The Delta WASP 2040 Clay is a compact delta-style 3D printer designed for ceramic materials like clay, porcelain, and earthenware, using Liquid Deposition Modeling (LDM) for precise prints up to Ø200 mm x h400 mm at 50-micron resolution. Its LDM WASP Extruder 3.0 combines a pressurized tank and screw system for steady extrusion, while features like Resurrection and Free Z-Systems allow print recovery after power loss. With an open frame for easy access and an aluminum-steel build for stability at speeds up to 150 mm/s, it suits artists, schools, and small manufacturers creating sculptures, vases, and prototypes. Recognized by 3D Hubs and used by institutions like NASA, King’s College London, Eindhoven University of Technology, The Bartlett School of Architecture, Aalto University, Istituto Marangoni, Goldsmiths, and Emily Carr University, it offers professional ceramic 3D printing in an accessible format.

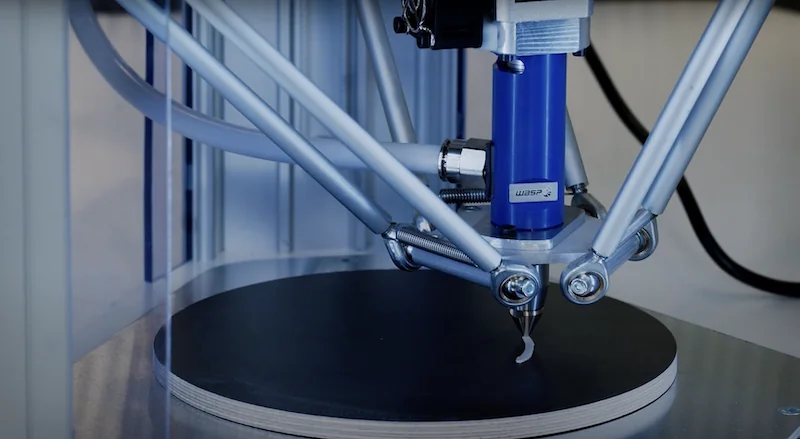

The Delta WASP 2040 Clay produces smooth, precise ceramic prints with 50-micron layers. Its all-metal frame and reinforced movement system—nylon wheels on aluminum slides—minimize vibration and maintain dimensional accuracy.

The Delta WASP 2040 Clay prints at up to 150 mm/s, supported by WASP’s suspended Bowden system that reduces inertia for stable, high-speed output. Auto-leveling removes the need for manual calibration, and two interchangeable LDM extruders (1.2 mm and 2 mm) with pressure chambers ensure optimized ceramic flow.

