The DeltaWASP 3MT Concrete / Clay is a large-format 3D printer designed for architecture and construction, offering a 1000 x 1000 mm build volume within a 305 cm tall, 350 kg steel frame. It features interchangeable extruders for concrete, earth, clay, and porcelain, supported by a continuous feeding system with a mortar pump and pressure sensors for stable extrusion. Built for industrial use, it includes metal carters for stability, a removable MDF pallet bed for easy print removal, and supports remote operation via touchscreen, USB, Wi-Fi, and HD camera. Its resurrection system resumes prints after power loss, making it ideal for long, complex projects such as architectural components or ecological structures like 3D-printed coral reefs.

The Delta Wasp 3MT Concrete 3D Printer delivers precise large-scale prints with axis accuracy of 0.1 mm (X/Y) and 0.05 mm (Z), layered extrusion of 9–15 mm at speeds up to 200 mm/s, and stable, dimensionally reliable results enabled by metal carters and a 350 kg steel frame.

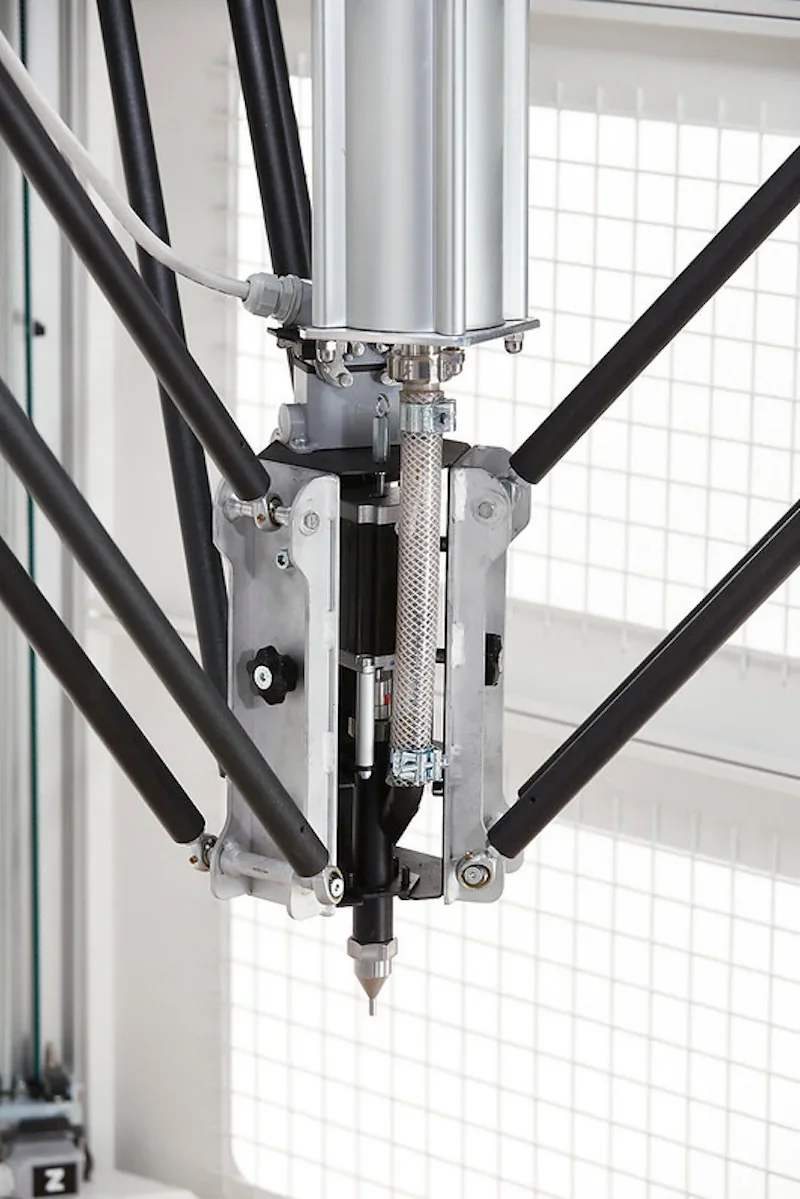

With the XXL extruder for concrete printing, it prints 9–15 mm layers and 20–40 mm thickness, using 18–30 mm nozzles for materials with particles up to 1 mm. The XL extruder for clay and porcelain achieves finer 1–2 mm layers with 4, 6, or 8 mm nozzles.

The DeltaWASP 3MT uses a Delta kinematic system for consistent printing within its Ø1000 x 1000 mm build volume. A real-time pressure control system monitors and adjusts material flow, enabling reliable extrusion with challenging mixes like fiber-reinforced concrete (fibers up to 30 mm) and clay. Its 350 kg steel frame ensures the stability needed for precise large-scale additive manufacturing of conrete mortars.

The Delta WASP 3MT supports over 8 materials including concrete mortars with particles up to 1 mm, fiber-reinforced concrete with fibers up to 30 mm, foamed concrete, clay, porcelain, gres, and biohybrid mixes like mycelium-clay blends.

For ceramic work, the DeltaWASP 3MT uses the LDM WASP Extruder XL 3.0, designed for clay, porcelain, and gres. It provides finer control with smaller nozzles (4–8 mm nozzle diameters) compared to the concrete extruder’s 8–30 mm range. A mortar pump with real-time pressure sensing maintains steady material flow across varying viscosities.

