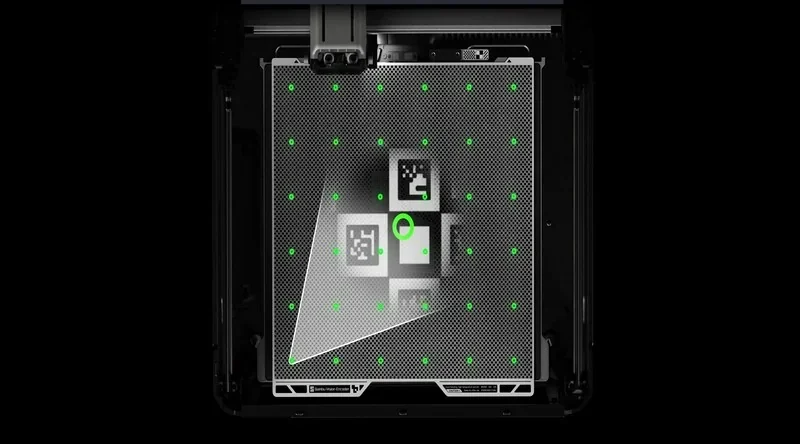

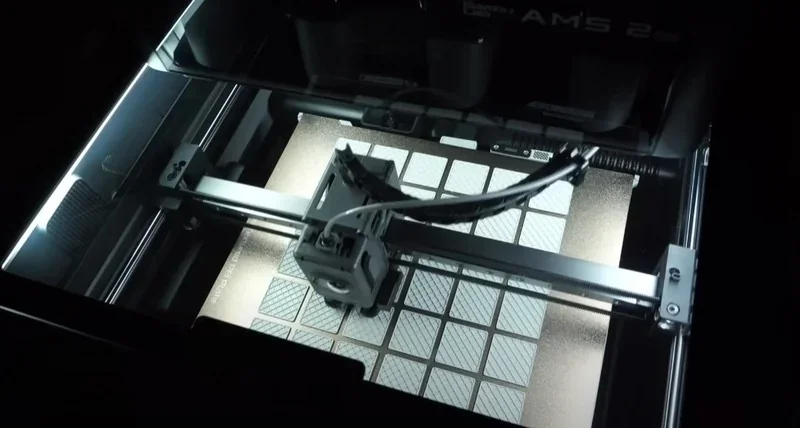

Bambu Lab H2S is a large-format, single-nozzle, enclosed CoreXY FDM 3D printer designed for high-speed, high-accuracy production: it offers a 340 × 320 × 340 mm build volume, a 350 °C hotend, 120 °C bed, and a 65 °C actively heated chamber. Its precision stack combines a PMSM servo extruder with eddy-current nozzle sensors, Active Vibration Compensation, Auto Hole/Contour Compensation, and the optional Vision Encoder plate that calibrates motion to < 50 µm, while an AI monitoring suite (23 sensors, on-device cameras) guides pre-flight checks and failure detection; a 10 W Laser Upgrade Kit (adds the BirdsEye camera) extends the platform to engraving/cutting.

The H2S is engineered for high-accuracy single-nozzle printing: with the optional Vision Encoder plate it calibrates XY motion to under 50 µm accuracy, and Auto Hole/Contour Compensation (in Bambu Studio, with designated Bambu filaments) tightens fit-critical dimensions such as holes and shafts.

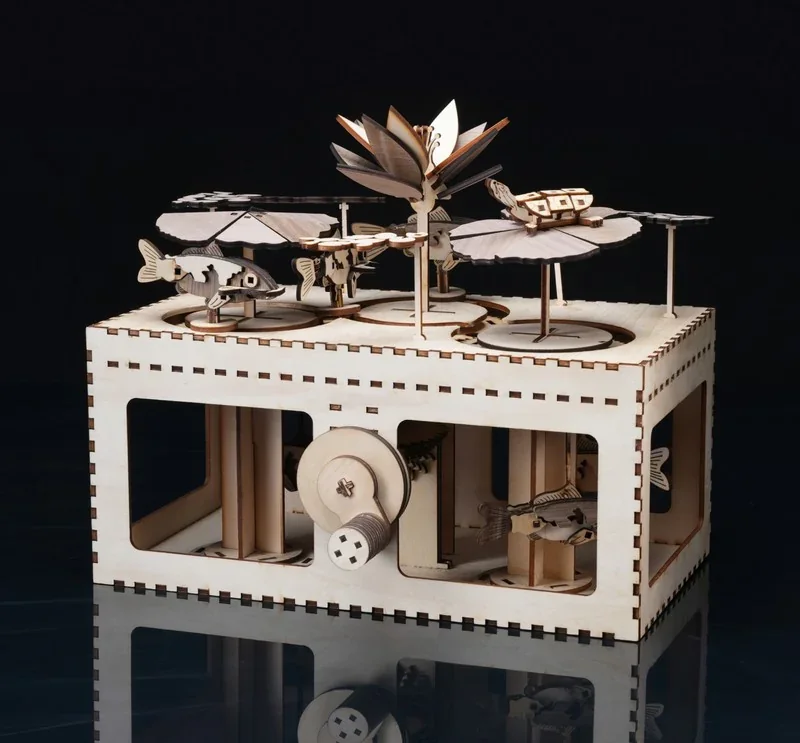

Print Sample: Bambu Lab H2S printed a max-size PLA 3DBenchy (1.1 kg) in 28 hours, showing excellent dimensional accuracy, surface finish, consistent layer adhesion, and fine detail.

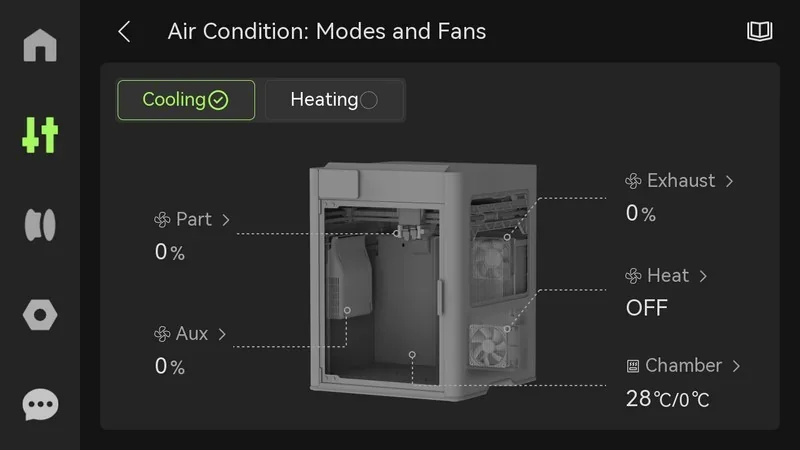

Print quality is stabilized by a 350 °C hotend, 120 °C bed and 65 °C actively heated chamber with closed-loop fan control to reduce warping and improve layer adhesion on engineering polymers.

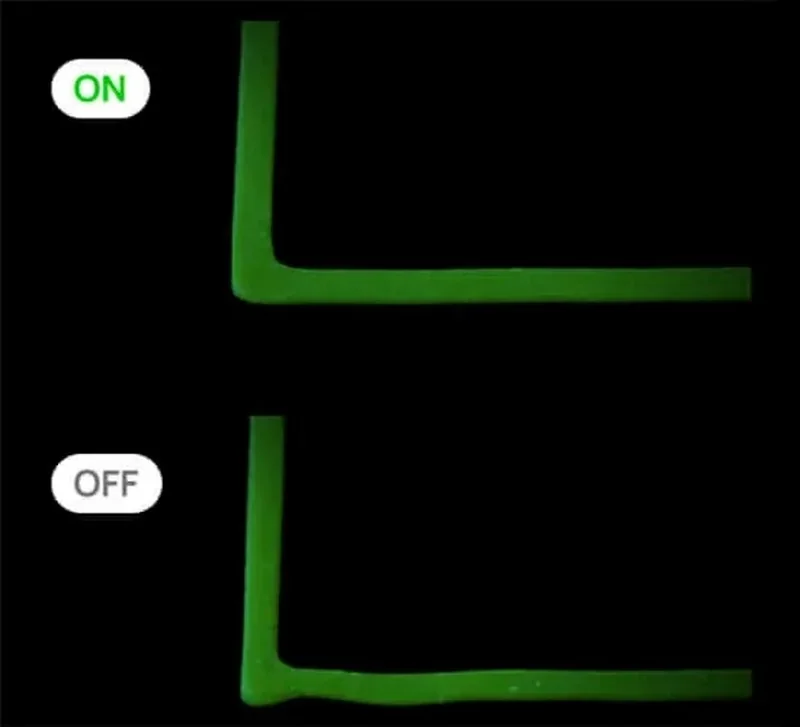

Extrusion smoothness and edge definition are further improved by the servo-motor extruder plus eddy-current nozzle sensors that measure nozzle pressure and auto-tune PA per filament.

Active Vibration Compensation suppresses resonance for cleaner walls at speed.

During testing, PLA, PETG, and PPS-CF parts – printed at 300 mm/s with a 0.4 mm nozzle – showed smooth, artifact-free surfaces, consistent layer stacking, and uniform first-layer adhesion — even at 20,000 mm/s² acceleration. Only some fine PLA details appeared slightly softer than on the H2D due to a less powerful cooling fan.

The enclosure integrates safety interlocks (front door/top cover) and fire-resistant construction.

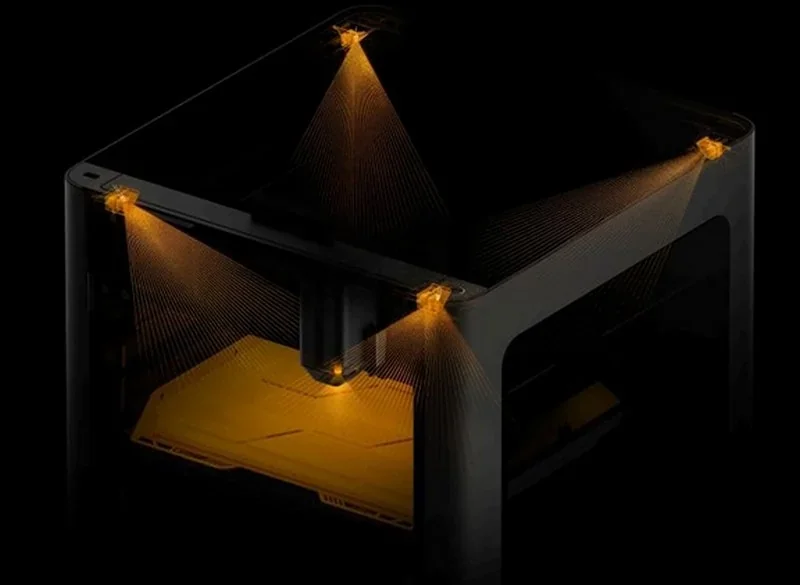

Process control & repeatability: the system uses 23 sensors and 3 cameras for AI monitoring (spaghetti, clumping, purge-chute jams), a vision-guided pre-flight checklist (debris scan, plate identification), and multi-point thermal sensing to actively regulate the print environment and airflow/filtration.