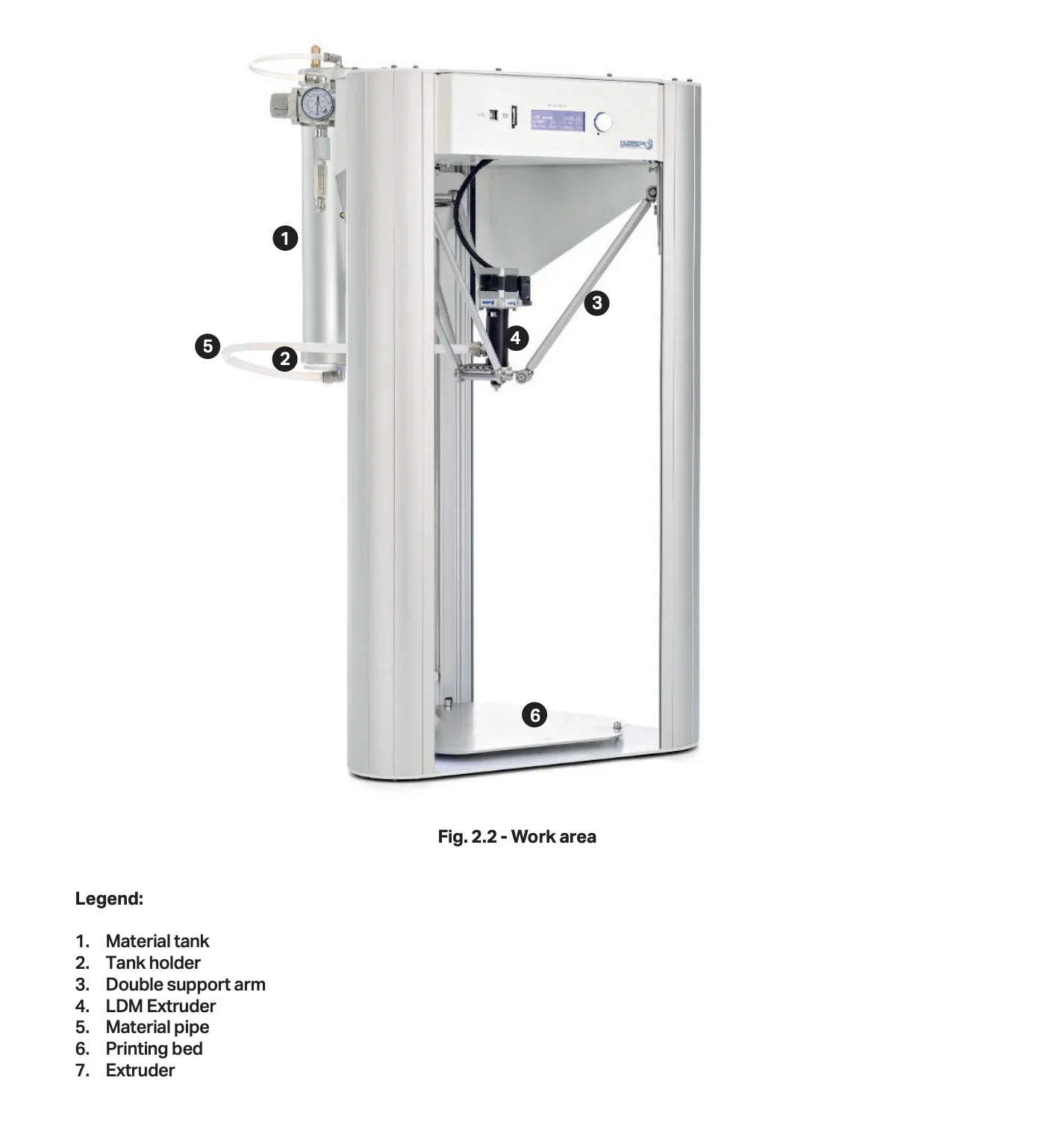

The Delta WASP 2040 Clay uses an air pressure system to remove bubbles, ensuring smooth flow and preventing clogs when printing dense ceramics. Its open-frame design gives easy access to the print area for monitoring and interacting with prints.

The Delta WASP 2040 Clay produces detailed ceramic prints with smooth finishes and supports objects up to 200 mm wide and 400 mm tall. Its Resurrection and Free Zed Systems allow recovery of interrupted prints, crucial for ceramics that require steady drying conditions.

The Delta WASP 2040 Clay supports clay, porcelain, gres, and earthenware through its LDM technology. It includes 10 kg of porcelain for immediate use, with WASP certifying its LDM extruders for these ceramic materials.

For best results, WASP recommends mixing 95% porcelain with 5% water, creating the right consistency for the 1.2 mm and 2 mm nozzles. Water content can be adjusted based on extruder, nozzle size, and environmental conditions to ensure optimal flow.

The Delta WASP 2040 Clay comes with two interchangeable LDM extruders for dense materials. Using pressure chambers and an air compressor (minimum 8 bar), they remove bubbles, prevent clogs, and ensure smooth, consistent extrusion.

The Delta WASP 2040 Clay’s heated, multi-layer wooden print bed provides an ideal surface for ceramics, while its integrated air pipe system helps maintain proper material consistency during clay 3D printing.

The Delta WASP 2040 Clay offers a cylindrical build volume of Ø200 mm x 400 mm within a compact frame (490 x 440 x 870 mm). Its tall capacity supports sizable vases, sculptures, and models while keeping the printer’s footprint small.

