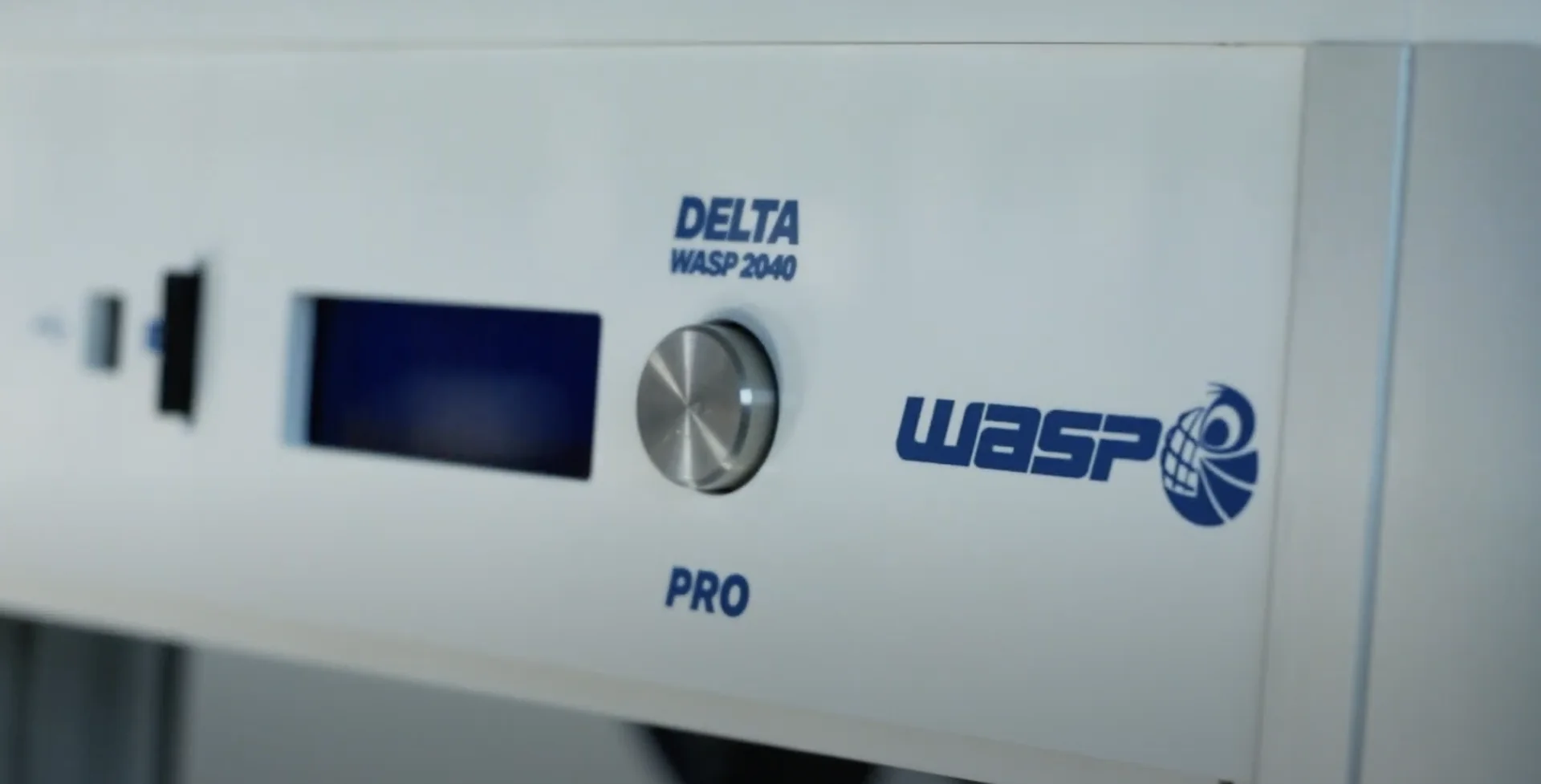

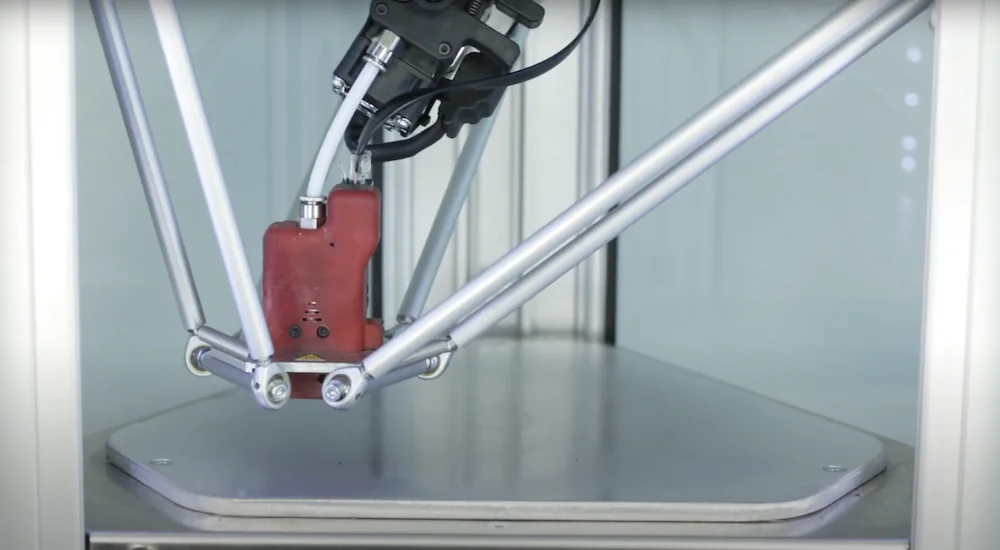

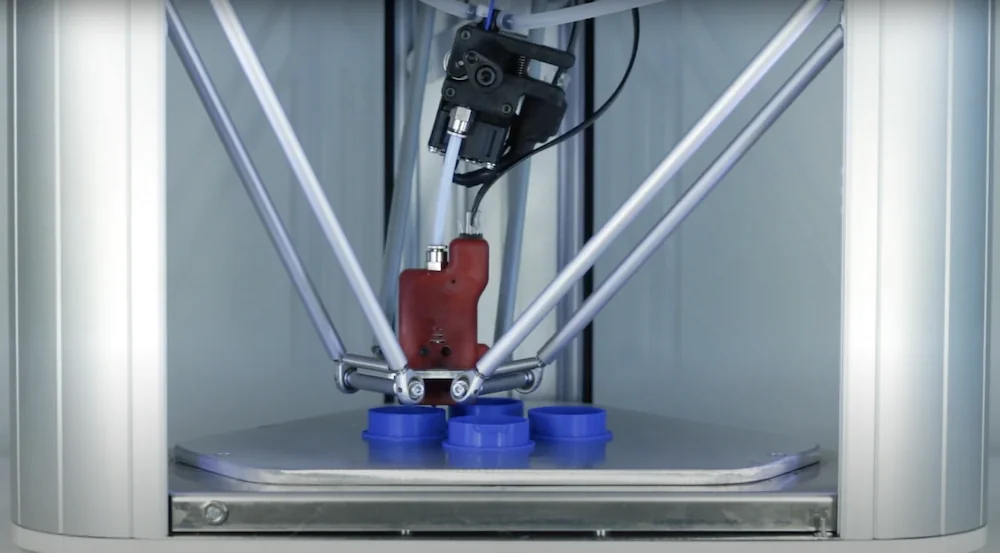

The Delta WASP 2040 Pro is a delta-style FDM 3D printer with a 200×400mm build volume, designed for high-speed, precise printing using materials like PLA, PETG, ABS, and PA Carbon. Its lightweight Bowden system with elastic bands enhances speed and quality, while features like auto-calibration, a filament sensor, and a user-friendly interface support both beginners and professionals. The printer includes Resurrection and Free Zeta systems for print recovery and can be upgraded with the LDM WASP Extruder 3.0 to print clay, ceramics, and more (a paid add-on). Its durable aluminum-PMMA frame, steel-cored belts, and speeds up to 500 mm/s (FDM) make it ideal for artists, educators, designers, and engineers.

The Delta WASP 2040 Pro achieves high detail with a 50-micron layer height in FDM and 0.5mm in LDM. Its rectified aluminum plate ensures strong adhesion, while auto-calibration maintains consistent quality across the 200mm × 400mm build area.

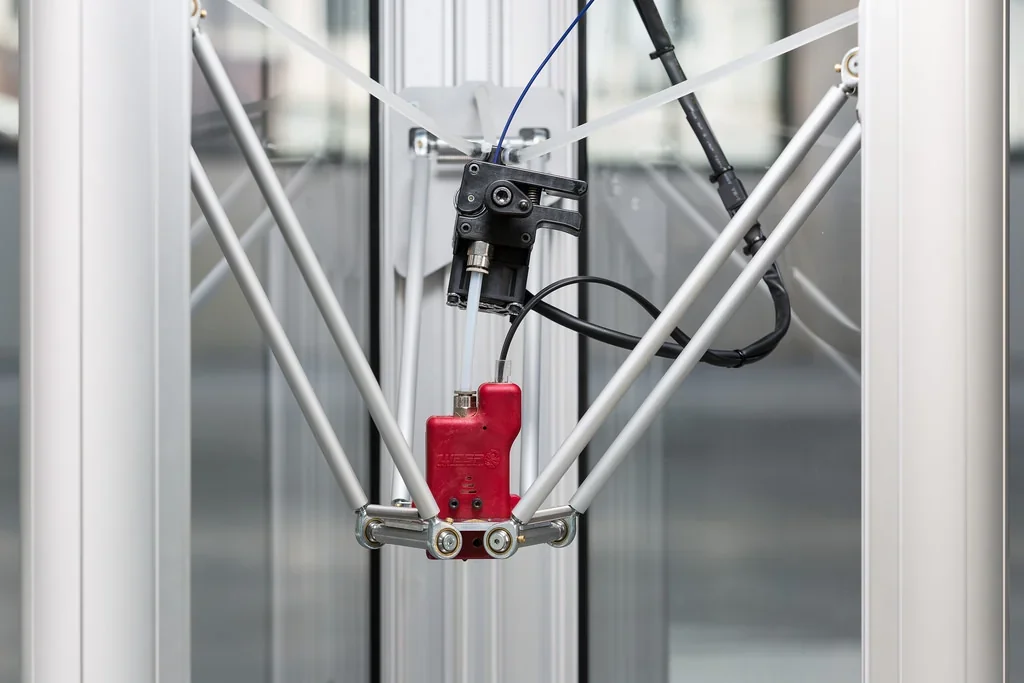

The Delta WASP 2040 Pro prints up to 500 mm/s in FDM and 150 mm/s in LDM, with travel speeds of 800 mm/s and acceleration up to 15,000 mm/s². Its delta design and suspended Bowden system reduce inertia for fast, precise printing, while steel-cored belts resist heat and deformation for reliable long runs.

The Delta WASP 2040 Pro’s aluminum-PMMA frame and nylon wheels on anodized sliders ensure smooth, precise motion. Motor cooling prevents overheating, and a filament sensor pauses prints when material runs out. With the LDM 3.0 upgrade, users can print clay using interchangeable nozzles (1.2–3mm) for different viscosities and detail levels.

The Delta WASP 2040 Pro supports both FDM and clay printing by swapping between the Spitfire Extruder (0.4–1.2mm nozzles) and the optional LDM 3.0 Extruder. Its heated bed (up to 110°C) enables printing with ABS, PA Carbon, and other technical materials, allowing both functional prototypes and ceramic artworks on one machine.

The Pro model prints with filament, while the Clay version prints clay. Both can be upgraded for dual-material use.

