The WASP 40100 LDM is a professional ceramic 3D printer designed for medium- to large-scale production, using LDM technology to print clay, porcelain, and other dense materials at speeds up to 150 mm/s with high precision. Its Ø400 x 1000 mm build volume supports large-format pieces, while the LDM WASP Extruder 3.0 ensures steady material flow and precise retraction. The printer features a three-sided open design, a stable aluminum-steel frame, and a removable platform for efficient workflow. Used by artists, designers, universities, and industries, it supports everything from sculptural installations to 24/7 serial production with optional Continuous Feeding System (CFS) and Automated Production System (APS).

The WASP 40100 LDM uses a precision delta system to deliver high print quality with layer resolution down to 50 microns and speeds up to 150 mm/s. Its stable extrusion system ensures smooth surfaces, while adjustable layer heights from 0.5 to 5 mm allow both detailed work and fast production of larger pieces.

The WASP 40100 LDM’s delta motion system, built with anodized aluminum guides and a bearing sliding system, ensures smooth head movement while the stationary bed reduces vibrations. Its aluminum-steel frame adds stability, preserving dimensional accuracy even at high speeds with dense ceramic materials.

The WASP 40100 LDM relies on the LDM WASP Extruder 3.0, a stainless-steel screw system that precisely regulates material flow, enables rapid interruption, and ensures accurate retraction for complex prints. It includes 1.5, 2, and 3 mm nozzles, while the optional XL 3.0 extruder offers 4–8 mm nozzles for higher flow. Both use degassing technology to remove air bubbles, improving consistency and reducing failures.

The WASP 40100 LDM ensures reliability with two recovery systems: Resurrection, which saves extrusion data to resume prints after shutdowns, and Free Zed, which restarts from a chosen Z-height if needed. It can print on the floor or a removable steel plate, and its movable design lets production continue without waiting for pieces to dry—ideal for efficient workflows.

The WASP 40100 LDM prints with standard ceramic materials—clay, stoneware, porcelain, and earthenware—adapted from traditional pottery and ceramic processes for 3D printing.