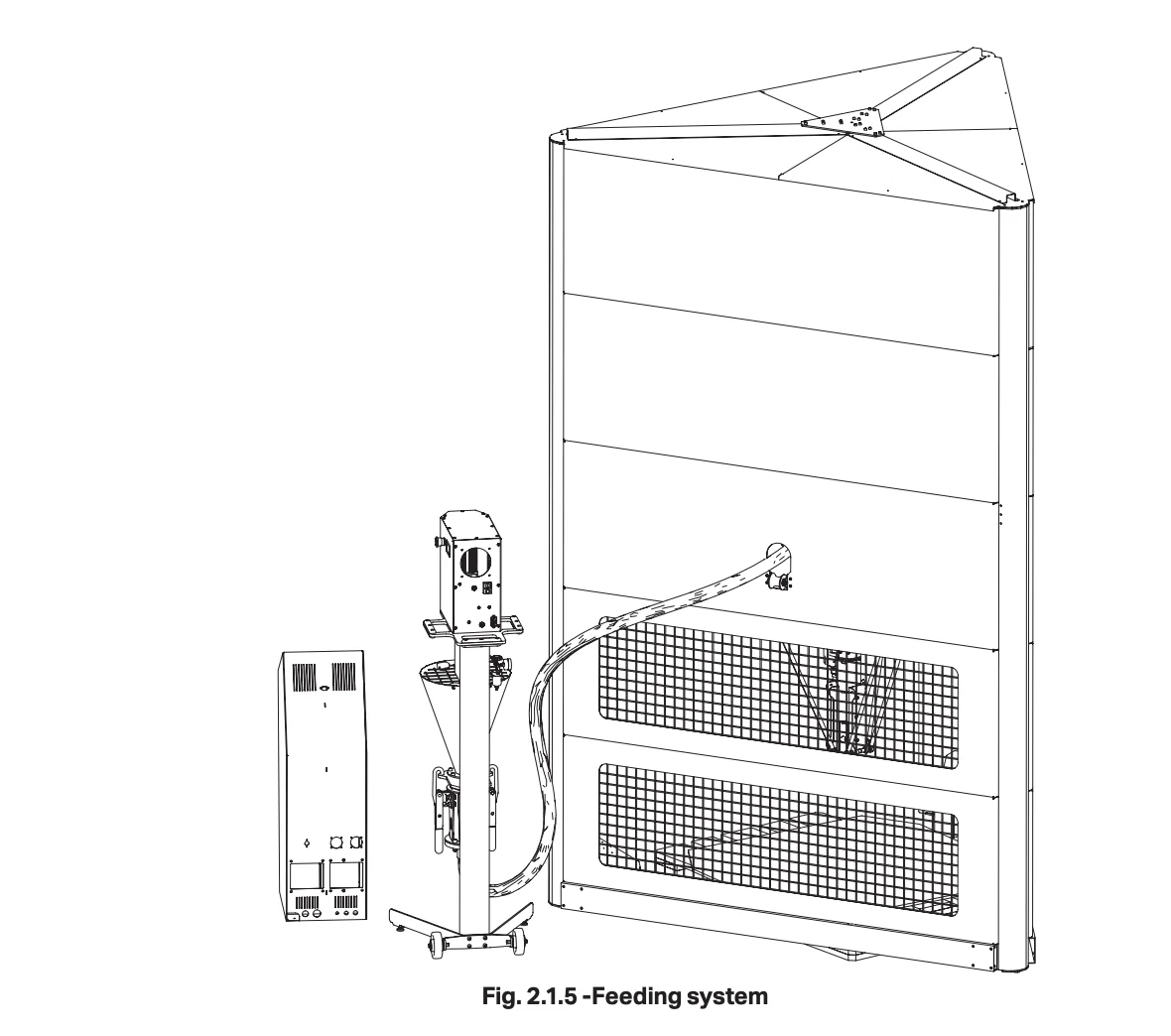

The DeltaWASP 3MT’s continuous feeding system ensures uninterrupted printing with real-time pressure sensors at the material inlet. This adaptive control adjusts for variations in concrete and clay consistency, enabling reliable extrusion even with difficult formulations.

The WASP 3MT has been used to print a modular mycelium-clay beehive from a biohybrid mix of clay, plant fibers, and bio-based additives. Its tower-like, parametrically generated design creates controlled porosity, ensuring ventilation, insulation, and stability while supporting wood-decay fungi growth.

The WASP 3MT has been used to create a ceramic vase collection from 100% natural clay, modeled in Grasshopper for complex parametric geometries. Designs include: Ripple (ø80 × 135 mm) with wave patterns, Intertwined (ø80 × 195 mm) with root-inspired forms, Kilim (ø115 × 290 mm) referencing carpet weaving, Melting (ø100 × 170 mm) using clay deformation, and Bulky (140, 185, 240 mm heights) with textile-like textures.

The WASP 3MT printed large ceramic suspension lamps with a parametric honeycomb design using stoneware deposited mid-air. The Haibu pendant lamps, part of Paolo Castelli’s Acquerello Collection, exploit natural material behavior to form overlapping scale patterns with integrated apertures. Their dome-shaped geometry combines structural integrity, organic texture, and optimal light diffusion—achieved without support structures.

The DeltaWASP 3MT Concrete is built for additive manufacturing of concrete mortars, while the 3MT HDP model uses a pellet extruder, printing with plastic pellets such as PET and ABS.

| Model | Materials | Build Volume (Diameter x Height) |

|---|---|---|

| Delta WASP 2040 Clay | Clay, Porcelain, Gres, Earthenware, and other ceramic mixtures | 200 mm x 400 mm |

| Delta WASP 40100 LDM | Clay, Stoneware, Porcelain, Terracotta, Earthenware, and other fluid-dense materials | 400 mm x 1000 mm |

| Delta WASP 3MT Concrete |

Construction Materials: Concrete mortars, earth-based mixtures, and materials reinforced with natural fibers Ceramics: Clay and Porcelain |

1000 mm x 1000 mm |

The DeltaWASP 3MT professional 3D printer features a 1000 × 1000 mm cylindrical build volume (785.4 L), ideal for medium to large parts. Its delta motion system ensures precision and handles complex geometries. The MDF pallet bed with a removable beam allows easy removal of heavy prints using pallet trucks or forklifts.

