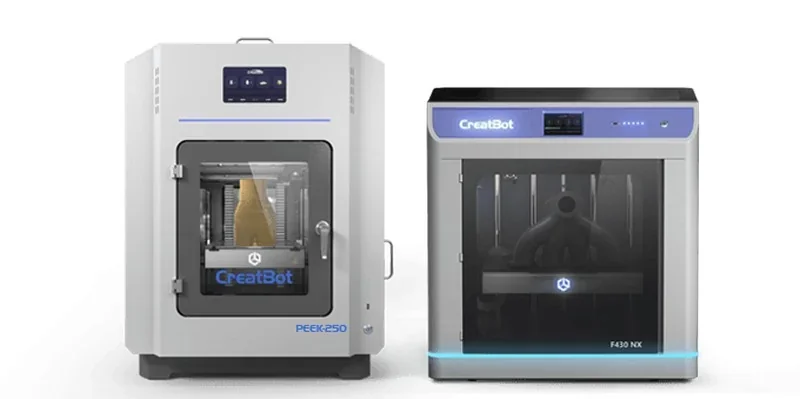

The CreatBot PEEK-250 is an industrial FDM printer built for high-performance polymers such as PEEK, PEI (ULTEM), and other engineering thermoplastics, offering a 250 × 250 × 300 mm build volume with precision down to 50 µm. As the first desktop model with a 200 °C chamber, it reaches 180 °C in just 20 minutes while keeping exterior surfaces below 40 °C, and its integrated annealing function minimizes warping by enabling printing and annealing in one device. A 480 °C water-cooled extruder with a silicon carbide nozzle, paired with an aviation-grade 200 °C heated platform that requires no manual leveling, ensures consistent extrusion and dimensional stability at extreme temperatures.

Designed for demanding applications in medical, aerospace, automotive, and defense sectors, the PEEK-250 delivers the strength, heat resistance, and chemical stability needed for organizations transitioning from traditional to additive manufacturing.

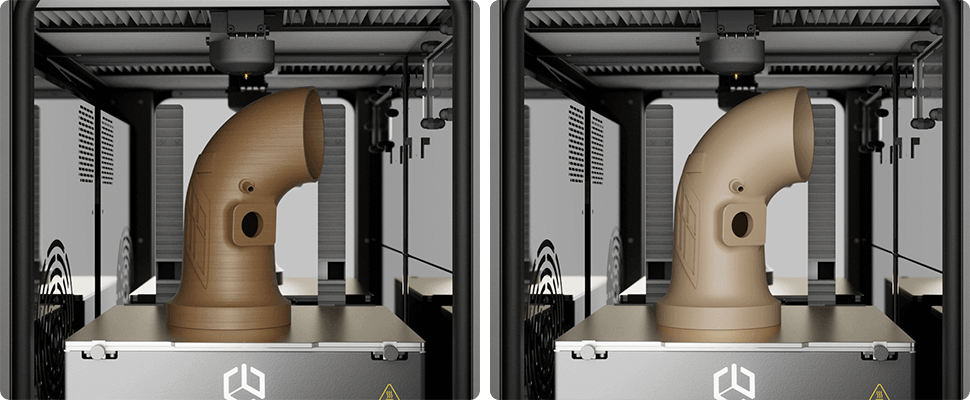

The CreatBot PEEK-250 achieves 50 µm layer heights with XY accuracy of 0.0127 mm and Z accuracy of 0.00125 mm, producing smooth surfaces and fine details with strong dimensional stability. Its combination of high-temperature capability and precise motion control minimizes warping and adhesion issues common with advanced filaments like PEEK and PEI. For example, a 3DBenchy printed in PEEK showed no warping and strong interlayer fusion, with an even first layer, clean chimney bore, and minimal stringing — only slight faint Z-seam, all tunable via slicer settings.

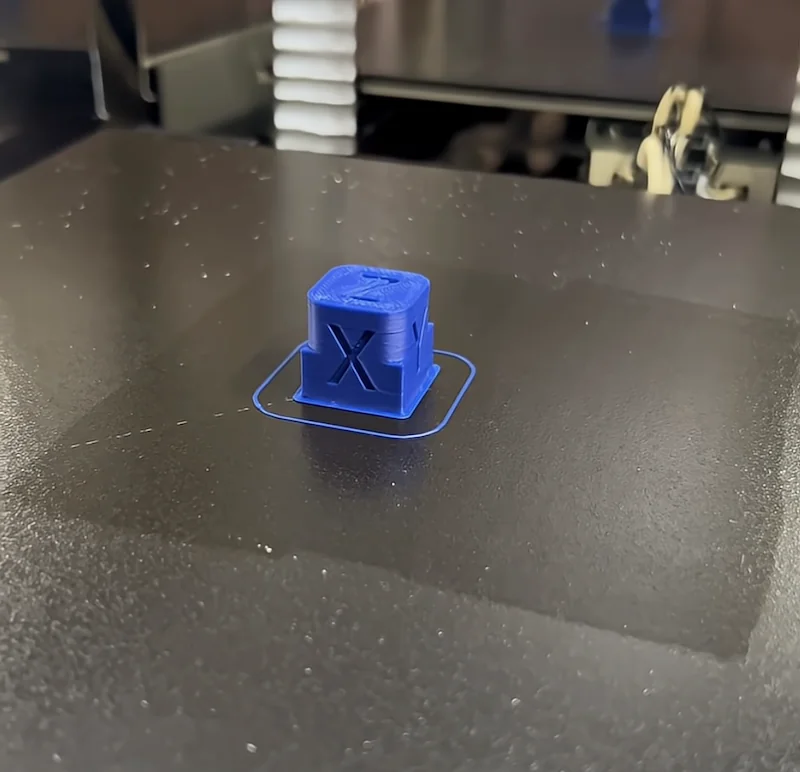

ABS XYZ Calibration Test Cube:

PEEK XYZ Calibration Test Cube:

The CreatBot PEEK-250 prints optimally at 55 mm/s, with speeds up to 200 mm/s supported by its Cartesian motion system running on precision linear rails.