Example: When printing the Autodesk benchmark set, the printer produced clean layers, sharp overhangs, stable bridges, and showed no ringing or Z-banding.

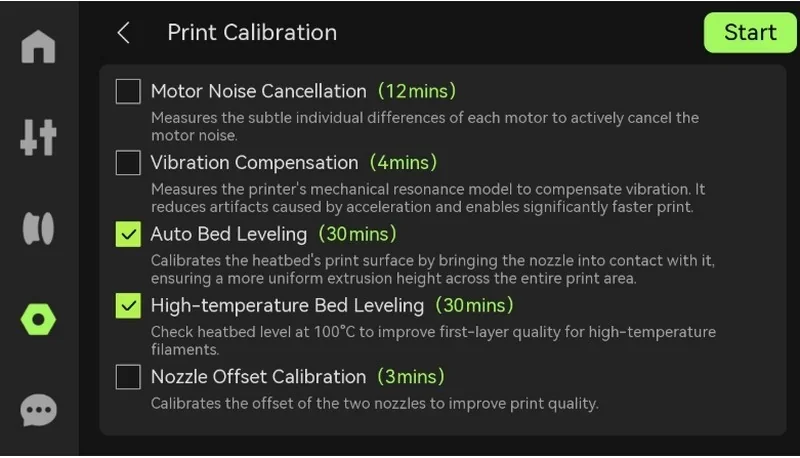

Leveling & first-layer reliability: the H2S implements an automatic leveling routine working in concert with vibration compensation and pressure advance; initial self-check and leveling can be lengthy but are hands-free.

Example: During full bed prints, first layers adhered well across the surface despite the bed only reaching 104°C (set to 120°C), as the heated chamber compensated for the lower bed temperature.

Credit: Albert KeyDot, 247printing YouTube Channel (https://www.youtube.com/watch?v=EUHZtyOmQGg)

The Bambu Lab H2S supports 29 material types, including PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS, and carbon- or glass-fiber-reinforced variants of PLA, PETG, PA, PET, PC, ABS, ASA, PPA, and PPS. Its hardware ensures broad material compatibility, featuring a 350 °C all-metal hotend, 120 °C heated bed, 65 °C actively heated chamber, and closed-loop cooling. For optimal results with flexible or brittle filaments, the rear direct-feed path (bypassing the AMS) minimizes bending and improves consistency; TPU should be loaded via its dedicated rear port. The printer is open to third-party filaments, with proven reliability across multiple non-proprietary brands, while AMS 2 Pro and AMS HT units provide integrated drying for hygroscopic materials.

PLA, ABS-GF, PPS-CF, and PPACF Test Prints:

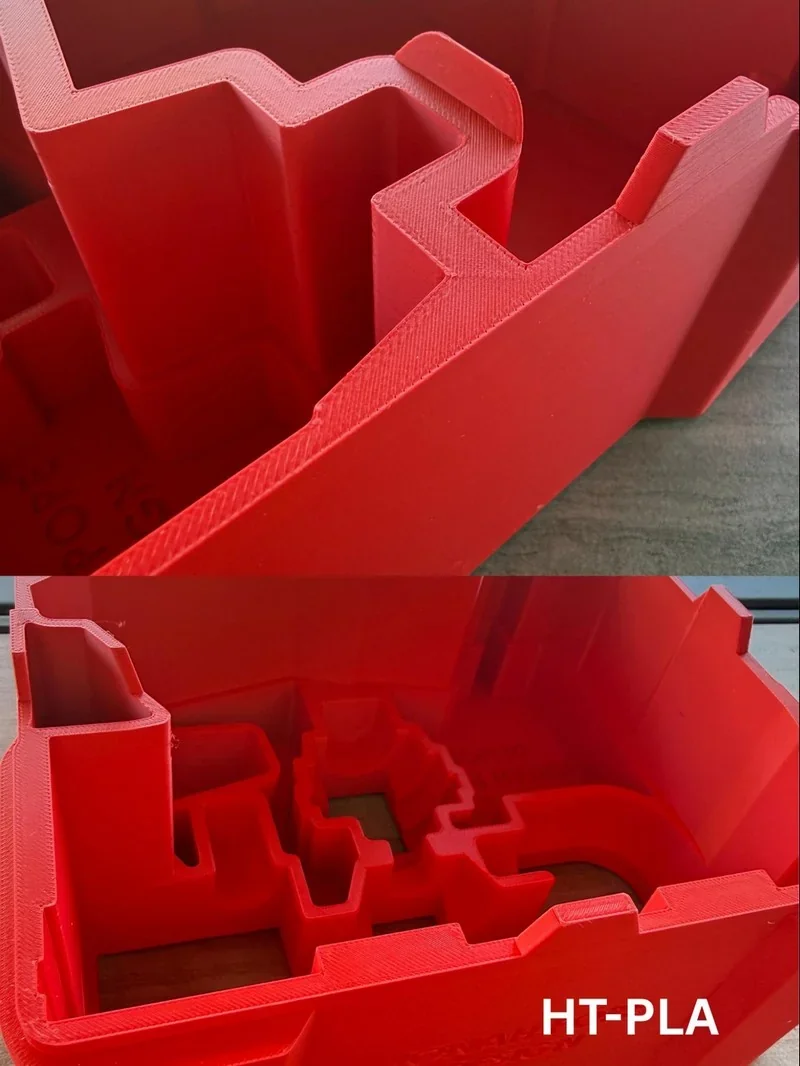

HT-PLA 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

HT-PLA 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

HT-PLA-GF Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

PETG-HF Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

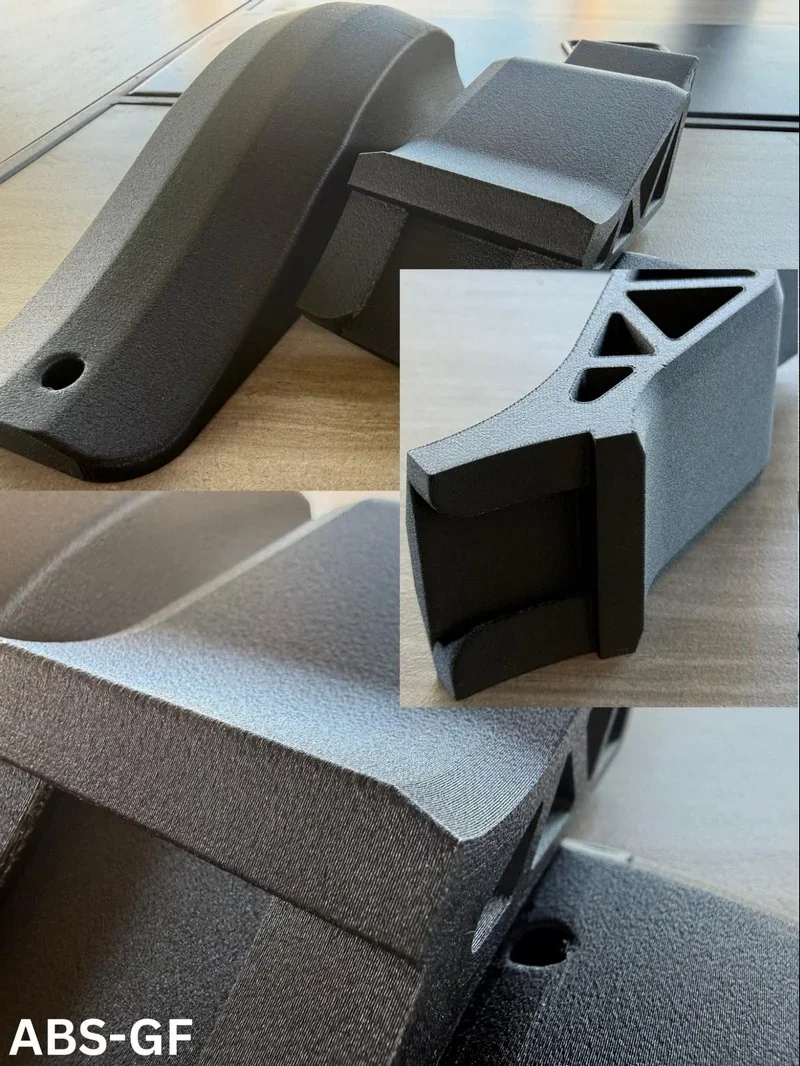

ABS-GF 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

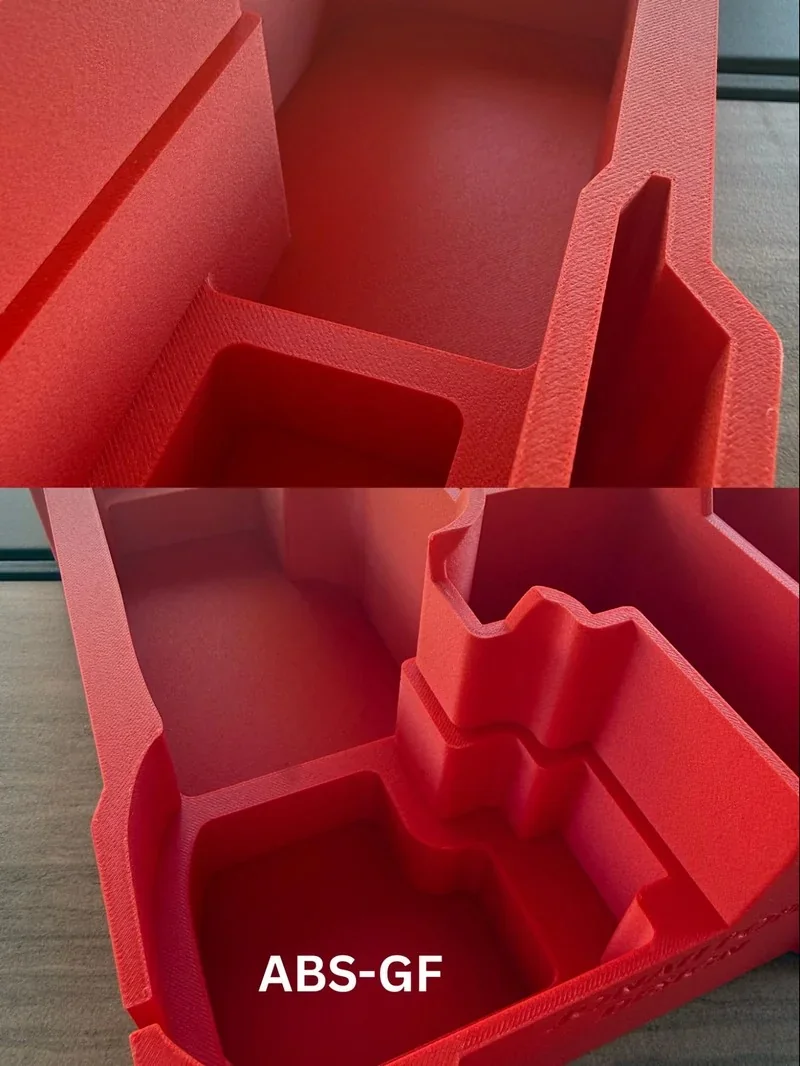

ABS-GF 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

Nylon 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

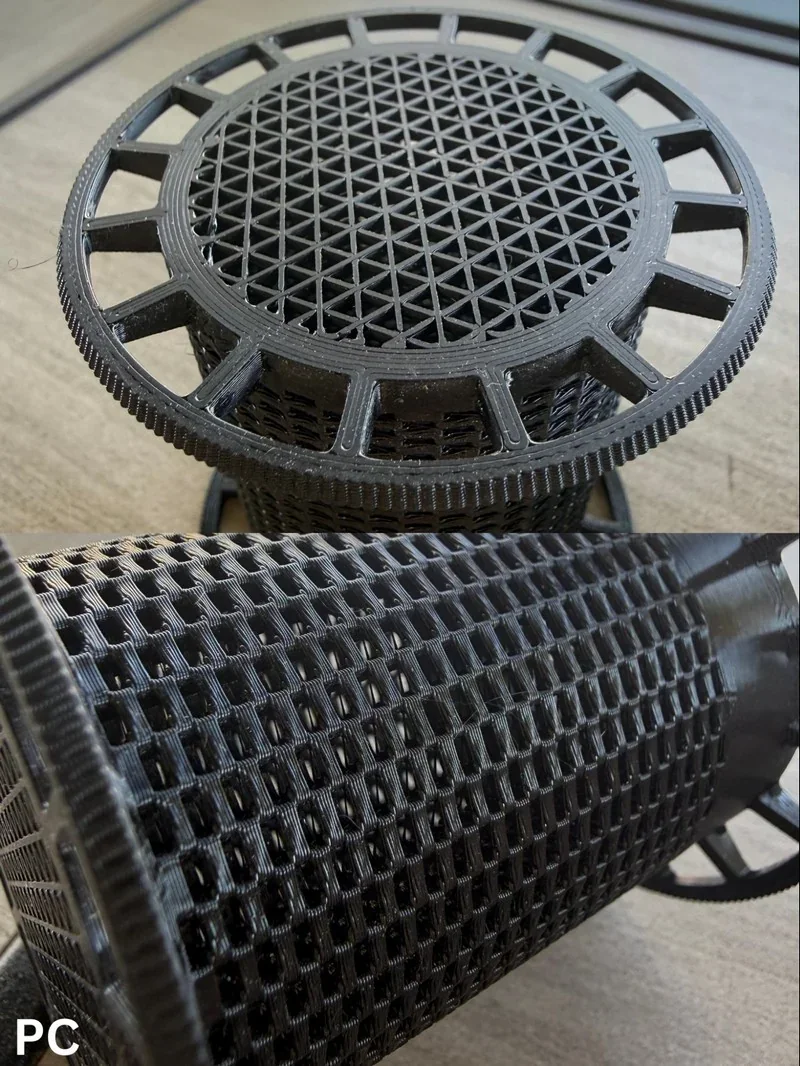

Polycarbonate 3D Print Sample:

Credit: Tyler Reichelt, Bambu Lab Facebook Group

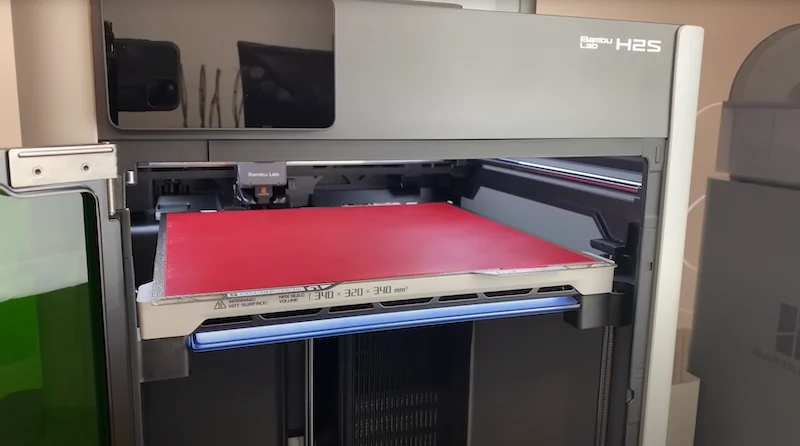

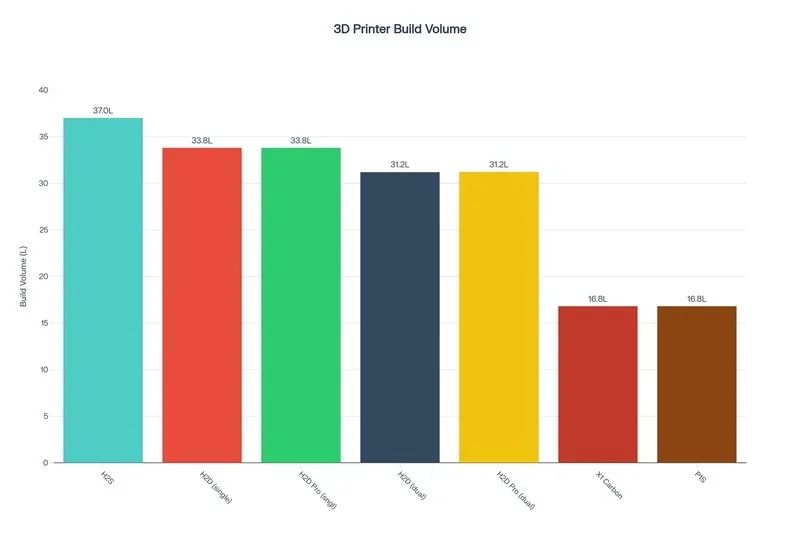

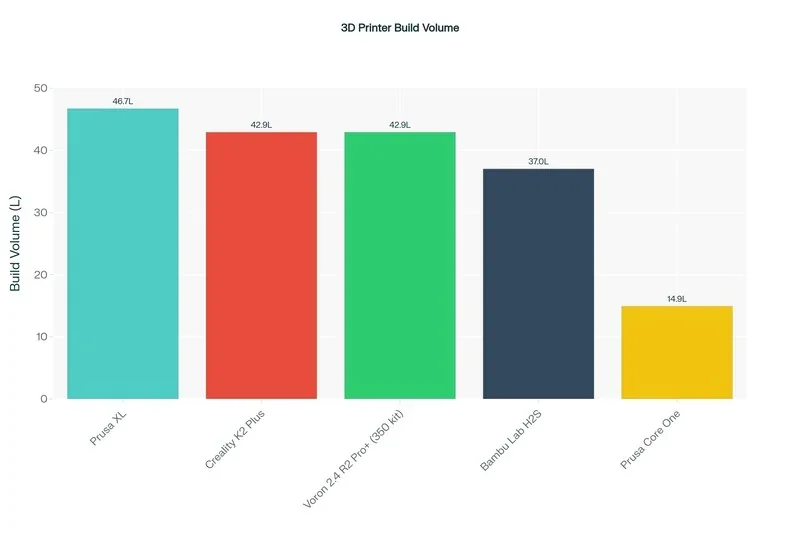

The Bambu Lab H2S provides a 340 × 320 × 340 mm build volume, and — thanks to its single-nozzle architecture and a cutter mechanism that does not restrict motion — it uses the full X–Y range with no build-volume reduction during printing.