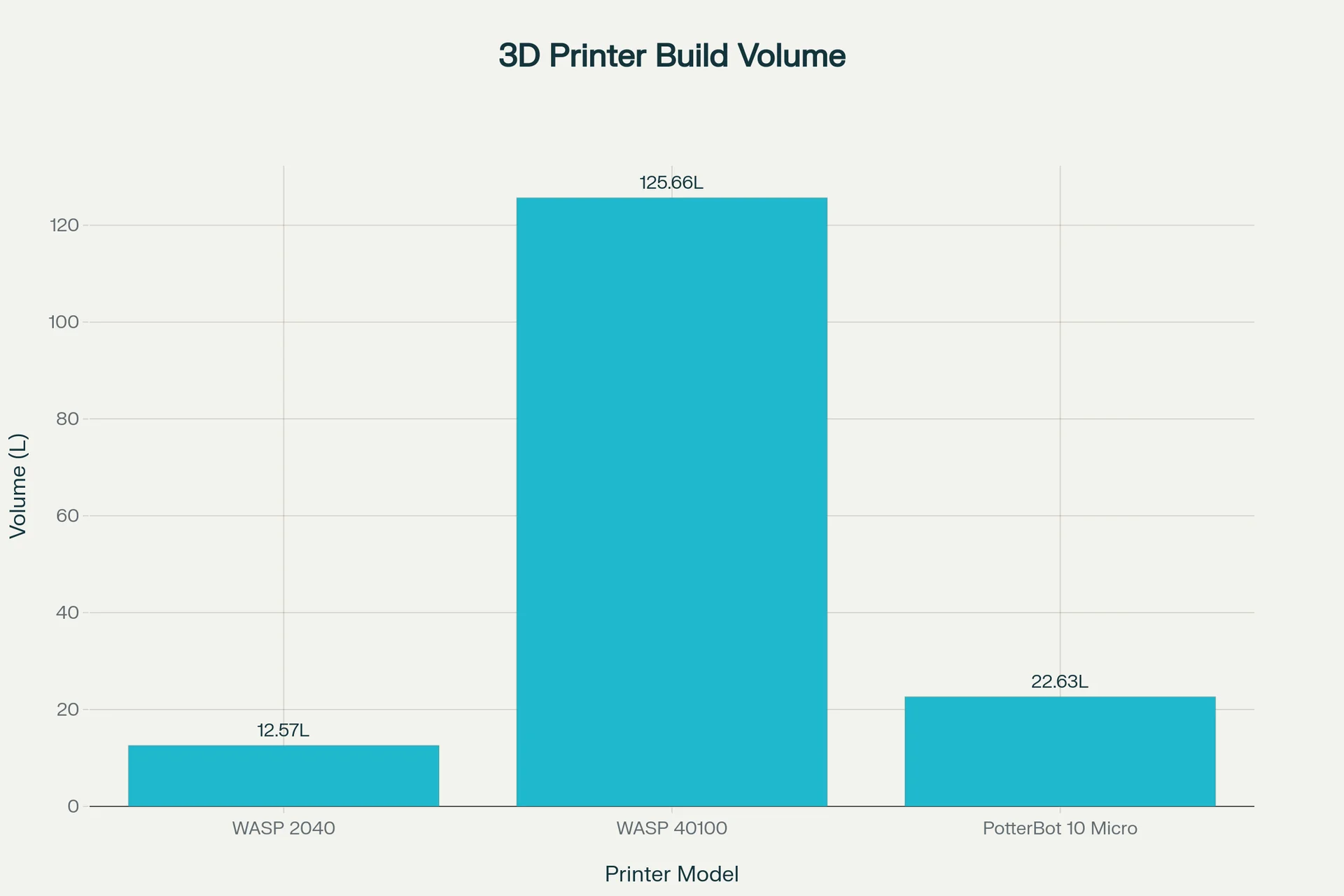

Compared to other ceramic 3D printers, the Delta WASP 2040 Clay offers a strong balance of size and capability as an entry-level professional option. The 3D PotterBot 10 Micro provides more width but less height, while WASP’s larger Delta WASP 40100 Clay expands capacity to Ø400 mm x 1000 mm.