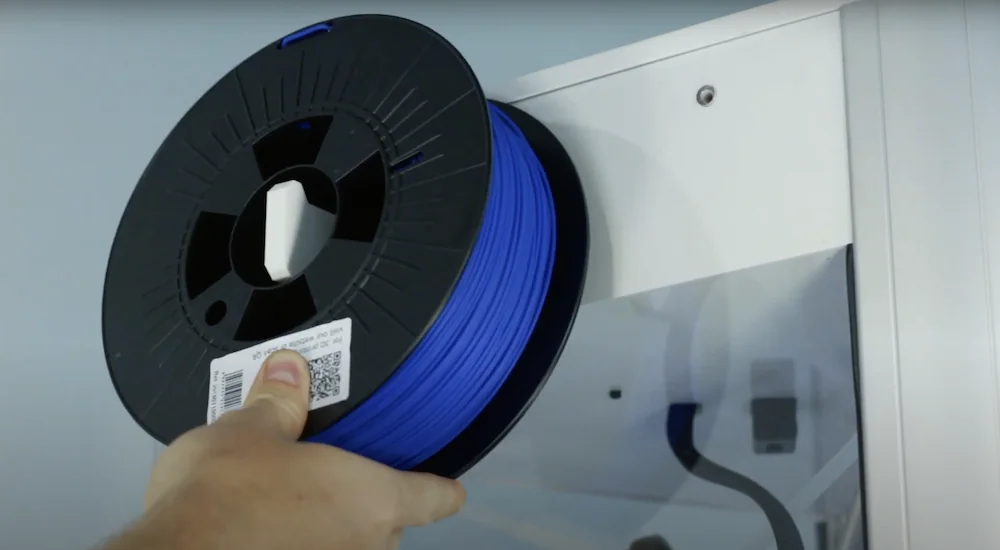

The Delta WASP 2040 Pro supports filament materials like 1.75mm PLA, PETG, ABS, and PA Carbon with 0.4–1.2mm nozzles on the Spitfire Extruder, and ceramic materials such as porcelain, clay, stoneware, and earthenware with 1.2–3mm nozzles on the LDM WASP Extruder (optional upgrade).

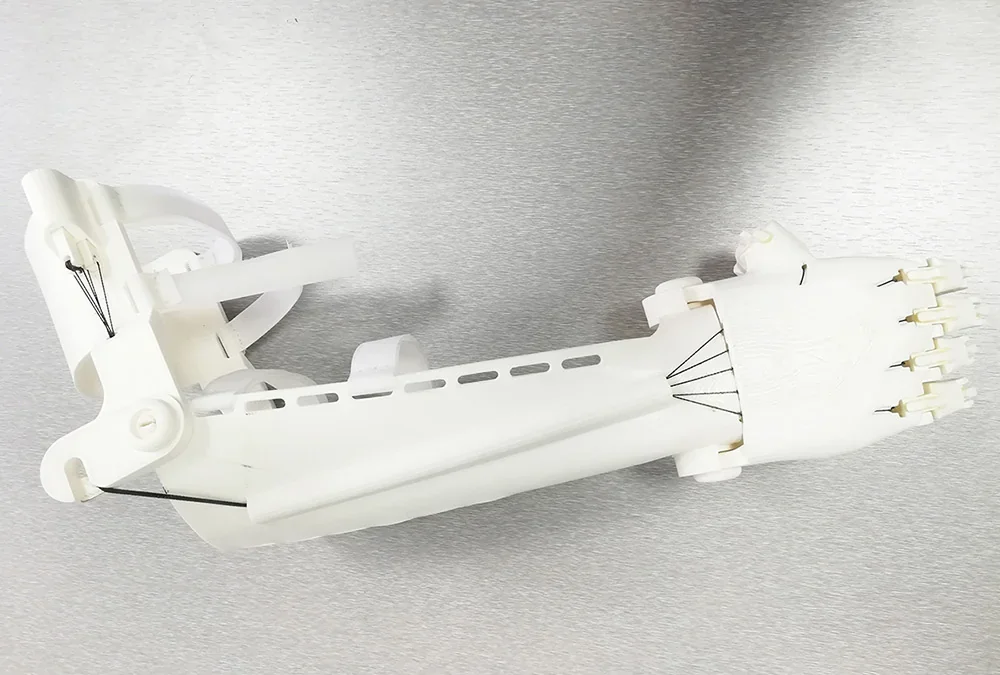

3D Printed Prosthetics in a Syrian Laboratory

The Delta WASP 2040 Pro supports both proprietary and third-party materials, giving users flexible sourcing options.

Material compatibility is supported by the suspended Bowden system for FDM and the precision LDM extruder for clay. Steel-cored belts withstand high temperatures for consistent performance, while a wooden build plate ensures proper clay adhesion and drying. Switching extruder heads lets the Delta WASP 2040 Pro operate as two specialized printers in one.

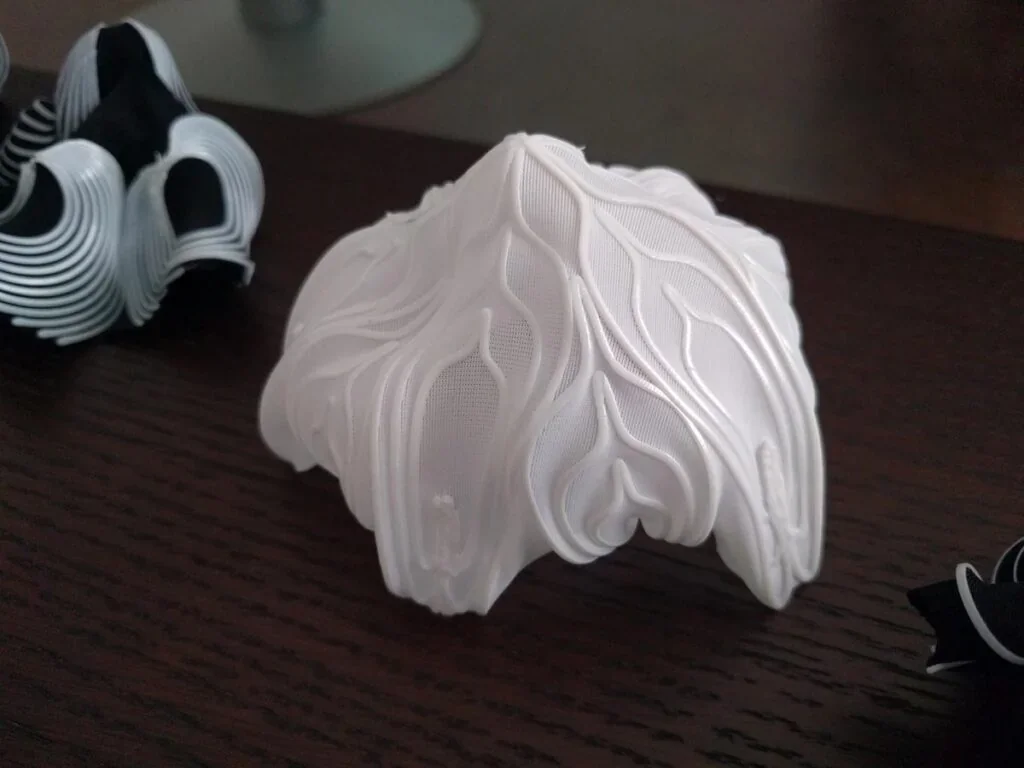

3D printed geometries on textile fabric

The Delta WASP 2040 Pro has a 200mm × 400mm cylindrical build volume (12.6L), ideal for both filament and clay printing. Its tall, vertical design is well-suited for creating slender objects that cube-shaped printers cannot accommodate.