The Bambu Lab H2S offers the H-series' high performance — 65 °C active chamber, 350 °C nozzle, and 1000 mm/s speed — at the lowest price, with the largest build volume (340 × 320 × 340 mm). For dual-material printing, the H2D and H2D Pro add that capability with a slightly smaller build area (300 × 320 × 325 mm) but cost more ($1,999 and ~$3,799). In contrast, the X1 Carbon and P1S are cheaper but have smaller volumes, a 300 °C nozzle limit, no active chamber heating, and 500 mm/s speed — making them better suited for general use than for high-performance engineering prints.

|

Model |

Build volume (mm) |

Chamber |

Max nozzle (°C) |

Max speed (mm/s) |

Price (USD) |

|

Bambu Lab H2S |

340×320×340 |

Active to 65 °C |

350 |

up to 1000 |

From $1,249 |

|

Bambu Lab H2D |

325×320×325 (single); 300×320×325 (dual) |

Active to 65 °C |

350 |

up to 1000 |

From $1,999 |

|

Bambu Lab X1 Carbon |

256×256×256 |

Enclosed (no active heat) |

300 |

up to 500 |

From $799 (printer) / $1,249 (Combo) |

|

Bambu Lab P1S |

256×256×256 |

Enclosed (no active heat) |

300 |

up to 500 |

From $549 (printer) / $749 (Combo) |

|

Bambu Lab H2D Pro |

325×320×325 (single); 300×320×325 (dual) |

Active to 65 °C |

350 |

up to 1000 |

From $3,799 |

The Bambu Lab H2S offers the best balance of speed, temperature capability, and cost — supporting engineering-grade materials with a 65 °C chamber, 350 °C nozzle, and 1000 mm/s speed for $1,249. The Creality K2 Plus matches build volume (350³ mm) and adds a heated enclosure but falls short on nozzle temp (300 °C) and speed (600 mm/s) at $1,726, not to mention reliability issues and long wait times to get support and spare parts from China. The Voron 2.4 R2 Pro+ is cheaper ($779) with similar volume, but its passive chamber and 250 mm/s speed suit hobbyists, not high throughput. Prusa XL has the largest volume (360³ mm) but lacks chamber heat, maxes at 290 °C, and costs $2,463. The smaller Prusa Core One offers a 55 °C chamber and 290 °C nozzle for $1,584. For fast, high-temp FFF production, the H2S is the strongest value.

|

Model |

Build volume (mm) |

Chamber |

Max nozzle (°C) |

Price |

|

Bambu Lab H2S |

340×320×340 |

Active to 65 °C |

350 |

From $1,249 |

|

Creality K2 Plus |

350×350×350 |

Closed (heated/enclosed) |

300 |

From $1,099 |

|

Voron 2.4 R2 Pro+ (350 kit) |

350×350×350 |

User-enclosed (passive) |

300 |

From $899 |

|

Prusa XL |

360×360×360 |

Enclosed (no active heat) |

290 |

From $2,439 |

|

Prusa Core One |

250×220×270 (smaller class) |

Up to 55 °C |

290 |

From $1,567 |

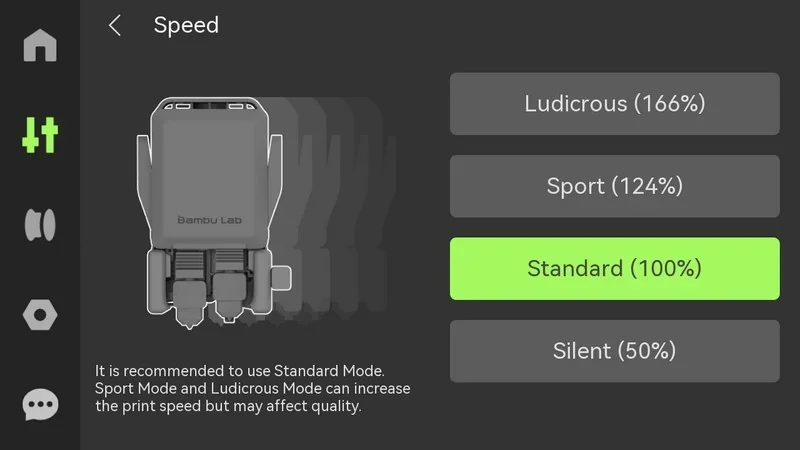

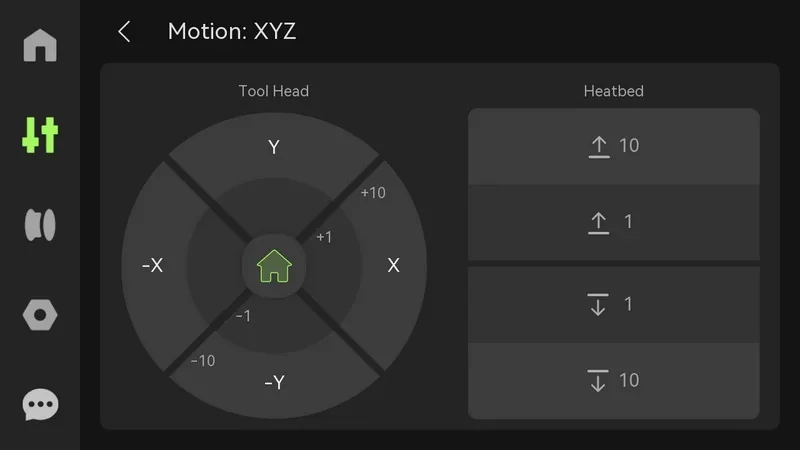

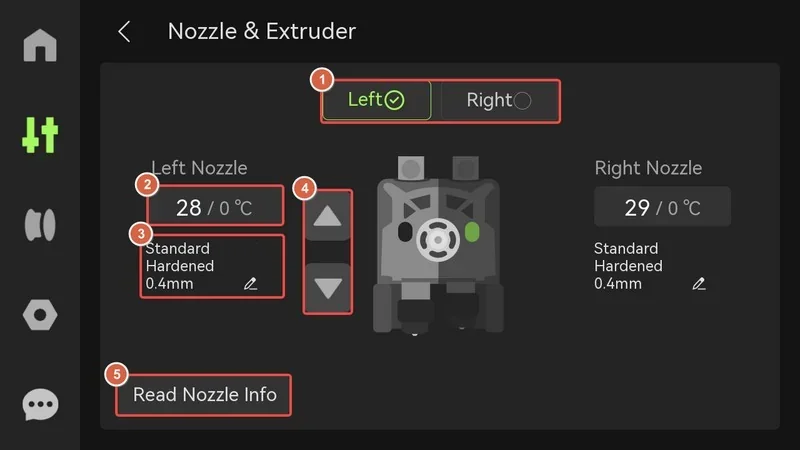

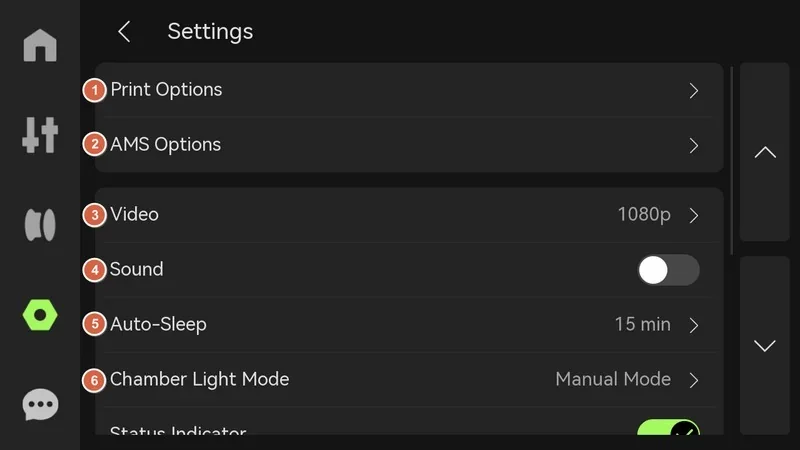

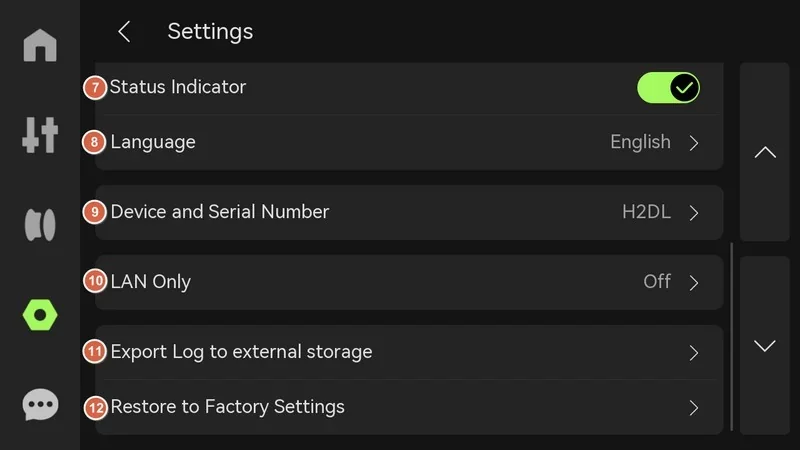

The H2S uses an on-printer 5-inch, 1280×720 capacitive touchscreen with a left rail of primary tabs—Homepage, Controls, Filaments, Settings, and HMS—plus quick tiles for Print Files, Nozzle Temp, Filament, and Status; this layout centralizes job launch and routine adjustments without a computer.

On-device UI & menu system.

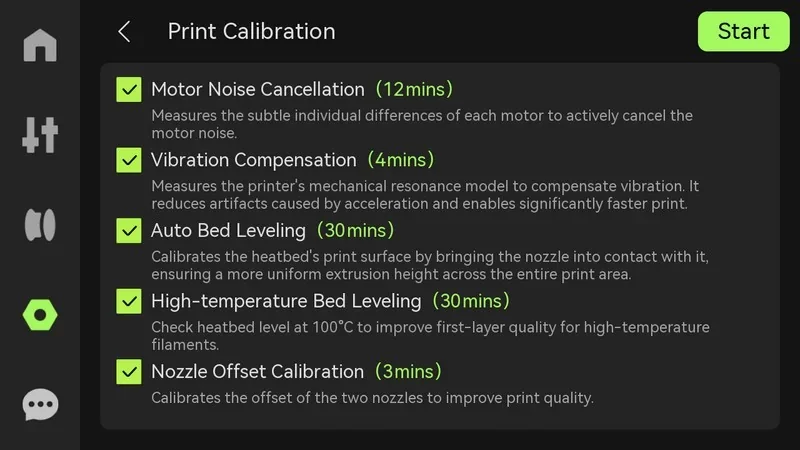

Built-in calibration & adjustment controls.

From Settings → Calibration / Print Calibration, the printer runs motor noise cancellation, vibration compensation, auto bed leveling, high-temperature bed leveling, and dual-nozzle offset calibration; partial pre-print leveling can auto-probe only the model’s footprint to save time. The UI also guides multi-stage 8×8 / 22×22 probing routines and documents when to rerun high-temp leveling after hardware changes.

Physical Controls

Direct operation controls include a physical Start/Pause button required to begin and pause laser/cutting tasks (the 3D printing pause is initiated from the screen).

