The Bambu Lab P1S is a fully enclosed CoreXY 3D printer with a 256 × 256 × 256 mm build volume, offering fast print speeds up to 500mm/s and 20,000 mm/s² acceleration. It supports a wide range of materials, including PLA, PETG, TPU, ABS, and ASA, and includes features like auto-bed leveling, a built-in camera for remote monitoring and timelapses, and optional AMS support for up to 16-color printing. An activated carbon filter helps reduce odors from materials like ABS and ASA. With a 300°C hotend, advanced cooling, and simple 15-minute setup, the P1S is designed for both beginners and experienced users, and can be controlled remotely via Bambu Studio and Bambu Handy.

The Bambu Lab P1S delivers high-quality prints at speeds up to 500mm/s using a CoreXY system with vibration compensation and input shaping. It maintains dimensional accuracy and clean layer stacking across materials, with minimal difference in quality between standard (200–300mm/s) and high-speed prints. It prints fine details at 0.08mm layer height using the stock 0.4mm nozzle, with optional nozzles from 0.2mm to 0.8mm.

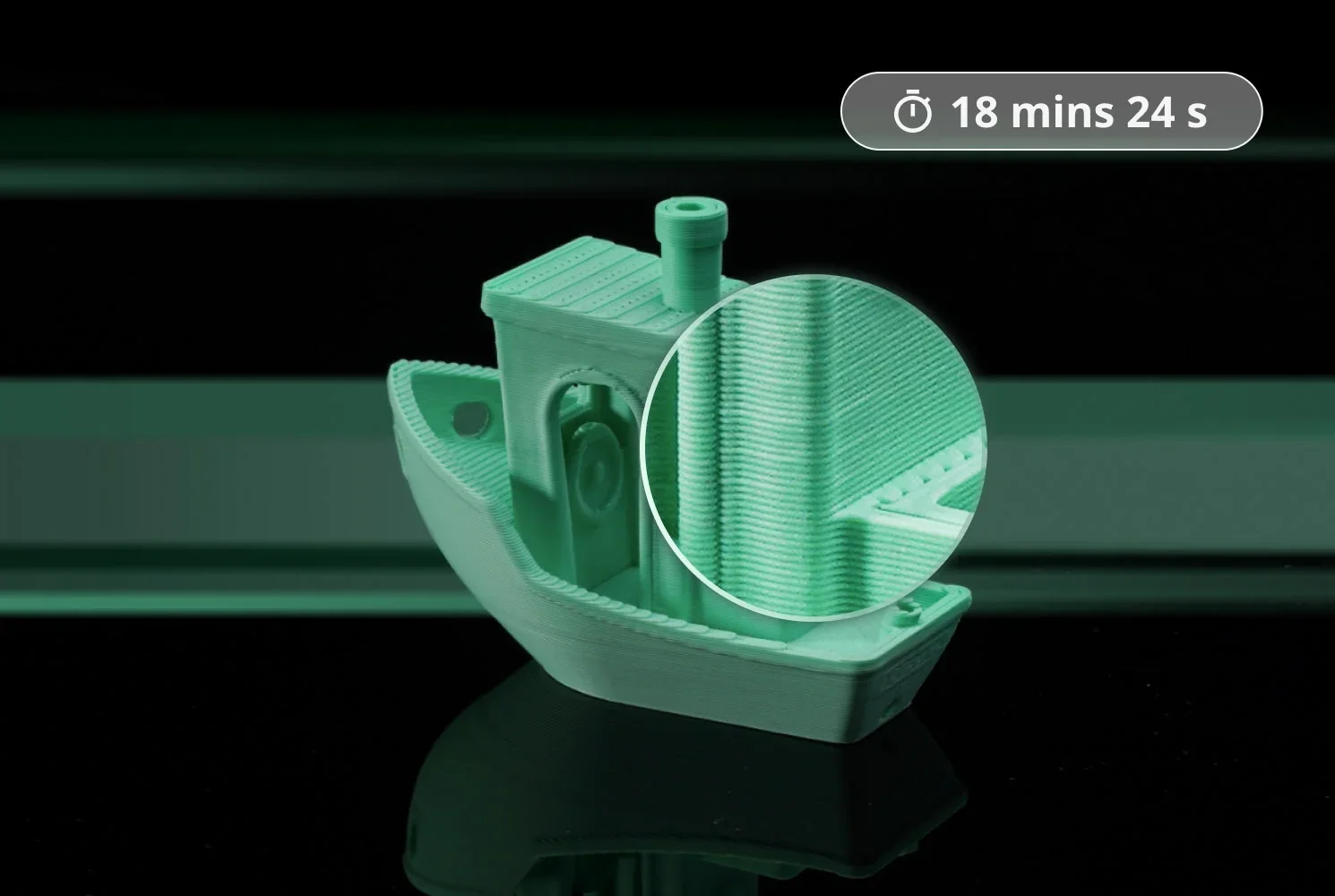

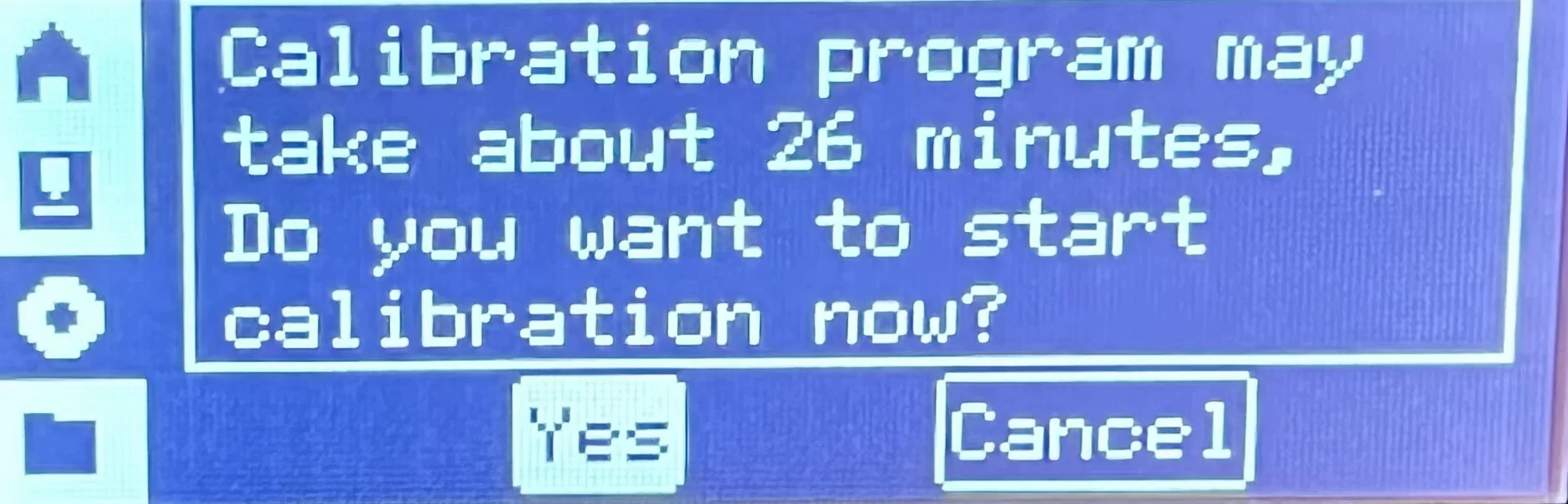

The Bambu Lab P1S reaches speeds of 500mm/s with 20,000mm/s² acceleration and offers three modes: standard, sport (124% faster), and ludicrous (164% faster). A Benchy prints in 18 minutes at full speed versus 26 at normal speed. Most prints finish in 1–2 hours — about four times faster than entry-level printers. The slicer’s volumetric speed limit ensures reliable material flow across filament types.

