The Construction-3D MaxiPrinter is a giant industrial 3D printer equipped with a concrete extrusion system for automated, eco-friendly, and time-efficient on-site construction. The machine has been developed by the young French company Construction-3D with durability, practicality, and ease of use in mind.

The MaxiPrinter is a turnkey solution. Apart from the printer itself, the manufacturer offers the dedicated software developed specifically for the MaxiPrinter and a training course, so that the customers could start construction as soon as they get the machine. To provide convenient transportation and prevent the risk of equipment damage, the MaxiPrinter is supplied in a 20-foot container with a marine certificate, which protects the machine from harsh weather conditions and can be also used for storage. Once on site, the MaxiPrinter can be deployed and installed in as little as two hours by just two people.

The MaxiPrint is built on the base of a hydraulic lifting crane and is equipped with a 7-meter telescopic 4-axis robotic arm with a screwed replaceable nozzle.

The printer comes stock with a pumping system and a material silo with a capacity of 1.2 m³.

The extrusion system of the MaxiPrinter is equipped with interchangeable nozzles of variable diameters ranging from 20 to 50 mm. The minimum layer thickness of 5 mm is fairly enough for any construction task. Depending on the required precision, the printing speed can vary from 20 to 300 mm, providing a significant gain in overall building speed compared to conventional methods. Another advantage of concrete 3D printing is the ability to create sophisticated shapes of any complexity that would otherwise be impossible to build.

Here is the first 3D printed house in France built in 2019 with the MaxiPrinter — the Pavillon.

The MaxiPrinter uses concrete mortar to build houses. Construction-3D team of engineers is working on development of new materials that are recyclable, environmentally friendly, and optimized for 3D printing.

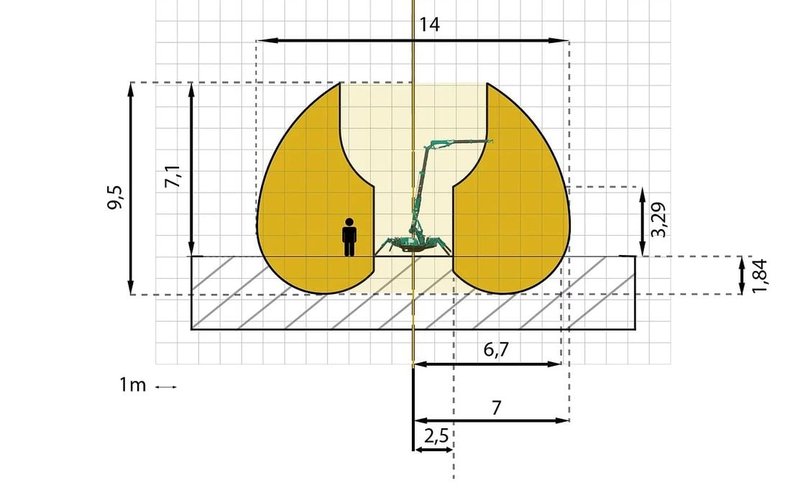

The build area of the MaxiPrinter differs from what we are used to on cartesian or delta 3D printers. It consists of two non-adjacent segments limited by the reach of the printer’s arm.

Credit: fabbaloo.com

The largest printable square is 9.5 x 9.5 m with a height of 3.3 m. The maximum printing height can reach 7.5 m. Due to its mobility, the machine can be easily relocated to extend the build area and continue printing.

The printer comes with a control system for convenient operation. Construction-3D has developed dedicated software allowing it to configure STL files and prepare 3D models for printing.

To provide users with a comprehensive concrete 3D printing solution, the company offers special training for operators and after-sales customer support.

Construction-3D MaxiPrinter

Automated pumping system with silo kit

Remote control screen

Loading ramps

20-foot container for transportation

Dedicated software

For some items, package content may change. In case of any questions, please get in touch.

The Construction-3D MaxiPrinter is available in a turquoise-and-black color scheme. Its industrial foldable design and durability make it ideal for on-site construction.

The folded machine dimensions are 118.1 x 33.5 x 78.7 in (3000 x 850 x 2000 mm). It weighs approximately 5511.6 lb (2500 kg).

To learn the current price of the Construction-3D MaxiPrinter, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now