Compared to other industrial 3D printers, the DeltaWASP 3MT balances build space and mobility. The CyBe RC 3Dp offers 2500 × 5000 × 4000 mm capacity, while the modular COBOD BOD2 scales up to 14620 × 50520 × 8140 mm for commercial projects. WASP’s Crane model, with Ø8200 × 3200 mm build area, targets housing construction within its Maker Economy Starter Kit.

|

Feature |

Delta WASP 3MT Concrete |

COBOD BOD2 |

Crane WASP |

CyBe RC 3Dp |

|

Type |

Delta Robot |

Gantry |

Gantry/Crane |

Robotic Arm on Crawler |

|

Build Volume |

Ø 1000 x 1000 mm |

Modular, up to 14.6m width x 8.1m height |

Ø 8200 mm × 3200 mm height |

5m diameter x 4.5m height (with feet) |

|

Max Print Speed |

200 mm/s |

1000 mm/s (250 mm/s unfenced) |

300 mm/s |

500 mm/s |

|

Key Differentiator |

Interchangeable extruders for concrete and clay |

Modular, expandable frame with tangential control for smooth walls |

Designed for on-site sustainable housing |

High mobility for varied on-site terrain |

|

Materials |

Concrete mortars, earth mixtures, clay, porcelain |

Materials with aggregates up to 10 mm |

Natural/recycled materials, cement mortars, geopolymers |

Proprietary CyBe Mortar |

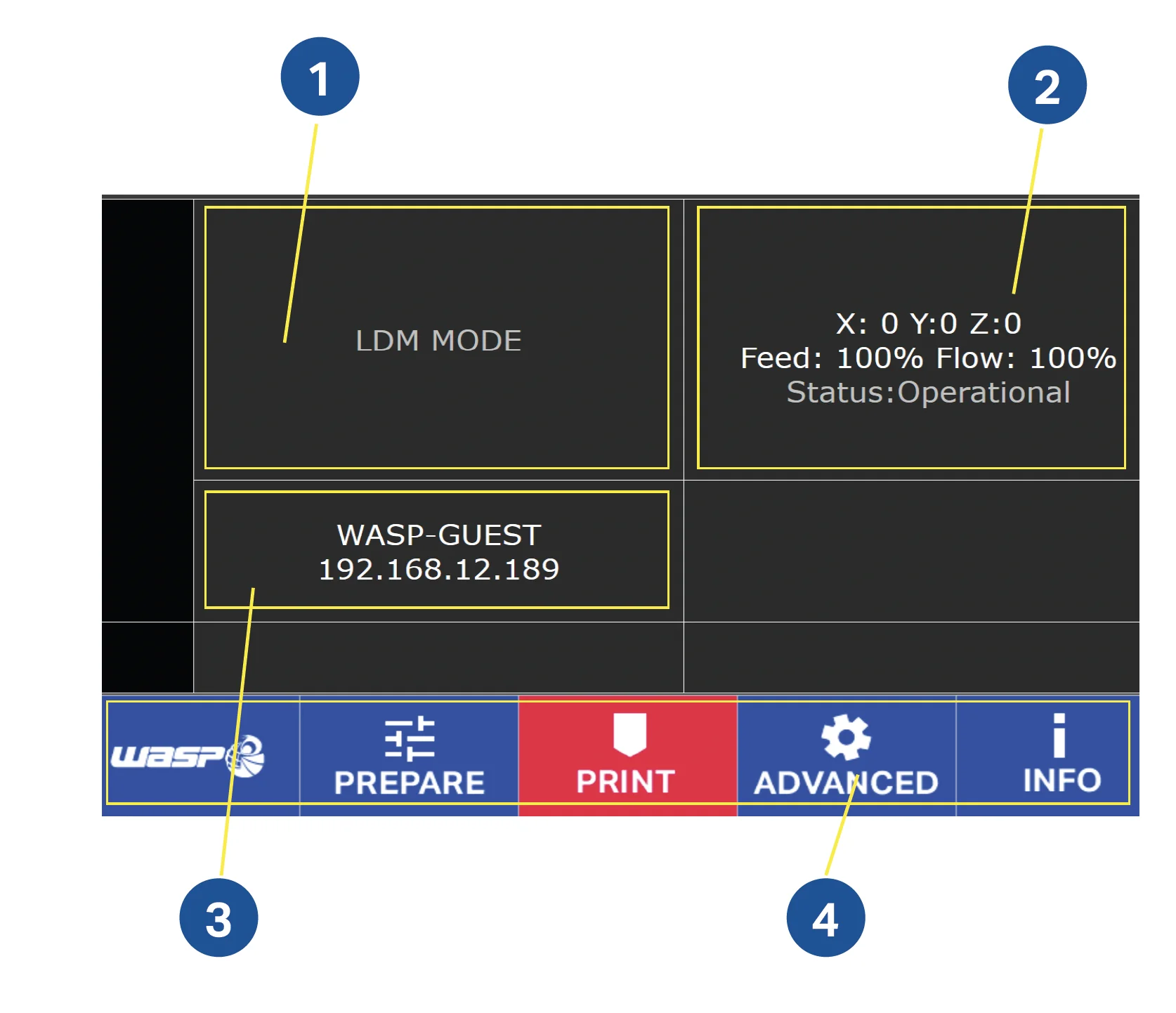