The Delta WASP 2040 Pro maintains the same build volume in both modes. For FDM, a heated aluminum plate (up to 110°C) supports adhesion for plastics like ABS and PA Carbon. In LDM mode, a wooden plate provides proper adhesion and drying for ceramics.

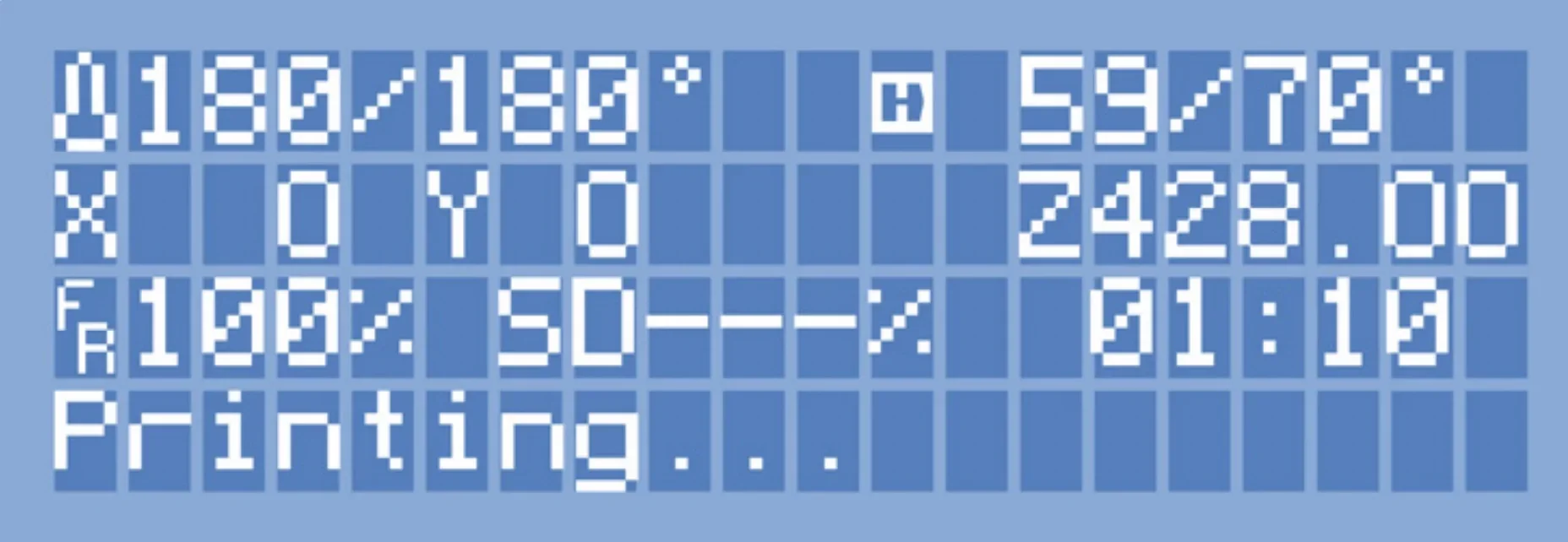

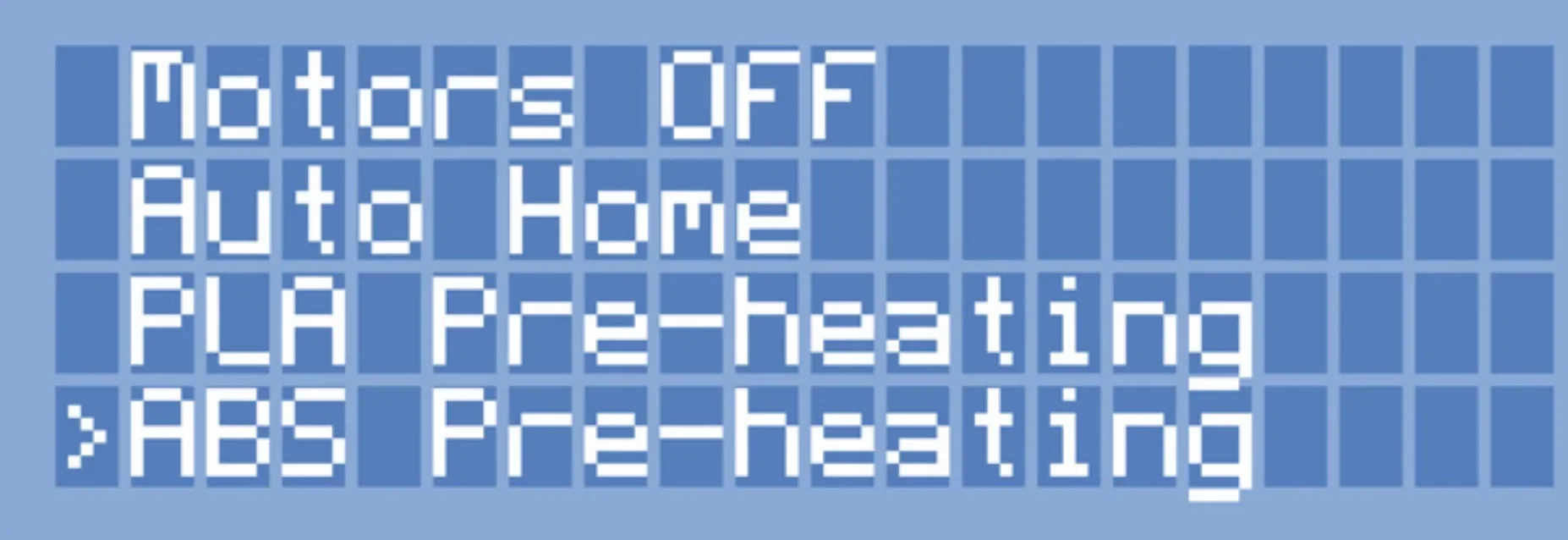

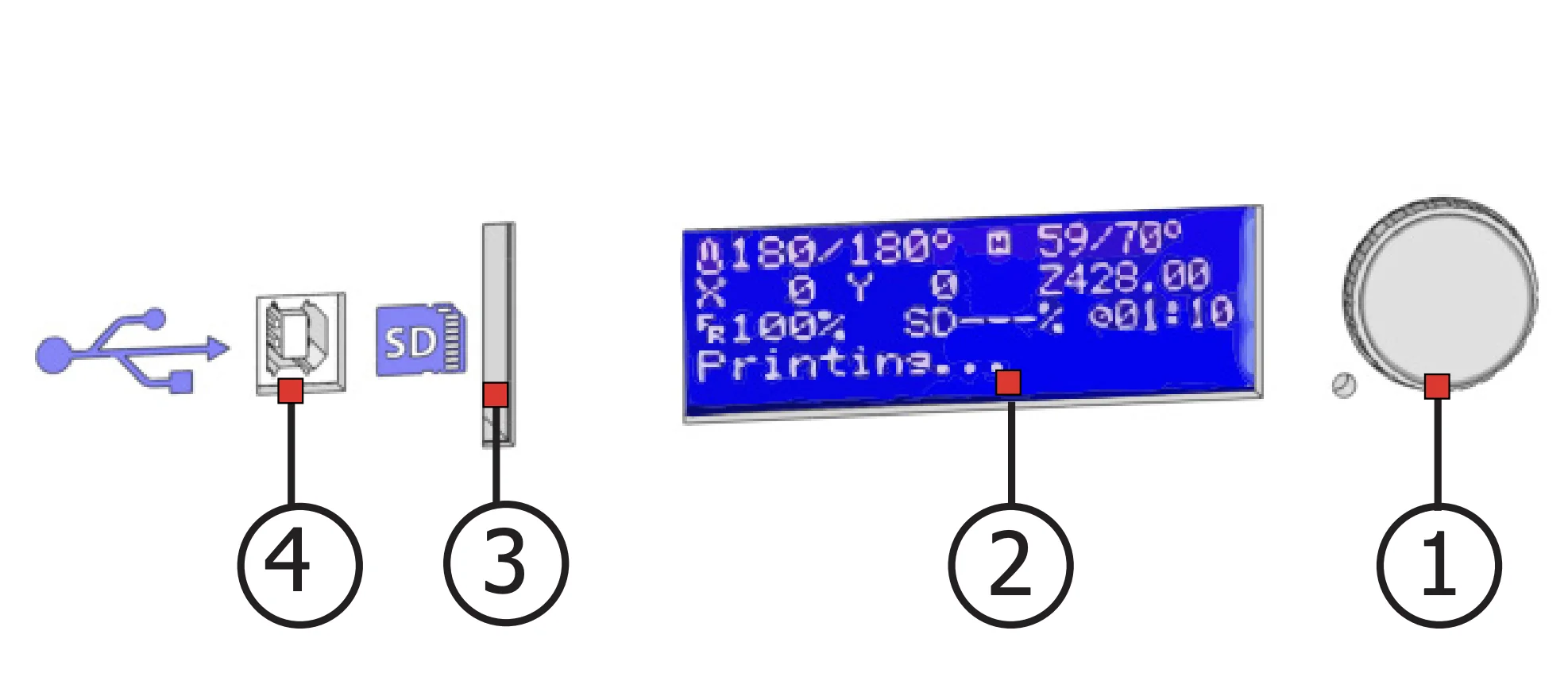

The Delta WASP 2040 Pro features a circular navigation wheel and an LCD display for menu navigation and printer control, supporting temperature adjustments up to 260°C for the nozzle and 100°C for the bed, filament management, and standalone print job initiation from an SD card.

Physical Control Components

Menu System Access:

The Delta WASP 2040 Pro offers two connectivity options: an SD card slot for direct G-code printing and a USB Type B port for computer-controlled operation and file transfer.

The Delta WASP 2040 Pro works with Cura, Slic3r, and Simplify3D, compatible with Windows, Mac, and Linux. Cura suits beginners with its simple interface, while Simplify3D offers advanced controls for professionals.

The Delta WASP 2040 Pro supports .stl and .obj model files and .gcode instructions, ensuring compatibility with most design software. Separate slicing profiles are required for FDM and LDM, with optimized settings for both included on the SD card to set correct extrusion rates, temperatures, and speeds.