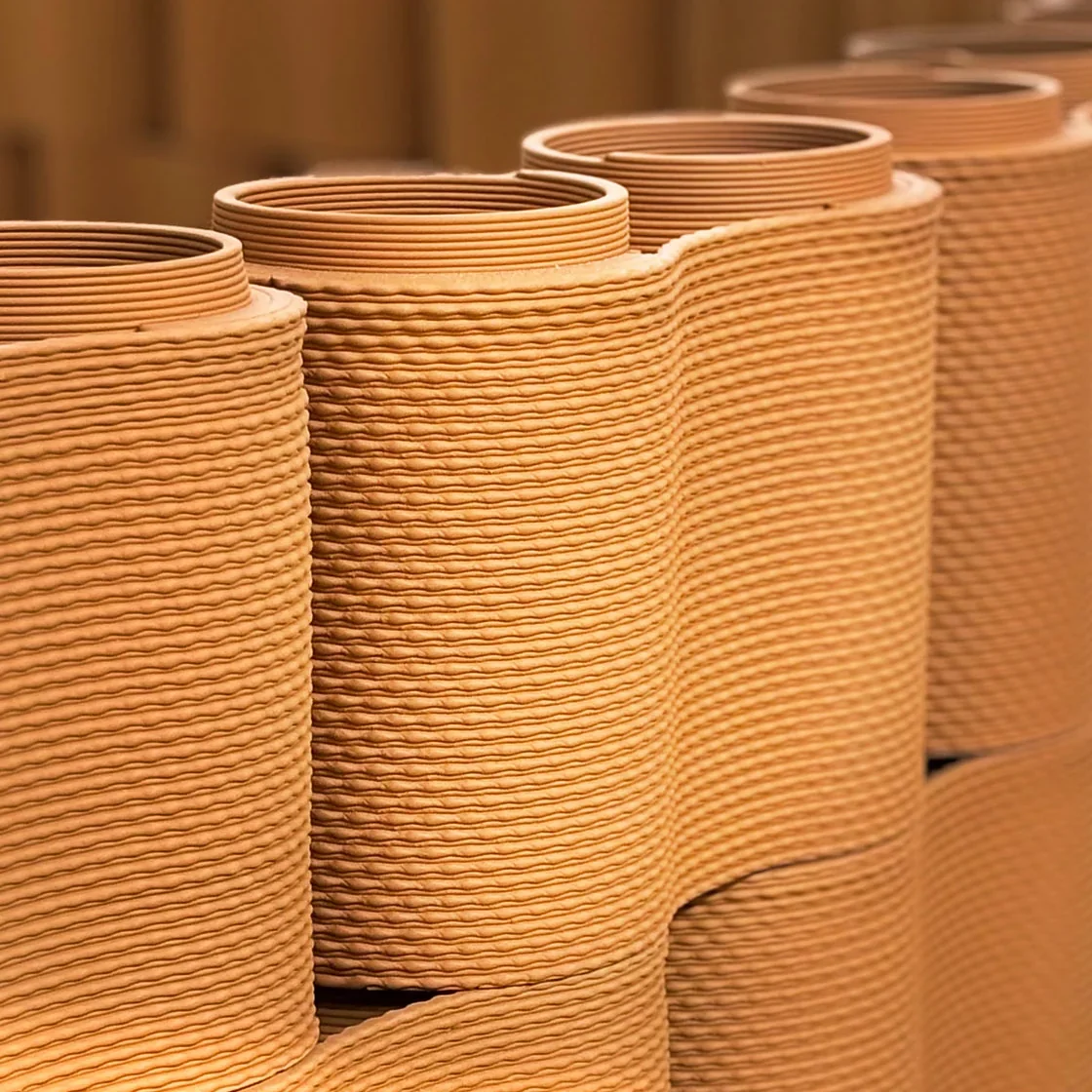

An example is the production of ceramic cylinders using local Faenza clay. Their honeycomb texture highlights parametric design, created directly through material deposition rather than post-processing. As seen in Virginia San Fratello’s Future Archeologies 2049 installation of 1,000 ceramic bricks, varying clay compositions and firing methods produced colors from natural terracotta to deep reds.

With optional accessories, the WASP 40100 LDM can print beyond ceramics. The Manual Feeding extruder enables use of rapid-setting cement and geopolymers, featuring a stainless-steel funnel and self-cleaning system for construction materials. Its LDM WASP Extruder 3.0 further supports diverse material densities with screw-driven flow control and degassing to prevent air bubbles.

An example of advanced material use is the printing of geopolymer structural elements, a sustainable cement alternative producing 80% less COₒ than traditional cement. Processed with the Manual Feeding Extruder, these viscous, abrasive compounds form strong, water-resistant parts without firing, avoiding ceramic shrinkage or warping while maintaining accuracy. The fine surface texture and uniform layers demonstrate the system’s ability to handle challenging materials.

The WASP 40100 LDM adapts to different materials and speeds with interchangeable nozzles. The LDM Extruder 3.0 supports themaximum aggregate size up to 0.2 mm in diameter, and includes 1.5, 2, and 3 mm nozzles plus 1.2 and 1.5 mm Luer lock tips. The optional XL 3.0 handles aggregates up to 0.5 mm with larger 4, 6, and 8 mm nozzles for faster flow. This flexibility enables both fine detailing and large-scale production.

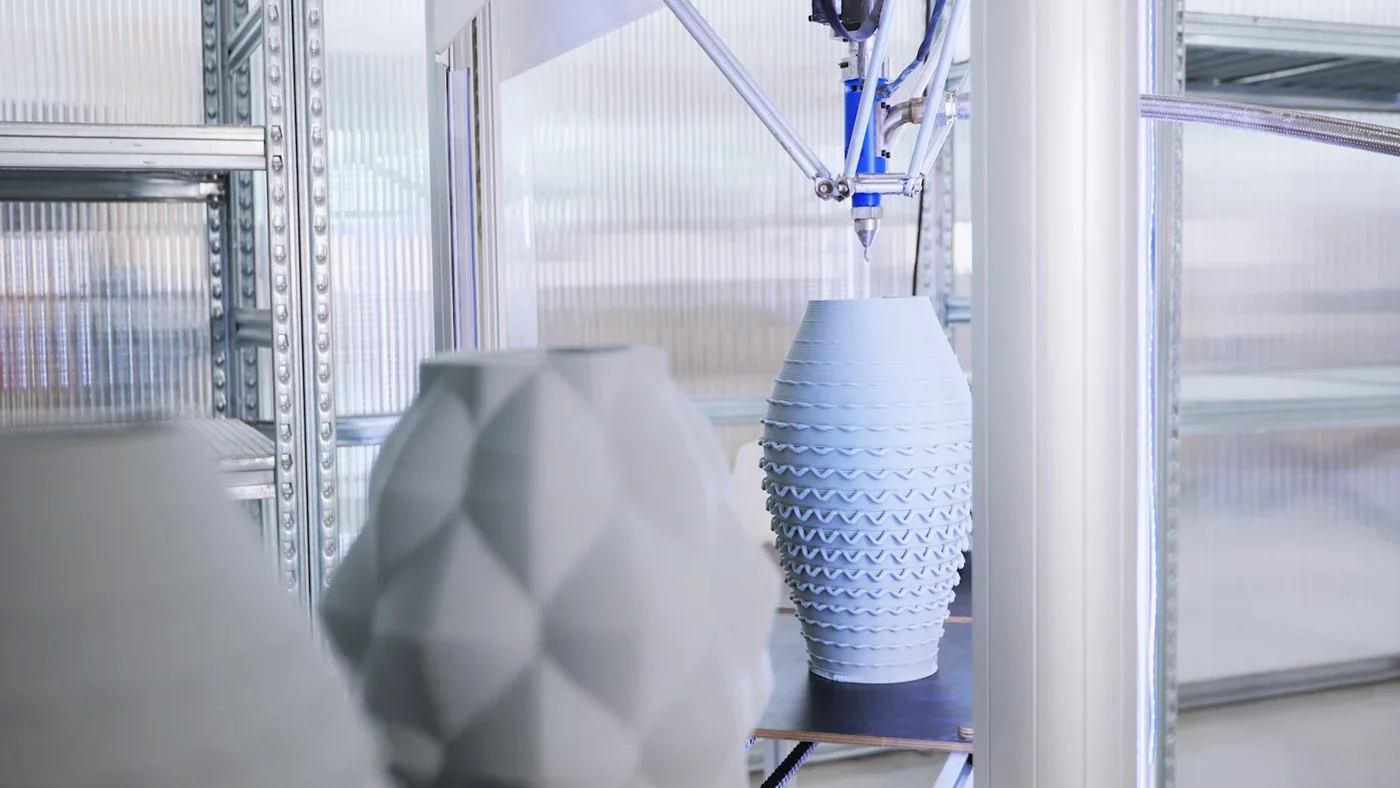

An example is a ceramic vase collection printed with 100% natural clay and algorithmic modeling in Grasshopper. The series demonstrates parametric geometries and varied textures: Ripple with wave patterns (ø80×135 mm), Intertwined with root-like forms (ø80×195 mm), Kilim inspired by woven carpets (ø115×290 mm), Melting using clay’s natural deformation (ø100×170 mm), and Bulky in three sizes (140, 185, 240 mm) with textile-like surfaces.