Real-world prints show the P1S's versatility: a multi-color Baby Yoda was printed in 2h 36m (0.8mm layer height); a multi-part action figure was printed in 2h 43m (0.16mm layer height, 3 wall perimeters); nylon RC car gears in 1h 13m; ASA tape dispensers in 1h 17m; and TPU car spoilers in 5h 47m at 40mm/s.

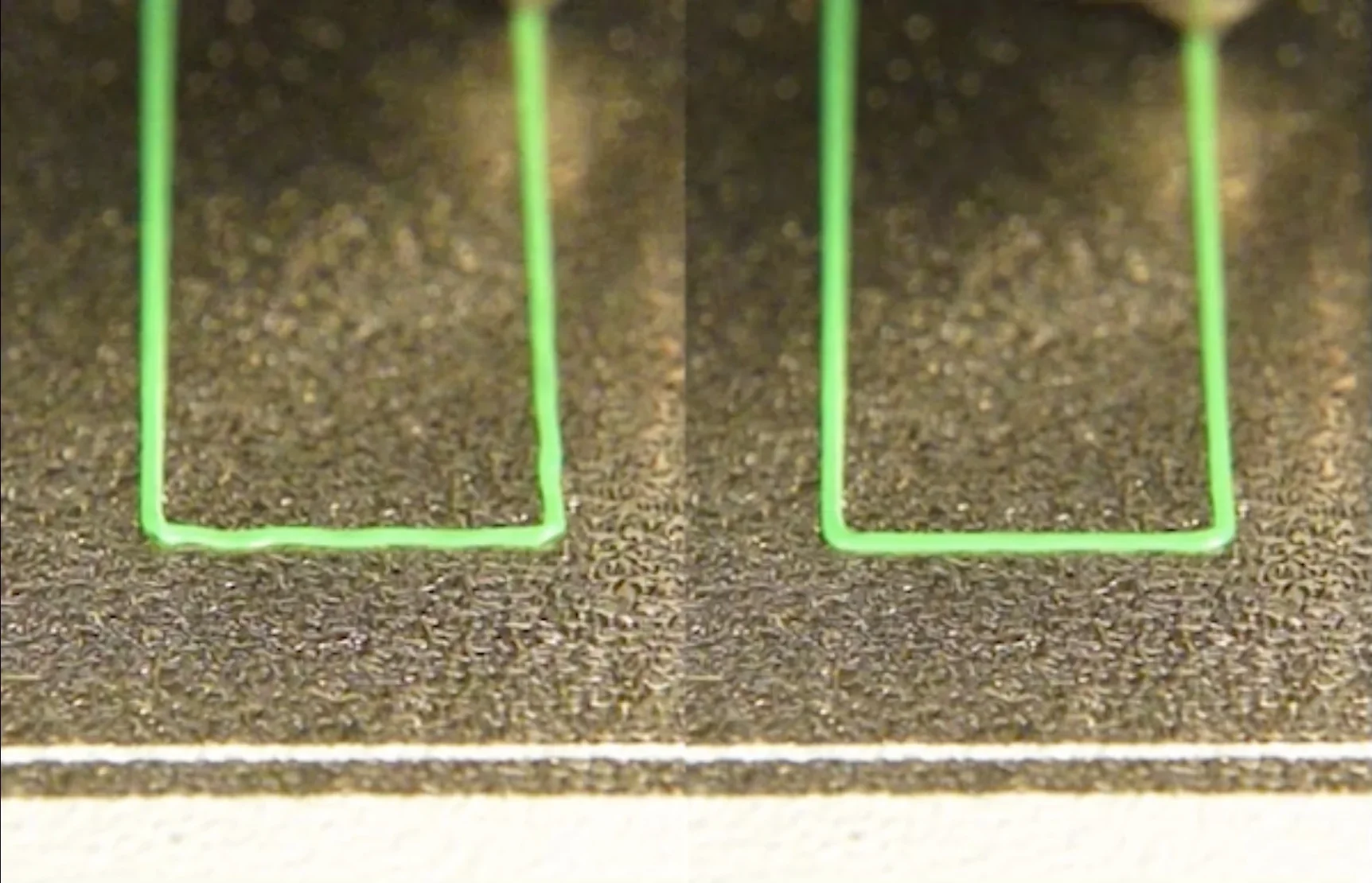

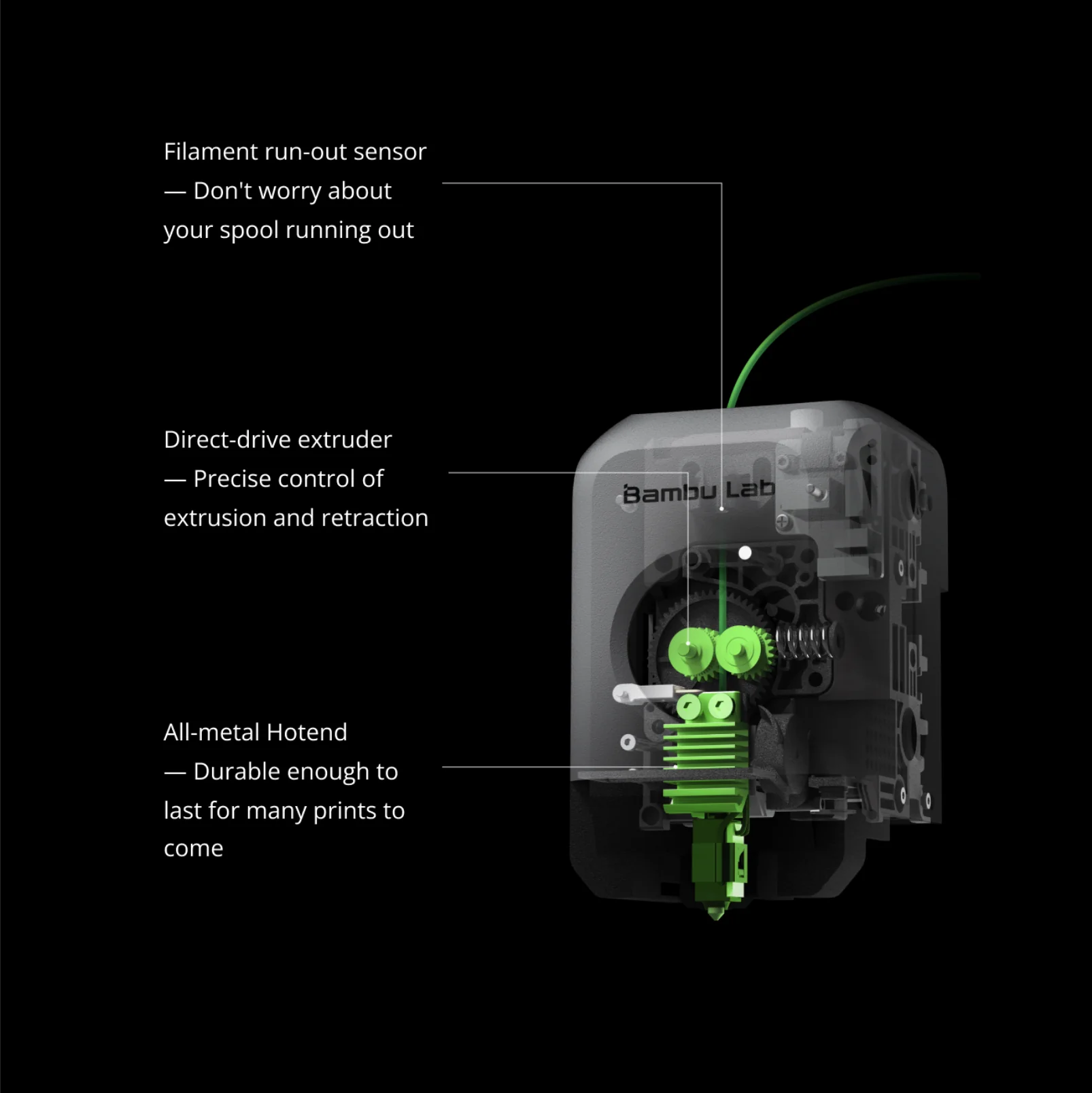

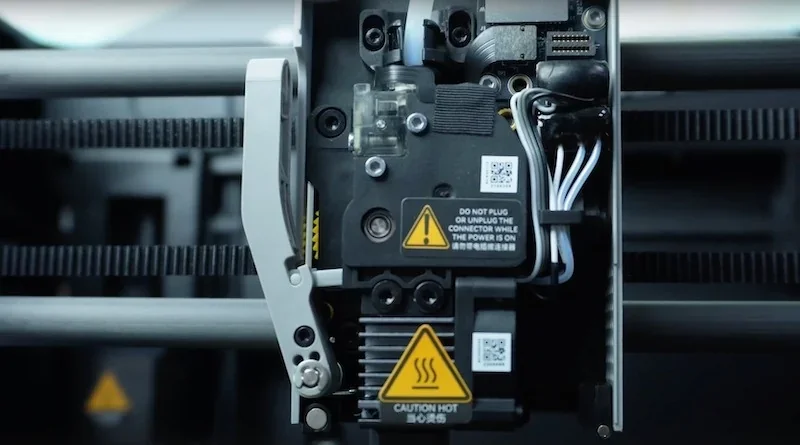

The Bambu Lab P1S delivers consistent print quality through key mechanical features: auto bed leveling for a perfect first layer, a direct-drive extruder for precise filament control (especially with flexibles), and an enclosed design for chamber temperature stability. Its cooling system — hotend, front cover, and auxiliary part cooling fans — supports various materials. Vibration compensation and pressure advance reduce artifacts, ensuring clean results at any speed or complexity.

Yes — it has a direct-drive extruder, offering superior control over filament extrusion and retraction of flexible filaments.

Before printing, the P1S measures X/Y axis resonant frequencies and applies input shaping with an advanced control algorithm to avoid them, reducing ringing. Pressure Advance adjusts flow based on movement — boosting during acceleration and retracting on deceleration — to maintain consistent line width, even at 500mm/s.

The AMS uses 3 sensors:

During pauses, the AMS retracts, cuts, and purges filament to prevent oozing or layer shifts before resuming.

| Feature | P1S | X1 Carbon | X1E |

|---|---|---|---|

| Enclosure & Frame | Plastic/glass panels on steel frame — passive chamber | Full aluminum & glass shell — passive chamber | Aluminum & glass shellwith active heating(up to 60 °C) and industrial gasketing |

| Hot-end / Nozzle | Stainless-steel, 300 °C max | Hardened-steel, 300 °C max | Hardened-steel,320 °C maxfor engineering polymers |