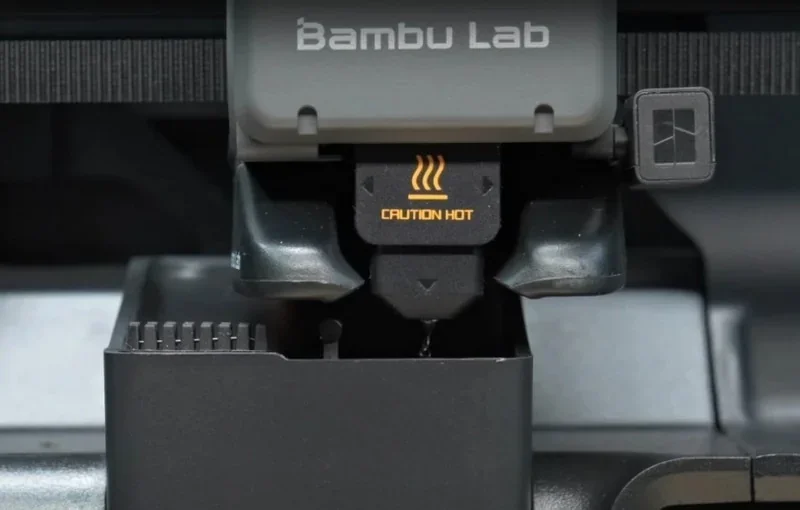

An Emergency Stop (required for laser) and Safety Key interlock govern power/enablement. The printer automates first-layer prep with a nozzle-cleaning routine at job start and manages scraps via a material ejection/wiper system during startup, pause/resume, and filament load/unload events.

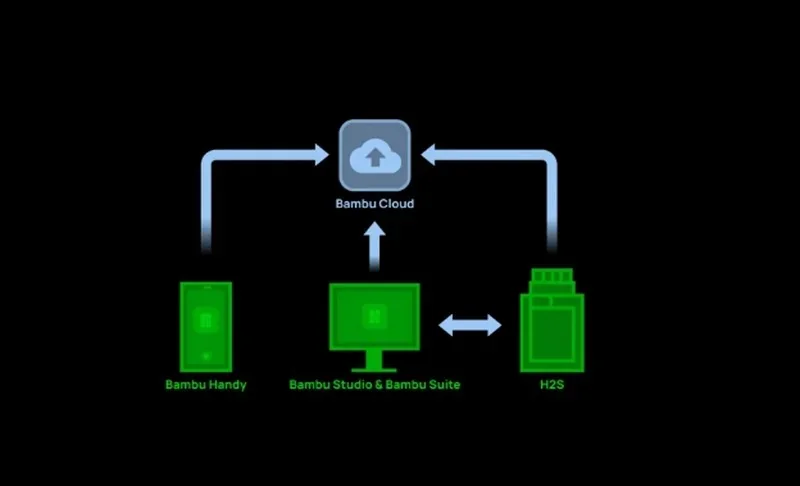

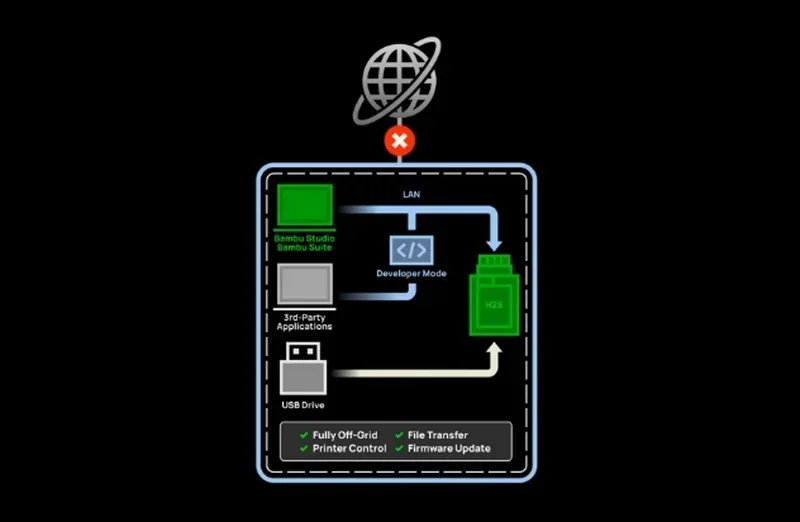

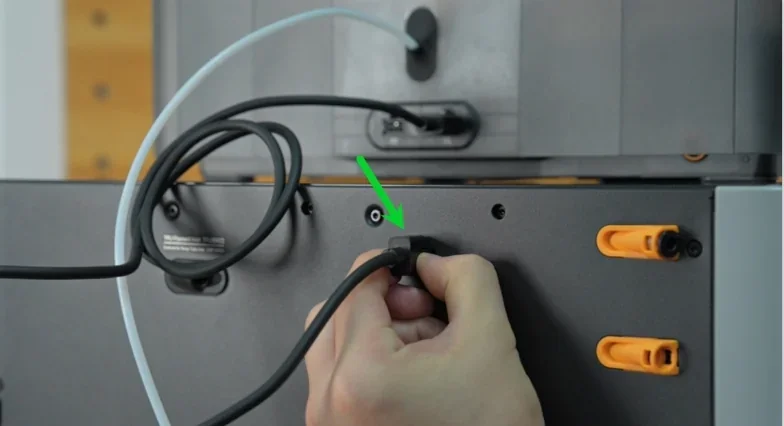

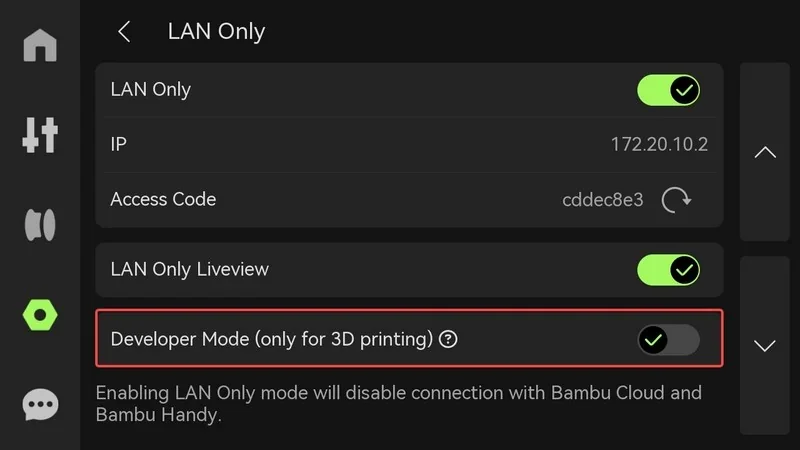

The H2S features dual-band Wi-Fi (2.4 & 5 GHz, IEEE 802.11 a/b/g/n) for network printing and remote control via the Bambu Studio PC app and mobile app, though it lacks an Ethernet port, 802.1X support, a network kill switch, or a removable network module. It also includes 8 GB of internal eMMC storage and a USB port; inserting a USB flash drive (USB 2.0+, ≥10 MB/s write, FAT32/exFAT, one drive only) enables LAN printing, file transfers from Bambu Studio, log exports, and time-lapse recording, while the printer can still run jobs from internal storage without a USB inserted.

The printer supports both cloud-based and fully offline operation, including offline firmware updates.

Integrated cameras include a 1920×1080 chamber camera and a 1600×1200 toolhead camera, with a 3264×2448 Bird’s-Eye camera on the Laser Edition. They support on-device monitoring and remote viewing via apps.

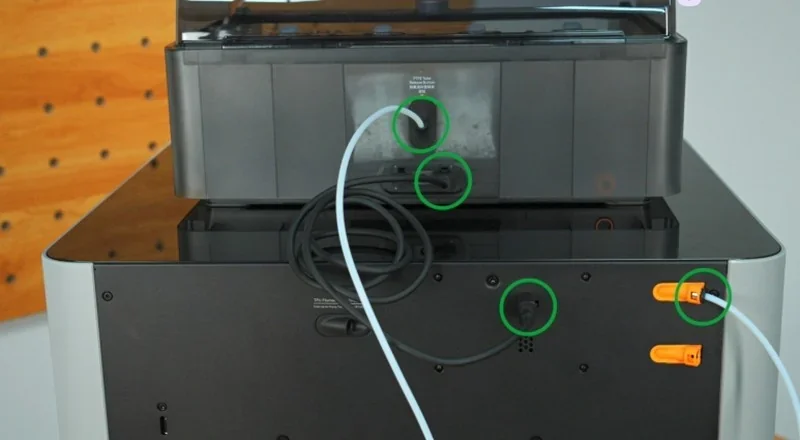

For accessory links, the rear panel provides a 6-pin AMS interface plus two reserved 4-pin ports used by expansion accessories (e.g., the external air pump when upgrading a non-laser unit to Laser). For developer workflows, Developer Mode exposes MQTT access while the system still supports fully offline operation (file transfer/firmware updates without internet).

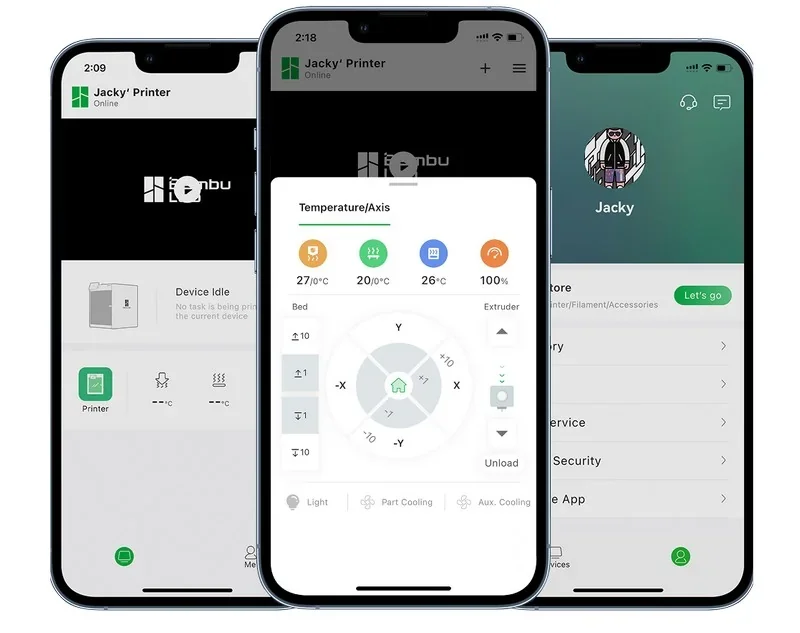

Software offered with the Bambu Lab H2D: Bambu Studio, Bambu Handy, and Bambu Suite.