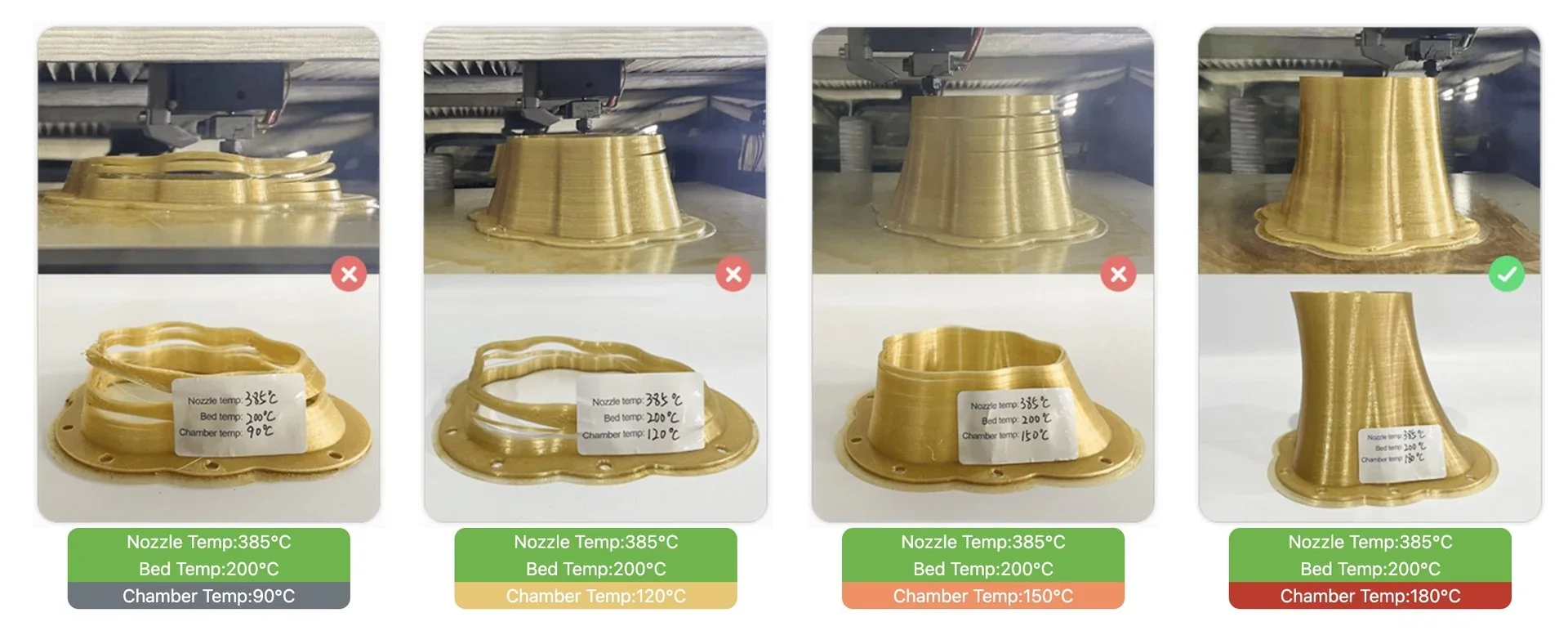

Thermal management includes a 480 °C nozzle, 200 °C platform, and 200 °C chamber that heats to 180 °C in just 20 minutes, providing the controlled environment needed for crystallization and bonding of high-performance filaments.