| Motion & Sensors | CoreXY, carbon-X rod, lidar-free; 720 p camera | CoreXY, carbon-X rod,built-in micro lidarfor first-layer & flow calibration (aka advanced AI detection); 1080 p camera | Same as X1 plus extra vibration dampers |

| Air Management | Single activated-carbon filter | Same filter | Three-stage system:G3 pre-filter + H12 HEPA + coconut-carbon VOC |

| Connectivity | Wi-Fi 2.4 GHz; cloud only | Wi-Fi 2.4 / 5 GHz; cloud only | Wi-Fi 2.4 / 5 GHz& Gigabit Ethernet, LAN-only mode, physical radio kill-switches, WPA2-Enterprise |

| Screen & UI | 2.7-inch monochrome button panel | 5-inch 1280×720 touchscreen | Same touchscreen |

| Build Volume | 256 × 256 × 256 mm | 256 × 256 × 256 mm | 256 × 256 × 256 mm |

| Bed Temperature | 100 °C max | 120 °C max | 120 °C max |

| Materials out-of-box | PLA, PETG, TPU, ABS, ASA | Adds carbon-fiber nylons, PC blends | Adds PPS-CF, PPA-GF/CF, PEI-blend, etc. |

| AMS Support | One AMS standard; up to 4 with hub | Same | Same |

| Target User | Hobbyists & schools wanting an enclosed high-speed printer | Advanced makers / prosumers needing lidar QA & tougher materials | Engineering, R&D, enterprise sites requiring secure networking, high-temp & filtered chamber |

The Bambu Lab P1S supports over 8 printing filaments — PLA, PETG, TPU, PVA, PET, ABS, ASA, Nylon (PA), and Polycarbonate (PC) — thanks to its enclosed chamber, 300°C all-metal hotend, and 100°C heated print bed. The fully enclosed printing chamber for materials like ABS and ASA, while an activated carbon filter reduces odors and emissions.

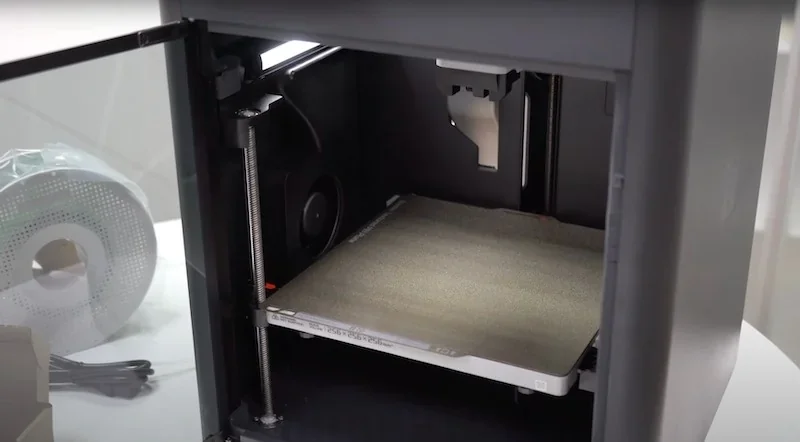

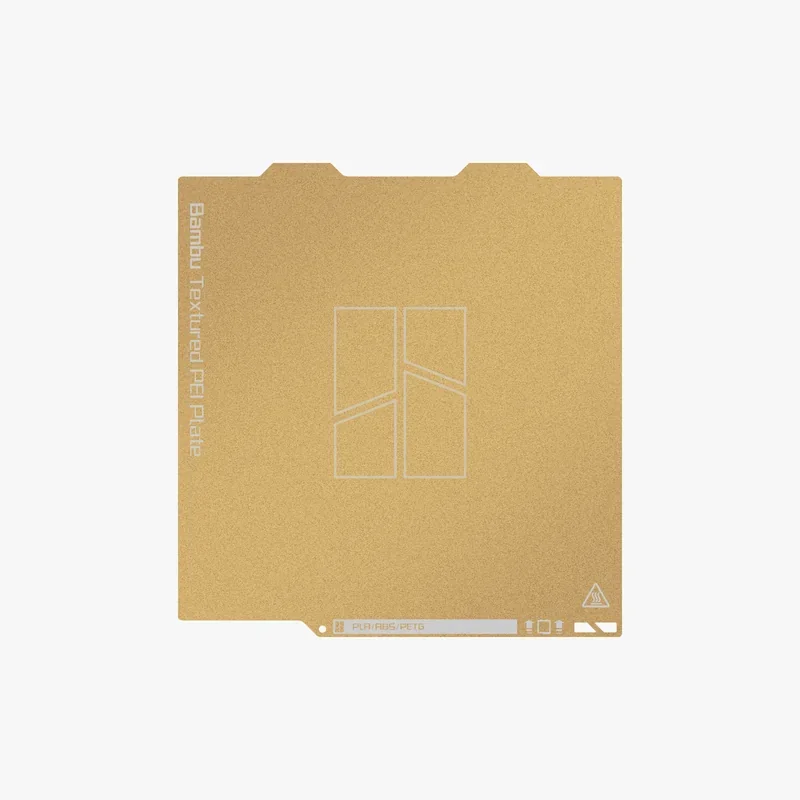

The included textured PEI plate offers good adhesion for most materials, but Bambu Lab recommends their Engineering Plate for better results with high-temp filaments like polycarbonate and nylon.

