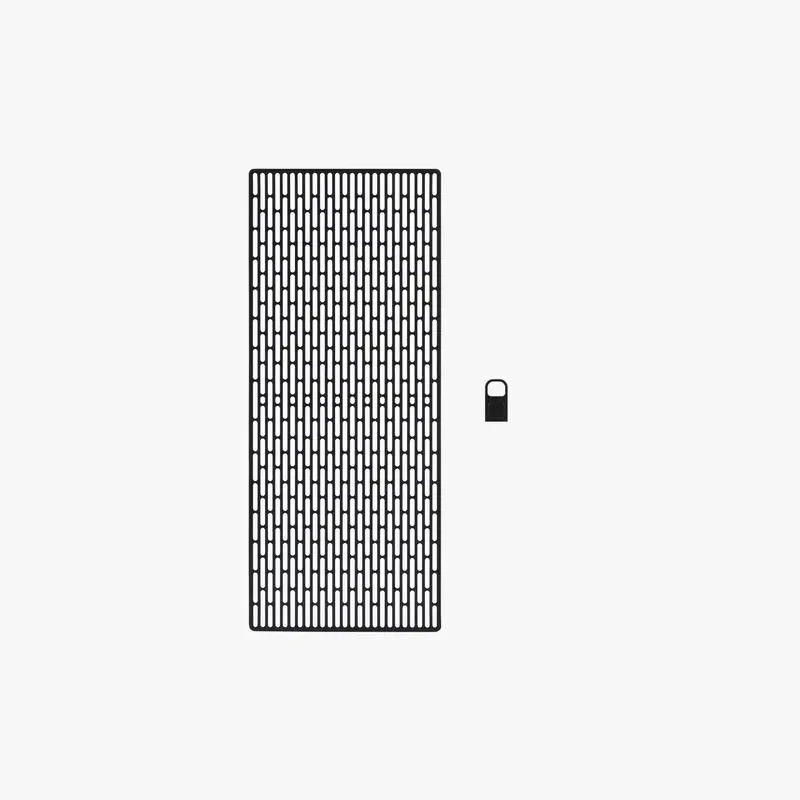

Laser Grid Panel |

Stainless support grid with fine pins to support and register thin/flexible materials during laser jobs |