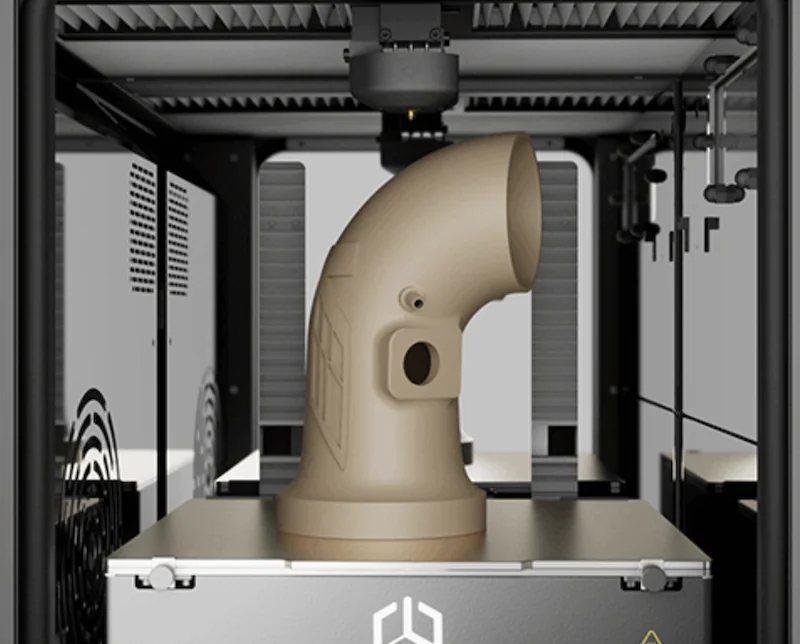

Example: Architectural models printed with PEEK

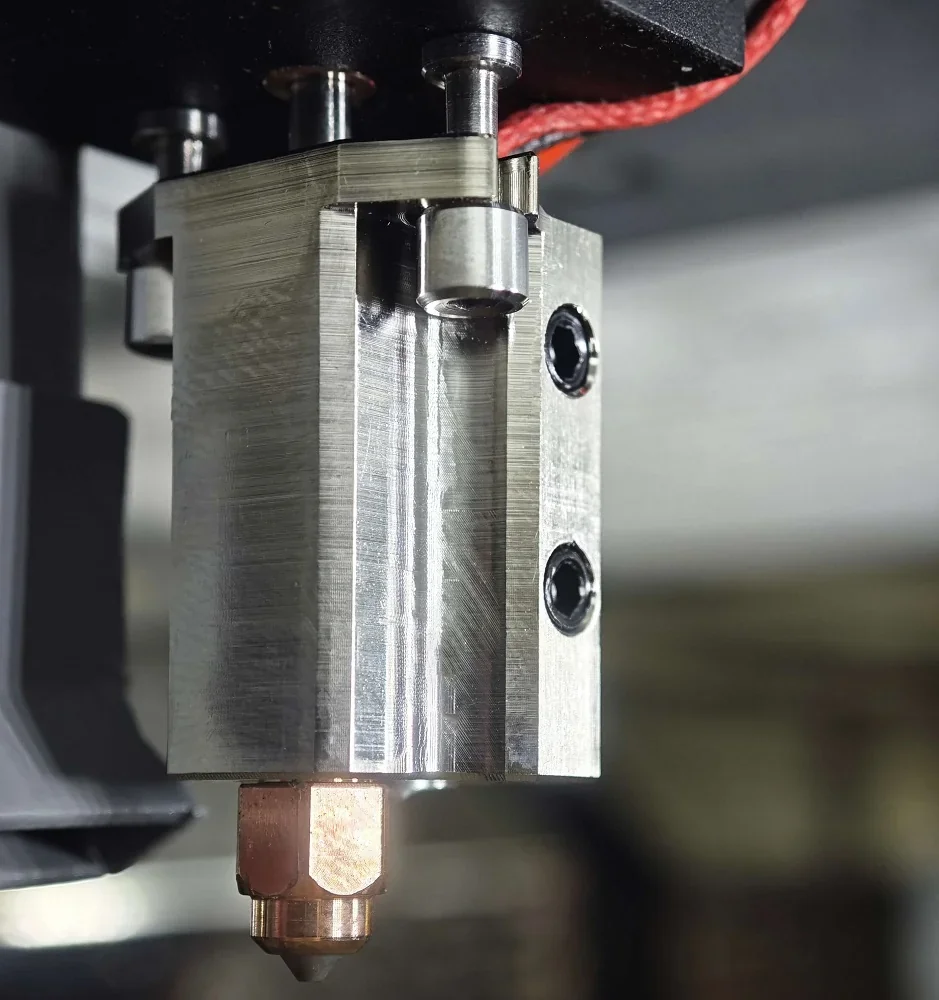

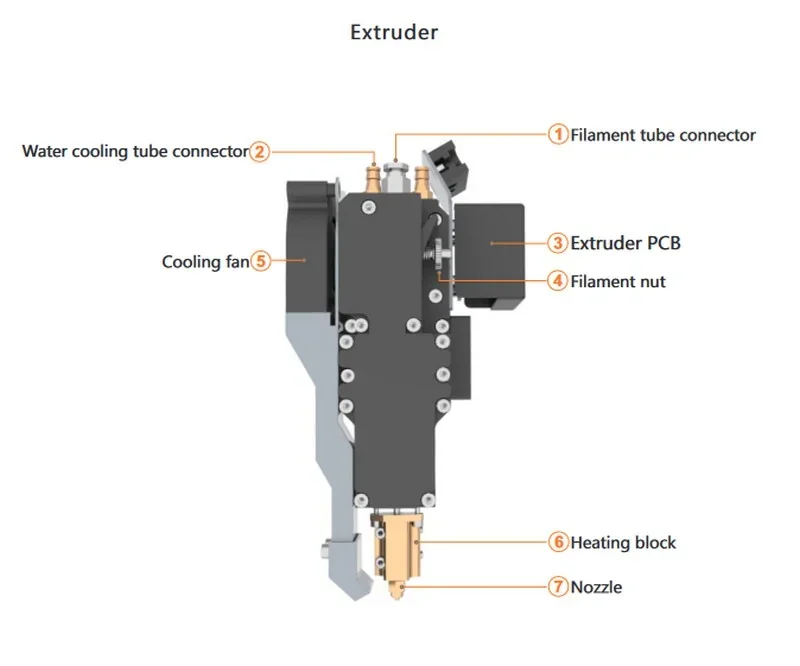

The CreatBot PEEK-250’s design enhances print quality with a double-tooth silicon carbide extruder for high torque and wear resistance, ideal for abrasive composites.

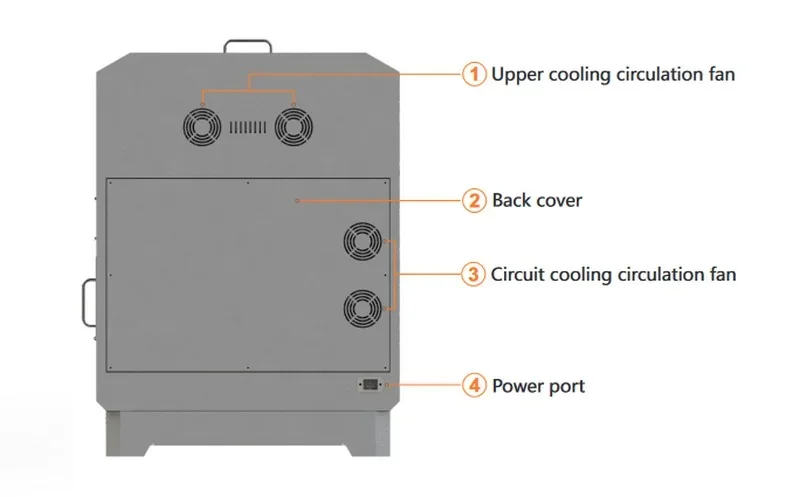

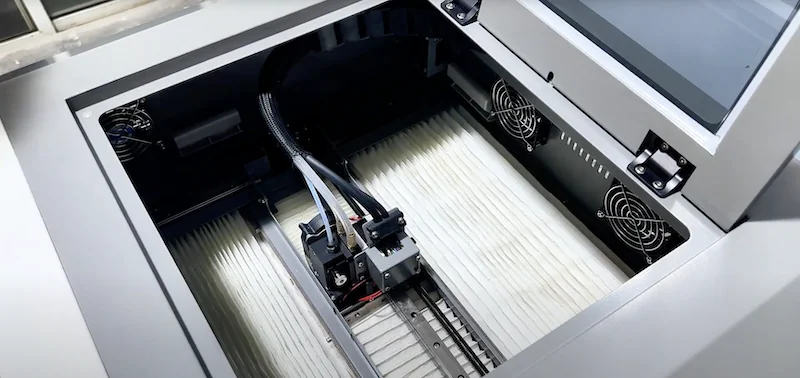

An integrated water cooling system ensures stable extrusion at extreme temperatures, while a spoiler device circulates hot air 360° for uniform chamber heating.