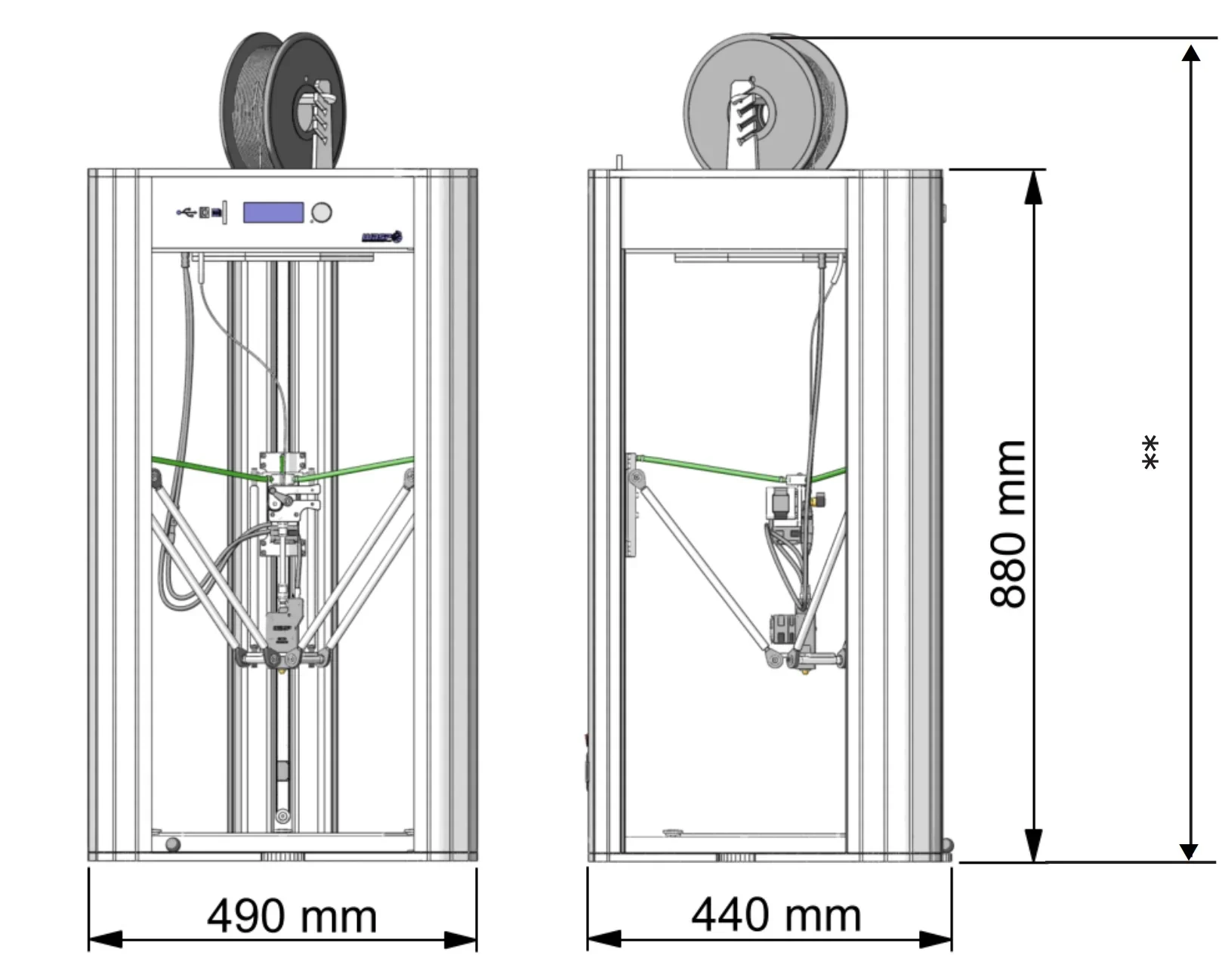

The Delta WASP 2040 Pro features a robust three-pillar delta design with an aluminum, PMMA, and polycarbonate frame measuring 49 × 44 × 87 cm and weighing 25 kg, an enclosed yet visible build area, a flat rectified aluminum plate for strong adhesion, and ergonomic modular controls with tool-free extruder switching.

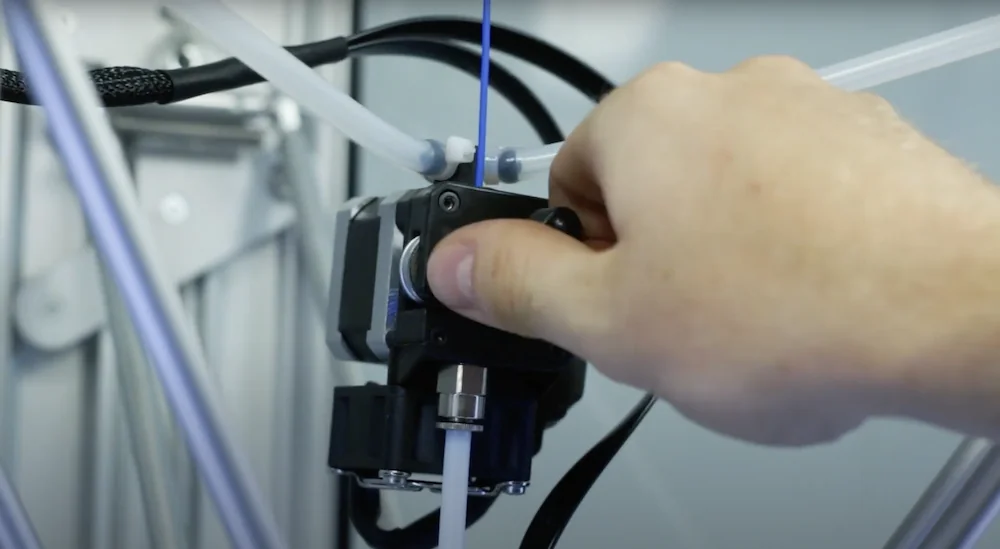

The Delta WASP 2040 Pro features an ergonomic design with a top-mounted LCD and control button for easy access. Its modular extruder system enables quick, tool-free switching between FDM and LDM. For clay printing, an optional aluminum tank with stand ensures consistent material flow.