From $39.99 USD |

|

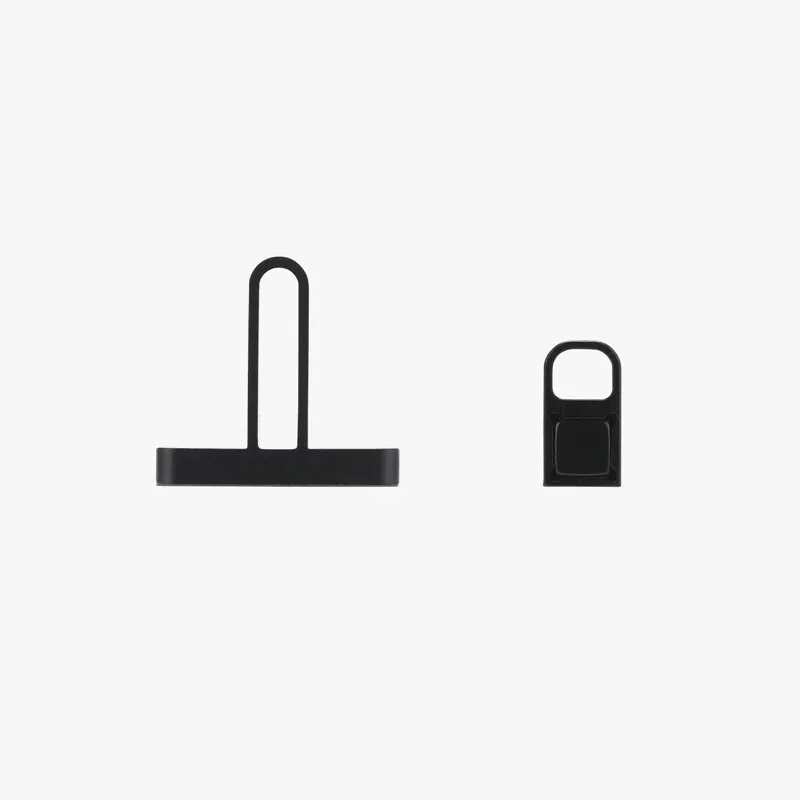

Material Pins |

Pin set to mechanically secure thin or flexible workpieces to the laser platform/grid |

From $34.99 USD |

|

Smoke Purifier |

External multi-stage filtration (G4, F8, activated carbon, HEPA H13) with hose interface for fume control |

From $649.00 USD |

|

Nozzle Wiping Pad – H2D |

Replacement wiping pad for the H2D purge/wipe station |

From $6.99 USD |

The Bambu Lab AMS 2 Pro is an add-on for multi-material 3D printing that supports up to 24 colors (add multiple AMS units to achieve this) and provides 65 °C filament drying, airtight storage, and RFID-based auto-detection. It uses a high-speed servo for faster feeding, supports most 1.75 mm filaments (excluding fiber-filled and flexible types), and connects via a 6-pin cable. Key features include real-time environment monitoring, tool-free access, ceramic inlets, and a 4-in-1 PTFE adapter for multi-unit setups.

The Bambu Lab AMS HT is a high-temperature filament drying and storage system designed for advanced materials like PA, PC, and carbon fiber composites. It supports drying up to 85 °C with an automated electromagnetic vent and airtight storage. RFID sync auto-sets drying parameters for official filaments, while auto-rotating spools ensure even heat distribution. The AMS HT connects via a 6-pin bus, requires 220V power for drying, and supports multi-material printing by linking up to 8 units with 4 AMS 2 Pro units to support printing with up to 24 filaments.

The Bambu High Flow Hotend for H2 Series printers boosts volumetric speed by up to 62.5% over standard nozzles, enabling faster prints with consistent extrusion, crisp edges, and smooth surfaces; it supports up to 350°C, handles carbon-fiber materials, and includes a quick-swap 0.4mm hardened steel nozzle.

The Bambu Smooth PEI Plate is a dual-sided magnetic build surface with a 0.125 mm matte PEI sheet bonded to a 0.5 mm spring steel plate for improved adhesion and warp resistance. It supports print bed temperatures up to 120 °C and is compatible with materials like PLA, TPU, PETG, ABS, PC, and Nylon. The matte surface provides a smooth finish and improved Z-axis accuracy. The bonded PEI layer is non-removable, and glue is recommended for all materials except PLA to prevent damage during part removal.

The H2D Laser Upgrade Kit adds high-precision 10W or 40W blue laser cutting and engraving to compatible H2D printers, with safety systems, air assist, 3D mesh measurement, and support for materials like wood, rubber, metal, leather, and stone — maintaining a Class 1 safety rating despite using Class 4 lasers.

The Cutting Upgrade Kit converts H2 Series printers into cutters with drawing capability, including mats, blades, tools, and markers, requiring minimal installation and the Laser Module for full camera calibration.

| Feature | Cutting module | 10 W laser module | 40 W laser module |

|---|---|---|---|

| Process | Blade cutting / pen drawing (no laser) | Blue-light laser engraving & light cutting | Blue-light laser engraving & heavier cutting |

| Typical use | Vinyl, paper/cardstock, HTV, thin plastic films; pen plotting | Engraving photos/text; cutting thin wood/leather | Faster engraving; cutting thicker wood/leather; higher throughput |