This consistent temperature supports proper crystallization and uniform mechanical properties in printed parts.

Test PEEK samples

The CreatBot PEEK-250 employs an aviation-grade three-layer thermal insulation system with optimized heat dissipation (managed by active air cooling) and high-temperature resistant components, keeping all external surfaces below 40 °C even when the chamber reaches 180 °C to ensure user safety.

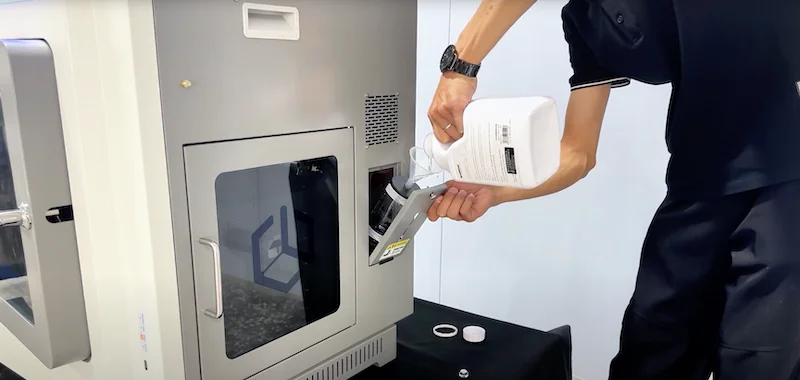

Its one-stop annealing function allows PEEK and PEI parts to be annealed directly in the printer without any time delay, avoiding transfer-related warping and ensuring optimized mechanical properties and dimensional stability for end-use applications.

The CreatBot PEEK-250 is a high-performance 3D printer supporting over 18 filament types, from standard engineering plastics to ultra-performance polymers such as PEEK, PEI (ULTEM™), PEKK, and their carbon- and glass-fiber reinforced variants. The printer accepts standard 1.75 mm filaments, supports third-party materials, and includes a one-stop annealing function to enhance part strength and stability without post-processing transfers.

PEEK 3D Print Sample: A hexagonal nut

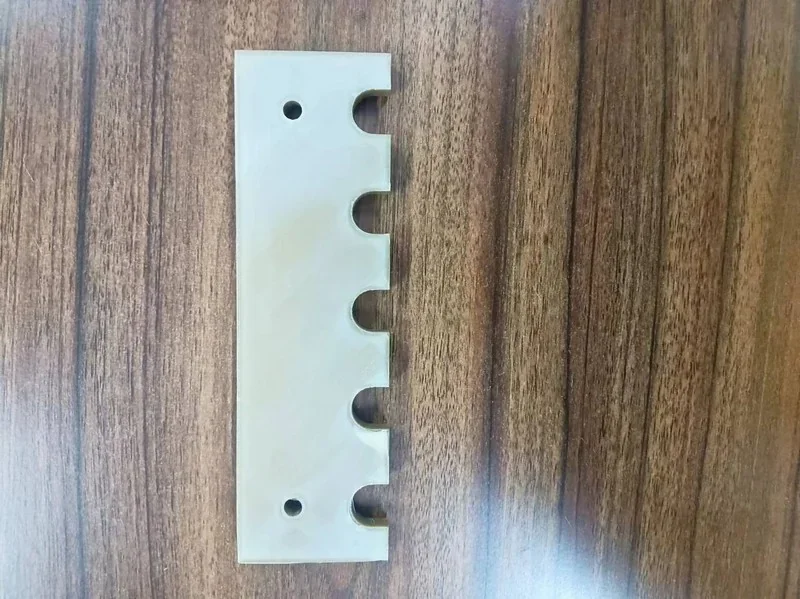

PEEK 3D Print Sample: Alignment plate

PEEK-CF (PEEK w/ Carbon Fiber) 3D Print Sample: Holder

PEEK 3D Print Sample: Grip

PEEK 3D Print Sample: Implant

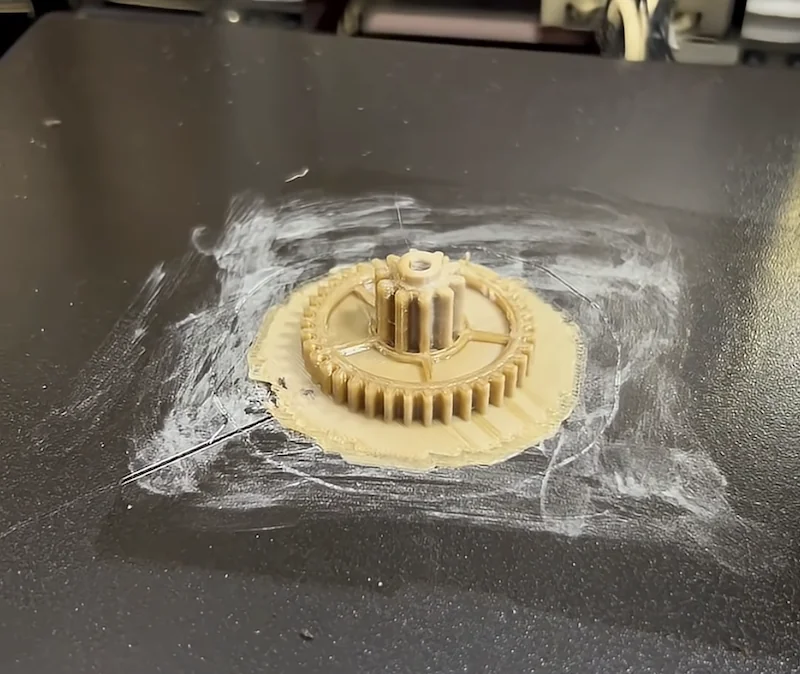

CF-PEEK 3D Print Sample: Sprocket

PEEK 3D Print Sample:

The CreatBot PEEK-250 offers a 250 × 250 × 300 mm (9.8 × 9.8 × 11.8 in) build volume.