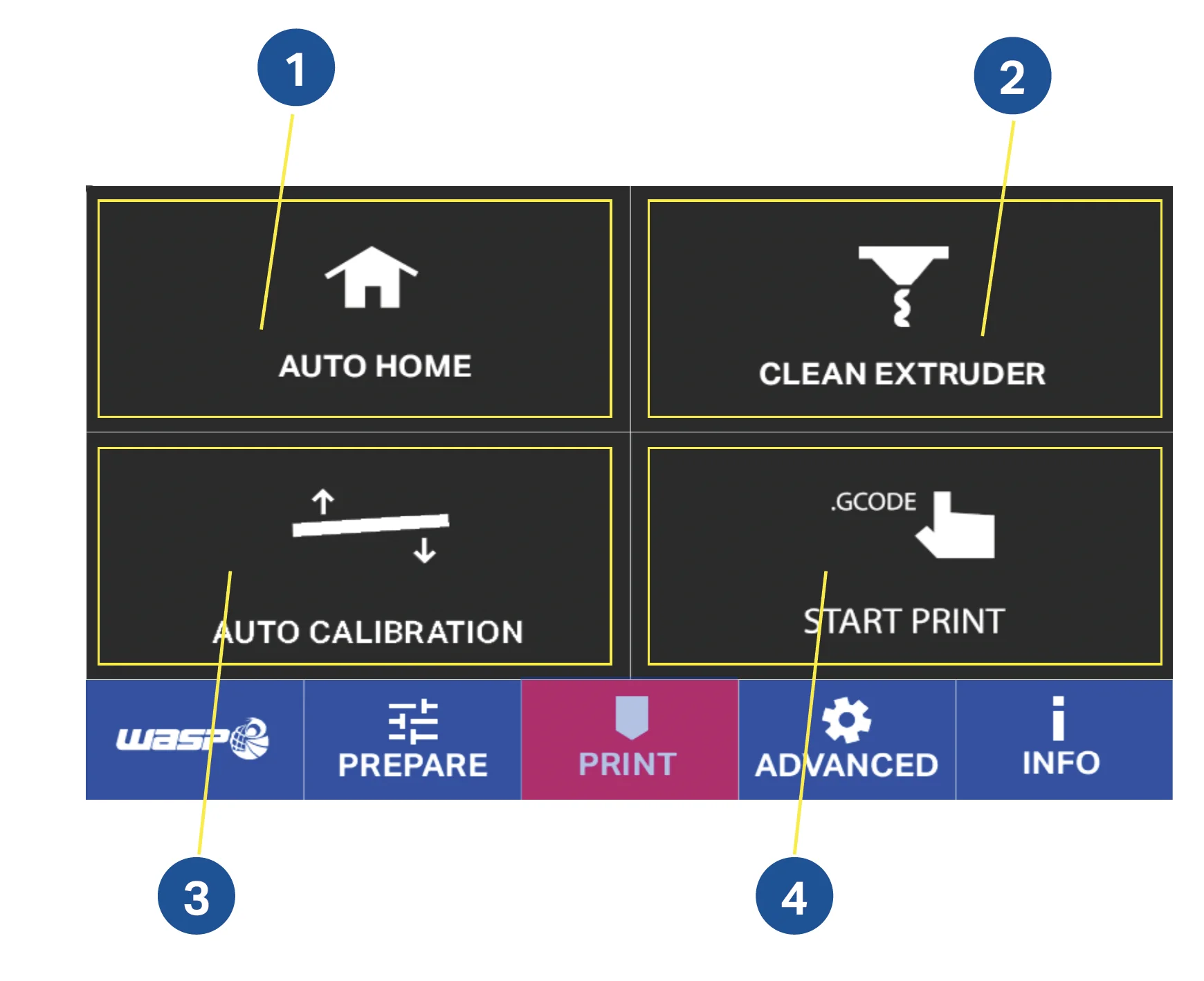

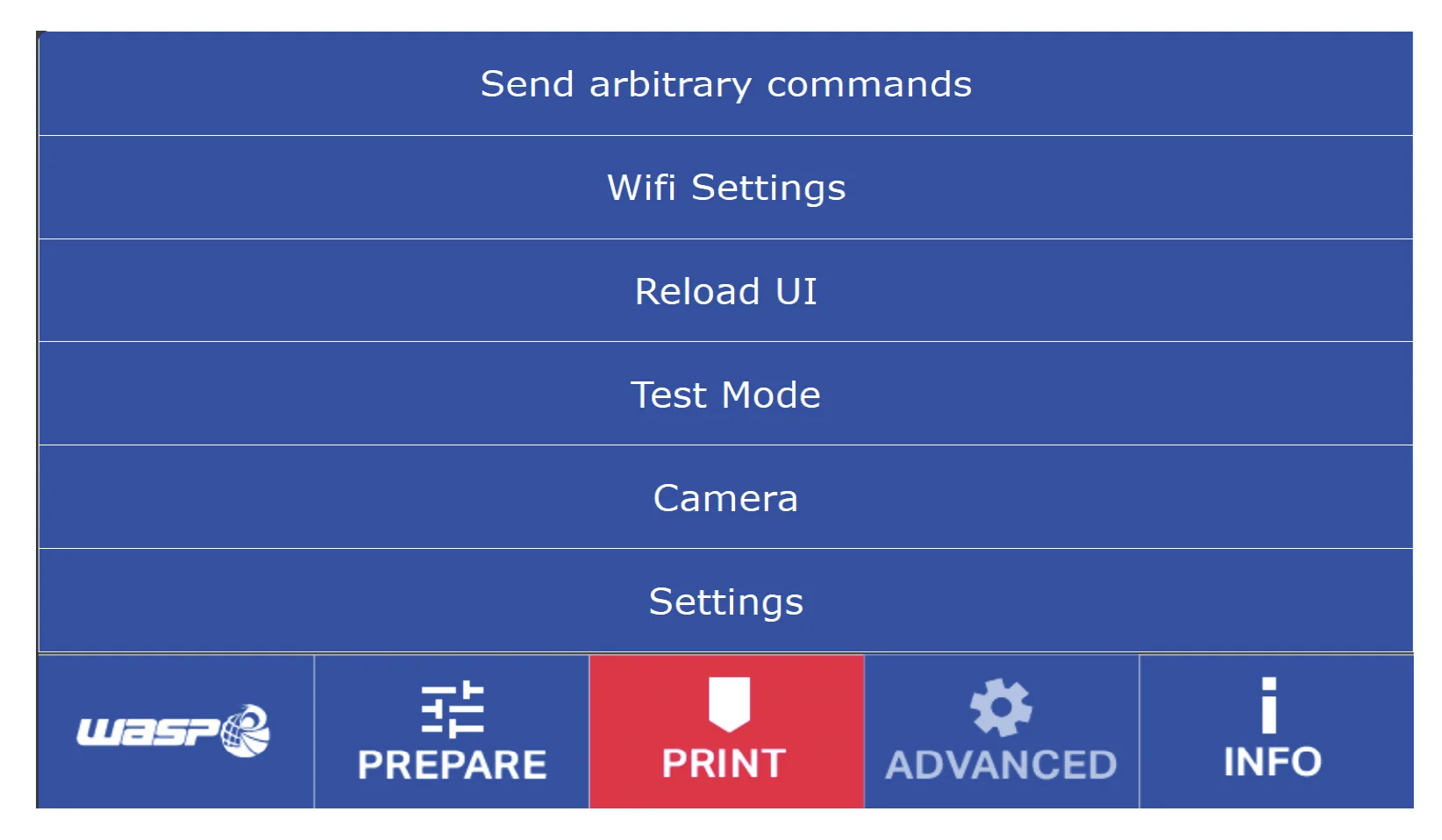

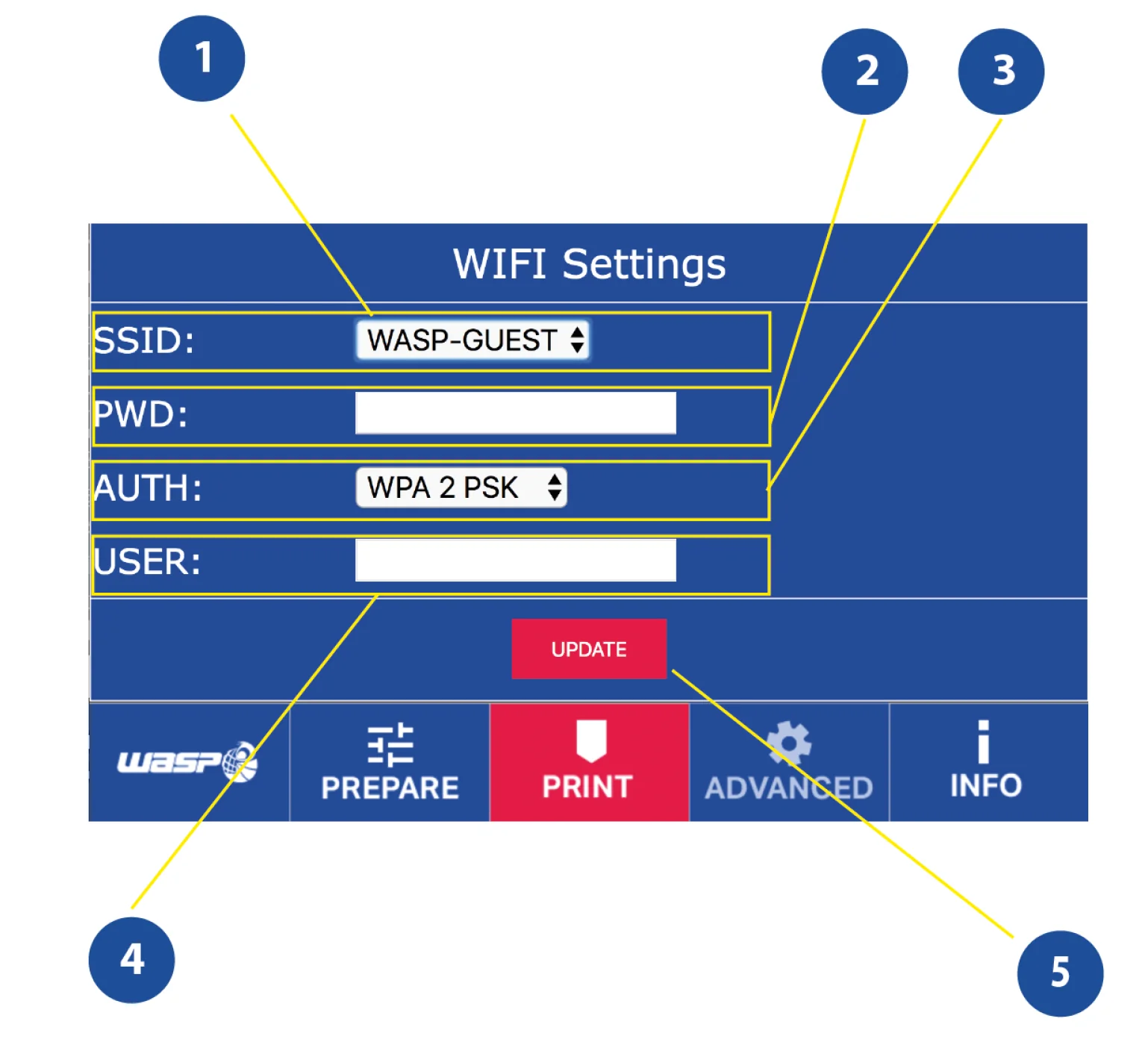

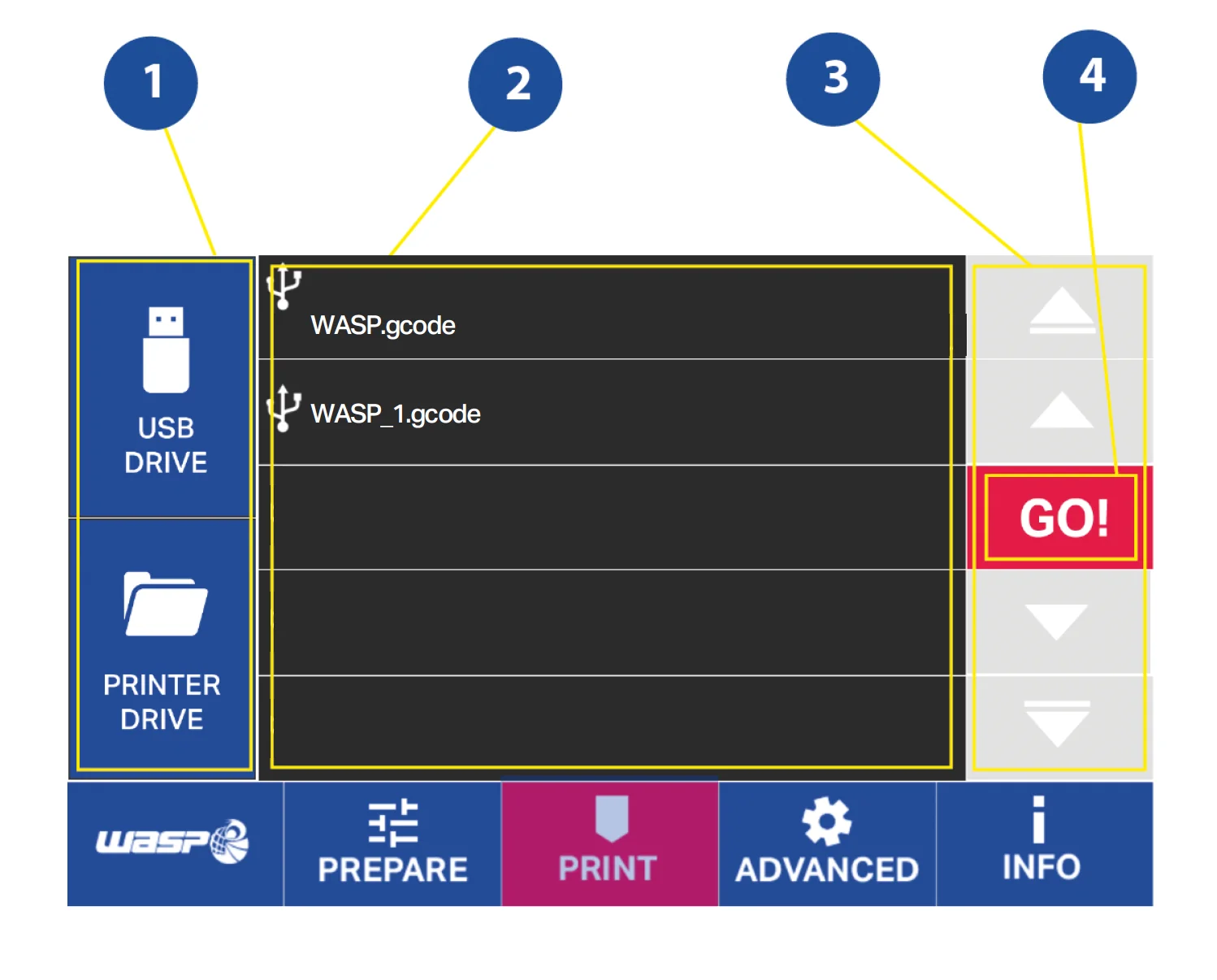

The concrete 3D printer Delta WASP 3MT features 25 touchscreen software controls including Auto Home, Auto Calibration, Start Print, Free Zeta System, Manual Leveling, Send Arbitrary Command, WiFi settings, Camera monitoring, and G-code file management, alongside physical controls such as an ON/OFF switch, USB port, and rotary handle for navigation.

MAIN MENU

CALIBRATION MENU

ADVANCED MENU

ADVANCED MENU

WIFI SETTINGS MENU

FILE MANAGEMENT MENU

The DeltaWASP 3MT Concrete / Clay supports three connectivity options: USB for file transfer, Wi-Fi for wireless integration, and Ethernet for stable wired networking. These allow G-code uploads directly via flash drive or over the network to the printer’s internal memory.

The DeltaWASP 3MT includes an HD camera for live remote monitoring and a browser-based control interface accessible via the printer’s IP address. Operators can track progress, adjust settings, and manage prints from any connected device. Its resurrection system records progress and resumes prints after power loss, ensuring uninterrupted operation for long projects.