|

3D Printer Model |

Build Volume |

Price (USD) |

|

Delta WASP 2040 Clay |

Ø200 mm x 400 mm |

$5,000+ |

|

Delta WASP 40100 Clay |

Ø400 mm x 1000 mm |

$11,000+ |

|

3D PotterBot 10 Micro |

280 mm x 265 mm x 305 mm |

$3,500+ |

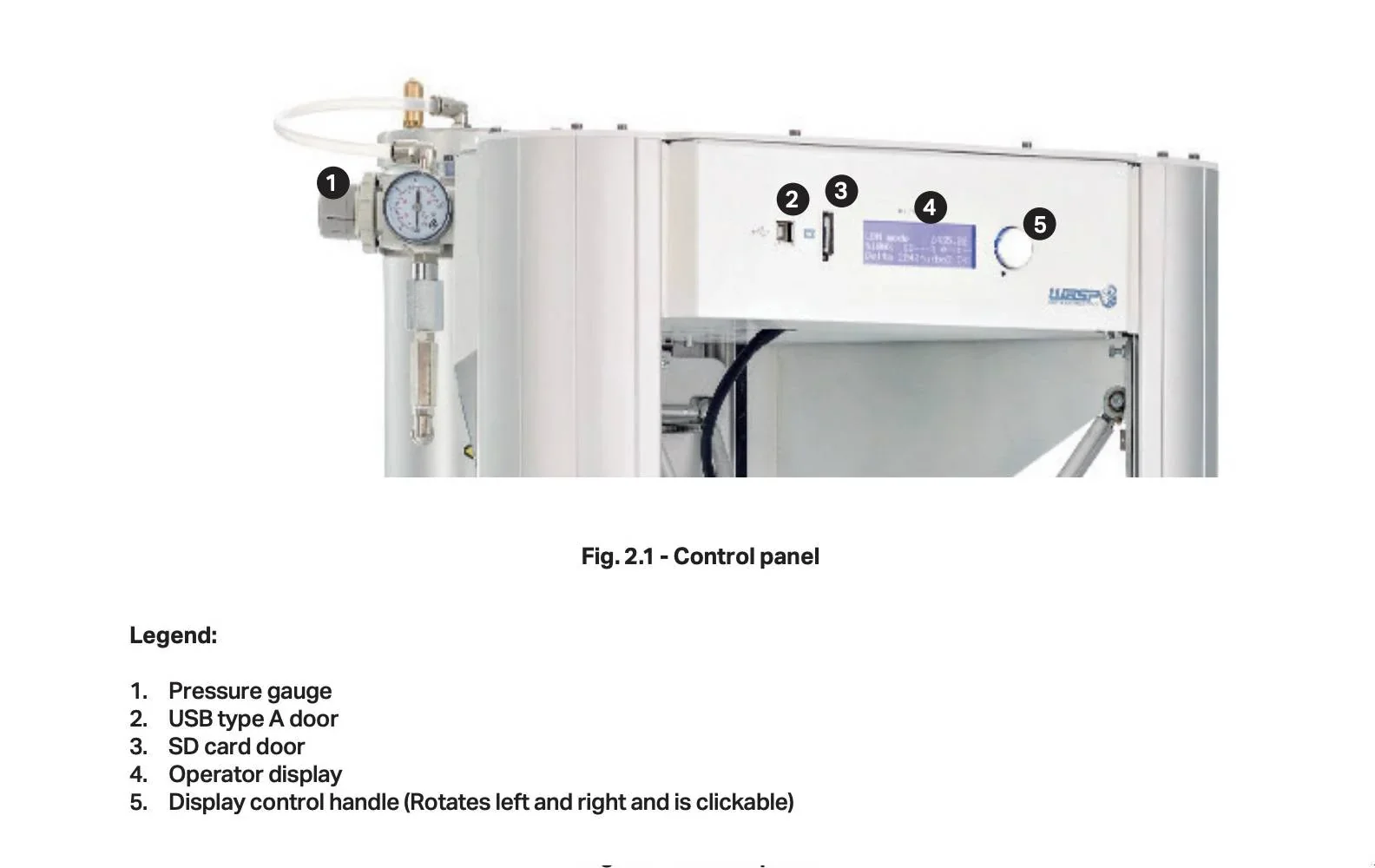

The Delta WASP 2040 Clay features a touchscreen with rotary handle navigation offering 24 controls including manual axis zeroing, nozzle height adjustment, bed leveling, real-time speed and flow tuning, material changes mid-print, print pausing, stopping with save/resume, and direct SD card file access.

When idle, the Delta WASP 3MT Industrial 4.0 provides several menu options. The Prepare menu handles printer management tasks such as axis zeroing, manual positioning, nozzle height adjustment, and bed leveling. The Advanced menu offers system settings including movement parameters, acceleration, Auto-Resurrection, language selection, and EPROM save/load. The SD Card menu allows direct file access and printing. Free Zeta lets users restart prints from a chosen height, while Resurrection recovers prints after power loss. The Info menu displays firmware details.

During the printing process, the Delta WASP 3MT Industrial 4.0 offers different controls. The Tune menu adjusts speed and flow in real time, while Pause temporarily suspends the print. Users can swap materials mid-print with Change Material, save progress with Stop & Save for later resumption, or end the job with Stop Print. All functions are managed through the touchscreen with rotary handle, supported by a physical ON/OFF switch and USB port for file loading.

The Delta WASP 2040 Clay supports two connectivity options: an SD card reader for direct G-code printing without a computer, and a USB Type A port for external storage or peripherals.