Full Video Tutorial Playlist:

https://www.youtube.com/playlist?list=PLFUVS59deIm2mawl3Zjk1XI9yp7H7955J

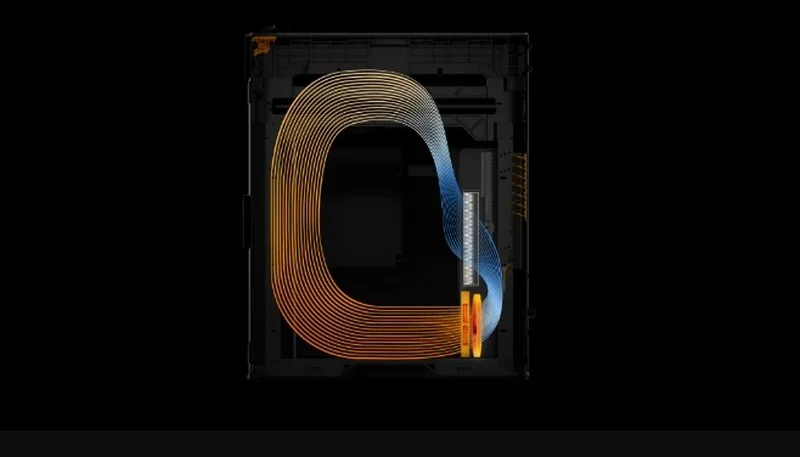

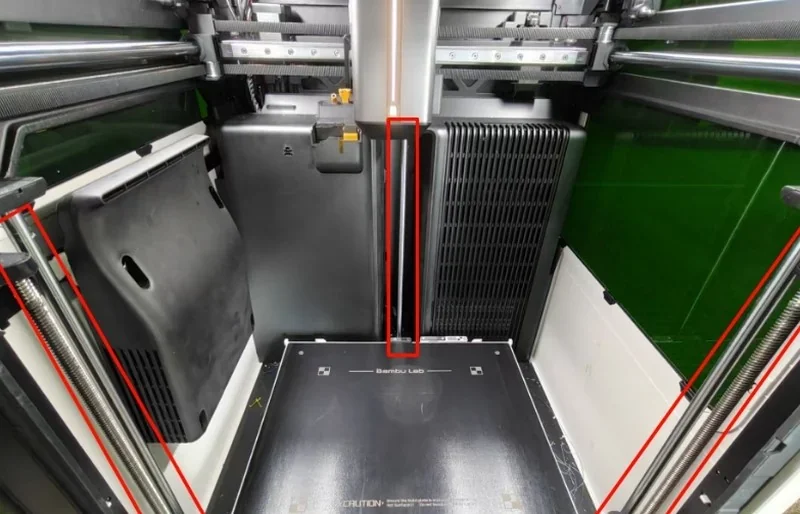

The H2S features a CoreXY gantry with a Z-axis driven by three lead screws connected to a single stepper via belt.

The X-axis uses a linear guideway, the Y-axis uses linear rods, and a Belt Tension Monitor (BTM) provides real-time feedback on belt tension.

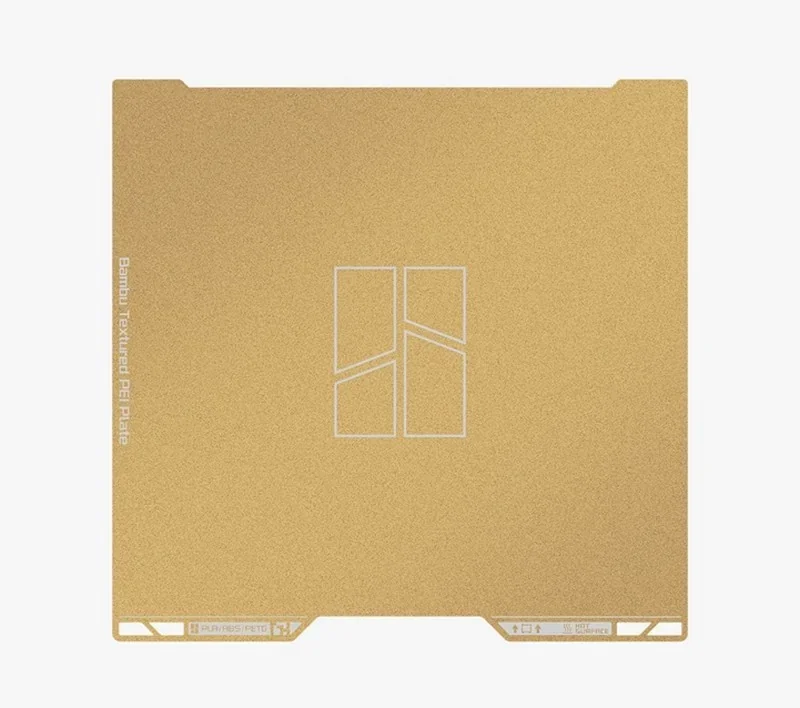

The heated bed measures 340 × 320 × 340 mm, and reaches up to 120 °C and supports both Textured and Smooth PEI Plates, with cross-compatible build plates between the H2S and H2D models.

The standard hotend sustains ≈40 mm³/s flow (or ≈65 mm³/s with the High-Flow hotend).

The all-metal hotend with a hardened-steel nozzle (0.4 mm included; supports 0.2/0.4/0.6/0.8 mm) is rated up to 350 °C and paired with a direct-drive extruder powered by a Bambu Lab high-precision Permanent Magnet Synchronous Motor (PMSM); a built-in filament cutter is also included.

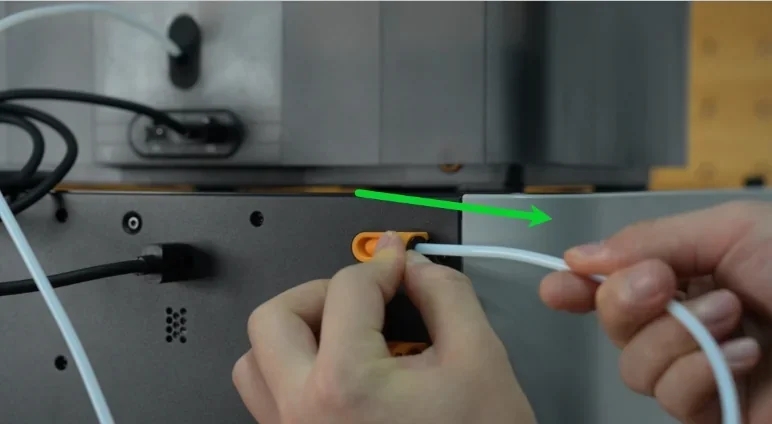

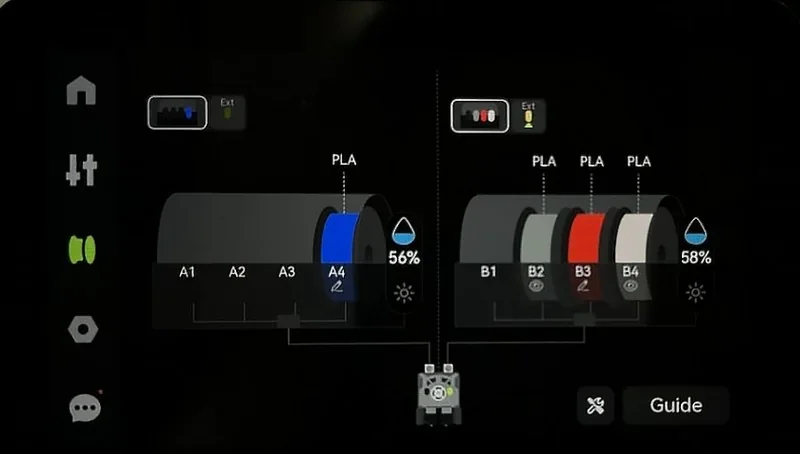

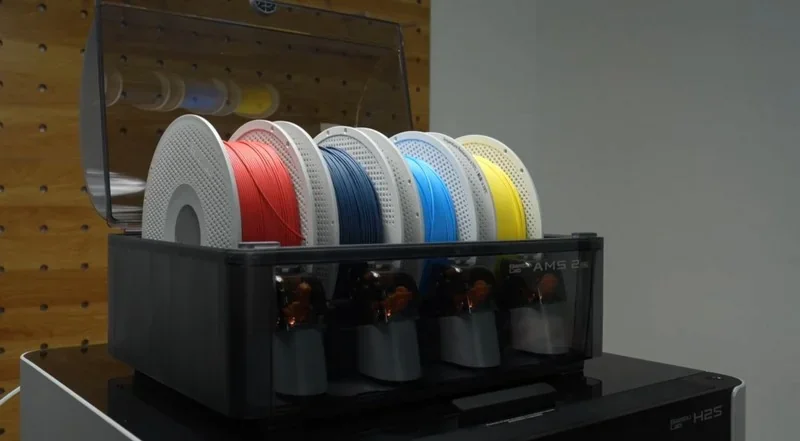

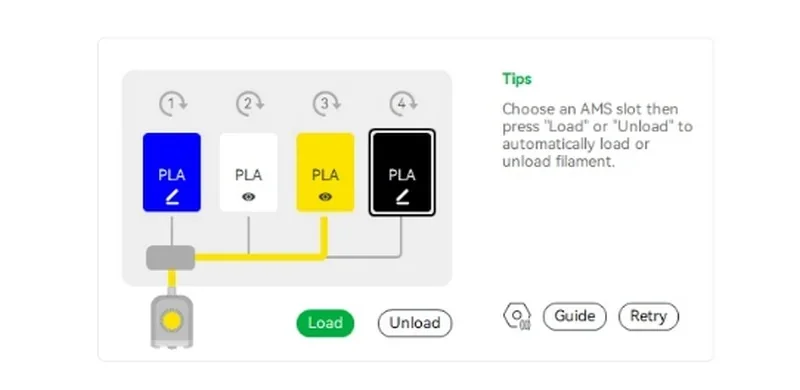

The H2S natively supports AMS 2 Pro and AMS HT through its built-in buffer and rear filament coupler; the buffer includes Hall-sensor-based filament detection and tension management.

The H2S is compatible with the first-generation AMS (without AMS drying) but not with AMS Lite, and supports up to 4× AMS 2 Pro or 8× AMS HT for a total of 24 filament slots and up to 24-color printing.