| Max cutting thickness (basswood) | ~0.5 mm | 5 mm | 15 mm |

| Max engraving speed (basswood) | n/a (mechanical) | 400 mm/s | 1000 mm/s |

| Work area (H2D) | 300×255 mm (drawing/cutting) | 310×270 mm | 310×250 mm |

| Fixtures/platform | Cutting platform with LightGrip/StrongGrip mats | Laser platform with slats/grid + air-assist | Laser platform with slats/grid + air-assist |

| Air assist | Not applicable | Built-in pump (≈30 kPa, 30 L/min) | Built-in pump (≈30 kPa, 30 L/min) |

| Safety | No E-Stop required when used alone; standard machine interlocks | Class-4 module in a Class-1 enclosure; Emergency Stop required, door interlocks | Class-4 module in a Class-1 enclosure; Emergency Stop required, door interlocks |

| Calibration | Mount calibration for tool-tip; blade/pen height setting | Begin Setup (XYZ focus) + Mount calibration; BirdsEye camera calibration when needed | Same as 10 W |

| Notes on materials | Cleanest edges on vinyl/paper; no burning/fumes | Blue lasers can struggle on reflective/transparent surfaces unless darkened | Same wavelength limits as 10 W; just deeper/faster |

The Bambu Lab Laser Protective Goggles provide essential eye protection for H2D and H2S Laser systems, blocking 99.9999% of harmful laser energy with OD5+ and OD6+ shielding across key wavelengths, while reducing glare and eye strain during precision work.

The Bambu Lab Laser Grid Panel is a durable stainless steel base system for H2D and H2S Lasers, designed to securely hold flexible or small materials using two grid panels and six magnetic pins, enabling precise, batch laser processing with stable alignment across slats and grid surfaces.

Material Pins are durable black metal clamps that keep materials stable and aligned during laser cutting on H2D and H2S systems, with 4 large and 4 small pins designed to secure various sizes and prevent warping for precise, consistent results.

The Bambu Lab Smoke Purifier is a compact, multi-stage filtration system for H2D and H2S Laser setups that removes 99% of particles ≥0.3μm and VOCs and captures smoke and dust generated by laser operations using G4, F8, carbon, and HEPA H13 filters, with high dust capacity, filter life alerts, and a 2-meter vent pipe for external exhaust.

The Nozzle Wiping Pad for H2D is a silicone-based, consumable component that cleans the hotend nozzle during automated purge cycles, installs with clips inward and a flat surface outward, and should be replaced when worn to maintain print quality.

The Bambu Lab H2D Pro requires over 20 maintenance procedures to preserve dimensional accuracy, uptime, and safe operation across weekly, monthly, and 3-monthly intervals. These include:

Weekly

Monthly

Every 3 months

Usage-based / On-condition

Firmware-assisted reminders

If using the optional laser module

Warranty policy. Bambu Lab’s After-Sales Service covers manufacturing defects; it excludes damage from misuse/accidents, operation outside official docs, unauthorized modifications, failure to perform required maintenance, and issues caused by third-party accessories or unofficial firmware. Returns are accepted within 14 days and replacements within 30 days when qualifying conditions are met; all cases must be opened via the official Support page, and products must be returned to designated local warehouses in original/approved packaging.

Warranty Period:

Support channels (manufacturer only).

Self-Help Resources:

Guides and tutorials are available via Bambu Lab Wiki, Bambu Studio/Handy apps, and on-device QR codes:

The price of the Bambu Lab H2D Pro is $4,749.00. The value proposition centers on enterprise-ready networking (Ethernet, WPA2-Enterprise, hardware kill switch), standard Vision Encoder for motion accuracy, tungsten-carbide nozzles for abrasive composites, a 65 °C actively heated chamber, and the fact that it ships with both AMS 2 Pro and AMS HT—so moisture-controlled, multi-material workflows are ready on day one.

Configurations (and upgrade paths):

Buying guidance

If you need a tailored bundle (e.g., installation, training, additional AMS units, filtration accessories) or procurement documentation, contact Top 3D Shop for a personalized quote.

Update your browser to view this website correctly. Update my browser now