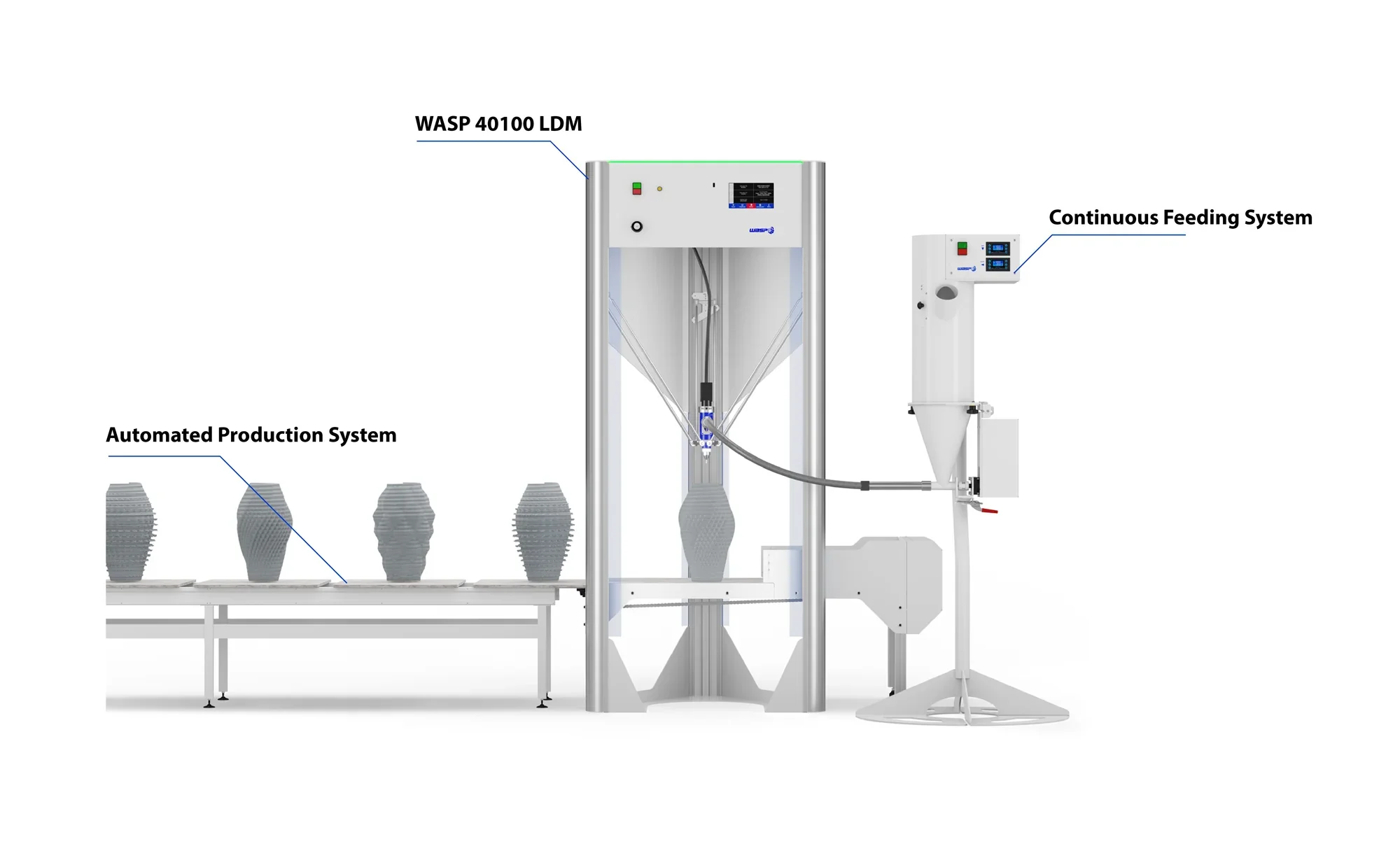

The WASP 40100 LDM includes a 5L aluminum tank and 12 kg of clay for immediate use. For higher output, the optional Continuous Feeding System (CFS) enables nonstop production by continuously adding and degassing material without a vacuum pump. This upgrade turns the printer into a digital factory for industrial-scale ceramic manufacturing.