A direct rear feed through the coupler is available for stiff or brittle filaments, while TPU uses a separate rear port to bypass the standard path when needed.

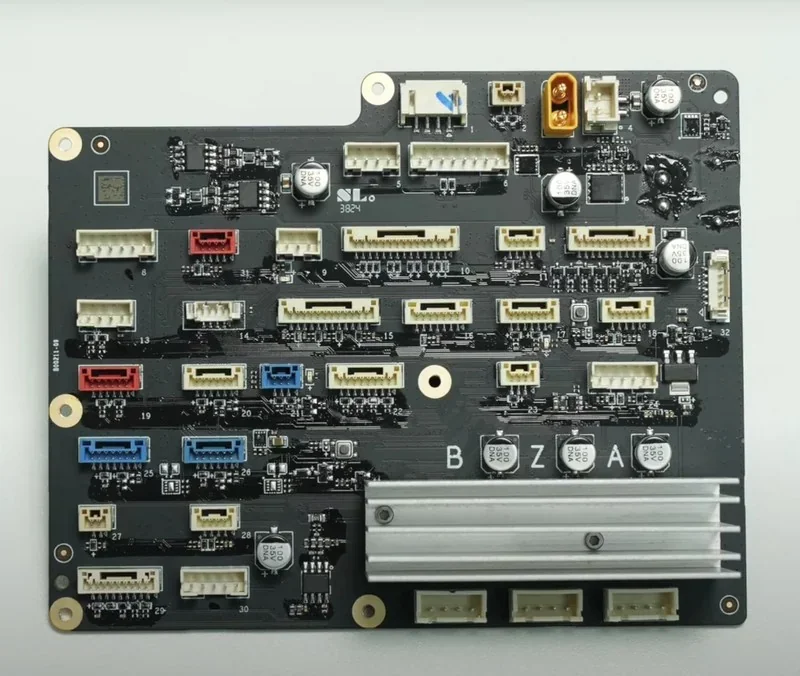

Two-board architecture: an AP Logic Main Control Board (quad-core CPU for UI/AI features and comms) and an MC Motion Control Board (dual-core M4 MCU + single-core M7 MCU with integrated stepper drivers) managing XYZ motion, temperature control, chamber status, and airflow/vent systems.

Input 100–240 V AC, 50/60 Hz, 20 A (110 V)/10 A (220 V); maximum power 2050 W @ 220 V or 1170 W @ 110 V.

Assembly state: Ships fully assembled; unpack, power on, and run the guided initialization.

Note: A USB flash drive is not included; the printer has internal storage and supports external USB drives that meet the stated specs if needed.

The H2S supports over 12 upgrades and accessories.

| Name | Specific functionality / problem it solves | Price |

|---|---|---|

| Smoke Purifier | External multi-stage filtration (G4, F8, activated carbon, HEPA H13) with hose interface for fume control. | From $649.00 USD |

| H2D Laser Upgrade Kit / Laser Module | A diode-laser head with integrated mounts and electronics adds cutting and engraving capabilities to H2-series printers. | From $349.00 USD |

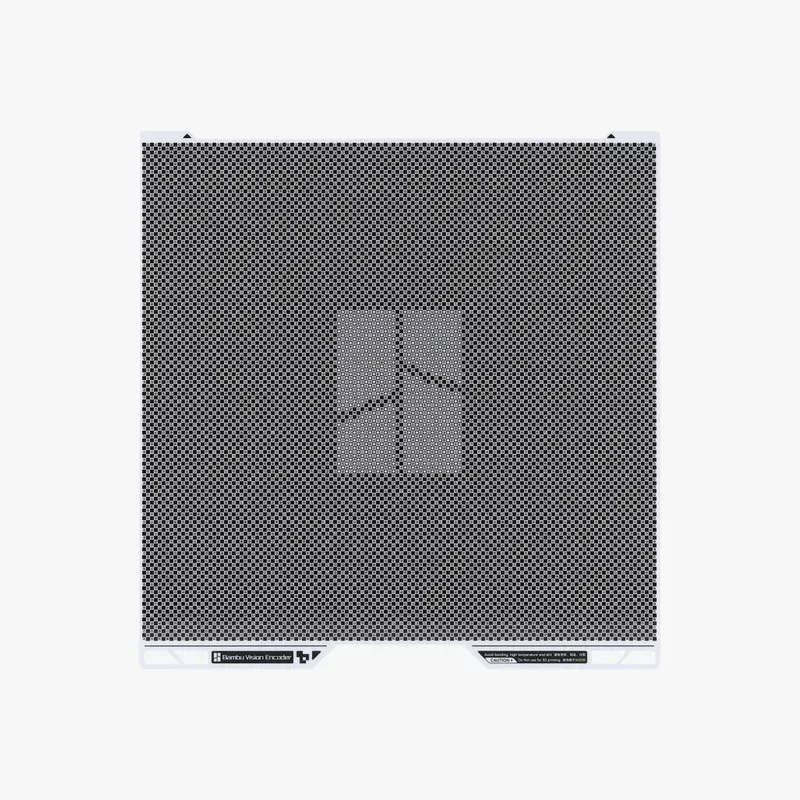

| Vision Encoder | Optical XY calibration target enabling <50 µm motion accuracy via toolhead camera compensation. | From $105.00 USD |

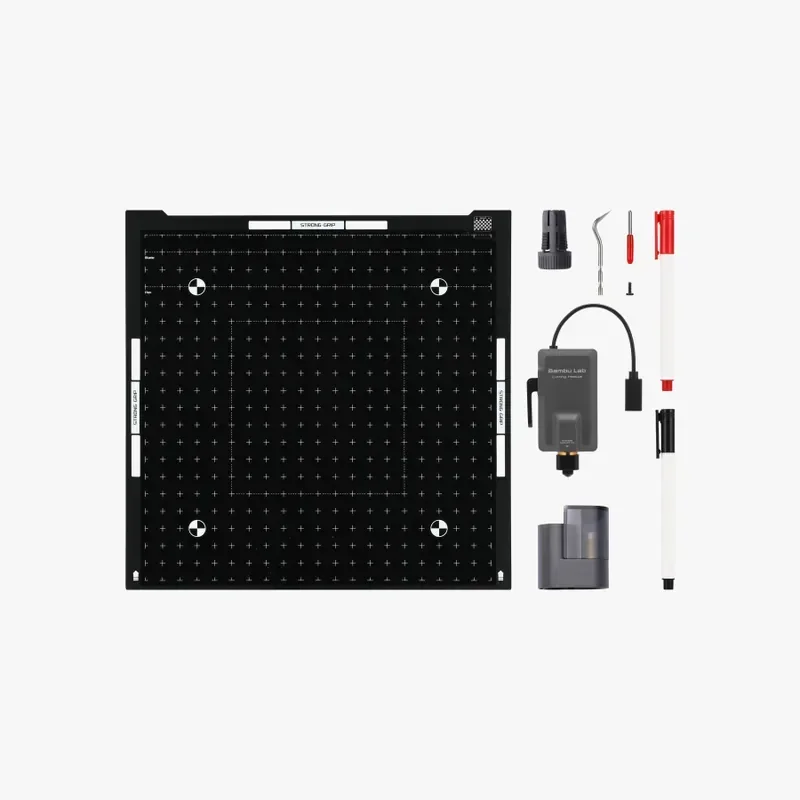

| H2 Series Cutting Upgrade Kit | Adds digital cutting and pen-drawing on the H2 platform with cutting module and dual-grip mats. | From $100 USD |

| Laser Protective Goggles | OD5+ at 200–460 nm and OD6+ at 900–1100 nm eyewear for safe laser operation. | From $39.99 USD |

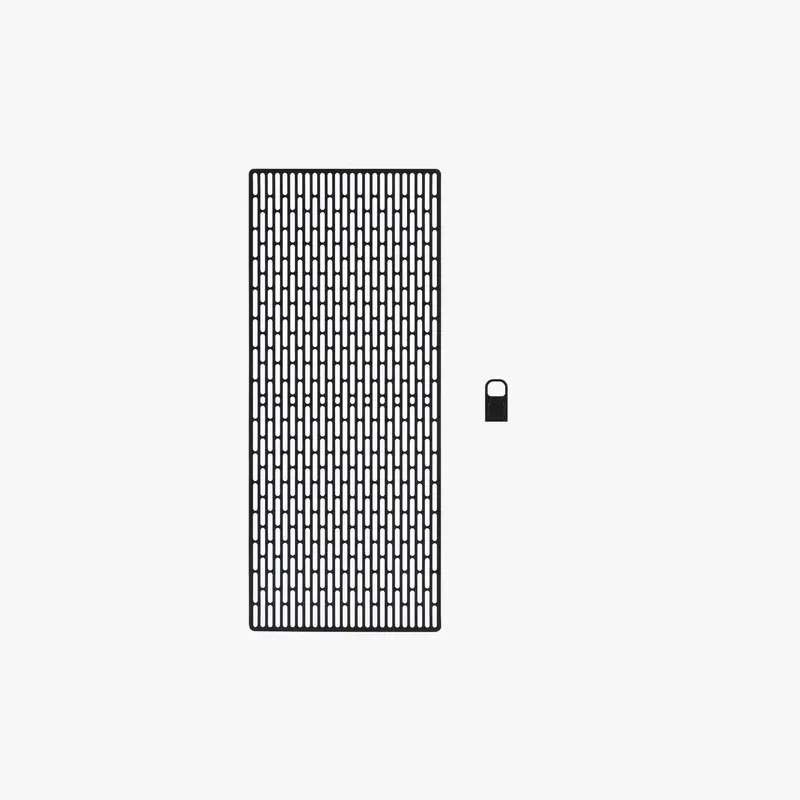

| Laser Grid Panel | Stainless support grid with fine pins to support and register thin/flexible materials during laser jobs. | From $39.99 USD |