CreatBot PEEK-250 is the first desktop PEEK 3D printer capable of printing with ULTEM. Main advantages over its competitors: a 200 °C active chamber with in-process direct annealing (no post-anneal step), 480 °C nozzle, 200 °C bed, and a water-cooled direct-drive extruder over a 250×250×300 mm volume at $11,999+ — aimed at strong crystallinity and dimensional stability without extra heat-treat cycles.

In contrast:

| Feature | CreatBot PEEK-250 | Intamsys Funmat HT | CreatBot PEEK-300 | 3D Labs HTX | Intamsys Funmat Pro 410 | Mosaic Element |

|---|---|---|---|---|---|---|

| Build Volume (mm) | 250 × 250 × 300 | 260 × 260 × 260 | 300 × 300 × 400 | 370 × 300 × 300 | 305 × 305 × 406 | 355 × 355 × 355 |

| Chamber Temp (°C) | 200 | 90 | 120 | 100 | 90 | 80 |

| Direct Annealing | Yes | No | Yes | No | No | No |

| Nozzle Temp (°C) | 480 | 450 | 480 | 500 | 500 | 500 |

| Bed Temp (°C) | 200 | 160 | 200 | 220 | 160 | 120 |

| Extruder | Single Direct Drive, Water Cooled | Single Direct Drive | Dual Direct Drive, Water-Cooled | Dual Direct Drive | Dual Direct-Drive, Water-Cooled | Single Direct Drive |