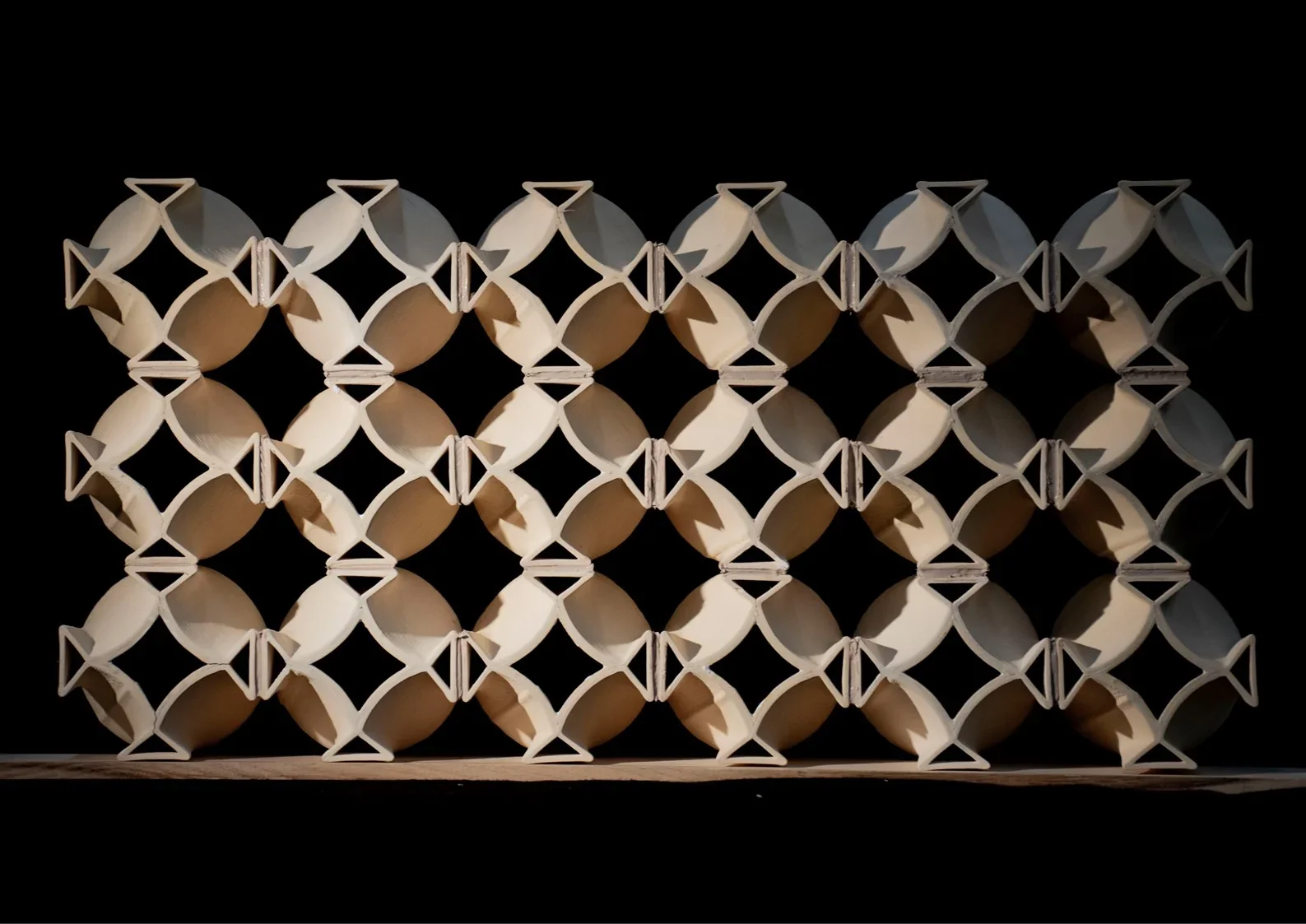

The WASP 40100 produced climate-responsive ceramic façade modules for the Ceram-Screens installation at Bartlett School of Architecture. Using clay, 18 identical frustum-conical units were arranged in a 3×6 grid, with parametric openings designed to improve airflow, reduce solar heat, and preserve privacy.

The WASP 40100 printed stoneware suspension lamps with a parametric honeycomb design for Paolo Castelli’s Haibu collection. The printer deposited material mid-air, where it settled into overlapping scales with integrated light apertures. The dome-shaped forms achieved strength and organic textures without supports, while the natural slits between layers optimized light diffusion.

The WASP 40100 LDM features a Ø 400 × 1000 mm cylindrical build volume, enabling ceramic prints up to 1 m tall when printing on the floor, or 450 mm with a raised steel plate. Its baseless design allows repositioning after each job, eliminating drying delays and reducing downtime. With optional Continuous Feeding and Automated Production Systems, it supports uninterrupted, 24/7 ceramic production.