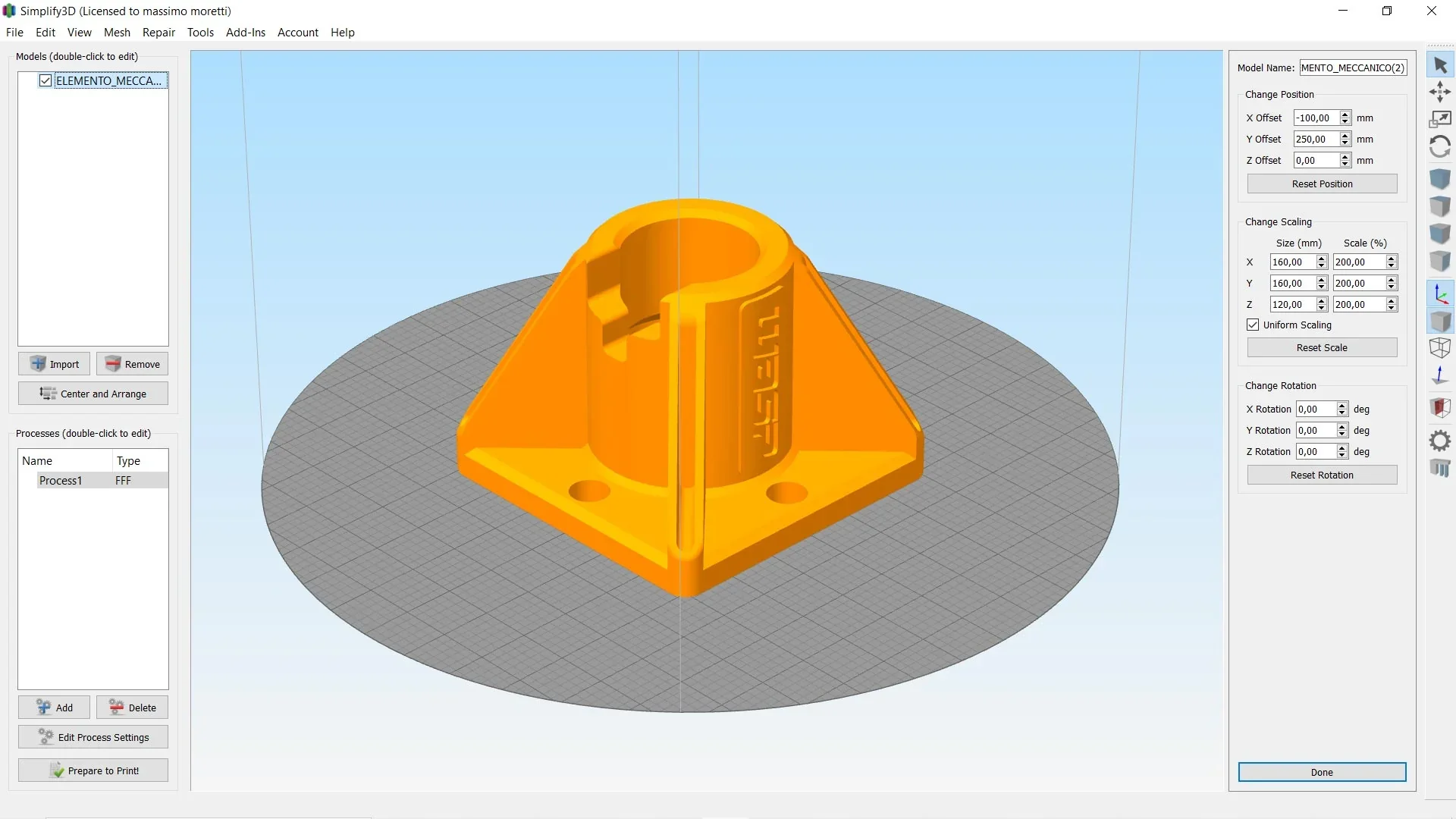

The Delta WASP 2040 Clay supports major slicing software like Cura, Slic3r, Simplify3D (officially recommended), and Repetier-Host for model preparation and slicing.

The Delta WASP 2040 Clay supports .STL, .OBJ, and .GCODE files across Windows, MacOS, and Linux, allowing users to choose their preferred design tools without software restrictions. Its 32-bit mainboard enables firmware updates via SD card, keeping the printer up to date with new features and improvements.

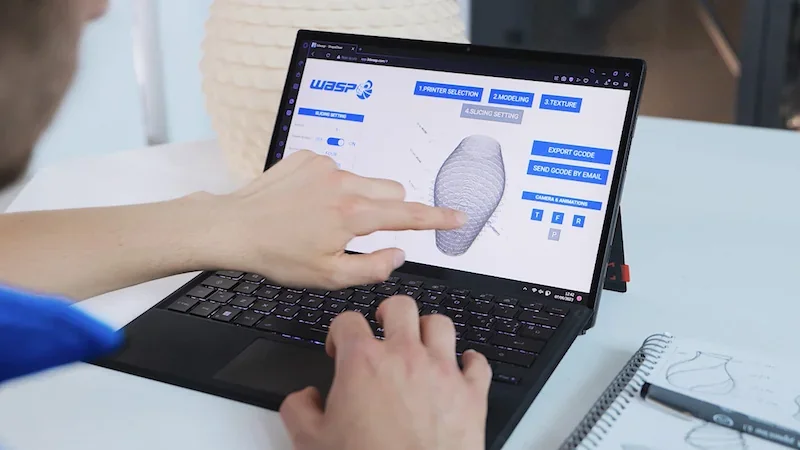

The WASP App lets users design custom objects by adjusting a range of parameters, including shape, size, texture, and slicing settings.

The Delta WASP 2040 Clay features a sturdy aluminum and steel delta-style frame measuring 490 x 440 x 870 mm and weighing 40 kg, designed for stable additive manufacturing at speeds up to 150 mm/s with minimal vibration.

The Delta WASP 2040 Clay’s open-frame design gives three-sided access for monitoring and adjusting prints. Ergonomic features include a bayonet-closure tank holder for secure material storage and a double support arm for extruder stability. Its detachable heated wooden bed, built for ceramics, lets users remove finished pieces without affecting calibration.