For optimal results, flexible filaments like TPU should be printed at 40mm/s to avoid jams during loading. Nylon benefits from reduced wall speeds around 75mm/s for better layer adhesion. Carbon- or glass-fiber filaments require a hardened steel nozzle, as the stock 0.4mm stainless steel nozzle wears quickly with abrasives.

The Bambu Lab P1S supports both Bambu Lab and third-party filaments. Bambu filaments include RFID tags for automatic detection of type, color, and remaining amount. Third-party filaments work well but require manual setup in Bambu Studio and lack auto-identification.

PLA 3D Print Sample - Battery charger case:The housing was printed from green PLA Basic with 120 micron layer height, requiring 2 hours and 24 minutes of print time.

PETG 3D Print Sample - Fog light housing:Produced in black PETG with 160-micron layer height and support structures, completing in 3 hours 11 minutes.

ABS 3D Print Sample - Plastic case: Printed from ABS plastic with 120-micron layer height, consisting of a lid requiring support structures, edited support-to-model adhesion parameters, and bed adhesion spray (1 hour 46 minutes), and a body printed without supports (1 hour).

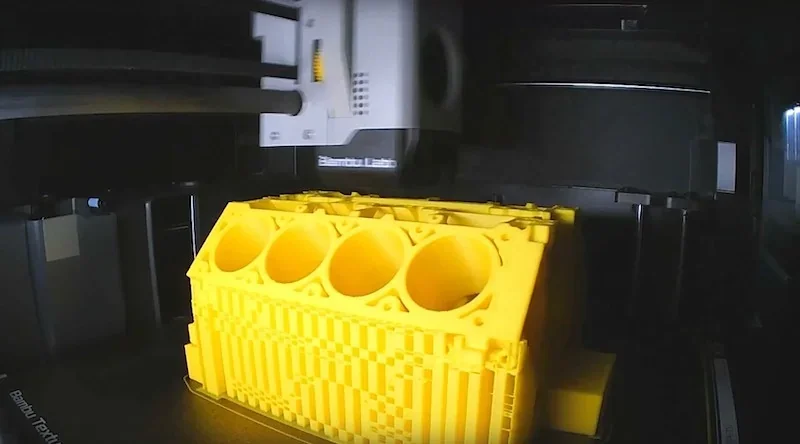

ABS 3D Print Sample: A 161 x 182 x 112 mm V8 Engine Block.

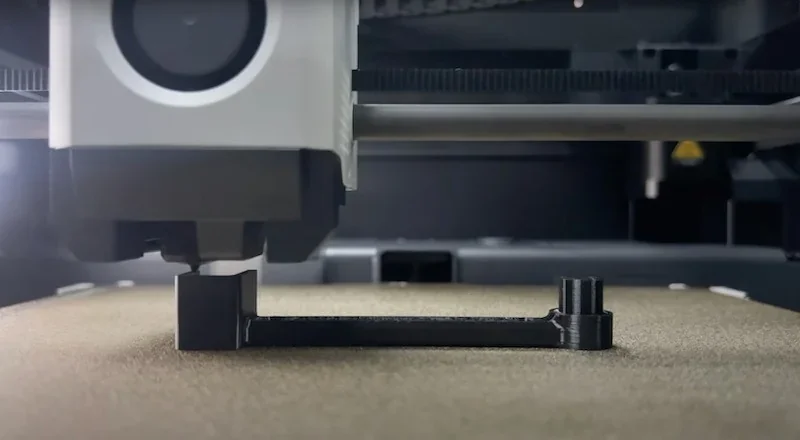

The Bambu Lab P1S has a 256 × 256 × 256 mm build volume, shared with the P1P and X1 Carbon. Bambu Studio limits the default printable height to 250 mm to avoid bed collisions, but the full height is accessible with safety precautions. The collapsible filament cutter stopper slightly reduces usable space when extended.

Bambu Lab P1S — enclosed CoreXY with 256 × 256 × 256 mm build, 300 °C nozzle, 100 °C bed, activated-carbon filtration, integrated chamber camera, and optional AMS for multi-material — aimed at balanced speed (≤500 mm/s travel) and turnkey usability.

In contrast:

| Specification ➜ | Creality K1 Max | Prusa Core One | Flashforge Adventurer 5M | Flashforge Adventurer 5M Pro | Bambu Lab P1S |

|---|---|---|---|---|---|

| Build volume (mm) | 300 × 300 × 300 | 250 × 220 × 270 | 220 × 220 × 220 | 220 × 220 × 220 | 256 × 256 × 256 |

| Enclosure / chamber | Enclosed; — | Enclosed; 55 °C chamber | Open frame | Enclosed; HEPA + activated-carbon filtration | Enclosed; activated-carbon filter |

| Nozzle temp (°C) | ≤ 300 | 290 | 280 | 280 | ≤ 300 |

| Bed temp (°C) | ≤ 100 | 120 | 100 | 100 | 100 |

| Max travel speed (mm/s) | ≤ 600 | — (not quoted) | ≤ 600 | ≤ 600 | ≤ 500 |

| Extruder | Dual-gear direct drive | Nextruder direct drive (10:1) | Direct drive (1×) | Direct drive (1×) | Direct drive; steel gears |

| Filtration | — | — (optional modules) | — | Internal + external (HEPA + carbon) | Activated-carbon |

| Camera | AI camera (+ AI LiDAR) | Optional | — | Camera monitoring | 720p chamber camera |

| Supported materials (short) | PLA, PETG, TPU, PA, ABS/ASA, PC, CF/GF | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB (ABS/ASA/PA with filters) | PLA/PETG; TPU/CF (0.6+ rec.) | PLA/PETG; ABS/ASA; TPU/CF (0.6/0.8 rec.) | PLA, PETG, TPU, ABS/ASA, PVA, PET; PA/PC capable |

Bottom-Line:

The Bambu Lab P1S provides 19 distinct printer controls accessible through its touchscreen interface.

Controls Overview (8 Functions):

Settings Overview (10 Controls):

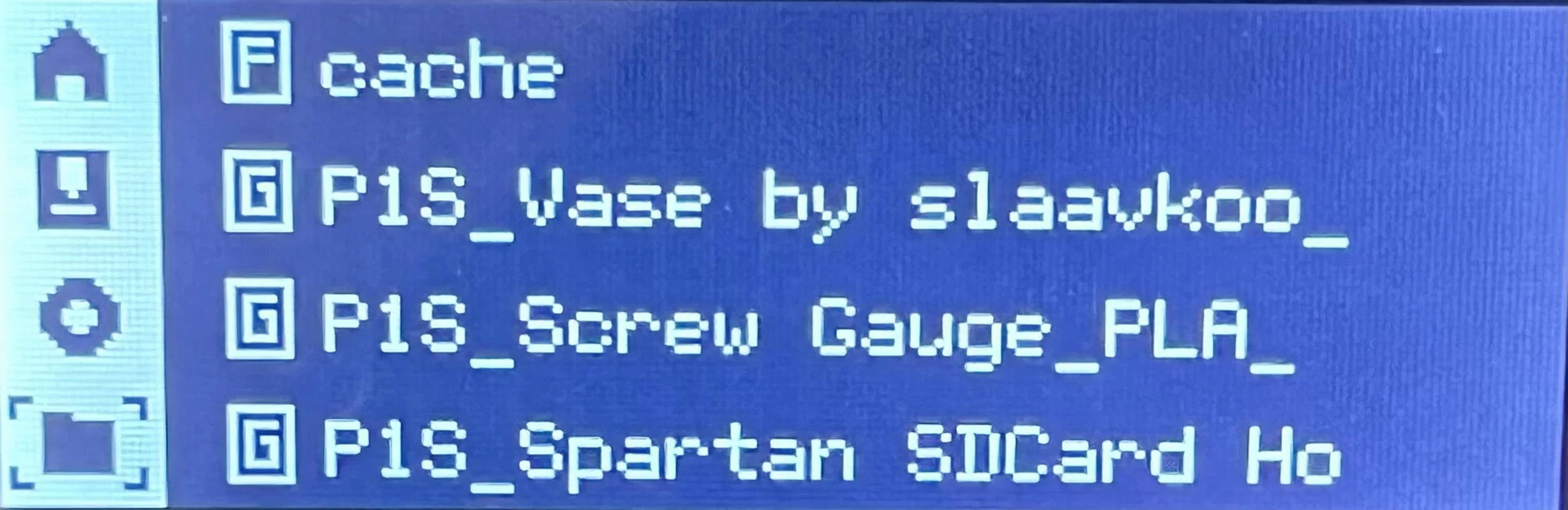

File Management (1 Control)

.gcode files.