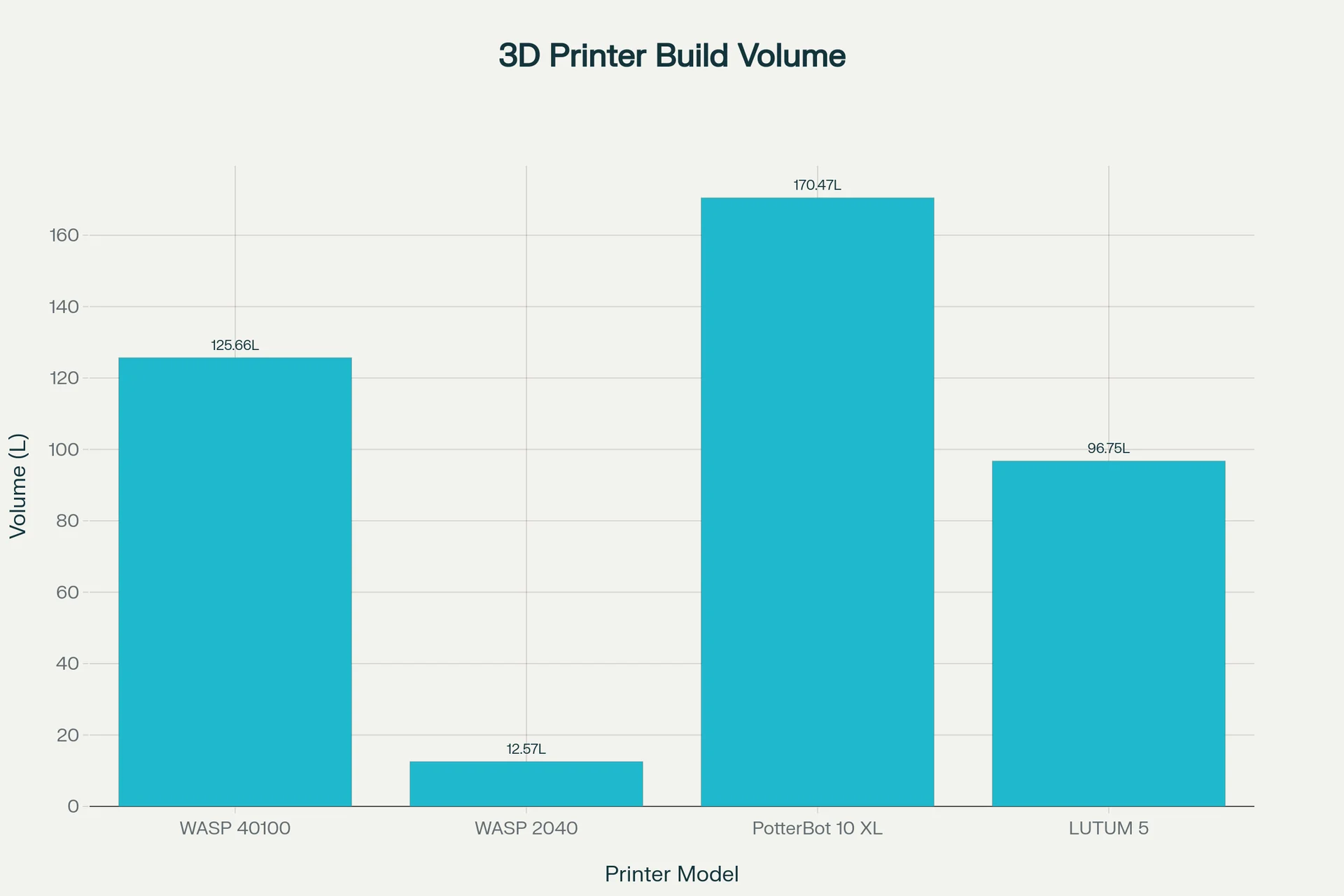

The WASP 40100 LDM surpasses desktop clay printers with its industrial-scale build volume. Compared to the smaller Delta WASP 2040 Clay (Ø 200 × 400 mm), the PotterBot 10 XL (490 × 490 × 710 mm), and the VormVrij LUTUM 5 (430 × 450 × 500 mm), the 40100 offers a clear height advantage—290 mm taller than the PotterBot and 500 mm taller than the LUTUM—making it one of the largest dedicated clay printers available.