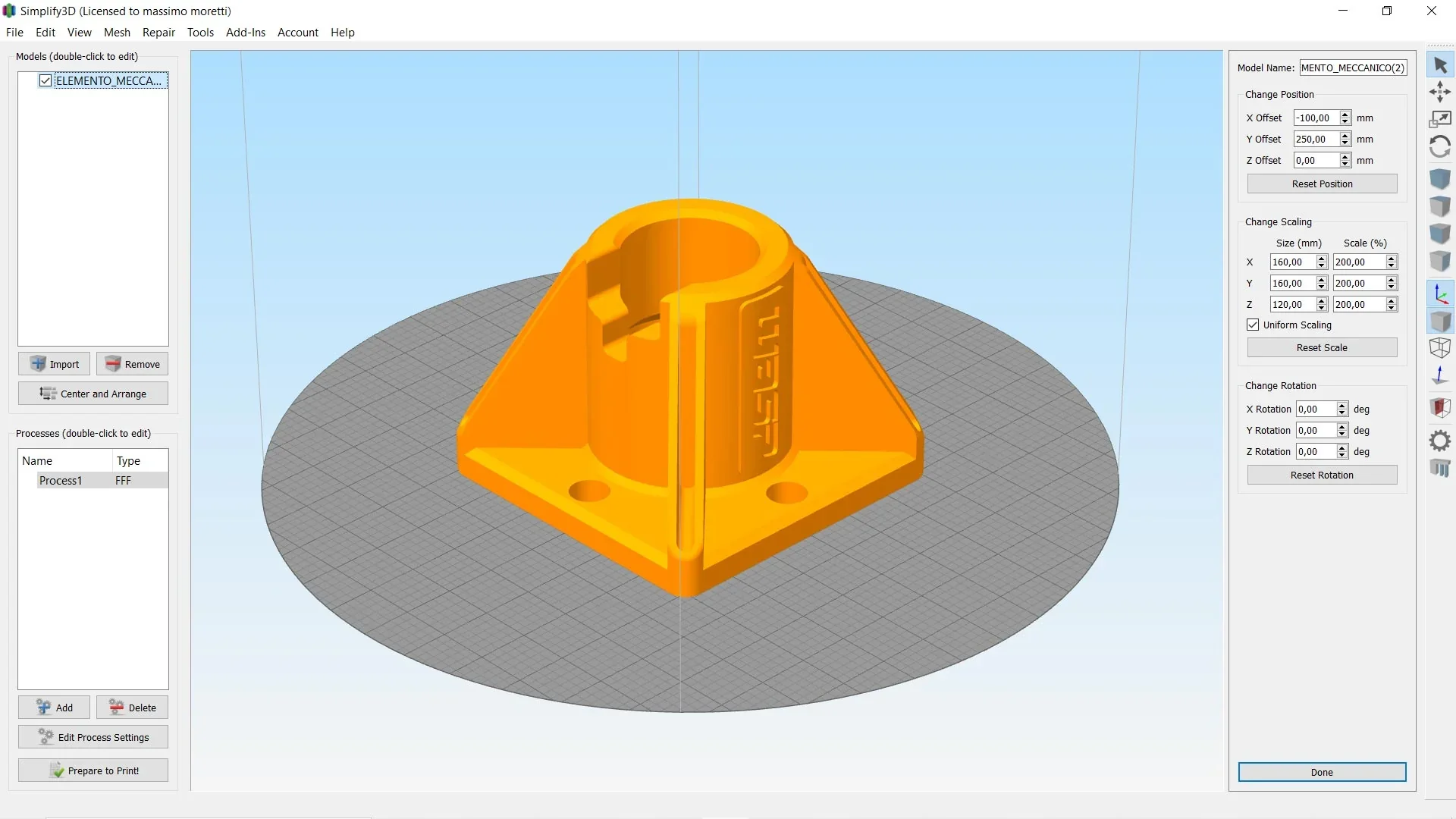

The DeltaWASP 3MT Concrete / Clay uses Simplify3D as its recommended slicer. Compatible with Windows, macOS, and Linux, it provides detailed control of extrusion, layer height, and travel speed, with settings tailored for concrete, clay, and earth-based materials—crucial for large-format printing.

The DeltaWASP 3MT offers a web interface accessible via any browser at the printer’s IP address + “/wasp.” This system supports full printer management, including file uploads, HD camera monitoring, and real-time parameter adjustments. Its firmware also features a resurrection system that tracks progress and resumes printing after power loss, ensuring uninterrupted long projects.

The Delta WASP 3MT features a robust 350 kg steel frame measuring 215 × 235 × 305 cm with metal carters to minimize vibrations, acoustic insulation for noise reduction, and a modular design enabling quick extruder swaps, all ensuring stable, precise printing with 0.1 mm accuracy in X/Y and 0.05 mm in Z.

The DeltaWASP 3MT’s delta kinematic system ensures efficient movement and consistent precision—0.1 mm in X/Y and 0.05 mm in Z—across its full build volume. An MDF pallet bed with a removable lower beam allows easy removal of heavy prints using pallet trucks or forklifts, avoiding manual lifting.