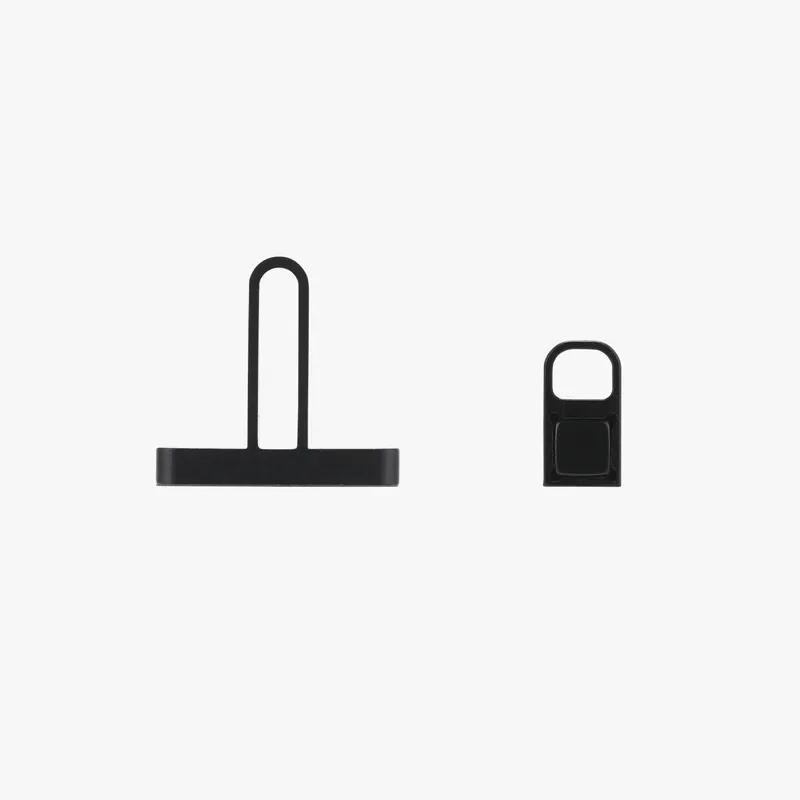

| Material Pins | Mechanically fixturing thin/flexible workpieces to keep them flat and immobile on the laser platform. | From $34.99 USD |

| Bambu High Flow Hotend – H2 Series | Quick-swap high-flow hotend/nozzle (to 350 °C) for higher volumetric flow and shorter print times. | From $33.79 |

| AMS 2 Pro Switching Adapter | Power adapter required to enable AMS 2 Pro drying function, especially with multi-AMS setups. | From $32.99 USD |

| Smoke Purifier Air Filter | Replacement filter sets (Primary, Medium-Efficiency, HEPA combo) to maintain purifier performance. | From $19.99 USD |

| SanDisk Ultra Fit USB 3.2 Flash Drive | Compact USB drive for file transfer and on-printer recording (up to 130 MB/s read). | From $9.99 USD |

| Bambu 4-in-1 PTFE Adapter | Manifold to combine up to four filament inputs (e.g., AMS + direct feeds) into the toolhead path. | From $4.99 USD |

The Bambu Lab Smoke Purifier is a compact, multi-stage filtration system for H2D and H2S Laser setups that removes 99% of particles ≥0.3μm and VOCs and captures smoke and dust generated by laser operations using G4, F8, carbon, and HEPA H13 filters, with high dust capacity, filter life alerts, and a 2-meter vent pipe for external exhaust.

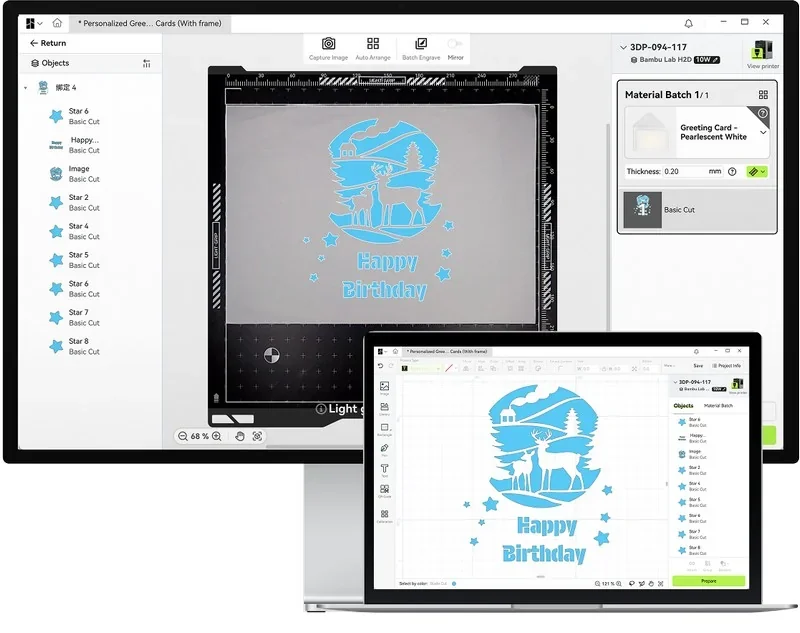

The H2S Laser Edition includes a high-precision 10 W blue laser cutting and engraving module with integrated safety systems, air assist, 3D mesh measurement, and support for materials like wood, rubber, leather, and coated metal. Although it uses a Class 4 laser, the enclosed design and interlocks ensure the system meets a Class 1 safety rating.

The Cutting Upgrade Kit converts H2 Series printers into cutters with drawing capability, including mats, blades, tools, and markers, requiring minimal installation and the Laser Module for full camera calibration.

| Feature | Cutting module | 10 W laser module |

|---|---|---|

| Process | Blade cutting / pen drawing (no laser) | Blue-light laser engraving & light cutting |

| Typical use | Vinyl, paper/cardstock, HTV, thin plastic films; pen plotting | Engraving photos/text; cutting thin wood/leather |

| Max cutting thickness (basswood) | ~0.5 mm | 5 mm |

| Max engraving speed (basswood) | n/a (mechanical) | 400 mm/s |

| Work area (H2D) | 300×255 mm (drawing/cutting) | 310×270 mm |

| Fixtures/platform | Cutting platform with LightGrip/StrongGrip mats | Laser platform with slats/grid + air-assist |

| Air assist | Not applicable | Built-in pump (≈30 kPa, 30 L/min) |

| Safety | No E-Stop required when used alone; standard machine interlocks | Class-4 module in a Class-1 enclosure; Emergency Stop required, door interlocks |

| Calibration | Mount calibration for tool-tip; blade/pen height setting | Begin Setup (XYZ focus) + Mount calibration; BirdsEye camera calibration when needed |

| Notes on materials | Cleanest edges on vinyl/paper; no burning/fumes | Blue lasers can struggle on reflective/transparent surfaces unless darkened |

The Bambu Lab Laser Protective Goggles provide essential eye protection for H2D and H2S Laser systems, blocking 99.9999% of harmful laser energy with OD5+ and OD6+ shielding across key wavelengths, while reducing glare and eye strain during precision work.

The Bambu Lab Laser Grid Panel is a durable stainless steel base system for H2D and H2S Lasers, designed to securely hold flexible or small materials using two grid panels and six magnetic pins, enabling precise, batch laser processing with stable alignment across slats and grid surfaces.

Material Pins are durable black metal clamps that keep materials stable and aligned during laser cutting on H2D and H2S systems, with 4 large and 4 small pins designed to secure various sizes and prevent warping for precise, consistent results.

The Bambu Lab Vision Encoder is a precision XY-axis calibration tool for H2 Series printers, using 10,000 Encode Markers and 5μm optical measurements to maintain sub-50μm accuracy, compensating for wear and belt issues, with 5-minute sessions enabling high-precision printing for weeks — ideal for large prints, functional parts, and use with Auto Hole-Contour Compensation in Bambu Studio.

The Bambu High Flow Hotend for H2 and A1 Series printers boosts volumetric speed by up to 62.5% over standard nozzles, enabling faster prints with consistent extrusion, crisp edges, and smooth surfaces; it supports up to 350°C, handles carbon-fiber materials, and includes a quick-swap 0.4mm hardened steel nozzle.

The AMS 2 Pro Switching Adapter lets multiple AMS 2 Pro units dry filament while printing on H2S, H2D, X1, P1, and A1. Use one adapter per unit. The adapter is required for drying on X1/P1/A1; on H2D/H2S it’s optional for a single unit but needed to maintain drying performance with multiple units.

The Bambu Lab Smoke Purifier Air Filter is a replacement system for maintaining 99% particle and VOC filtration efficiency, offered in three options—Primary (G4), Medium Efficient (F8), and a full Air Filter Combo with G4, F8, and HEPA H13 filters—each requiring replacement when cleaning no longer restores airflow or absorption.

The SanDisk Ultra Fit USB 3.2 Gen 1 Flash Drive offers compact, high-speed storage (up to 400MB/s) for devices like laptops and consoles, with capacities from 32GB to 1TB, AES password protection via SanDisk SecureAccess, and a low-profile design for plug-and-stay use without blocking adjacent ports.

The Bambu 4-in-1 PTFE Adapter enables up to 7 filament feeds for X1, P1, and H2 Series printers by connecting 4 inputs to 1 output via PTFE tubes, supporting AMS or direct feeds — including AMS-incompatible materials like TPU 95A and PET-CF—with directional installation for reliable multi-material printing.

The Bambu Lab H2S requires over 17 maintenance procedures to maintain print quality, smooth motion, and safe filtration/laser operation on weekly, monthly, quarterly, and spool-based intervals.

These include:

Weekly

Monthly

Every 3 months

Spool-based (usage-dependent)

Laser-equipped units (when the 10 W module is installed)

Automation & reminders

Consumables, tools, and solvents

Warranty Coverage:

Bambu Lab offers a limited warranty against manufacturing defects and failures not caused by the user. It excludes damage from misuse, third-party accessories, unofficial firmware, poor maintenance, accidents, and tampered serials. Claims must go through official Bambu Lab support channels.

Warranty Period:

Not Covered:

Damage from unofficial firmware, improper use, lack of maintenance (e.g., laser cleaning), cosmetic wear, shipping damage without proof, or missing proof of purchase. Consumables have no warranty.

Support Access:

Self-Help Resources:

Guides and tutorials are available via Bambu Lab Wiki, Bambu Studio/Handy apps, and on-device QR codes:

The price of the Bambu Lab H2S is $1,559.00.

Other configurations (percentage vs. base):

Value proposition: Even the base H2S delivers a 340 × 320 × 340 mm build volume, 350 °C nozzle, and 65 °C active chamber, with closed-loop extrusion control, AI monitoring, and optional Vision Encoder for sub-50 μm motion accuracy—providing large-format, high-speed capability in a single-nozzle platform.

Update your browser to view this website correctly. Update my browser now