| 3D Printer Model | Build Volume | Price (USD) |

| Delta WASP 40100 LDM | Ø 400 x 1000 mm | $11,000+ |

| Delta WASP 2040 Clay | Ø 200 x 400 mm | $5,000+ |

| 3D PotterBot 10 XL | 490 x 490 x 710 mm | $9,900+ |

| VormVrij LUTUM 5 | 430 x 450 x 500 mm | $9,900+ |

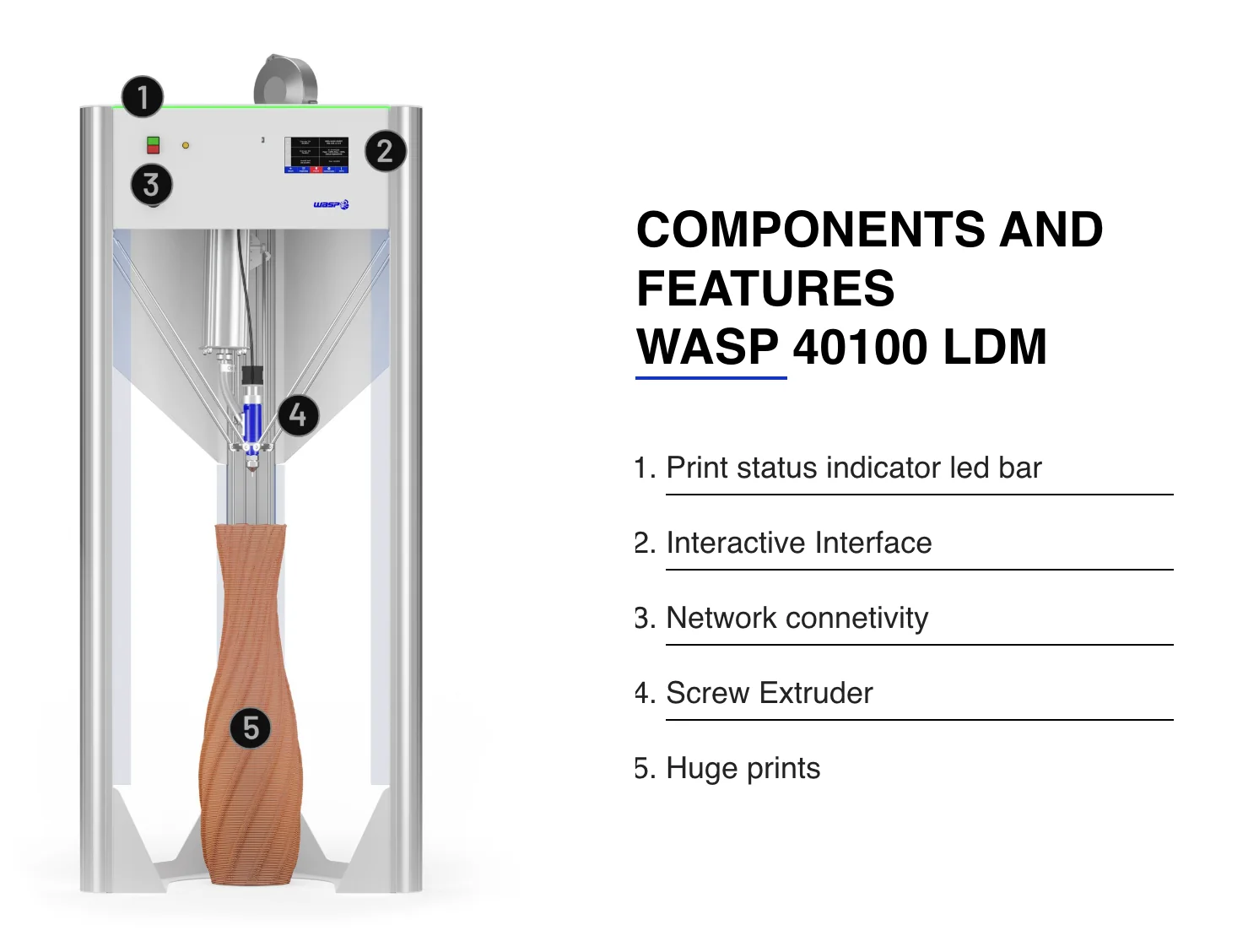

The Delta WASP 40100 Clay features 18 software controls accessed via a 7-inch TFT touchscreen—including Prepare, Advanced, Tune, and SD card menus—and 6 physical controls such as an ON/OFF button, extrusion pressure knob, pause button, and rotary navigation handle.

Physical Controls

Software Controls (Idle State)

Software Controls (Printing State)

Additional Feedback

The WASP 40100 LDM supports SD card, Wi-Fi, and LAN connections. The SD card slot is the primary method for transferring print files, enabling users to prepare models on a computer and print them independently.

The WASP 40100 LDM supports Wi-Fi and LAN connectivity for remote control through OctoPrint on mobile devices or computers. An onboard camera provides real-time monitoring and time-lapse recording of long prints, while a 60-LED RGB bar on top of the machine shows clear visual status indicators visible from across a room.

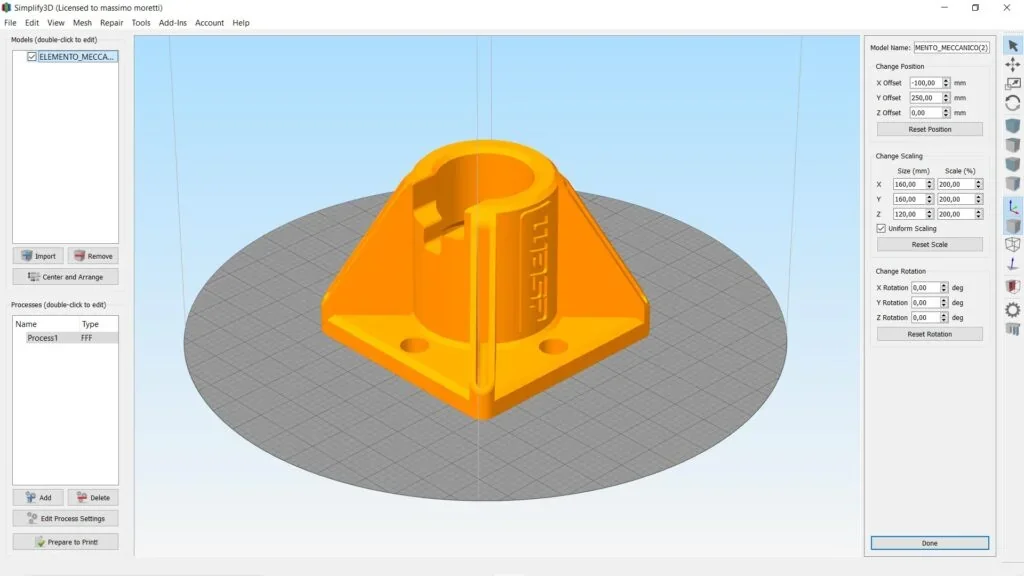

The WASP 40100 LDM includes a licensed copy of Simplify3D, pre-configured with settings optimized for the printer. This professional slicing software gives full control over print parameters, enabling high strength, speed, and quality in ceramic prints.