| Price | $11,999+ | $7,000+ | $15,000+ | $15,500+ | $28,000+ | $10,000+ |

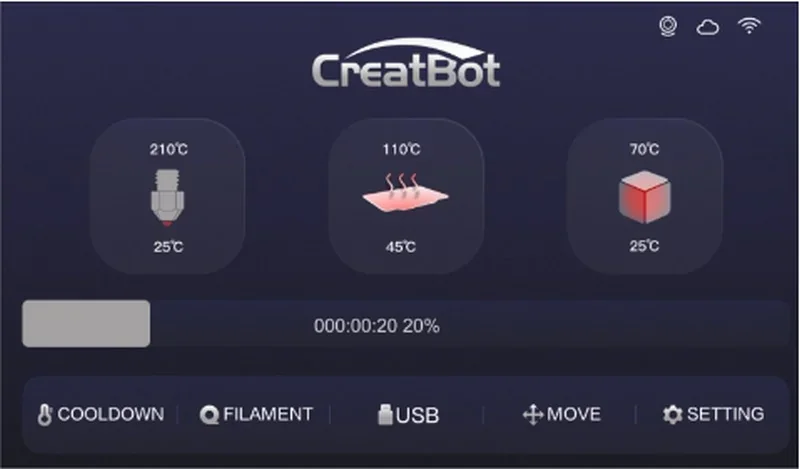

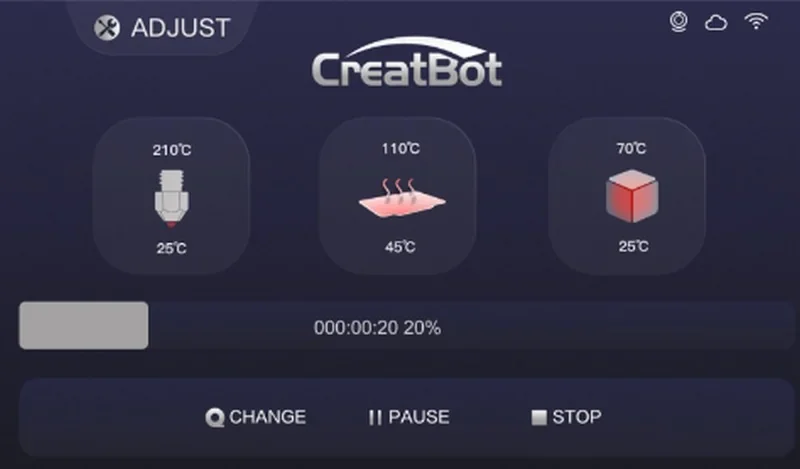

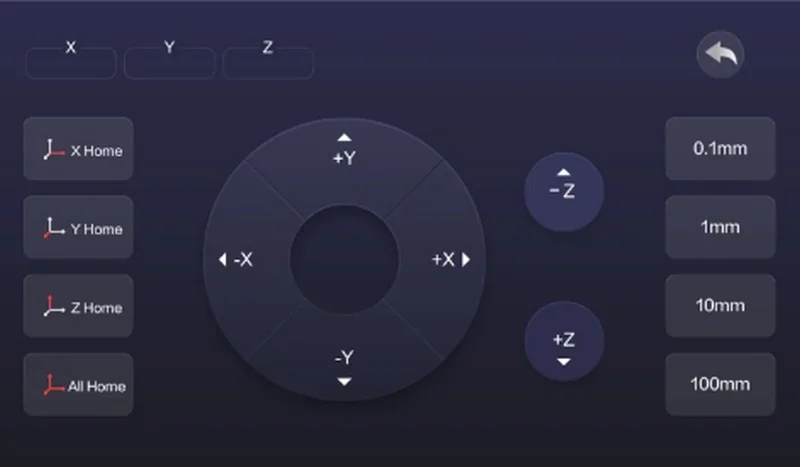

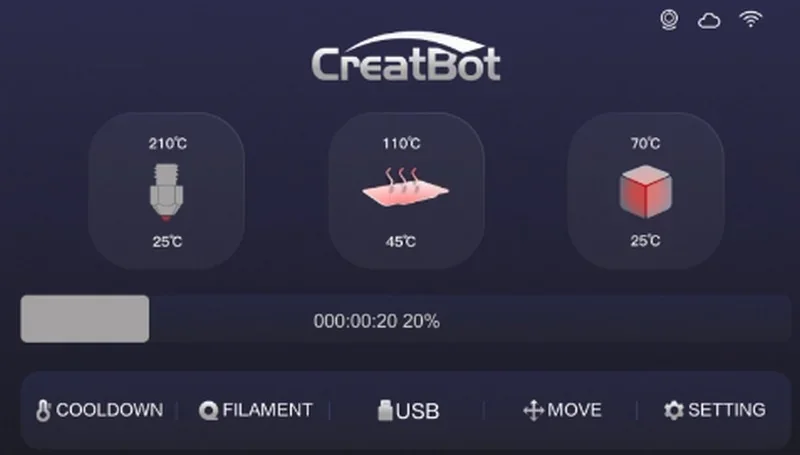

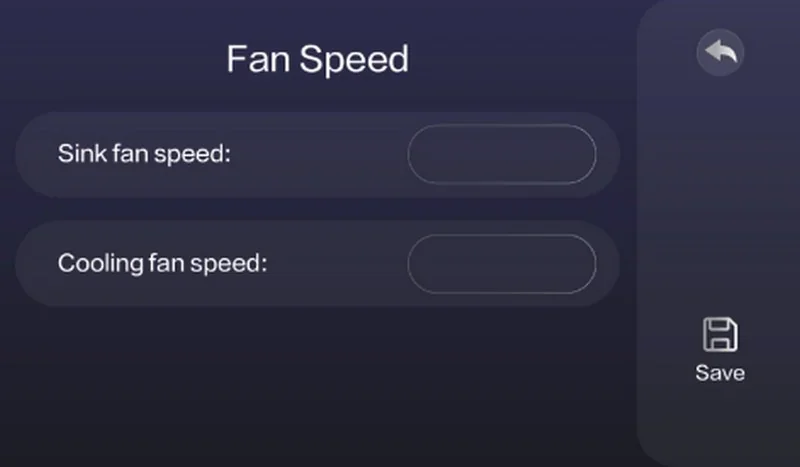

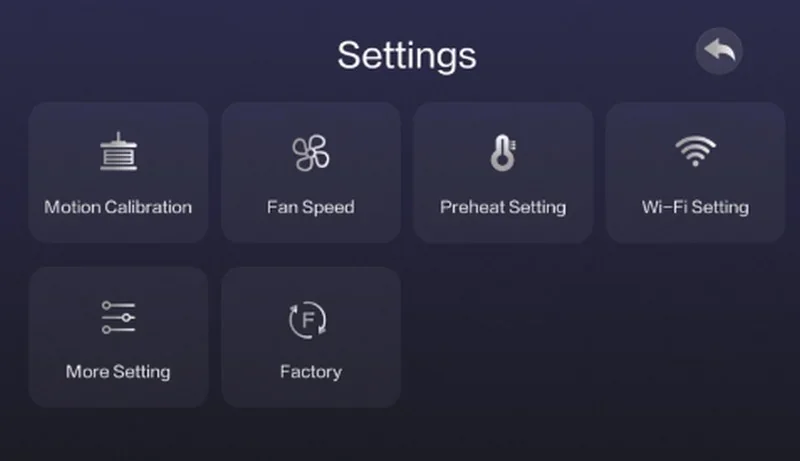

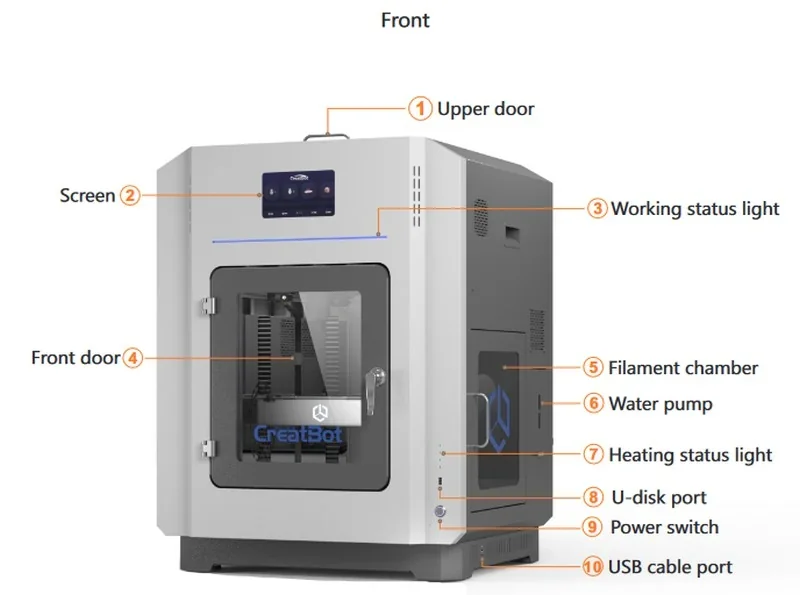

The CreatBot PEEK-250 has a 7-inch touchscreen for full printer control. It supports multiple languages and lets users monitor and adjust nozzle (up to 480°C), platform (up to 200°C), and chamber (up to 200°C) temperatures in real time.

