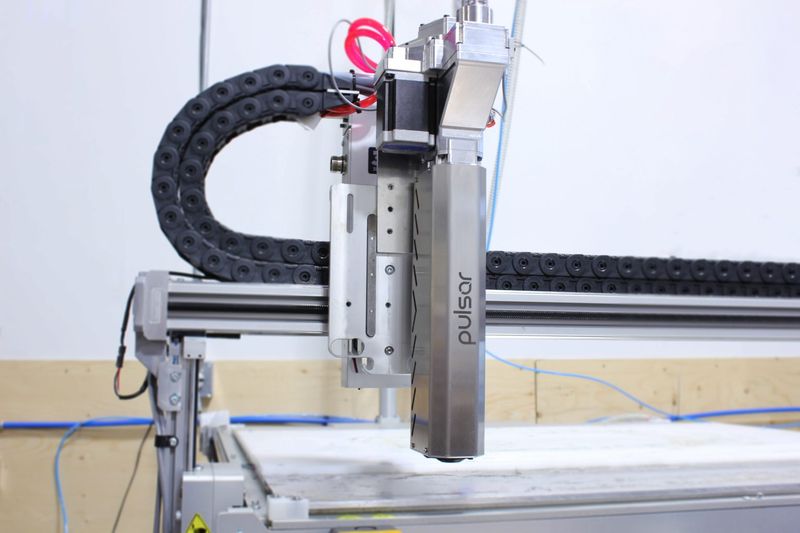

The Pulsar from Dyze Design is a large-scale high-flow plastic pellet extruder designed for rapid and cost-effective production of precise industrial parts of up to one m³. It combines outstanding output capabilities with state-of-the-art extruding technologies enabling it to print with all kinds of advanced polymer materials, from general purpose ones to professional engineering plastics.

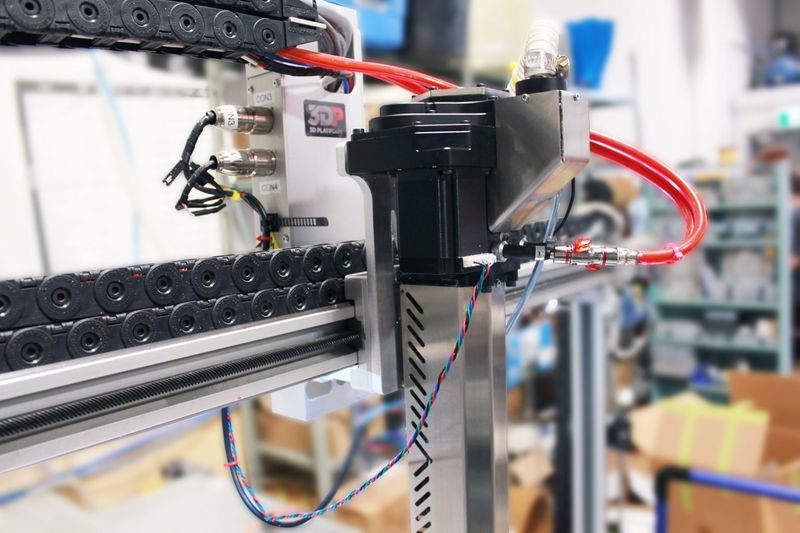

The extruder comes with an innovative three-level temperature control system, which guarantees quality printing with materials requiring uniform temperature throughout the process. Due to the sophisticated class A PT100 sensors, the circuit can assure the best resolution at temperatures of up to 500 °C. Since the sensors are placed 0.50 mm from the molten polymer, the readings provided are always precise and most accurate.

Apart from the mentioned benefits, the Pulsar boasts customized screw design enabling high-resolution printing, robust all-metal frame, abrasive resistant extrusion components, strong NEMA23 motor ensuring even and stable flow, handy anti-oozing mechanism, and optional automatic feeding system.

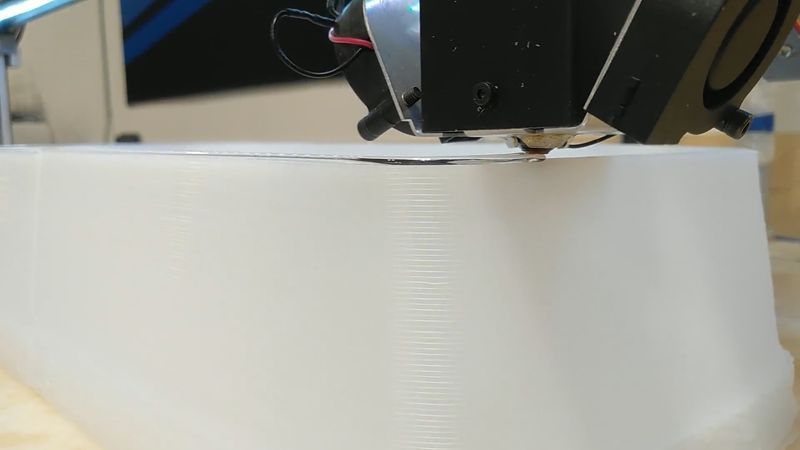

To assess the quality of parts manufactured by the Pulsar extruder, take a look at this timelapse video presenting a 12.3 kg chair manufacture. With the 1360 g/h flow rate, it took only 9 hours to print this item with the 3 mm nozzle and 2 mm layer height.

The Pulsar is a universally compatible extruder that can be easily used with your 3D printer or robotic arm. Due to its reliable construction and multiple advanced features, this high-performance solution is ideal for efficient application in manifold industries.

The Dyze Pulsar is a professional-grade high-flow extruder that provides output of up to 500 mm³/s (2.5 kg/h). At the moment, it is one of the fastest portable pellet extruders on the market. With the available nozzle sizes from 1 to 5 mm, you can produce parts with high resolution, smooth exterior surfaces, complex geometry, and detailed composition at exceptionally high speeds.

The Pulsar extruder features a triple heat zone ensuring constant temperature of the polymer printed, which results in smooth production. First, cold pellets are melted in the top section. Then, they are stabilized at a precise temperature in the middle zone. Finally, the nozzle heater enables an even flow. Uniform temperature throughout the whole extrusion process is also maintained thanks to the water-cooling loop and spiral heaters wrapped around the heated cylinder.

The advanced design features make the Pulsar ready for quality operation in any environmental conditions. With an extra heat shield, the device can handle external temperatures of up to 200 °C.

The Dyze Pulsar is capable of printing any type of plastic pellets currently available on the market, which means it can work with a wide range of standard, flexible, support, advanced, and engineering materials designed to satisfy all your needs. Furthermore, the device is compatible with wood, carbon fiber, and metal powder filled plastics.

Due to the high-temperature heaters, precise temperature sensors, and durable extrusion components, the extruder can work with highly demanding materials, such as PEEK, Ultem, and PSU, at a temperature of up to 500 °C.

Thanks to the abrasive resistant steel nozzle, the nozzle size and height remain unaffected during long print sessions with abrasive materials.

To further improve your printing experience, the Pulsar can be supplemented with an optional feeding system, which allows you to promptly check the pellet level. In addition, the mechanism is responsible for the convenient delivery of pellets from external sources.

The Dyze Pulsar pellet extruder is available in a steel body with black trimmings. Its stylish look makes it ideal for professional and industrial applications.

The extruder’s full length is 500 mm (19.7 in), while the screw’s length is 348 mm (13.7 in). It weighs approximately 7 kg (15.4 lb).

To learn the current price of the Dyze Pulsar pellet extruder, click the "request a quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now