In addition to Simplify3D, the WASP 40100 LDM is compatible with open-source slicers such as Cura and Slic3r, supporting STL, OBJ, and G-code formats for flexible workflows. For ceramic-specific design, WASP provides its web-based WASP App, which allows users to adjust parameters like shape, size, texture, and slicing settings without advanced modeling skills. The app generates print-ready G-code and supports sequential printing of multiple objects, complementing the printer’s production capabilities.

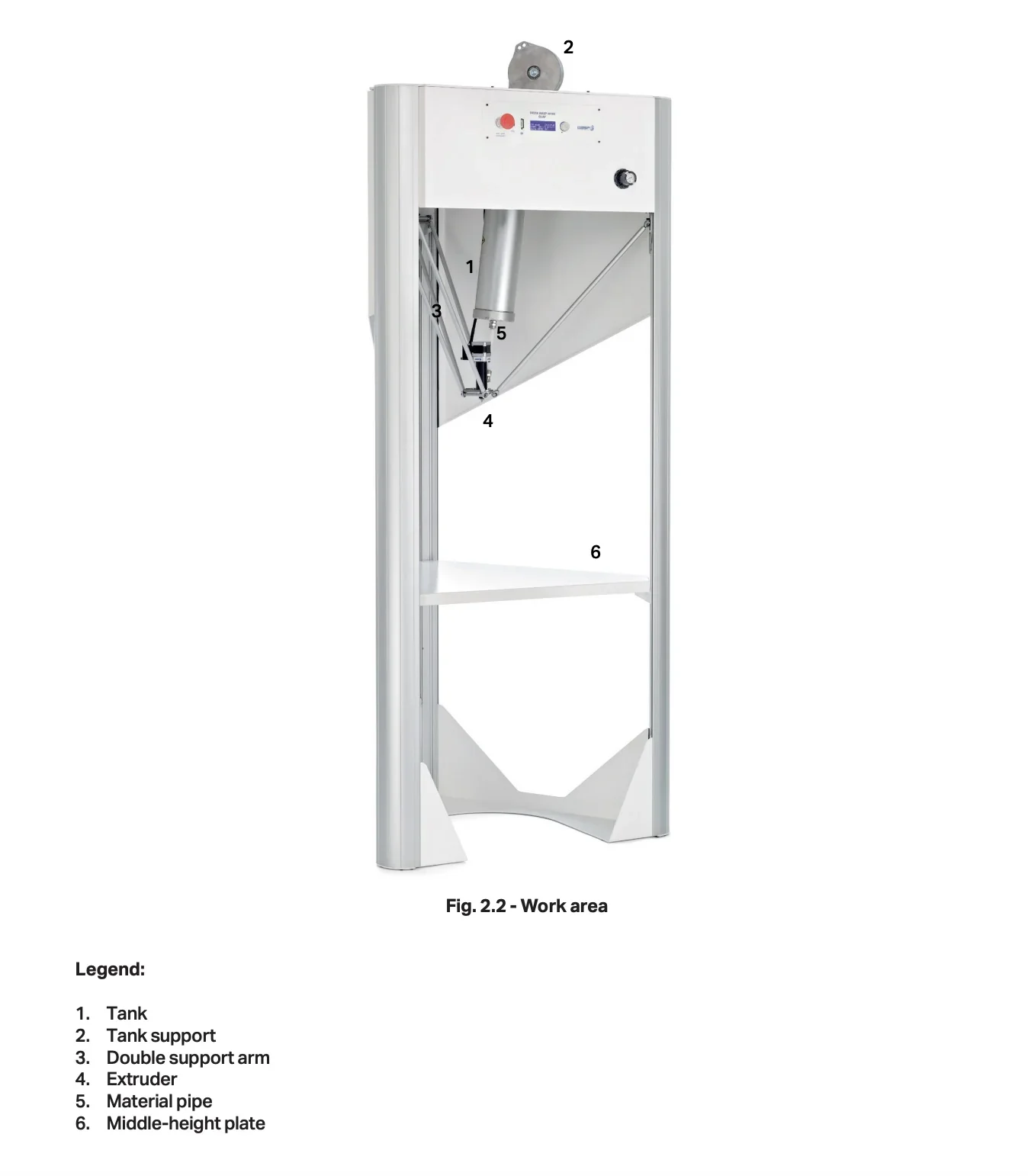

The Delta WASP 40100 LDM 3D printer features a robust aluminum and steel frame standing 195 cm tall (270 cm with optional tank support), with an 85 × 77 cm footprint and an open three-sided design, combining stability, precision delta motion with minimal vibration. Its open three-sided design allows direct access during printing, while a removable intermediate plate positioned 60 cm from the ground adds setup flexibility.

The WASP 40100 LDM uses a delta motion system with three vertical aluminum guides and a bearing sliding setup, eliminating bed movement and reducing vibrations when printing dense materials. Precision motors and belt systems drive each column with minimal maintenance, while six ball joints require periodic lubrication to maintain smooth, reliable operation.

The WASP 40100 LDM’s ergonomic design streamlines ceramic printing with a 5L aluminum tank and piston system that generates up to 4 bar of pressure (safety valve at 8 bar). Two top caps allow easy refilling and cleaning, while a back cap houses the valve. Material is delivered to the extruder through a 12 mm Teflon pipe. For industrial use, an optional tank support extends the printer’s height to integrate the Continuous Feeding System, enabling 24/7 production without material limits.