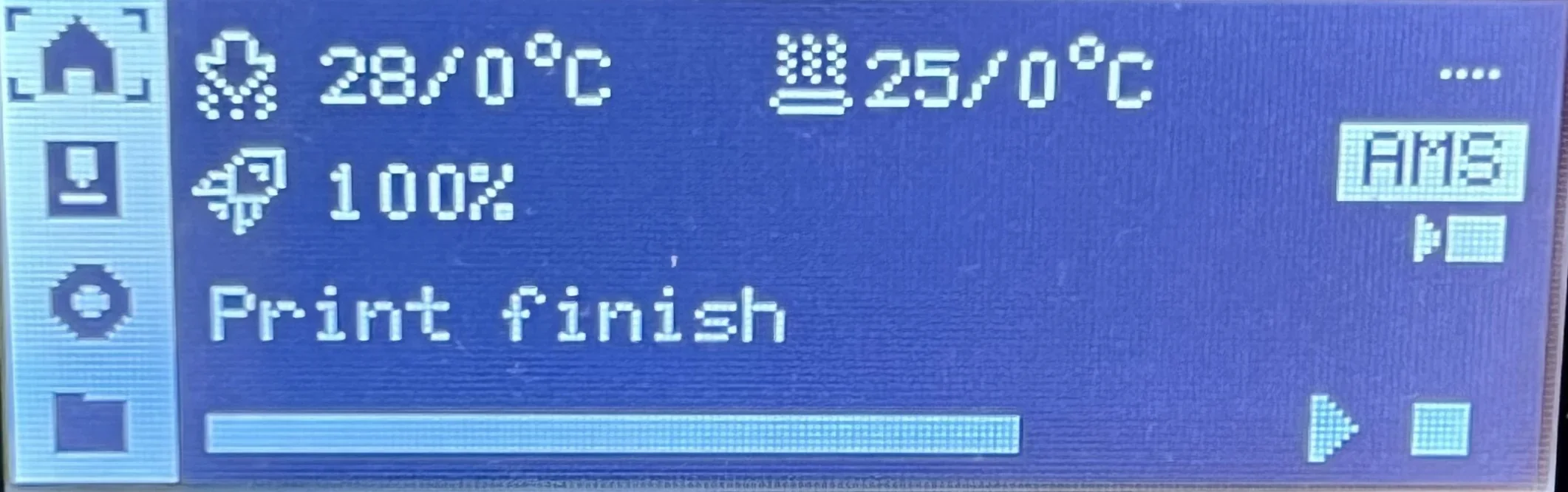

The interface displays real-time information including nozzle temperature, heatbed temperature, print speed, and active print job status on the home screen.

The Bambu Lab P1S supports Wi-Fi, Bluetooth (for pairing), and a MicroSD slot for remote printing. Setup involves connecting to Wi-Fi and linking a Bambu Lab account via the Bambu Handy app, enabling communication with Bambu Studio and the mobile app. A "LAN only" mode is available for local-only use, with access controlled by a printer-displayed code.

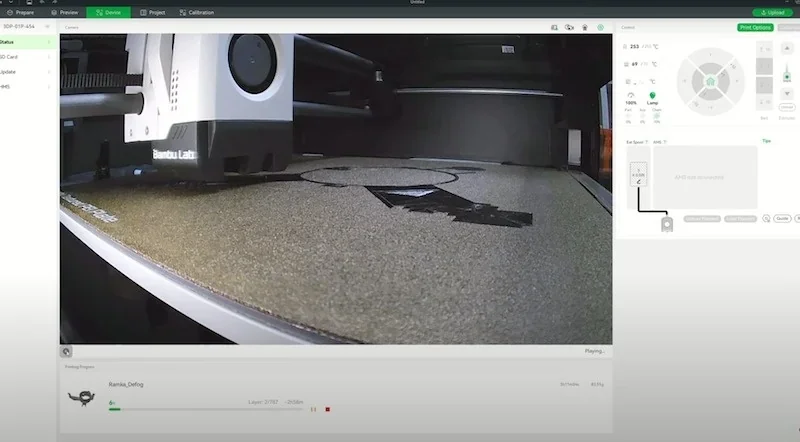

The Bambu Lab P1S runs on a software ecosystem built around Bambu Studio, a slicer based on PrusaSlicer. It includes material presets, multicolor painting for AMS, automatic filament-based settings, and flow calibration for optimized prints. The Bambu Handy mobile app (iOS/Android) offers remote control, live camera monitoring, and print management. Both apps connect to MakerWorld, Bambu Lab’s model library for direct downloads.

While the P1S supports third-party slicers via Bambu Connect, native tools offer the best experience — especially for AMS and high-speed printing.

Bambu Studio bundles every part, plate, filament preset, and slicer setting into a single 3MF “project.”