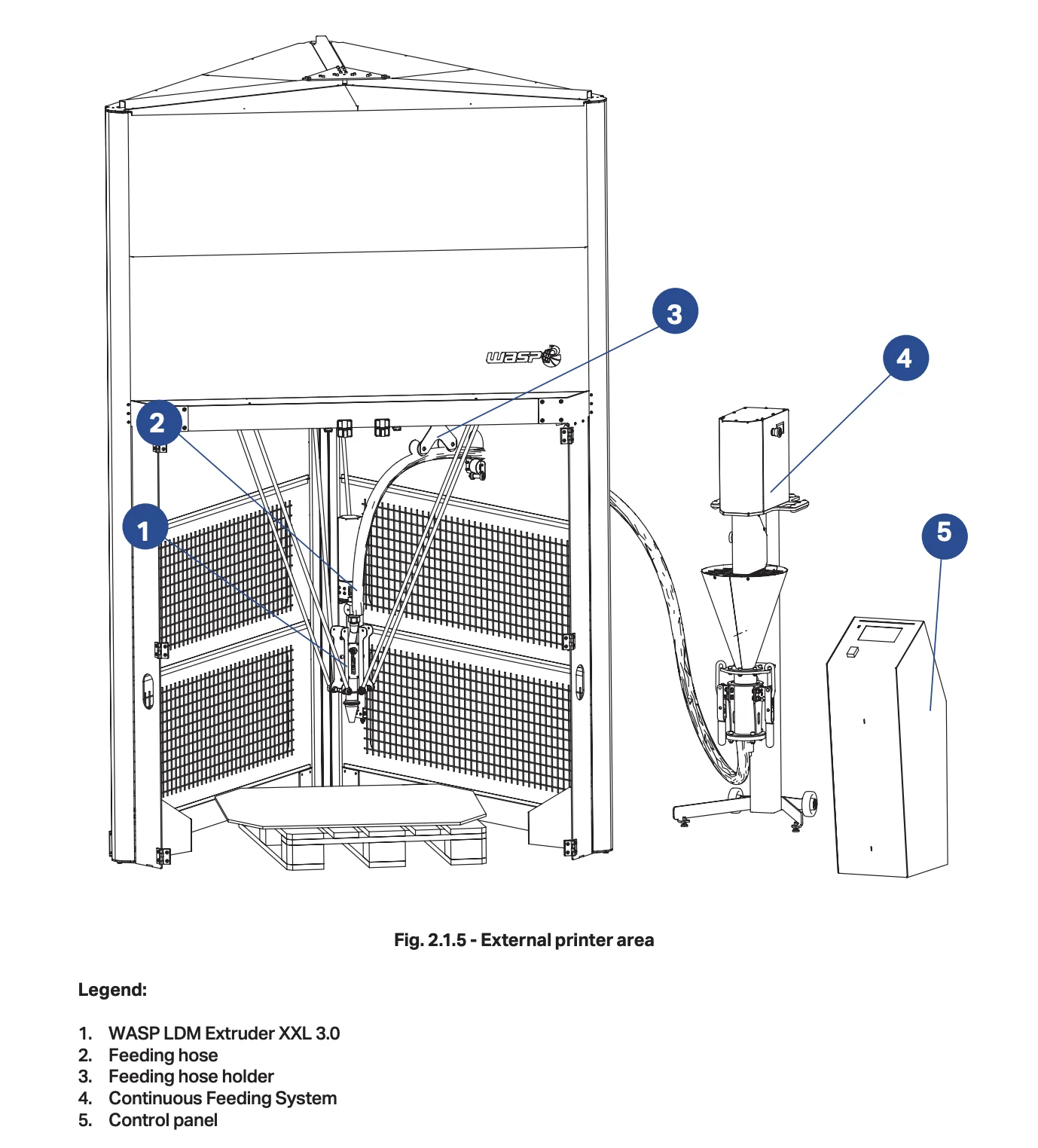

The DeltaWASP 3MT’s modular design allows quick swaps between the XXL extruder for concrete and the XL 3.0 for clay and porcelain. Both are built for rapid disassembly and easy cleaning, with durable parts for abrasive materials. A camlock coupling links the continuous feeding system to the extruder, while a pressure sensor regulates flow for consistent extrusion across varying materials.

The 3D printer Delta WASP 3MT Concrete / Clay ships disassembled in a 300 kg wooden crate. Assembly takes 2–3 people about 2.5 hours. It includes either the XXL extruder for concrete or the XL 3.0 for clay, plus a full toolbox with the required tools for setup, maintenance, and cleaning.

Note: Package contents may vary. Confirm included items with a Top3DShop sales representative before ordering.

WASP3D offers 6 accessories and replacement parts.

| Accessory | Function | Price (USD) |

|---|---|---|

| Spare Parts (Extruder & Nozzle Components) | ||

| Stainless-steel screw for WASP LDM XXL 3.0 Extruder — SKU DLK30XXL01 | Replacement extruder screw for the LDM XXL 3.0; used to restore stable, repeatable material feed if the original screw wears due to abrasive mixes. | 440 |

| LDM WASP Extruder XXL 3.0 (with 17 mm nozzle) — SKU DLK30XXL | Full spare extruder assembly for the Concrete configuration, supplied with 17 mm nozzle; used as a swap unit to minimize downtime during maintenance or wear-part replacement. | 14,500 |

| Stainless-steel nozzle for WASP LDM XXL 3.0 Extruder — SKU DLK30XXL03 | Replacement nozzle for LDM XXL 3.0; used to recover dimensional accuracy and stable flow after nozzle wear from abrasive mixes. | 350 |

| Nozzle kit for WASP LDM Extruder XL 3.0 (Ø4 / Ø6 / Ø8 mm) — SKU DLK00UX3N | Spare nozzle set for LDM Extruder XL 3.0 to change bead size and resolution (smaller nozzle for finer detail; larger nozzle for faster deposition). | 210 |

| POM screw for LDM WASP Extruder XL 3.0 — SKU DLAK00XL3 | Replacement POM screw component for LDM Extruder XL 3.0; used to restore reliable paste feed in clay / ceramic workflows. | 100 |

| LDM WASP Extruder XL 3.0 for Delta 3MT 4.0 LDM (+ Ø4/6/8 mm nozzles) — SKU DLK3M0143 | Full spare extruder for Clay setup (includes Ø4/6/8 mm nozzles); swap unit to reduce downtime during cleaning or maintenance. | 3,550 |

After Each Print/Use

Every 48 Hours (Clay Version)

Every 160 Hours

Periodic Maintenance

Extraordinary Maintenance

Safety Requirements

After flushing with water, operators disconnect the cables and feeding hose, then disassemble the extruder by removing the nozzle, motor, pressure sensor, and screw. Each part is cleaned individually before reassembly.

The operator sets pressure through the mortar pump’s control panel. In automatic mode, a potentiometer adjusts values from 0–6, matching the outlet pressure in bar to the material’s density.

The DeltaWASP 3MT Concrete / Clay includes a warranty of 24 months for private EU customers and 12 months for business or non-EU customers. It covers defects and component failures under normal use, with support provided directly by WASP.

The DeltaWASP 3MT comes with a detailed user manual for setup, operation, and maintenance. WASP also provides an online FAQ at www.3dwasp.com for troubleshooting, and the printer’s INFO menu includes instructional videos accessible from the touchscreen.

Purchases through Top3DShop include on-site installation and a 2-day comprehensive training program.

| Service Package | Description | Price (USD) |

| Installation + Training on-site (Overseas) — SKU LVST000092 | On-site installation + training service: 2 WASP technicians plus help of 2 technicians at site, 2 days. | 17,500 |

| Remote assistance (valid 1 year, renewable) for 3MT IND 4.0 LDM / CONCRETE / HDP — SKU ASSIS00003 | Remote technical support package: remote assistance valid for 1 year. | 2,100 |

| Custom training: optimization of processes & product development — SKU CRS000008 | Custom training engagement focused on process optimization and product development. | 2,100 |

| Grasshopper training for clay 3D printing — SKU CRS000007 | Training course covering Grasshopper workflows for clay 3D printing | 725 |

The WASP 3MT LDM platform is offered in three base configurations, and the right choice depends on the material family you need to print and the extrusion / feeding hardware required for that material.

Update your browser to view this website correctly. Update my browser now