The Delta WASP 2040 Clay’s motion system is tailored for ceramic printing, using nylon wheels on aluminum slides for smooth, low-friction movement. Its suspended Bowden system reduces gantry inertia, maintaining print quality at higher speeds. The LDM extruder features a precision screw with adjustable zero play for steady flow, supported by an air pressure system that removes bubbles to protect print quality.

The Delta WASP 2040 Clay comes fully assembled with everything needed to start printing. Two LDM extruders offer different detail levels, while 10 kg of porcelain supports numerous first prints. An SD card provides optimized settings and sample files for immediate use. Operation requires an external air compressor with at least 8 bar pressure, which is not included.

Note: package contents are set by the manufacturer and may change without notice. Confirm the current inclusions with a Top3DShop sales representative before ordering.

The Delta WASP 2040 Clay supports 9 upgrades and accessories.

| Accessory | Function | MSRP (USD) |

|---|---|---|

| WASP CONTINUOUS FEEDING SYSTEM 220V / 110V – Including LDM Extruder XL 3.0 | Continuous-feed upgrade that reduces refills/interruptions on long clay prints and helps keep material delivery steady. | $10,300 |

| WASP Kit MINI LDM 3.0 – with LDM 3.0 Extruder and 0.5 lt Aluminum tank | Compact extrusion kit for small batches and quick swaps; useful for testing materials and short runs. | $2,225 |

| 3L Clay Tank complete with 2 lids and piston | Spare 3L tank to prep clay off-machine and swap tanks faster between prints. | $360 |

| STAINLESS STEEL Screw for LDM WASP Extruder 3.0 | Replacement screw/auger to restore consistent clay metering and stable extrusion flow. | $190 |

| KIT of nozzles for WASP LDM Extruder 3.0 (from 1.26mm to 3mm) | Nozzle set to tune bead width (detail vs speed) for the LDM Extruder 3.0. | $115 |

| TEFLON CONNECTING PIPE + accessories 2040 (Clay Kit) – PTFE 10x12x620 mm | Replacement PTFE line for the 2040 Clay kit to keep the material path reliable and leak-free. | $30 |

| LDM WASP Extruder 3.0 – MODU connector + nozzles kit | Connector + nozzle kit to simplify integration/service and speed up nozzle changes for the Extruder 3.0. | $430 |

| POM Screw for CONTINUOUS FEEDING SYSTEM | Replacement POM (acetal) screw to keep the continuous feeding mechanism operating smoothly. | $135 |

| RED TERRAGLIA material – ceramic mixture packs of 12.5 kg IRT | Consumable ceramic mix pack for replenishing print material. | $70 |

Daily / After Each Use

Weekly

Periodic

As Required

Safety Requirements

The Delta WASP 2040 Clay includes a 24-month warranty for private EU clients and 12 months for all other customer groups. It covers defects and component failures under normal use. WASP certifies the LDM extruders only for ceramic materials; use with other materials may void warranty and support.

Top 3D Shop offers custom training packages and consulting support for the WASP 3D printers, including setup help, troubleshooting, and performance guidance.

| Training Package | Description | Price |

| Basic Training Clay 3D Printing ONLINE RECORDED video training | Recorded onboarding training | $0 |

| Advanced 3D Printing Training – Clay Printing | Advanced training focused on process optimization + troubleshooting. | $310 |

| Grasshopper Training for Clay 3D Printing | Training for parametric (Grasshopper) workflows tailored to clay printing. | $430 |

The Delta WASP 2040 Clay ships with full documentation, including a user manual covering assembly, operation, maintenance, and troubleshooting, and a video online course. The SD card provides sample G-code files and pre-configured settings for reliable ceramic printing from the start.

Check out the online support portal here: https://www.3dwasp.com/en/support/

The Delta WASP 2040 Clay is priced at $4,949.00. It offers a 200 mm × 400 mm build volume with print speeds up to 150 mm/s while maintaining precision. Its aluminum and PMMA frame provides stability for printing ceramics like clay and porcelain, as well as plastics such as PLA and PETG.

Update your browser to view this website correctly. Update my browser now