The WASP 40100 LDM comes fully assembled and factory-tested for immediate use. It includes 10 kg of porcelain for first prints and an SD card with optimized software settings. The LDM WASP Extruder 3.0 is supplied with 1.2 mm and 2 mm nozzles, giving users the choice between fine detail and faster production from the start.

Note: Package contents may vary without notice. Please confirm the current included items with a Top3DShop sales representative before ordering.

WASP3D offers 15 optional upgrades and spare parts.

| Upgrade / Accessory | Function | MSRP (USD) |

|---|---|---|

| Accessories | ||

| WASP CONTINUOUS FEEDING SYSTEM 220V / 110V – Including LDM Extruder XL 3.0 | Continuous, pressurized material feeding system that supplies clay during printing for long, uninterrupted jobs; includes the LDM WASP Extruder XL 3.0. | $12,300 |

| MANUAL FEEDING SYSTEM for 40100 CLAY | Manual feeding extruder system that lets an operator load dense material into the feeder for testing and short prints on Delta WASP 40100 CLAY. | $2,400 |

| LDM WASP Extruder XL 3.0 for Delta 40100 CLAY + 4 / 6 / 8 mm nozzles | High-flow clay extruder upgrade for thicker layers and faster deposition; includes 4 mm, 6 mm, and 8 mm nozzles. | $1,750 |

| Spare Parts | ||

| 5L Clay Tank complete with 2 lids and piston | Spare 5 L clay tank for preparing material and swapping tanks between prints. | $490 |

| POM Screw for LDM WASP Extruder XL 3.0 | Replacement POM screw that meters material flow inside the LDM WASP Extruder XL 3.0. | $85 |

| KIT of nozzles for WASP LDM Extruder 3.0 (from 1.26 mm to 3 mm) | Replacement nozzle set for changing extrusion diameter on the LDM WASP Extruder 3.0. | $140 |

| KIT of nozzles for WASP LDM Extruder XL 3.0 (4 / 6 / 8 mm) | Replacement nozzle set for changing extrusion diameter on the LDM WASP Extruder XL 3.0. | $170 |

| LDM WASP Extruder 3.0 – MODU connector + nozzles kit + reticulated pipe (compatible ONLY with 40100 CLAY) | Connection and spare kit for installing/servicing the LDM WASP Extruder 3.0 on Delta WASP 40100 CLAY (includes MODU connector, nozzle kit, and reticulated connecting pipe). | $675 |

| POM Screw for CONTINUOUS FEEDING SYSTEM | Replacement POM screw used for material feeding in the Continuous Feeding System. | $160 |

| POM Screw for MANUAL FEEDING SYSTEM | Replacement POM screw used for material feeding in the Manual Feeding System. | $80 |

| STAINLESS STEEL Screw for LDM WASP Extruder 3.0 | Replacement stainless-steel screw that meters material flow inside the LDM WASP Extruder 3.0. | $230 |

| Reticulated connecting pipe for LDM WASP Extruder XL 3.0 + accessories | Replacement reticulated connecting pipe set used to transport material between the tank and the Extruder XL 3.0. | $150 |

| Reticulated connecting pipe for LDM WASP Extruder 3.0 + accessories (only for 40100 CLAY) | Replacement reticulated connecting pipe set used to transport material between the tank and the Extruder 3.0 (40100 CLAY only). | $140 |

| Material Packages | ||

| RED TERRAGLIA material – Ceramic mixture pack (12.5 kg) | Consumable ceramic mixture pack used as printing material for clay workflows. | $70 |

Continuous Feeding System (CFS), Automated Production System (APS):

LDM XL Extruder 3.0:

Manual Feeding Extruder:

After Each Use

Weekly

Periodic

The WASP 40100 LDM includes a 24-month warranty for private clients in the EU, and 12 months for all other clients. WASP covers labor and replacement of defective parts after inspection, while customers cover shipping costs. Warranty service requires the original invoice and packaging.

The WASP 40100 LDM includes access to a WASP Academy online course covering setup, operation, and maintenance. Technical support offers guidance on printing and troubleshooting, while advanced training and optimization are available through tailored courses or services. Basic print profiles are provided via the WASP download section to help users achieve reliable results.

The online portal is available at the following link: https://www.3dwasp.com/en/support/

WASP3D also offers paid training and services plans:

| Training / Service Plan | Description | MSRP (USD) |

|---|---|---|

| Dedicated Remote Assistance | Remote technical support service for setup and troubleshooting; valid for 1 year and renewable. | $875 |

| Basic Training Clay 3D Printing | Recorded online training that teaches the basic clay 3D printing workflow. | $210 |

| Advanced 3D Printing Training – Clay Printing | Advanced training focused on clay printing process setup and optimization. | $440 |

| Grasshopper Training for Clay 3D Printing | Training on using Grasshopper for clay 3D printing workflows (parametric design and toolpath-related workflow). | $625 |

| WASP Academy (Basic Courses access with printer purchase) | Online learning platform; purchasing a WASP printer provides access to the Basic Courses on the platform. | Included |

The WASP 40100 LDM is priced at $11,000.00. It offers strong value with large-scale production capacity, precision engineering, and wide material compatibility. For a customized quote, contact Top3DShop with your production needs and setup details.

Update your browser to view this website correctly. Update my browser now