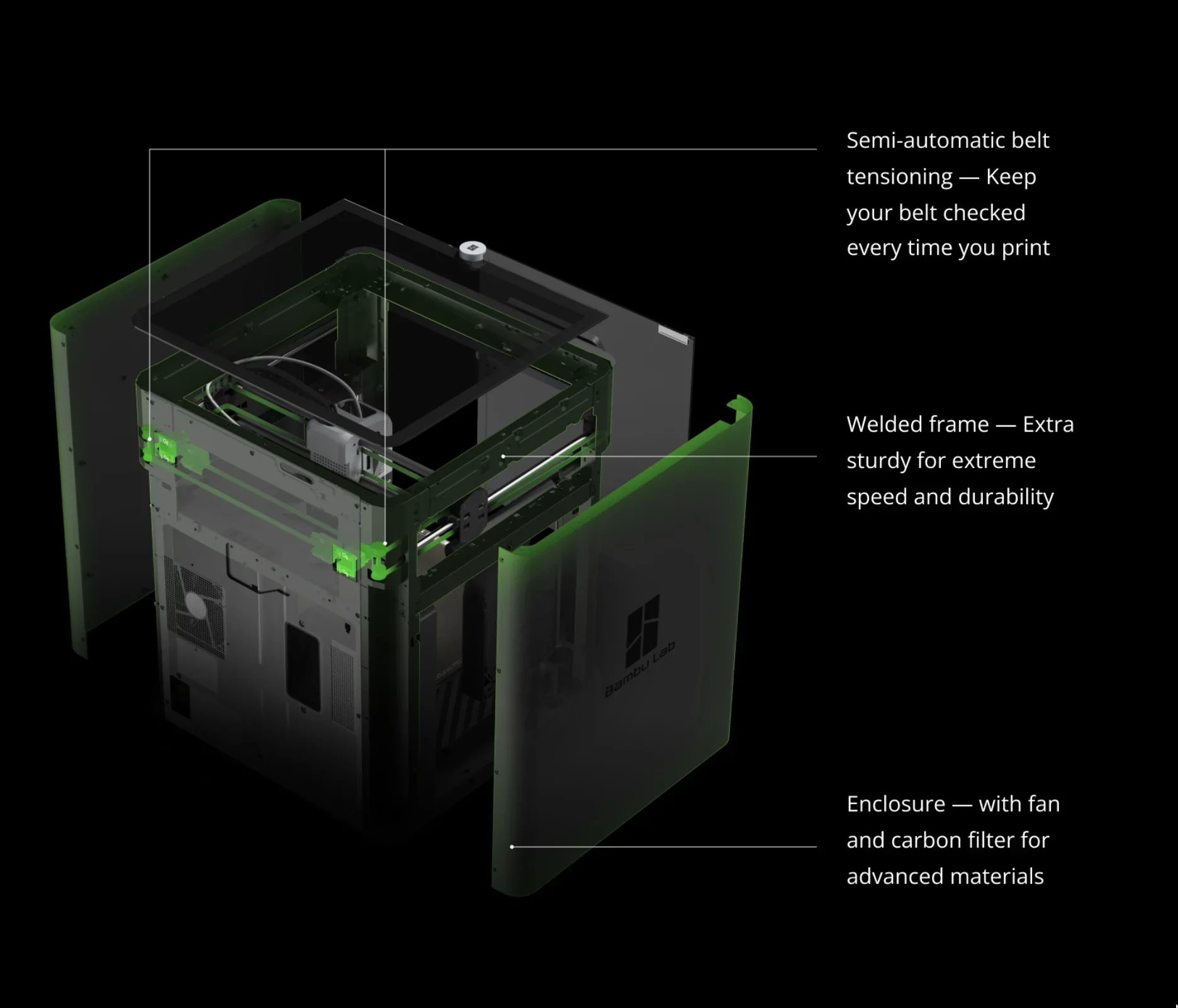

The Bambu Lab P1S features a fully enclosed, durable design with plastic side panels, a glass door and top, and a gunmetal finish. Built on a welded steel chassis for stability, it measures 389 × 389 × 458 mm (15.3 x 15.3 x 18 inches) and weighs 12.95 kg (28.5 lbs).

The glass door offers clear print visibility, and the removable glass top allows ventilation or supports the optional AMS. While the P1S has a sleek, functional design, it uses plastic panels instead of the aluminum found on the higher-end X1 Carbon.

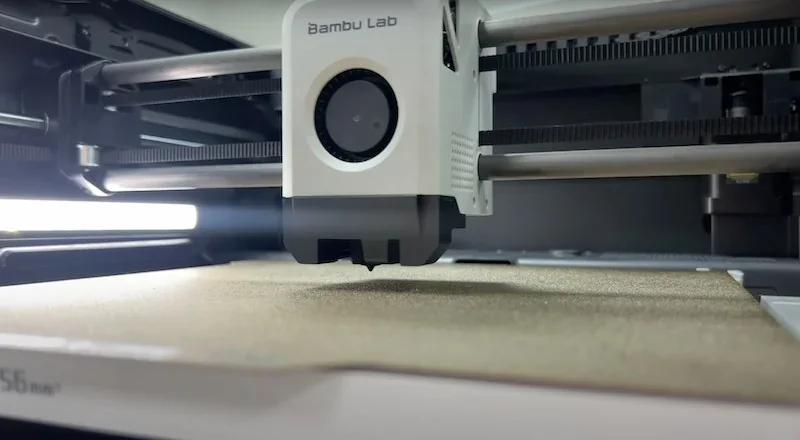

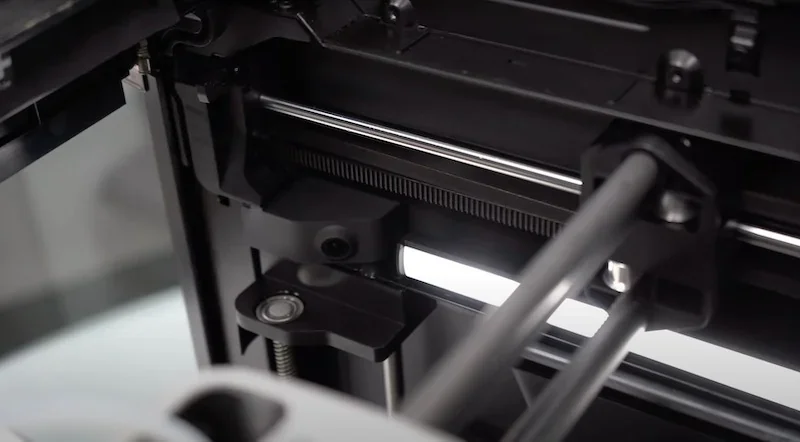

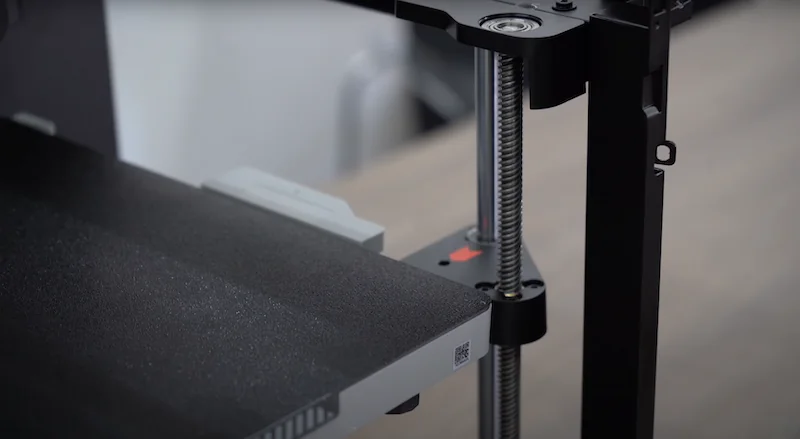

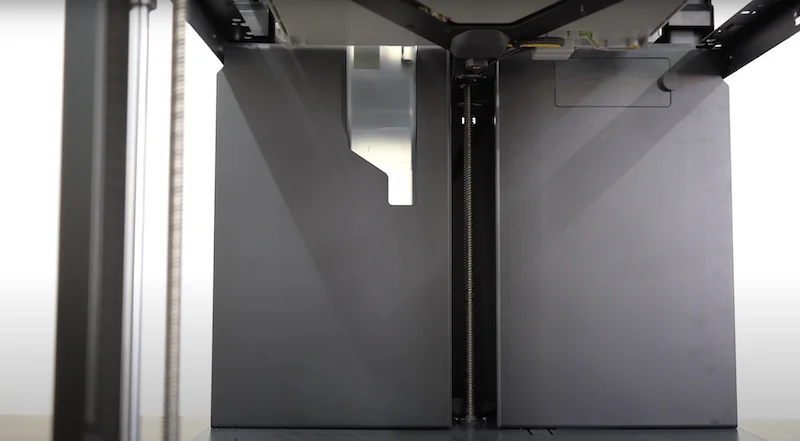

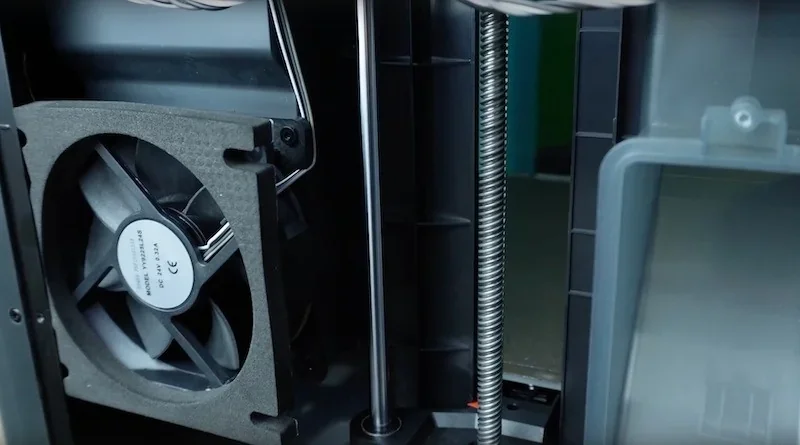

The Bambu Lab P1S uses a CoreXY system with carbon X-axis rods and LMU8-bearing linear rods for Y and Z movement, achieving speeds up to 500 mm/s and 20,000 mm/s² acceleration. Vibration damping, input shaping, and semi-automatic belt tensioning within the precision control system of the Bambu Lab enable rapid acceleration from zero to 500 mm/s in 0.025 seconds. The Bambu P1S prints up to 4× faster than bed-slingers without quality loss. A direct-drive extruder ensures precise and consistent extrusion.