Physical Controls (3 categories):

Touchscreen Controls (categories):

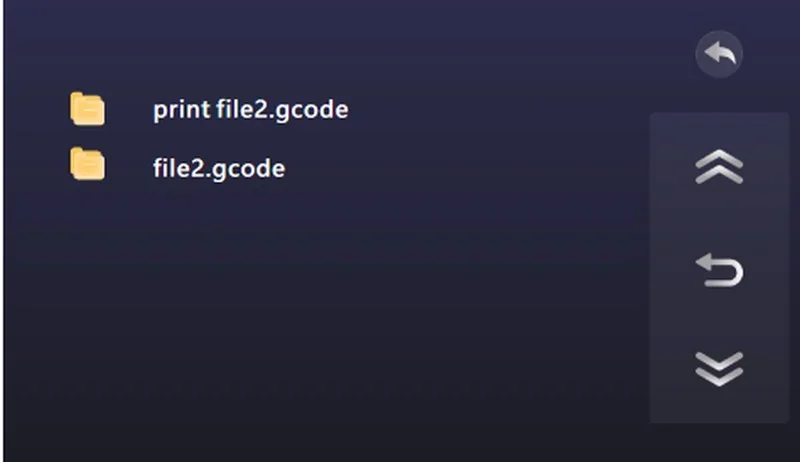

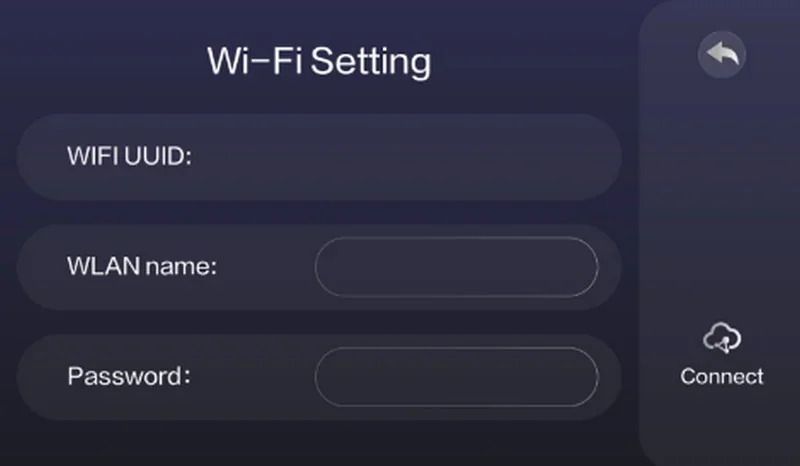

The CreatBot PEEK-250 offers both USB and 2.4 GHz WiFi connectivity, allowing it to operate as a standalone or networked device in professional manufacturing and R&D environments. Print files can be transferred directly via USB without a connected workstation, while WiFi setup is managed through the touchscreen interface.

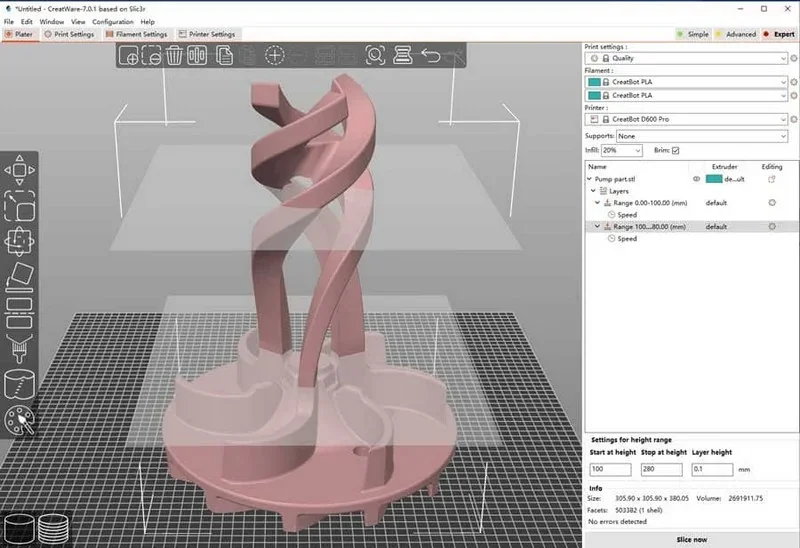

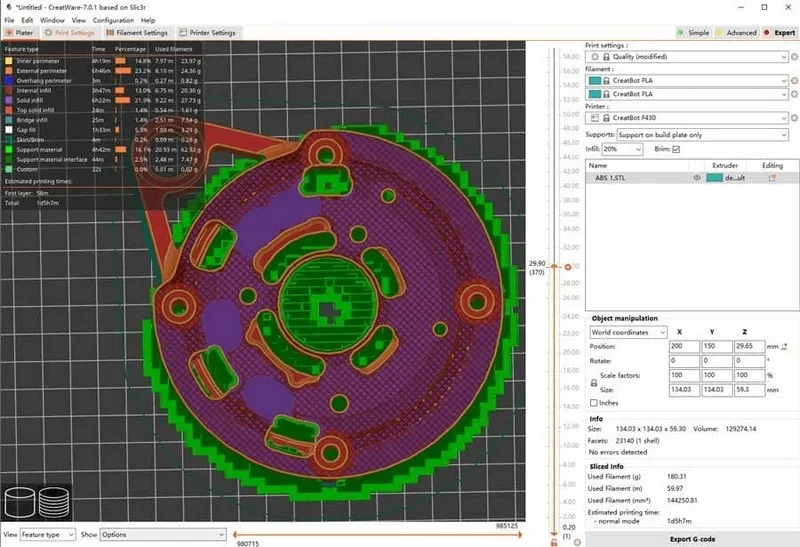

The CreatBot PEEK-250 includes CreatWare, a proprietary multilingual slicer optimized for high-temperature printing on Windows and macOS, while also supporting third-party slicers such as Simplify3D, Cura, and Slic3r with full compatibility for STL, OBJ, AMF, and G-code files. Designed for industrial reliability, CreatWare offers specialized temperature profiles and filament-specific settings for consistent results with advanced polymers, and it integrates directly with the printer’s 7-inch touchscreen, enabling seamless transfer and execution of print jobs via USB or storage device.