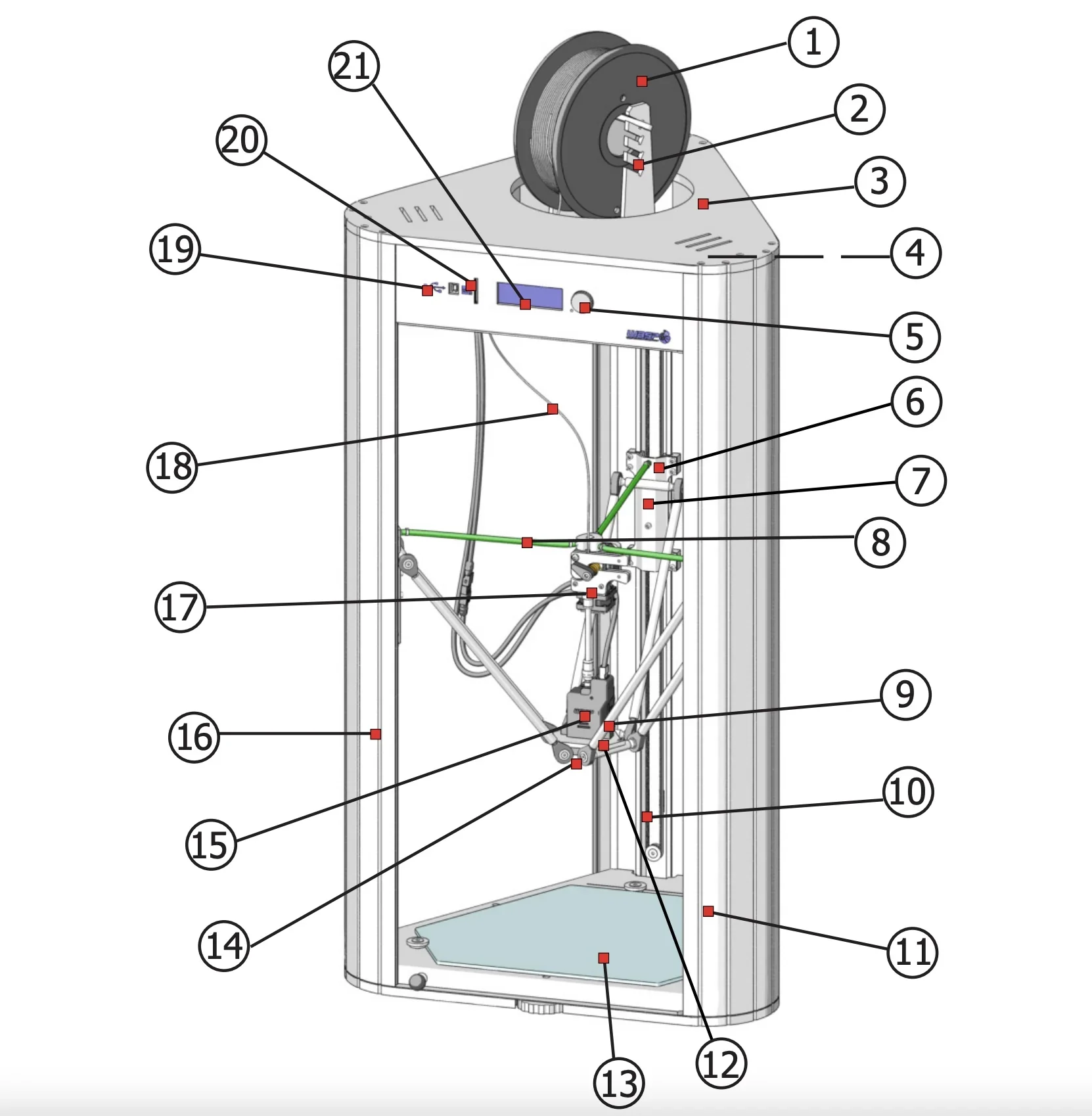

Material Holder Reel - Spool holder for filament storage

Reel Support- Mounting bracket for filament spool

Upper Cover- Top protective housing

Stepper Motors- Precision motors for axis movement

Navigation Button- Control knob for menu navigation

Sliding Block- Linear bearing component

Slide- Linear guide rail

Filament Puller Support Elastic Bands- Tension springs for filament feeding

Arms with Double Connecting Rod- Delta frame support arms

Axis Movement Toothed Belt- Drive belt for positioning system

Aluminum Profile Machine Structure- Main frame construction

Extruder Plate- Mounting platform for extruder assembly

Heated Bed with Height Adjustment- Build platform with temperature control

0.4mm Nozzle- Print head orifice

Extruder- Hot-end assembly for filament melting

Machine Lighting LED- Built-in illumination system

Filament Puller- Feed mechanism for material advancement

Filament to be Melted- Print material (plastic filament)

USB Type-B Port- Computer connection interface

SD Card Port- Memory card slot for standalone printing

LCD Display- Liquid crystal screen for printer information

The standard package include the following items:

The Delta WASP 2040 Pro comes fully assembled and ready to use.

Note: Package contents may vary by manufacturer. Contact a Top3DShop sales representative to confirm current inclusions before ordering.