Three Z-axis lead screws ensure stable bed movement, while the direct-drive extruder delivers precise filament control for clean, accurate prints.

The Bambu Lab P1S includes user-friendly features like a built-in LED light for chamber visibility, though some users find it dim.

The rear spool holder supports standard filament rolls, feeding through a PTFE tube to the print head when AMS isn't used. An "excess chute" expels waste filament during color changes but lacks a collection container. The enclosed design maintains stable temperatures for materials like ABS and ASA, while a carbon filter reduces odors. Maintenance is easy via the glass door, providing access to key components.

The cooling system includes an auxiliary part fan, chamber regulator fan, and control board fan to manage temperatures across different materials.

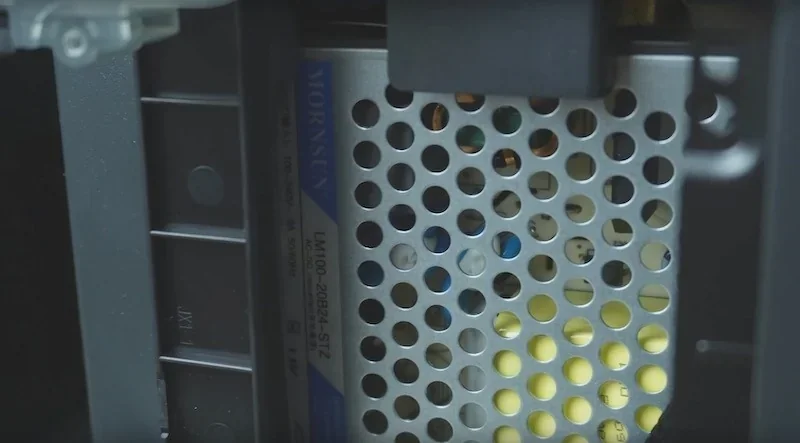

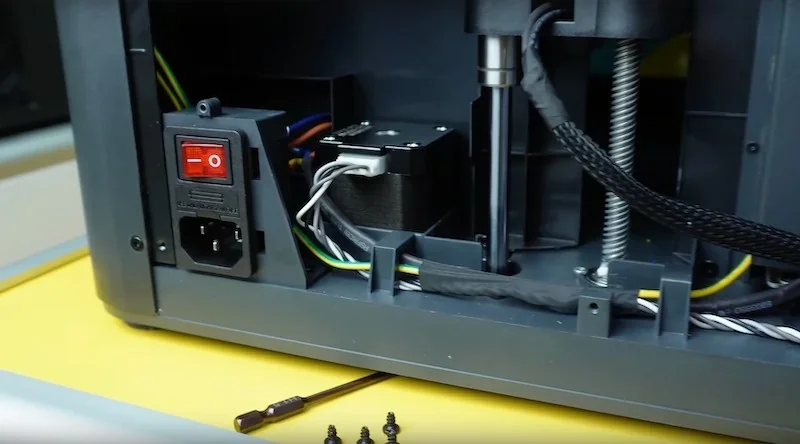

The power supply is made by MornSun, a reputable supplier.

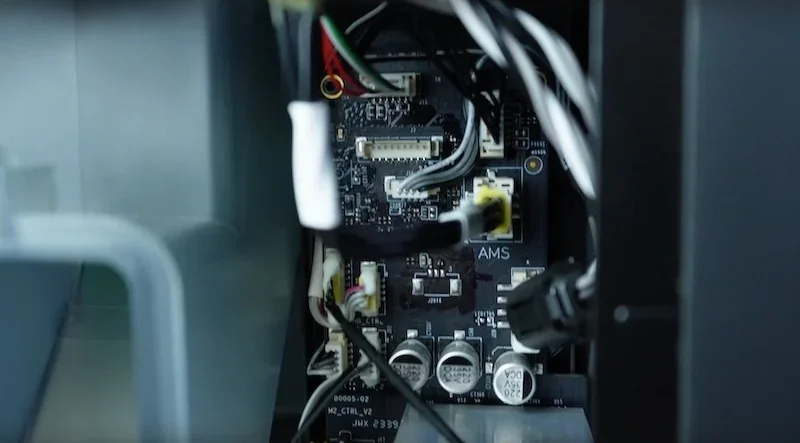

The main controller board is a proprietary Bambu Lab design with integrated motor drivers and an aluminum heatsink. Connectors lack thermal adhesive, making repairs easier.

Power Supply Unit:

The front cooling shroud uses a magnetic quick-release with built-in fan mounts. The visible, modular filament feed assembly and hotend are made from precision-built components and can be easily removed or disassembled.

Bambu Lab P1S:

Additional Items in Bambu Lab P1S Combo:

The Bambu Lab P1S arrives mostly assembled and takes about 15 minutes to set up right out of the box. Users remove shipping materials, install the spool holder and LCD with the included Allen key, and connect the AMS if included. It comes with sample filament and pre-loaded models on the MicroSD card for immediate printing. A quick start guide walks users through setup.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Group: Bundles and Combos | |||

| P1S AMS Combo |

Includes:

|

$180.99 |  |

| P1S AMS 2 Pro Combo |

Includes:

Conditionally included (choose your variant):

|

$289.99 |  |

| Group: Automatic Material Systems and Accessories | |||

| Accessory Box for AMS | Parts kit for AMS setup and maintenance, including PTFE tubes, couplers, and screws. | $9.99 |  |

| Desiccant for AMS Unit | Color-changing silica desiccant for AMS. Beads change from yellow to purple when saturated; reuse by drying. | $4.99 |  |

| Group: Filament Path and Tubing | |||

| Bambu 4-in-1 PTFE Adapter | PTFE adapter that connects up to four feeder modules to the printer. Supports AMS plus three external spools, including TPU 95A and fiber-filled filaments. | $6.99 |  |

| Group: Build Plates | |||

| Bambu Cool Plate SuperTack | SuperTack build plate for strong PLA and PETG adhesion at low bed temperatures and reduced warping on large prints. | $21.99 |  |

| Bambu Cool Plate SuperTack Pro | SuperTack Pro build plate for strong PLA and PETG adhesion at low bed temperatures. Extends plate life by 25%, lowers operating temperature by 10 °C, and improves scratch resistance. | $36.99 |  |

| Bambu Smooth PEI Plate | Smooth PEI build plate for accurate Z-height and a smooth matte bottom surface; supports PLA, TPU, and PETG. | $21.99 |  |

| Bambu Engineering Plate | High-temperature build plate for the full Bambu filament lineup when used with a glue layer. Durable coating resists scratches and corrosion and delivers a smooth surface finish. | $36.99 |  |

| Bambu 3D Effect Plate | Effect build plate that transfers decorative textures to the first layer. Includes Carbon Fiber, Starry, Galaxy, and Diamond patterns. | $14.99 |  |

| Bambu Dual-Texture PEI Plate | Dual-sided PEI plate with one textured side and one smooth side. 0.5 mm magnetic stainless steel base increases magnetic hold and reduces warping. | $33.99 |  |

| Bambu Textured PEI Plate | Textured PEI plate for durable, strong first-layer adhesion. Use glue for specific filaments; prints release after cooling. | $25.99 |  |