The CreatBot PEEK-250 is a desktop 3D printer, featuring a fully enclosed, office-compatible design built from aviation-grade materials for thermal insulation and safety.

The CreatBot PEEK-250 uses an aluminum base with a polymer-coated platform.

The CreatBot PEEK-250 uses a 480 °C direct-drive extruder with a silicon carbide hotend for high torque and wear resistance. Its die-casting wear-resistant nozzle can be replaced in 30 seconds without screws.

The motion system uses high temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing.

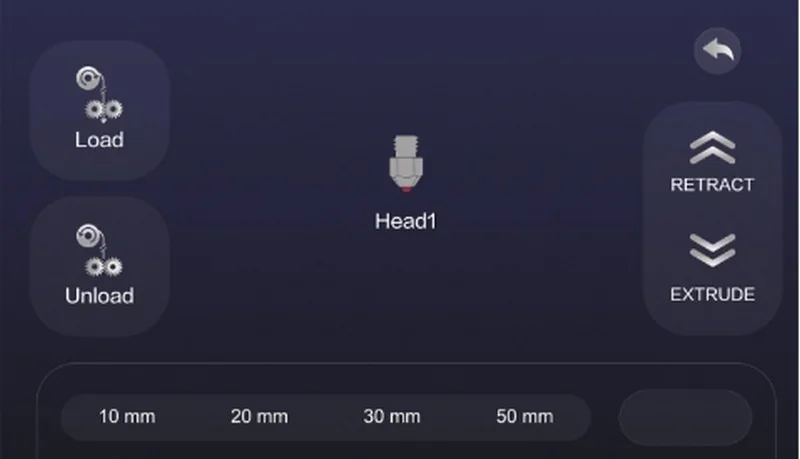

The CreatBot PEEK-250 includes a dedicated filament chamber with a run-out sensor for material monitoring. Filament is fed by the direct-drive extruder, with loading and unloading handled through a tube connector and nut as outlined in the manual.

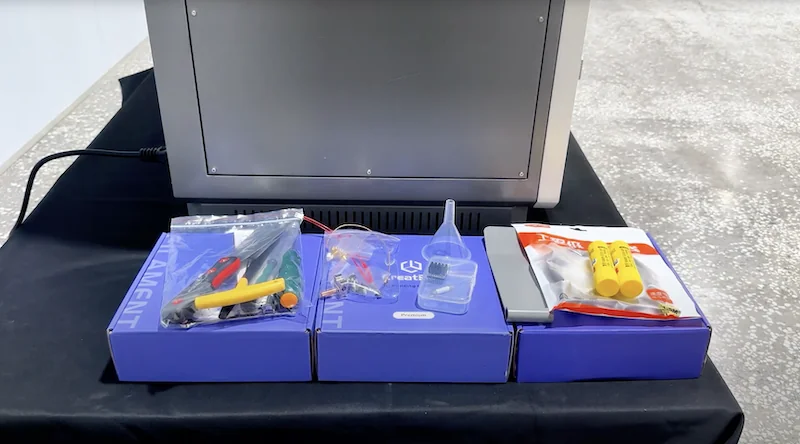

The CreatBot PEEK-250 ships fully assembled and ready to use, supplied with high-temperature nozzles for advanced polymers like PEEK and PEI, the CreatWare slicing software, a detailed user manual, and a complete tool set for routine maintenance.

Please note: Package contents are determined by the manufacturer and may change without notice. To confirm the current inclusions, contact a Top3DShop sales representative before placing your order.

Creatbot offers 6 accessories and replacement parts.

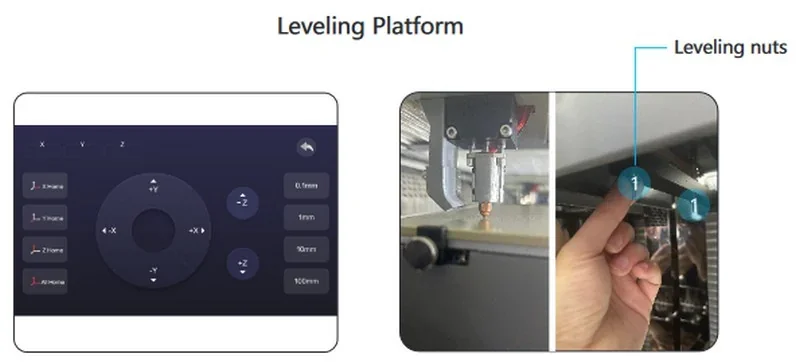

The PEEK-250 requires regular bed leveling, lubrication of rails, nozzle cleaning, belt inspection, and careful filament handling. Its water-cooled extruder and circulation fans should also be checked to maintain stable high-temp performance.

Regular Maintenance

Mechanical Maintenance

Extruder & Nozzle

Electrical & Cooling

Storage

The CreatBot PEEK-250 is backed by a 12-month manufacturer’s warranty covering conformance to published specifications, with free replacement parts and repair guidance provided during the period (excluding normal wear items). Nozzles and hot-end assemblies carry a separate 6-month warranty due to expected wear from high-temperature and abrasive filaments. Coverage applies to manufacturing defects and excludes damage from unauthorized modifications, uncertified materials, improper handling, or environmental factors.

Manufacturer support from Henan Creatbot Technology Limited is also available through support@creatbot.com, typically responding within 24 hours. Free lifetime online support, including manuals and maintenance documentation, is accessible through the support portal: https://www.creatbot.com/support/

Full warranty terms: https://www.creatbot.com/en/warranty.html

The CreatBot PEEK-250 high performance 3D printer is priced at $10,787.07, delivering professional-grade performance for ultra-high-temperature polymers like PEEK and PEI with its 480 °C nozzle and 200 °C chamber. Key features include a water-cooled extruder, one-click annealing, and aviation-grade insulation that keeps exterior surfaces under 40 °C even when the chamber reaches 180 °C. For bulk orders or custom configurations, contact the Top3DShop team for a personalized quote.

Update your browser to view this website correctly. Update my browser now