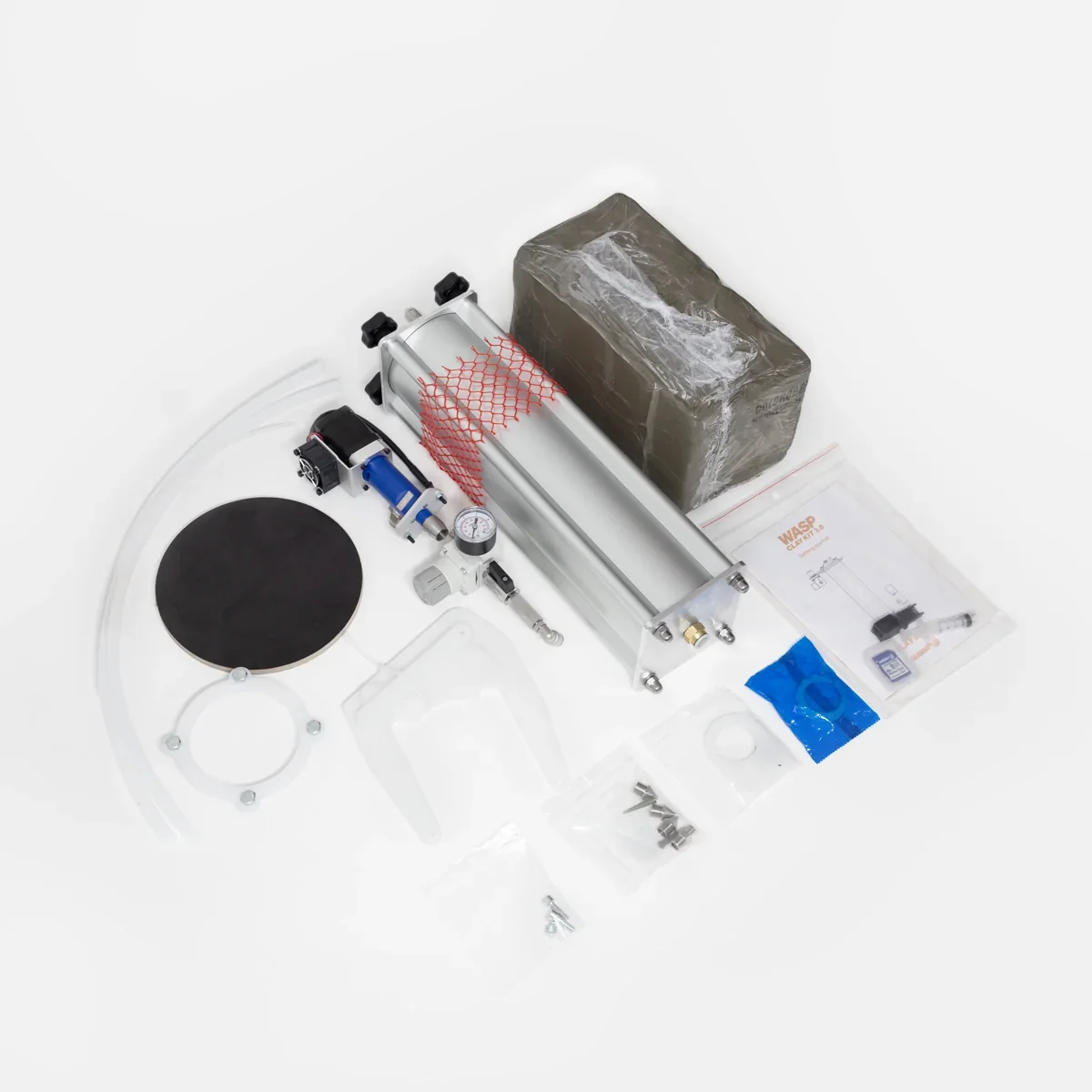

The LDM & FDM Hybrid package (optional upgrade) also includes the following items:

| Accessory | Function | Price (USD) |

|---|---|---|

| Group: Clay Printing Hardware and Ceramic Materials | ||

| WASP Clay Kit 3.0: 3 L tank + nozzle set (1.26–3.00 mm) + 12.5 kg clay | Clay printing kit: 3 L tank + nozzle set (1.26–3.00 mm) + 12.5 kg clay; intended for fluid-dense and ceramic materials. | $1,575 |

| RED TERRAGLIA ceramic mixture, 12.5 kg (pack) | Ceramic mixture material (RED TERRAGLIA), 12.5 kg pack. | $35 |

| Group: Extrusion System Parts | ||

| WASP SPITFIRE X Extruder 24V with 0.4 mm nozzle | SPITFIRE X filament extruder (24 V) supplied with 0.4 mm nozzle; dual-gear filament drive; designed for advanced materials such as Carbon Nylon on Delta WASP printers; uses removable nozzles for quick nozzle-size changes. | $405 |

| WASP SPITFIRE X Extruder 24V with 0.8 mm nozzle | SPITFIRE X filament extruder (24 V) supplied with 0.8 mm nozzle; dual-gear filament drive; designed for advanced materials such as Carbon Nylon on Delta WASP printers; uses removable nozzles for quick nozzle-size changes. | $405 |

| Bowden tube kit for SPITFIRE X Extruder: PTFE 2×4×85 mm + nylon 4×6×85 mm (5 pcs) | Bowden tube spare kit for SPITFIRE X extruder: PTFE 2×4×85 mm + nylon 4×6×85 mm; 5 pieces. | $25 |

| SPITFIRE X nozzle, hardened M2 steel, 0.4 mm | Replacement SPITFIRE X nozzle, hardened M2 steel, 0.4 mm diameter. | $60 |

| SPITFIRE X nozzle, hardened M2 steel, 0.8 mm | Replacement SPITFIRE X nozzle, hardened M2 steel, 0.8 mm diameter. | $60 |

| Group: Adhesion and Surface Consumables | ||

| DimaFix pen, 90 ml (build plate adhesive) | DimaFix pen for better adhesion, 90 ml | $35 |

| Magigoo pen, 50 ml (build plate adhesive) | Magigoo pen for better adhesion, 50 ml | $35 |

| Group: Motion System Spare Parts | ||

| Elastic band kit for Delta WASP 2040, 3 pcs | Elastic band replacement kit for Delta WASP 2040; 3 pieces. | $5 |

| Group: Filaments | ||

| PLA filament, black, 1.75 mm, 1 kg | PLA filament, black; 1.75 mm diameter; 1 kg spool. | $70 |

| PLA filament, white, 1.75 mm, 1 kg | PLA filament, white; 1.75 mm diameter; 1 kg spool. | $70 |

| PLA filament, industrial gray, 1.75 mm, 1 kg | PLA filament, industrial gray; 1.75 mm diameter; 1 kg spool. | $70 |

| ABS filament (WASP), black, 1.75 mm, 1 kg | ABS filament (WASP), black; 1.75 mm diameter; 1 kg spool. | $70 |

| ABS filament (WASP), neutral, 1.75 mm, 1 kg | ABS filament (WASP), neutral; 1.75 mm diameter; 1 kg spool. | $70 |

| Nylon Carbon filament, 1.75 mm, 0.9 kg | Nylon Carbon filament, 1.75 mm diameter; 0.9 kg spool. | $165 |

After Each Print Session

Periodic Inspection

Safety-Critical Procedures

Prohibited Maintenance Actions

The Delta WASP 2040 Pro requires little maintenance thanks to its aluminum, polycarbonate, and plexiglass frame and precision components. Its delta design with sliding blocks on anodized aluminum reduces wear versus traditional systems.

DeltaWASP offers technical support through a website section with manuals, troubleshooting guides, and video tutorials for FDM and LDM printing. Technical experts are also available via email for setup or printing issues.

The Delta WASP 2040 Pro comes with a manual detailing setup, calibration, and maintenance for both modes. It also covers filament and clay preparation, helping users get the most from the dual-technology system.

| Training and Education Package | Description | Price (USD) |

| Basic Training: Clay 3D Printing (online recorded video) | Basic training for clay 3D printing (online recorded video training). | $0 |

| Basic Training: 3D Printing (recorded training) | Basic 3D printing training (recorded training). | $0 |

| Advanced 3D Printing Training – Clay Printing | Advanced 3D printing training focused on clay printing. | $550 |

| Advanced Training 3D Printing | Advanced 3D printing training. | $550 |

The Delta WASP 2040 Pro costs $4,400.00. It supports FDM with PLA, PETG, ABS, and PA Carbon, and can be upgraded to LDM Hybrid for printing with porcelain, clay, stoneware, and earthenware.

Update your browser to view this website correctly. Update my browser now