| Group: Hotends and Extrusion | |||

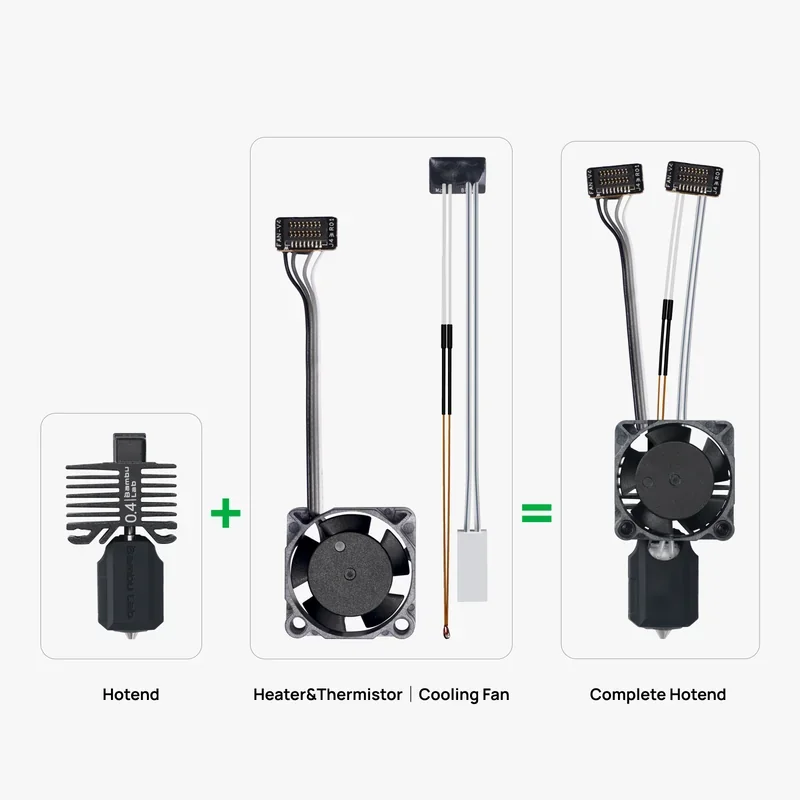

| Bambu Hotend - P1 Series | Complete replacement hotend for P1 Series rated to 320 °C. Nozzle options include 0.2 mm, 0.6 mm, and 0.8 mm; includes hotend, silicone sock, thermal grease, retaining clip, and screws. | $19.99 |  |

| E3D High Flow ObXidian™ Hotend | Bambu Lab × E3D high-flow hotend with 60% higher flow rate and an ObXidian hardened nozzle with E3DLC coating. | $92.99 |  |

| All-in-one Hotends Kit - P1 Series | P1 Series hotend kit with interchangeable 0.2/0.4/0.6/0.8 mm nozzle sizes for detail or high-throughput printing. | $65.99 |  |

| Hardened Steel Upgrade Combo - P1 Series | Hardened steel extruder gear and hardened steel hotend for abrasive engineering filaments with carbon fiber or glass fiber. | $36.99 |  |

| Group: Enclosures and Stability | |||

| P1P Enclosure Kit | Full enclosure kit for P1P with glass top cover, glass front door, and side and rear panels; adds auxiliary part cooling, control board, and chamber regulator fans for heat management. | $180.99 |  |

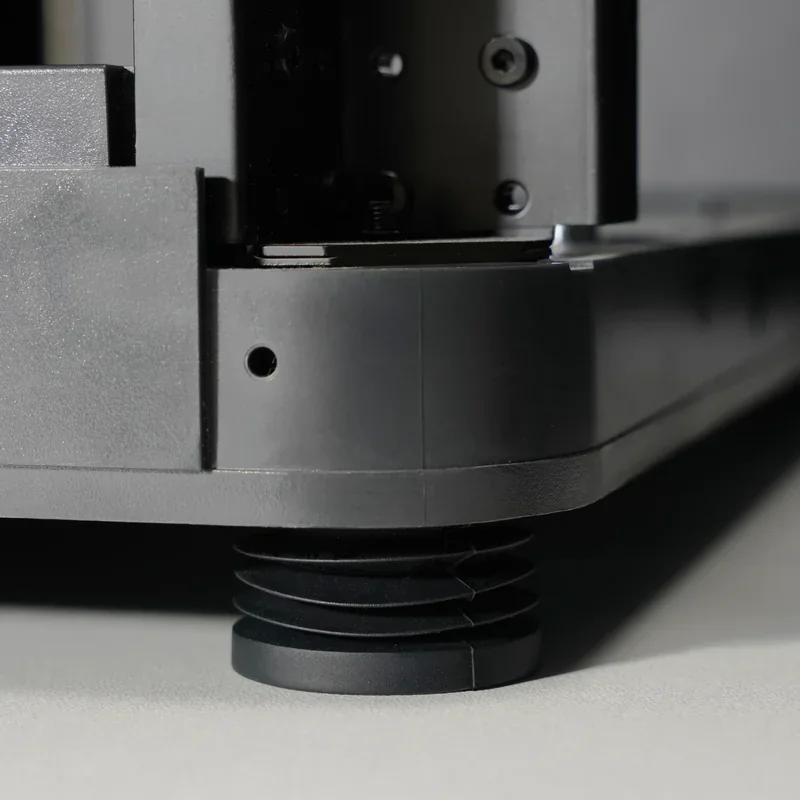

| Anti-Vibration Feet | Rubber feet that absorb vibration and improve printer stability. | $6.99 |  |

| Group: Adhesion Aids | |||

| Glue Stick | Formaldehyde-free glue stick that adds a controlled adhesion layer. Apply evenly on a clean build plate before printing. | $4.99 |  |

| Liquid Glue | Liquid adhesive for all Bambu build plates. Supports PLA, ABS, and PETG; maintains consistent adhesion, reduces warping, and improves release. | $20.99 |  |

| Group: Maintenance and Lubrication | |||

| Essential Consumables Kit - XP Series | Maintenance kit with lubricant oil, lubricant grease, activated carbon air filter, PTFE tubes, replacement filament cutter, and a hotend silicone sock. | $43.99 |  |

| Essential Consumables Kit - AMS | AMS maintenance kit with AMS feeding funnel, driven support shaft assembly, active support shaft assembly, and desiccant. | $19.99 |  |

| Accessory Box for X1C and P1S | Accessory kit for X1C and P1S with an unclogging pin, scraper blade, and XP Series screw kits for extruder and hotend service. | $24.99 |  |

| Accessory Box for P1P | Accessory kit for P1P with nozzle cleaning tools, precision screw sets, and filament system parts for routine upkeep. | $24.99 |  |

| Lubricant Grease | Grease for lead screws, belts, and idler pulleys to reduce noise, friction, and wear. | $4.99 |  |

| Lubricant Oil | Oil for linear guides, slide rails, steel shafts, and lead screws. | $7.99 |  |

The Bambu Lab P1S has proven reliable across 100,000+ print hours, maintaining consistent quality even after 4,000 hours. Carbon rods have shown no failures.

Common issues include bed adhesion problems (mostly user error), missed collision stops, and startup Z-offset errors from nozzle residue.

Monthly:

Quarterly:

Usage-Based:

Weekly / Before Each Print:

As Needed:

The Bambu Lab P1S includes a manufacturer warranty covering defects and hardware failures during normal use:

3-month limited warranty applies to select parts, including:

Consumables are not covered, including:

Full warranty details: https://bambulab.com/en/policies/warranty

Support System:

Ongoing Support:

The Bambu Lab P1S is available at $499.00, offering strong value with its enclosed design, fast CoreXY system, and robust features. Key highlights include 15-minute setup, automatic bed leveling, a built-in camera for monitoring and timelapses, and AMS compatibility for multi-color printing.

The P1S Combo version — about 35% more — includes the AMS, allowing automatic switching between four filaments. An AMS 2 Pro option further improves filament handling while maintaining the same print speed (500 mm/s) and acceleration (20,000 mm/s²).

All P1S models deliver the same print quality and reliability; price differences reflect added multi-material hardware.

Update your browser to view this website correctly. Update my browser now